- DL manuals

- Vacon

- Controller

- nxp/c

- User Manual

Vacon nxp/c User Manual

Summary of nxp/c

Page 1

Vacon nxp/c ac drives user manual ®.

Page 3

Vacon • 1 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com table of contents document id: dpd00890b revision release date: 9.10.2014 1. Safety .............................................................................................................4 1.1 warnings ........................

Page 4

Vacon • 2 tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2.5 control cable ........................................................................................................44 6.2.6 cable and fuse sizes, 380-500 v units..................................................................45 6....

Page 5

Vacon • 3 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com at least the following steps of the start-up quick guide must be performed during the installation and commissioning. If any problems occur, please contact your local distributor. Start-up quick guide 1. Check that the delivery c...

Page 6

1 vacon • 4 safety tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 1. Safety only a competent electrician may carry out the electrical installation 1.1 warnings = dangerous voltage! = warning or caution the vacon nx frequency converter is meant for fixed installations only. Do not perform any measu...

Page 7

Safety vacon • 5 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 1 1.2 safety instructions note! If a fault protection relay is used , it must be of at least type b, preferably b+ ( according to en 50178) , with a trip level of 300 ma. This is for fire protection, not for touch protecti...

Page 8

1 vacon • 6 safety tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 1.4 running the motor warning symbols for your own safety, please pay special attention to the instructions marked with the following symbols: motor run check list = dangerous voltage = general warning = hot surface – risk of burn b...

Page 9

Introduction vacon • 7 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2. Introduction the vacon nxc is a product range of free standing enclosed frequency converters for the high power range. The nxc is a modular product intended for use in all applications where reliability and high...

Page 10

2 vacon • 8 introduction tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.1 manufacturer's declaration of conformity below you can find the manufacturer's declarations of conformity assuring the compliance of vacon nxp/c frequency converters with the emc-directives..

Page 11

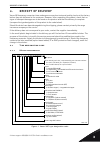

Receipt of delivery vacon • 9 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3. Receipt of delivery vacon nx frequency converters have undergone scrupulous tests and quality checks at the factory before they are delivered to the customer. However, after unpacking the product, check t...

Page 12

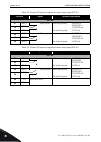

3 vacon • 10 receipt of delivery tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.2 nxc additional option codes the nxc enclosure solution contains additional pre-engineered hardware options. These options are appended to the basic type code by using “+” codes. The most common nxc options are list...

Page 13

Receipt of delivery vacon • 11 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.2.7 general (g-group) 3.2.8 auxiliary equipment (a-group) 3.2.9 door mounted (d-group) +g40 400 empty cabinet +g60 600 empty cabinet +g80 800 empty cabinet +gpl 100 mm base/plinth for 400 mm, 600 mm or 80...

Page 14

3 vacon • 12 receipt of delivery tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.3 storage if the frequency converter is to be kept in store before use make sure that the ambient conditions are acceptable: storing temperature –40…+70 ° c relative humidity the environment should also be free from ...

Page 15

Receipt of delivery vacon • 13 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.4 maintenance in normal conditions, vacon nx frequency converters are maintenance-free. However, we recommend to keep the converter clean, e.G. By cleaning the heatsink with compressed air whenever necess...

Page 16

3 vacon • 14 receipt of delivery tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.5 warranty only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for damages caused during or resulting from transport, receipt of the delivery, installation, commissionin...

Page 17

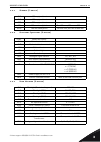

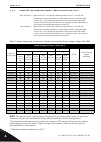

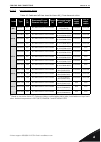

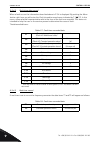

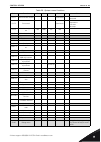

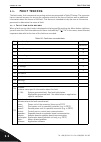

Technical data vacon • 15 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4. Technical data 4.1 power ratings 4.1.1 vacon nxc – mains voltage 380-500 v note! The rated currents in given ambient temperatures are achieved only when the switching frequency is equal to or less than the fa...

Page 18

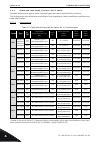

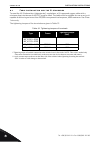

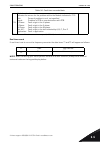

4 vacon • 16 technical data tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4.1.2 vacon nxc low harmonic drives – mains voltage 380-500 v note! The rated currents in given ambient temperatures are achieved only when the switching frequency is equal to or less than the factory default (automatic the...

Page 19

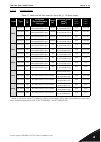

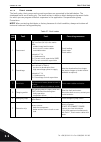

Technical data vacon • 17 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.1.3 vacon nxp/c 6 – mains voltage 500-690 v note! The rated currents in given ambient temperatures are achieved only when the switching frequency is equal to or less than the factory default (automatic thermal...

Page 20

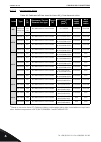

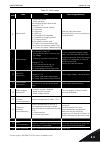

4 vacon • 18 technical data tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4.1.4 vacon nxc low harmonic drives – mains voltage 525-690 v note! The rated currents in given ambient temperatures are achieved only when the switching frequency is equal to or less than the factory default (automatic the...

Page 21

Technical data vacon • 19 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.2 technical data table 6. Technical data mains connection input voltage u in 380…500 v; 500…690 v; –10%…+10% 380...500 v;525...690 v; –10%…+10% (low harmonic drives) input frequency 45…66 hz connection to main...

Page 22

4 vacon • 20 technical data tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 ambient conditions ambient operating tem- perature –10 °c (no frost)…+40 ºc storage temperature –40 °c…+70 °c relative humidity 0 to 95% rh, non-condensing, non-corrosive, no dripping water air quality: - chemical vapours -...

Page 23

Technical data vacon • 21 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 * the rated currents in given ambient temperatures are achieved only when the switching frequency is equal to or less than the factory default. Thermal management might reduce the switching frequency. ** system ...

Page 24

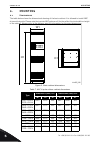

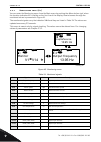

5 vacon • 22 mounting tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5. Mounting 5.1 dimensions the table below shows the dimensional drawing of the basic cabinet. It is allowed to install nxc drives side by side. Please note that certain nxc options will further affect the total width or height o...

Page 25

Mounting vacon • 23 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 * the options +gpl or +gph (plinth) increase the height by 100mm or 200mm respectively ** some options, e.G. +cit (top input cabling +400mm), +cot (top output cabling +400mm) and +odu (output du/dt filter +400mm) affe...

Page 26

5 vacon • 24 mounting tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.2 lifting the unit out of the transport packaging the unit is delivered either in a wooden box or a wooden cage. The box may be transported either horizontally or vertically, while transportation of the cage in a horizontal pos...

Page 27

Mounting vacon • 25 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.3 fixing the unit to the floor or to the wall before starting the installation work make sure that the level of the floor is within acceptable limits. The maximum deviation from the basic level can be no more than 5...

Page 28

5 vacon • 26 mounting tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.3.2 fixing to the floor only note! This option is not available for fr13 and bigger units. For fixing fr13 and bigger units see delivery specific documentation. If bottom-only fixing is used, additional fixing brackets (rittal ...

Page 29

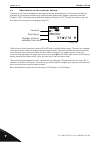

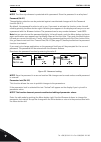

Mounting vacon • 27 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.4 ac choke connections note! The nxc low-harmonic drive incorporates an lcl filter instead of ac chokes and this instruction can be ignored. The ac input choke carries out several functions in the vacon nx 6- and 12...

Page 30

5 vacon • 28 mounting tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.5 auxiliary voltage transformer tappings note! An auxiliary voltage transformer is always included as standard in nxc low-harmonic drives. If the drive is ordered with an auxiliary voltage transformer for 230v auxiliary voltage...

Page 31

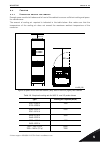

Mounting vacon • 29 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.6 cooling 5.6.1 free space around the cabinet enough space must be left above and in front of the cabinet to ensure sufficient cooling and space for maintenance. The amount of cooling air required is indicated in th...

Page 32

5 vacon • 30 mounting tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 1150 5 0920—1180 6 5000 1500 6 (6-p) 9000 1770—2150 5 1900—2250 6 10000 table 11. Required cooling air for nxc low-harmonic drives type cooling air required [m 3 /h) 0261—0520 5 0125—0416 6 3100 0590—1030 5 0460—0820 6 6200 1150—...

Page 33

Mounting vacon • 31 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.7 power losses the power loss of the frequency converter varies greatly with load and output frequency as well as with the switching frequency used. For dimensioning of cooling or ventilation equipment for electrica...

Page 34

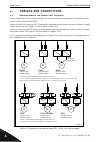

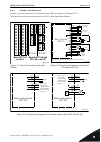

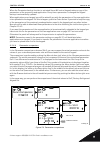

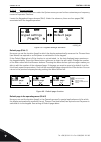

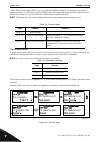

6 vacon • 32 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6. Cabling and connections 6.1 understanding the power unit topology figure 9 and figure 10 show the principles for mains and motor connections of the basic 6-pulse drive in frame sizes fr10 to fr14. Some units bui...

Page 35

Cabling and connections vacon • 33 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 10. Topology of mechanical sizes nxc low-harmonic drives af9 – af14 note! Some options affect the wiring direction and principle for power cables; always check delivery specific documentation for...

Page 36

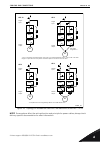

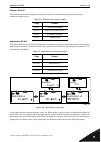

6 vacon • 34 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2 power connections 6.2.1 lcl filter wiring diagram of nxc low-harmonic drive the lcl filter in the nxc low-harmonic drive contains a choke on the mains side, capacitors and a choke on the afe side. The lcl filte...

Page 37

Cabling and connections vacon • 35 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 12. Hf capacitors in nxc low-harmonic drive mechanical sizes af9, af10 and af12 lcl filter figure 13. Hf capacitors in nxc low-harmonic drive mechanical sizes af13-af14 lcl filter remove remove 1...

Page 38

6 vacon • 36 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2.2 mains and motor cables the mains cables are connected to terminals l1, l2 and l3 (12-pulse units 1l1, 1l2, 1l3, 2l1, 2l2, 2l3) and the motor cables to terminals marked with u, v and w, see figure 15. In conve...

Page 39

Cabling and connections vacon • 37 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 for more detailed cable installation instructions, see chapter 8, step 6. Use cables with a temperature rating of at least +70 ° c. As a rule of thumb, cables and the fuses can be dimensioned according ...

Page 40

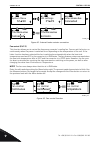

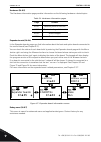

6 vacon • 38 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 15. Routing of power cables, 6- and 12-pulse drives, bottom cabling, frames fr10-fr12 (fr10 +ils as example) figure 16. Routing of power cables, bottom cabling, frame fr13 connect motor cables to terminals u...

Page 41

Cabling and connections vacon • 39 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 17. Routing of power cables, bottom cabling, frame fr14 figure 18. Routing of power cables, bottom cabling, frame af10 conn c th pe conductors to the pe bar connect the pe conductors to the pe ba...

Page 42

6 vacon • 40 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 19. Routing of power cables, bottom cabling, frame af12 +odu (optional) figure 20. Routing of power cables, bottom cabling, frame af13 connect the pe conductor to the pe bar connect motor cables to terminals...

Page 43

Cabling and connections vacon • 41 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 21. Routing of power cables, bottom cabling, frame af14 6.2.2.1 routing of power cables in fr13-14 or af13-14 through bottom of cabinet route the supply and motor cables in fr13-14/af13-14 throug...

Page 44

6 vacon • 42 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 23. Components of the cable gland set installing the cable gland unless the cable gland is already installed by the manufacturer, follow the procedure below to do this: 1. Assemble the rubber sealing in the ...

Page 45

Cabling and connections vacon • 43 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2.2.2 installation of ferrite rings (+ocm) on the motor cable slip only the phase conductors through the rings; leave the cable screen below and outside the rings, see figure 24. Separate the pe condu...

Page 46

6 vacon • 44 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 24. Installation of ferrite rings on single (left) and parallel (right) motor cables 6.2.3 thermal supervision of option +odc option +odc is equipped with a thermal supervision which will indicate if the fil...

Page 47

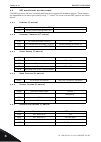

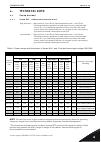

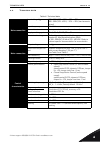

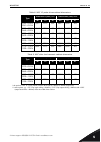

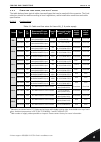

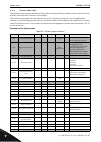

Cabling and connections vacon • 45 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2.6 cable and fuse sizes, 380-500 v units the table below shows typical cable sizes and types that can be used with the converter. The final selection should be made according to local regulations, ca...

Page 48

6 vacon • 46 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2.6.2 12-pulse drives table 14. Cable and fuse sizes for vacon nx_5, 12-pulse supply frame type i l [a] bussmann / ferraz shawmut fuse type fuse i n [a] mains and motor cable 1) [mm 2 ] no. Of supply cables no. O...

Page 49

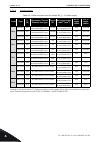

Cabling and connections vacon • 47 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2.6.3 low-harmonic drives table 15. Cable and ar fuse sizes for vacon nx_5 low-harmonic drive frame type i l [a] bussmann/ferraz shawmut fuse type fuse i n [a] mains and motor cable 1) [mm 2 ] no. Of ...

Page 50

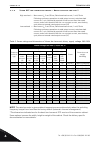

6 vacon • 48 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2.7 cable and fuse sizes, 500/525-690 v units the table below shows typical cable sizes and types that can be used with the converter. The final selection should be done according to local regulations, cable inst...

Page 51

Cabling and connections vacon • 49 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2.7.2 12-pulse drives table 17. Cable and ar fuse sizes for vacon nx_6, 12-pulse supply frame type i l [a] bussmann /ferraz shawmut fuse type fuse i n [a] mains and motor cable 1) [mm 2 ] no of supply...

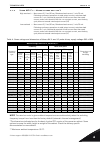

Page 52

6 vacon • 50 cabling and connections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.2.7.3 low-harmonic drives table 18. Cable and ar fuse sizes for vacon nx_6 low-harmonic drive frame type i l [a] bussmann / ferraz shawmut fuse type fuse i n [a] mains and motor cable 1) [mm 2 ] no of supply cabl...

Page 53

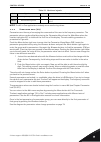

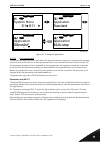

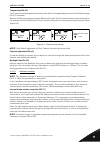

Low harmonic cabinet drive vacon • 51 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 7 7. Low harmonic cabinet drive this chapter describes the functionalities of control devices (switches, push-buttons and led lamps) of the nxc low-harmonic drive (mechanical units af9-14). 7.1 nxc low...

Page 54

7 vacon • 52 low harmonic cabinet drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 7.1.1 manual operation (man) the operator can control the circuit-breaker (mccb) and the charging circuit manually from the cabinet while the mccb control switch –s6 is in man position. The 0–1-start switch is u...

Page 55

Low harmonic cabinet drive vacon • 53 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 7 figure 27. Afe ready indicator the run command has to be given to the afe unit from the keypad, i/o signal or bus communication before the inverter inu can be started (operated). 7.1.2 remote operati...

Page 56

7 vacon • 54 low harmonic cabinet drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 28. Circuit diagram of remote contacts for the control of the mccb and pre-charging circuit (nxc low-harmonic fr12) in case of a voltage drop of n or a blackout in the supplying network, the undervoltage ...

Page 57

Low harmonic cabinet drive vacon • 55 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.1.4 circuit-breaker trip due to overload or short-circuit the electronic trip unit will open/trip the circuit-breaker in case of an overload or short circuit. The trip indication contacts of circui...

Page 58

8 vacon • 56 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 8. Installation instructions 1 before starting the installation, check that none of the components of the frequency converter is live. 2 make sure that the space where the converter is installed, and the converte...

Page 59

Installation instructions vacon • 57 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 6 connect the cables: • strip the motor and mains cables . • remove the protection grids for the input terminals and the protection covers on the converter module(s). • pull the cable through the bott...

Page 60

8 vacon • 58 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 8.1 cable installation and the ul standards to meet the ul (underwriters laboratories) regulations, a ul-approved copper cable with a minimum heat-resistance of +60/75 ° c must be used. The cable must be suitable...

Page 61

Installation instructions vacon • 59 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 8.1.1 cable and motor insulation checks 1. Motor cable insulation checks disconnect the motor cable from terminals u, v and w of the frequency converter and from the motor. Measure the insulation resi...

Page 62

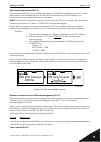

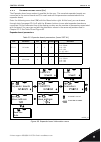

8 vacon • 60 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 8.2 control unit the control unit of the frequency converter consists roughly of the control board and additional boards (see figure 31 and figure 32) connected to the five slot connectors (a to e) of the control...

Page 63

Installation instructions vacon • 61 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 8.2.1 control connections the basic control connections for boards a1 and a2/a3 are shown in chapter 8.2.2. The signal descriptions are presented in the all in one application manual. Figure 35. Gener...

Page 64

8 vacon • 62 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 8.2.1.1 control cables the control cables shall be at least 0.5 mm 2 screened multicore cables, see table 12. The maximum terminal wire size is 2.5 mm 2 for the relay terminals and 1.5 mm 2 for other terminals. F...

Page 65

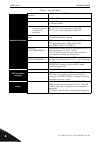

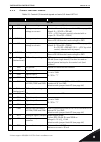

Installation instructions vacon • 63 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 8.2.2 control terminal signals table 21. Control i/o terminal signals on basic i/o board opt-a1 terminal signal technical information opt-a1 1 +10 v ref reference voltage maximum current 10 ma 2 ai1+ ...

Page 66

8 vacon • 64 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 table 22. Control i/o terminal signals on basic relay board opt-a2 terminal signal technical information opt-a2 21 ro1/1 relay output 1 switching capacity 24 vdc/8 a 250 vac/8 a 125 vdc/0.4 a 22 ro1/2 23 ro1/3 mi...

Page 67

Installation instructions vacon • 65 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 8.2.2.1 digital input signal inversions the active signal level depends on which potential the common inputs cma and cmb (terminals 11 and 17) are connected to. The alternatives are either +24 v or gr...

Page 68

8 vacon • 66 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 39. Jumper selection for opt-a1 if you change the ai/ao signal content, also remember to change the corresponding board parameter in menu m7. A b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d...

Page 69

Installation instructions vacon • 67 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 8 8.3 connecting power supply and internal control cables you might need to establish the fibre cable connections from the star coupler board to the power module. Connect the cables according to figure ...

Page 70

8 vacon • 68 installation instructions tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 8.4 optic fibre cables, signal listing and connections figure 41. Internal fibre cable connections star coupler board on control unit h18 trip signal from power module 2 h17 vaconbus data from asic 2 to control b...

Page 71

Control keypad vacon • 69 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 9. Control keypad the control keypad is the link between the vacon frequency converter and the user. The vacon nx control keypad features an alphanumeric display with seven indicators for the run status (run, , ...

Page 72

9 vacon • 70 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.1.2 control place indications the symbols i/o term, keypad and bus/comm (see figure 42) indicate the choice of control place made in the keypad control menu (m3) (see chapter 9.3.3). 9.1.3 status leds (green – green – red...

Page 73

Control keypad vacon • 71 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 9.2 keypad push-buttons the vacon alphanumeric control keypad features 9 push-buttons that are used for the control of the frequency converter (and motor), parameter setting and value monitoring. Figure 43. Keyp...

Page 74

9 vacon • 72 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3 navigation on the control keypad the data on the control keypad are arranged in menus and submenus. The menus are used for example for the display and editing of measurement and control signals, parameter settings (chap...

Page 75

Control keypad vacon • 73 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 figure 44. Keypad navigation chart f t1 t7 stop fault i/ote rm stop i/ote rm fault h1 h3 ready i/ote rm t1 t7 i/o te rm ready i/oterm ready s1 s9 stop r eady i/ote rm stop r eady i/ote rm enter g1 g5 ready i/ote...

Page 76

9 vacon • 74 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.1 monitoring menu (m1) you can enter the monitoring menu from the main menu by pushing the menu button right when the location indication m1 is visible on the first line of the display. How to browse through the monitor...

Page 77

Control keypad vacon • 75 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 note! The all in one applications embody more monitoring values. 9.3.2 parameter menu (m2) parameters are the way of conveying the commands of the user to the frequency converter. The parameter values can be edi...

Page 78

9 vacon • 76 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 46. Parameter value change procedure 9.3.3 keypad control menu (m3) in the keypad controls menu , you can choose the control place, edit the frequency reference and change the direction of the motor. Enter the submen...

Page 79

Control keypad vacon • 77 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 figure 47. Selection of control place 9.3.3.2 keypad reference the keypad reference submenu (p3.2) displays and allows the operator to edit the frequency reference. The changes will take place immediately. This ...

Page 80

9 vacon • 78 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.3.4 stop button activated by default, pushing the stop button will always stop the motor regardless of the selected control place. You can disable this function by giving parameter 3.4 the value 0. If the value of this ...

Page 81

Control keypad vacon • 79 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 9.3.4.1 fault types in the nx frequency converter, there are four different types of faults. These types differ from each other on the basis of the subsequent behaviour of the drive. See table 26. Figure 48. Fau...

Page 82

9 vacon • 80 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.4.2 fault time data record when a fault occurs the information described above in 9.3.4 is displayed. By pushing the menu button right here you will enter the fault time data record menu indicated by t.1t.13. In this m...

Page 83

Control keypad vacon • 81 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 9.3.5 fault history menu (m5) the fault history menu can be entered from the main menu by pushing the menu button right when the location indication m5 is visible on the first line of the keypad display. Find th...

Page 84

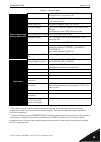

9 vacon • 82 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.6 system menu (m6) the system menu can be entered from the main menu by pushing the menu button right when the location indication m6 is visible on the display. The controls associated with the general use of the freque...

Page 85

Control keypad vacon • 83 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 p6.7.1 internal brake resistor connected not connected connected p6.7.2 fan control continuous continuous temperature first start calc temp p6.7.3 hmi acknowledg. Time- out 200 5000 ms 200 p6.7.4 hmi number of r...

Page 86

9 vacon • 84 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.6.1 language selection the vacon control keypad offers you the possibility to control the frequency converter through the keypad in the language of your choice. Locate the language selection page under the system menu ....

Page 87

Control keypad vacon • 85 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 figure 51. Change of application 9.3.6.3 copy parameters the parameter copy function is used when the operator wants to copy one or all parameter groups from one drive to another or to store parameter sets in th...

Page 88

9 vacon • 86 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 52. Storing and loading of parameter sets upload parameters to keypad (to keypad, s6.3.2) this function uploads all existing parameter groups to the keypad provided that the drive is stopped. Enter the to keypad page...

Page 89

Control keypad vacon • 87 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 when the parameter backup function is activated vacon nx control keypad makes a copy of the parameters of the presently used application. Every time a parameter is changed the keypad backup is automatically upda...

Page 90

9 vacon • 88 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.6.5 security note! The security submenu is protected with a password. Store the password in a safe place! Password (s6.5.1) the application selection can be protected against unauthorised changes with the password funct...

Page 91

Control keypad vacon • 89 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 figure 56. Parameter locking start-up wizard (p6.5.3) the start-up wizard is a feature on the control keypad to facilitate the commissioning of the frequency converter. If selected active (default), the start-up...

Page 92

9 vacon • 90 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.3.6.6 keypad settings in the keypad settings submenu under the system menu you can further customise your frequency converter operator interface. Locate the keypad settings submenu (s6.6). Under the submenu, there are fou...

Page 93

Control keypad vacon • 91 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 timeout time (p6.6.3) the timeout time setting defines the time after which the keypad display returns to the default page (p6.6.1) see above. Move to the edit menu by pressing the menu button right . Set the ti...

Page 94

9 vacon • 92 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 62. Internal brake resistor connection fan control (p6.7.2) this function allows you to control the frequency converter’s cooling fan. You can set the fan to run continuously when the power is switched on or dependin...

Page 95

Control keypad vacon • 93 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 hmi acknowledge timeout (p6.7.3) this function allows the user to change the timeout of the hmi acknowledgement time in cases where there is an additional delay in the rs-232 transmission due to use of modems fo...

Page 96

9 vacon • 94 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 in the total counters page (s6.8.1) you can find information related to the frequency converter operation times, i.E. The total numbers of mwh, operation days and operation hours passed so far. Unlike the counters in the tr...

Page 97

Control keypad vacon • 95 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 software (s6.8.3) the software information page includes information on the following frequency converter software related topics: applications (s6.8.4) at location s6.8.4 you can find the applications submenu c...

Page 98

9 vacon • 96 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 hardware (s6.8.5) the hardware information page provides information on the following hardware-related topics: expander boards (s6.8.6) in the expander boards pages you find information about the basic and option boards con...

Page 99

Control keypad vacon • 97 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 9 9.3.7 expander board menu (m7) the expander board menu makes it possible for the user 1) to see what expander boards are connected to the control board and 2) to reach and edit the parameters associated with the...

Page 100

9 vacon • 98 control keypad tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9.4 further keypad functions the vacon nx control keypad embodies additional application-related functions. See vacon nx application package for more information..

Page 101

Commissioning vacon • 99 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 10 10. Commissioning 10.1 safety before commissioning, note the following directions and warnings: internal components and circuit boards of the frequency converter (except for the galvanically isolated i/o termina...

Page 102

10 vacon • 100 commissioning tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 10.2 commissioning of the frequency converter 1. Read carefully the safety instructions in chapter 1 and above and follow them. 2. After the installation, pay attention to: - that both the frequency converter and the motor...

Page 103

Commissioning vacon • 101 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 10 9. Run the start-up tests without the motor being connected to the process, if possible. If this is not possible, secure the safety of each test prior to running it. Inform your co-workers of the tests. 10. Con...

Page 104

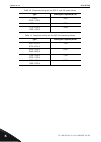

11 vacon • 102 fault tracing tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 11. Fault tracing the fault codes, their causes and correcting actions are presented in table 37 below. The converter has an internal memory for storing the converter status at the time of fault as well as additional infor...

Page 105

Fault tracing vacon • 103 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 11 real time record if real time is set to run on the frequency converter the data items t1 and t2 will appear as follows: note! When contacting your vacon partner because of a fault condition, always write down a...

Page 106

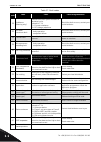

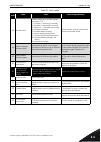

11 vacon • 104 fault tracing tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 11.2 fault codes the fault codes, their causes and correcting actions are presented in the table below. The shadowed faults are a faults only. The items written in white on black background present faults for which you can...

Page 107

Fault tracing vacon • 105 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 11 8 system fault - component failure - faulty operation note exceptional fault data record subcode in t.14: s1 = feedback of motor voltage s2 = reserved s3 = reserved s4 = asic trip s5 = disturbance in vaconbus s...

Page 108

11 vacon • 106 fault tracing tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 18 unbalance (warning only) unbalance between power modules in paralleled units. Subcode in t.14: s1 = current unbalance s2 = dc-voltage unbalance should the fault re-occur, contact your local distributor. 22 eeprom checks...

Page 109

Fault tracing vacon • 107 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 11 43 encoder fault problem detected in encoder signals. Sub code in t.14: s1 = encoder 1 channel a is missing s2 = encoder 1 channel b is missing s3 = both enc. 1 channels are missing s4 = encoder reversed s5 = e...

Page 112

Document id: rev. B manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2013 vacon plc. Find your nearest vacon office on the internet at: www.Vacon.Com.