- DL manuals

- Vailant

- Boiler

- ecoTEC plus 937

- Installation And Maintenance Instructions Manual

Vailant ecoTEC plus 937 Installation And Maintenance Instructions Manual

Summary of ecoTEC plus 937

Page 1

For the heating engineer installation and maintenance instructions gb; ie ecotec plus 937 vui.

Page 2

Contents 2 installation and maintenance instructions ecotec plus 937 0020031552_06 contents 1 notes on the documentation ................................4 1.1 documents also having validity ..............................4 1.2 storing documents .....................................................4 1...

Page 3

Contents 3 installation and maintenance instructions ecotec plus 937 0020031552_06 6.5 flushing the system for the first time ("cold") ..41 6.6 filling the condensate drain trap ..........................41 6.7 setting the pump output .........................................41 6.8 adjusting the byp...

Page 4

4 installation and maintenance instructions ecotec plus 937 0020031552_06 1 notes on the documentation the following information is intended to help you throughout the entire documentation. Further documents apply in combination with this instal- lation and maintenance manual. We accept no liability...

Page 5

Installation and maintenance instructions ecotec plus 937 0020031552_06 5 1.7 benchmark i vaillant ltd. Supports the benchmark initia- tive. You will find the benchmark logbook on the last page of this instruction manual. It is very important that this document be filled out properly when installing...

Page 6

6 installation and maintenance instructions ecotec plus 937 0020031552_06 2.2 technical data name ecotec plus 937 combination unit unit nominal heat output range of central heating 80 °c feed/60 °c return 60 °c feed/40 °c return 50 °c feed/30 °c return 40 °c feed/30 °c return 12.0 - 28.0 12.3 - 28.9...

Page 7

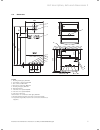

Installation and maintenance instructions ecotec plus 937 0020031552_06 7 2.3 dimensions 24 1 20 64 2 72 0 883 323 100 100 440 35 35 13 0 180 17 5 273 24 3 566 59 8 8 6 4 3 2 1 5 7 9 1 2 3 4 5 10 11 12 fig. 2.1 dimensions ecotec plus 937 legend: 1 heating return pipe, Ø 22 mm 2 cold water connection...

Page 8

8 installation and maintenance instructions ecotec plus 937 0020031552_06 24 1 20 64 2 72 0 88 3 100 100 440 35 35 17 5 6 4 3 2 1 5 130 180 198 1 2 3 4 5 7 8 fig. 2.2 dimensions shift load storage tank legend: 1 heating return pipe, Ø 22 mm 2 cold water connection, Ø 15 mm 3 gas connection Ø 22 mm 4...

Page 9

Installation and maintenance instructions ecotec plus 937 0020031552_06 9 2.4 structure and functional elements the ecotec plus 937 consists of a modified combination boiler and a 15 litre shift load storage tank. Mains cold water heated by the combi unit is fed to the heat insulated storage tank by...

Page 10

10 installation and maintenance instructions ecotec plus 937 0020031552_06 2.5 functional description 1 2 3 4 14 13 12 6 7 8 9 11 10 16 17 15 20 19 18 5 c b a 21 fig. 2.5 sequence diagram legend: 1 exhaust gas 2 heat exchanger 3 combustion chamber 4 condensate siphon 5 expansion vessel 6 operating d...

Page 11

Installation and maintenance instructions ecotec plus 937 0020031552_06 11 the ecotec plus 937 is a fully-automatic wall-mounted unit with condensing technology for central heating and hot water preparation and with a shift load storage tank for the storage of hot water. Mains cold water heated by t...

Page 12

12 installation and maintenance instructions ecotec plus 937 0020031552_06 the unit is not intended for use by persons (including children) with reduced physical, sensory or mental capa- bilities, or lack of experience and/or knowledge, unless they have been given supervision or instruction con- cer...

Page 13

Installation and maintenance instructions ecotec plus 937 0020031552_06 13 preliminary remarks for room sealed appliances this appliance should only be installed in conjunction with either a vaillant flue system or an alternative approved system (details of flue approval categories can be found in t...

Page 14

14 installation and maintenance instructions ecotec plus 937 0020031552_06 4 general requirements 4.1 scope of supply and accessories 1 1 10 9 8 7 6 5 4 3 2 1 fig. 4.1 scope of supply and accessories the shift load storage tank and the combi boiler are delivered pre-assembled in one packaging unit. ...

Page 15

Installation and maintenance instructions ecotec plus 937 0020031552_06 15 it is possible to mount onto a wall made of flammable material if the regulations of the local authority and the legal building regulations are fulfilled. In this case however, the unit would have to be mounted in a spe- cial...

Page 16

16 installation and maintenance instructions ecotec plus 937 0020031552_06 8 4 1456 542 901 fig. 4.3 item no. 0020060570, 0020060571 and 0020065937 (60/100) 4.4.2 optional 125 mm flue pipe a concentric flue pipe having an outside diameter of 125 mm is available, which can be extended to a length of ...

Page 17

Installation and maintenance instructions ecotec plus 937 0020031552_06 17 location of the junction mm a directly under or above an opening or the horizontal to an opening, a hollow ventilation tile, an opening window etc. 300 b under gutters, soil pipes or drainpipes 75 c unter eaves 200 d under ba...

Page 18

18 installation and maintenance instructions ecotec plus 937 0020031552_06 4.8 system requirements 4.8.1 water circulation system detailed recommendations concerning the water circu- lation system can be taken from bs 6798 and bs 5449, part 1 (for "small bore” and "micro bore” central heat- ing syst...

Page 19

Installation and maintenance instructions ecotec plus 937 0020031552_06 19 jenaqua 110 sentinel x 100 sentinel x 200 additives for frost protection intended to remain per- manently in the system fernox antifreeze alphi 11 sentinel x 500 inform the operator of the necessary measures in case you have ...

Page 20

20 installation and maintenance instructions ecotec plus 937 0020031552_06 4.8.5 heating circuit expansion vessel the boiler of the ecotec series are equipped with a 10 litre expansion vessel which is suitable for a sealed heating system with a maximum water volume of 100 litres. If the nominal capa...

Page 21

Installation and maintenance instructions ecotec plus 937 0020031552_06 21 5 sequence of operations during installation 5.1 transporting the appliance important: with regards to the manual handling operations, 1992 regulations, the following lift operation exceeds the rec- ommended weight for a one ...

Page 22

22 installation and maintenance instructions ecotec plus 937 0020031552_06 packing and remove carton by sliding up over the boiler. Ensure safe lifting techniques are used – keep back straight – bend using legs. Keep load as close to body as possible. Always use assistance if required. Dispose of pa...

Page 23

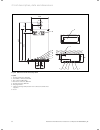

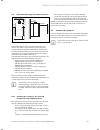

Installation and maintenance instructions ecotec plus 937 0020031552_06 23 5.2 required minimum gaps/assembly clearances min min 5 min 5 min 500 min 180 16 5/ 246 fig. 5.1 distances during installation (dimensions in mm) the combination of units must be installed on a flat vertical wall which is lar...

Page 24

24 installation and maintenance instructions ecotec plus 937 0020031552_06 5.4 using the installation template 00 2 00 3 99 7 5_00 10 2 006 180 60/100 140 195 ( ) 40 60/100 17 3 2 7 6 ( ) 80/125 80/125 (art.-nr. 303210) (art.-nr. 303910) 5 5 223 25 6 a a 25 a a a 117 6 450 fig. 5.2 assembly template...

Page 25

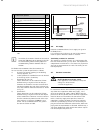

Installation and maintenance instructions ecotec plus 937 0020031552_06 25 5.7 fitting the appliance hanging bracket 1 3 2 fig. 5.3 shift load storage tank with hanging bracket fix the hanging bracket (1) to the wall using the plugs and screws (2) provided with the appliance. Lift the shift load sto...

Page 26

26 installation and maintenance instructions ecotec plus 937 0020031552_06 5.9 removing the front case 1 2 fig. 5.5 removing/fixing the front case proceed as follows to remove the front cladding: release the screw (1) on the base of the unit. Push the two retaining clips (2) on the base of the unit ...

Page 27

Installation and maintenance instructions ecotec plus 937 0020031552_06 27 2 1 3 6 2 4 5 1 fig. 5.6 gas connection proceed as follows for gas connection: remove the gas connection pipe elbow (2) and gas isolator valve (1) from the packaging. Push the union nut (3) and the olive (4) onto the gas pipe...

Page 28

28 installation and maintenance instructions ecotec plus 937 0020031552_06 push the union nut (4) with the inserted olive (3) onto the copper tail (5) included with the combi boiler. The diameter of this pipe is 15 mm. Insert the copper tail into the cold water isolating valve up to the stop. Tighte...

Page 29

Installation and maintenance instructions ecotec plus 937 0020031552_06 29 5.14 connecting the heating supply and return lines a danger! Risk of scalding and damage due to leaking water. Possible leaks in water pipes. Make sure there is no tension in the supply lines when they are installed. B cauti...

Page 30

30 installation and maintenance instructions ecotec plus 937 0020031552_06 5.15 installing the condensate drain line a danger! Risk of poisoning due to an improperly installed condensate drain line. Blockages in the condensate drain line may cause exhaust gas to escape. Install the condensate drain ...

Page 31

Installation and maintenance instructions ecotec plus 937 0020031552_06 31 min. 180 fig. 5.12 installation space condensate siphon there must be a minimum clearance of 180mm below the siphon for access. 5.16 connecting the drain pipe to the pressure relief valve 4 3 2 1 fig. 5.13 installing the disc...

Page 32

32 installation and maintenance instructions ecotec plus 937 0020031552_06 5.19 electrical connection 5.19.1 general requirements e danger! Risk of fatal electric shock from live con- nections. Voltage is continuously present in the l and n terminals of the turquoise coloured plug, even when the mai...

Page 33

Installation and maintenance instructions ecotec plus 937 0020031552_06 33 pull the electronics box forward and lower. Unclip the back cover of the electronics box and lift the cover upwards to reveal the connections. 1 2 3 fig. 4.16 cable run on the underside of the unit feed the wiring harness (2)...

Page 34

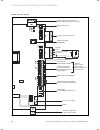

34 installation and maintenance instructions ecotec plus 937 0020031552_06 5.19.4 connection diagrams burner cable harness wiring harness hydraulics connection for external ebus controller room thermostat 24 v: connection 7, 8 und 9 no bi-directional interface (only analogue) room thermostat 230 v/5...

Page 35

Installation and maintenance instructions ecotec plus 937 0020031552_06 35 x 2 bus — + 24v 7 8 9 230v l n 3 4 5 x 20 x40 x3 1 x12 x41 electronics box hot water outlet (ntc) fan ignition electrode flow temperature sensor (ntc) diverter valve gas valve water pressure sensor return temperature sensor (...

Page 36

36 installation and maintenance instructions ecotec plus 937 0020031552_06 bus — + 24v 7 8 9 230v l n 3 4 5 x3 1 x12 boiler electronics box storage tank charging sensor (ntc) x 1/3 violet x 1/1 black pump x 1/7 green x 1/1 black x 1/8 red storage tank sensor (ntc) x 1/4 orange x 1/1 black plug conne...

Page 37

Installation and maintenance instructions ecotec plus 937 0020031552_06 37 5.20 control units 5.20.1 vaillant control units and accessories controller item no. Connection vrc 400 (1-circuit controller, weather-controlled) 00 2001 0843 installation in electronics box (plug-and-play) vrt 360 (room tem...

Page 38

38 installation and maintenance instructions ecotec plus 937 0020031552_06 5.20.4 optional plug-in timers by vaillant further details for the connection can be found in the relevant instructions of the accessories. The cover on the electronics box should be replaced after all the elec- trical connec...

Page 39

Installation and maintenance instructions ecotec plus 937 0020031552_06 39 6 commissioning, part i 6.1 preparatory checks of the electrical system check the electrical installation for short circuits, proper earthing and earth resistance and for correct polarity. 6.2 gas supply a danger! Risk of exp...

Page 40

40 installation and maintenance instructions ecotec plus 937 0020031552_06 6.4.2 filling device for ecotec plus 937 the ecotec plus 937 is fitted with a filling loop. Push the double check (1) of the filling loop into the cold water stop valve (2) and secure the double check valve (1) with the sprin...

Page 41

Installation and maintenance instructions ecotec plus 937 0020031552_06 41 6.5 flushing the system for the first time ("cold") i the entire heating system must be flushed through completely at least twice: once cold and once hot, in accordance with the follow- ing instructions. Check if all radiator...

Page 42

42 installation and maintenance instructions ecotec plus 937 0020031552_06 6.9 checking the gas setting a caution! Malfunctions or reduction in working life of the boiler! If the boiler version does not correspond to the local gas family, there will be malfunc- tions or you have to change components...

Page 43

Installation and maintenance instructions ecotec plus 937 0020031552_06 43 6.9.2 checking the gas flow rate the boiler is fitted with a multifunctional automatic gas valve which ensures that the precise air/gas ratio is pro- vided under all operating conditions. The gas flow rate has been set during...

Page 44

44 installation and maintenance instructions ecotec plus 937 0020031552_06 check if there is any blockage in the pipework or if the pipework is undersized. If the supply pressure is out of tolerance contact your emergency service provider. If the gas inlet working pressure at the reference test poin...

Page 45

Installation and maintenance instructions ecotec plus 937 0020031552_06 45 the setting mode is also de-activated if a button is not pushed within a period of 4 minutes. Appliance heating output in kw ecotec plus 937 12 - 28 table 6.3 setting the part load ranges of the heating system 6.12 converting...

Page 46

46 installation and maintenance instructions ecotec plus 937 0020031552_06 fig. 7.2 display in heating mode 7.1.3 hot water operation switch on the appliance. Open the hot water tap fully. Press "i" to activate the status indicator. If the hot water operation is operating properly, the dis- play sho...

Page 47

Installation and maintenance instructions ecotec plus 937 0020031552_06 47 the symbol " “ is displayed. Turn the hot water temperature control knob to the temperature you require. Press "i" to activate the status indicator. During the storage tank charging the display shows "s.24“. Fig. 7.5 display ...

Page 48

48 installation and maintenance instructions ecotec plus 937 0020031552_06 leave the operating and installation instructions with the operator of the appliance. Go through the operating manual with the user and answer any questions. Draw special attention to the safety instructions, which the user m...

Page 49

Installation and maintenance instructions ecotec plus 937 0020031552_06 49 we recommend the conclusion of an inspection and maintenance contract with an approved company or installer. The inspection serves to determine the actual condition of the respective boiler and compare it with the speci- fied...

Page 50

50 installation and maintenance instructions ecotec plus 937 0020031552_06 always perform the following steps prior to inspection or maintenance work: switch off the main switch. Disconnect the boiler from the power mains by disconnecting the mains plug or de-energising the boiler via an isolating d...

Page 51

Installation and maintenance instructions ecotec plus 937 0020031552_06 51 8.1.4 adjusting the co 2 concentration (or the air ratio) a danger! Increased risk of poisoning due to incorrect settings! Incorrect setting may increase the risk of poi- soning. If one of the flue gas values is greater than ...

Page 52

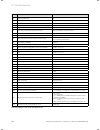

52 installation and maintenance instructions ecotec plus 937 0020031552_06 8.1.5 inspection and maintenance work steps no. Activity column 1 inspection must be carried out each year column 2 maintenance must be carried out at regular intervals – but no longer than 5 years 1 check the air flue gas in...

Page 53

Installation and maintenance instructions ecotec plus 937 0020031552_06 53 8.2 maintaining the compact thermal module 8.2.1 removing the compact thermal module a danger! Risk of burns caused due to hot compo- nents. The compact thermal module, all water-carry- ing parts and the heating water may bec...

Page 54

54 installation and maintenance instructions ecotec plus 937 0020031552_06 8.2.2 cleaning the integral condensation heat exchanger b caution! Risk of damage to the electronics. Water may damage the electronics and cause power failures. Protect the open switch box from spray water. Dismantle the comp...

Page 55

Installation and maintenance instructions ecotec plus 937 0020031552_06 55 10 9 8 4 5 7 6 fig. 8.7 fitting the thermo-compact module insert the compact thermo module (9) in the integral condensation heat exchanger (10). Tighten the four nuts (4) alternately on the left and right until the burner doo...

Page 56

56 installation and maintenance instructions ecotec plus 937 0020031552_06 fill the lower section with water until about 10 mm below the upper edge. Re-fit the lower section to the condensate siphon. 8.4 cleaning strainer in cold water supply there is a strainer in the cold water supply to the combi...

Page 57

Installation and maintenance instructions ecotec plus 937 0020031552_06 57 8.6 checking filling pressure of the expansion vessel of the shift load storage tank i this check need not be performed every year – a check every three years is sufficient. Close the stop valves of the hot water system. Rele...

Page 58

58 installation and maintenance instructions ecotec plus 937 0020031552_06 9 troubleshooting 9.1 logical fault finding procedure carry out the following checks before the actual trou- bleshooting: carry out the tests to check electrical safety (see section "preparatory checks on the electrical sys- ...

Page 59

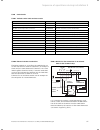

Installation and maintenance instructions ecotec plus 937 0020031552_06 59 display meaning heating mode: s.0 no heat demand s.1 fan running s.2 pump running s.3 ignition s.4 burner ignited s.5 fan and pump running s.6 fan over run s.7 pump overrun time s.8 anti-cycling mode hot water mode (ecotec pl...

Page 60

60 installation and maintenance instructions ecotec plus 937 0020031552_06 display meaning displayed value/settable value d.0 heating partial load adjustable heating partial load in kw (factory setting: max. Out- put) d.1 water pump over run time for heating mode 2 - 60 minutes (factory setting: 5 m...

Page 61

Installation and maintenance instructions ecotec plus 937 0020031552_06 61 second diagnostic level as described above in the first diagnostic level, scroll through to the diagnosis number d.97. Change the displayed value to 17 (password) and push the button "i". You are now in the second diagnostic ...

Page 62

62 installation and maintenance instructions ecotec plus 937 0020031552_06 display meaning displayed value/settable value d.72 pump overrun time after warm start or shift load storage tank charging setting range in seconds: 0, 10, 20 to 600 factory setting: 80 d.73 offset for warm start target tempe...

Page 63

Installation and maintenance instructions ecotec plus 937 0020031552_06 63 code meaning cause f.0 flow ntc open circuit ntc faulty, ntc cable faulty, faulty plug connection on ntc, faulty plug connection on the electronics f.01 return ntc open circuit ntc faulty, ntc cable faulty, faulty plug connec...

Page 64

64 installation and maintenance instructions ecotec plus 937 0020031552_06 code meaning cause f.74 signal water pressure sensor in the wrong range (too high) harness to water pressure sensor has a short-circuit at 5 v / 24 v or internal fault in water pressure sensor f.75 no sudden change in pressur...

Page 65

Installation and maintenance instructions ecotec plus 937 0020031552_06 65 9.2 test programmes display meaning p.0 bleeding test program. The heating circuit and the hot water circuit are bled via the automatic air vent (the cap of the automatic air vent must be released two turns). P.1 test program...

Page 66

66 installation and maintenance instructions ecotec plus 937 0020031552_06 10.2 replacing the burner a danger! Risk of personal injury and/or material damage as a result of non-compliance with the safety instructions. Before replacing the component, comply with the safety instructions in chapter 10....

Page 67

Installation and maintenance instructions ecotec plus 937 0020031552_06 67 release both fixing screws (5) on the gas valve and remove the fan from the gas valve. Replace the faulty component. B caution! Possible material damage caused by improper installation. The gas valve and the fan may be damage...

Page 68

68 installation and maintenance instructions ecotec plus 937 0020031552_06 10.5 replacing the primary heat exchanger a danger! Risk of personal injury and/or material damage as a result of non-compliance with the safety instructions. Before replacing the component, comply with the safety instruction...

Page 69

Installation and maintenance instructions ecotec plus 937 0020031552_06 69 b caution! Possible material damage caused by loos- ening or retightening the screws. The primary heat exchanger may become damaged. You must not loosen or tighten the four screws (fig. 8.4, 1). B caution! Possible material d...

Page 70

70 installation and maintenance instructions ecotec plus 937 0020031552_06 2 1 5 4 3 6 fig. 10.8 replacing storage tank pump remove the discharge pipe (1) of the heating pres- sure relief. Lower the electronics box as described in sec- tion 5.19.2. Unclip the back cover of the electronics box and sw...

Page 71

Installation and maintenance instructions ecotec plus 937 0020031552_06 71 replacing components 10 fit the pipe elbow onto the new aqua-sensor and use new gaskets. Mount the new aqua-sensor in reverse order and replace the seals. Connect the line plug of the aqua-sensors with the wiring harness. Re-...

Page 72

72 installation and maintenance instructions ecotec plus 937 0020031552_06 11 recycling and disposal both the gas fired boiler and its transport packaging consist mainly of recyclable raw materials. Appliance do not dispose of your vaillant ecotec gas fired wall hung boiler appliance or any of its a...

Page 73

Installation and maintenance instructions ecotec plus 937 0020031552_06 73 ec declaration of conformity ec declaration of conformity.

Page 74

74 installation and maintenance instructions ecotec plus 937 0020031552_06.

Page 75

Installation and maintenance instructions ecotec plus 937 0020031552_06 75 installation, commissioning and service record.

Page 76

76 installation and maintenance instructions ecotec plus 937 0020031552_06.

Page 77

Installation and maintenance instructions ecotec plus 937 0020031552_06 77.

Page 80

0020031552_06 gbie 102010 — subject to alterations.