- DL manuals

- Vaillant

- Heat Pump

- aroTHERM VWL ../2 A 230 V series

- Installation Instructions Manual

Vaillant aroTHERM VWL ../2 A 230 V series Installation Instructions Manual

Summary of aroTHERM VWL ../2 A 230 V series

Page 1

For the competent person installation instructions arotherm vwl ../2 a 230 v gb installation instructions publisher/manufacturer vaillant gmbh berghauser str. 40 d-42859 remscheid tel. +49 21 91 18‑0 fax +49 21 91 18‑2810 info@vaillant.De www.Vaillant.De.

Page 2

Contents 2 installation instructions arotherm 0020147164_07 contents 1 safety .................................................................... 3 1.1 action-related warnings ......................................... 3 1.2 risk caused by inadequate qualifications.............. 3 1.3 general safety...

Page 3

Safety 1 0020147164_07 arotherm installation instructions 3 1 safety 1.1 action-related warnings classification of action-related warnings the action-related warnings are classified in accordance with the severity of the possible danger using the following warning signs and signal words: warning sym...

Page 4

1 safety 4 installation instructions arotherm 0020147164_07 1.3.5 risk of injury or material damage due to incorrect handling of the product using the fins on the front side of the product as conductors may lead to injuries (due to falling) or to material damage. ▶ do not use the fins as conductors....

Page 5

Safety 1 0020147164_07 arotherm installation instructions 5 which is available from the heating and hot- water industry council who manage and pro- mote the scheme. Visit www.Centralheating.Co.Uk for more in- formation. Planning consent and building works notific- ation should be submitted either to...

Page 6

1 safety 6 installation instructions arotherm 0020147164_07 improper use of any kind is prohibited..

Page 7

Notes on the documentation 2 0020147164_07 arotherm installation instructions 7 2 notes on the documentation 2.1 observing other applicable documents ▶ you must observe all the operating and installation in- structions included with the system components. 2.2 storing documents ▶ pass these instructi...

Page 8

3 system overview 8 installation instructions arotherm 0020147164_07 3 fan 4 compressor 5 electronic expansion valve 6 plate heat exchanger 3.3.3 application limits operation of the pump outside the application limits results in the heat pump being switched off by the internal control and safety dev...

Page 9

Overview of the equipment 4 0020147164_07 arotherm installation instructions 9 3 ribbed pipe heat ex- changer 4 temperature sensor of the ribbed pipe heat exchanger 5 4-way valve 6 return heating circuit temperature sensor 7 high-efficiency pump with flow sensor 8 purging valve 9 flow heating circui...

Page 10

5 assembly and installation 10 installation instructions arotherm 0020147164_07 5 assembly and installation 5.1 preparing for fitting and installation 5.1.1 delivery, transport and positioning 5.1.1.1 transporting the product warning. Risk of injury from lifting a heavy weight. Lifting weights that ...

Page 11

Assembly and installation 5 0020147164_07 arotherm installation instructions 11 5.1.1.3 checking the scope of delivery ▶ check the contents of the packaging units quant- ity description 1 condensate discharge 1 bag with seals 4 vibration-isolating feet 1 purge hose 5.1.2 complying with clearances an...

Page 12

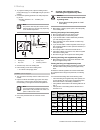

5 assembly and installation 12 installation instructions arotherm 0020147164_07 162 162 778 1103 463 1380* 437 vwl 155/2 a 230v 437 11 * size increases by 45 mm when using the vibration dampers sup- plied. 5.1.2.2 installation clearance c b d a a e 0.5 m clearance for heating mode a > 250 mm b > 100...

Page 13

Assembly and installation 5 0020147164_07 arotherm installation instructions 13 5.1.2.3 selecting the installation site ▶ observe all valid regulations. ▶ install the product outside the building. ▶ do not install the product: – near a heat source, – near flammable materials, – near ventilation open...

Page 14

5 assembly and installation 14 installation instructions arotherm 0020147164_07 5.1.2.4 installing the heat pump 1. Note the safety information in this manual and in the operating instructions before installing the product. 2. Install the product on steel beams, concrete blocks or using a wall holde...

Page 15

Assembly and installation 5 0020147164_07 arotherm installation instructions 15 5.2.2 aligning the product m10 8mm 1. Only use bolts of a specific length. – maximum length: ≤ 8 mm 2. Align the product horizontally so that condensate can flow. Note the product must be installed with the vi- bration-i...

Page 16

5 assembly and installation 16 installation instructions arotherm 0020147164_07 installation without decoupling hydraulic module – drain cock – air separator (if required) – dirt filter – an expansion vessel suitable for the complete hydraulic installation – expansion relief valve 0.3 mpa (3 bar) – ...

Page 17

Assembly and installation 5 0020147164_07 arotherm installation instructions 17 b a 365 Ø25 1 2 3 4 5 6 > 0,1 m 1 condensate drain pipe 2 adaptor 3 cable tie 4 elbow 5 seal 6 heating wire 1. Observe the various installation dimensions for the products. Product dimension value – vwl 55/2 a 70.0 mm b ...

Page 18

5 assembly and installation 18 installation instructions arotherm 0020147164_07 5.4.2 standard tariff 5.4.2.1 230 v connection x4 x9 ebus x7 floor h x2 21 2 1 1 mains connection ter- minal in the product 2 partition caution. Risk of material damage due to high con- nected voltage. At mains voltages ...

Page 19

Assembly and installation 5 0020147164_07 arotherm installation instructions 19 5.5 connection diagrams 5.5.1 connection diagram (vwl 55/2 a 230 v, vwl 85/2 a 230 v, vwl 115/2 a 230 v, vwl 155/2 a 230 v) x8 x1 x6 x4 x7 x60da x14 x700 x16 x11 f1 x1 x15 x13 x26 x23 x21 x22 x30 x25 x24 x25 x5 x10ca x9 ...

Page 20

5 assembly and installation 20 installation instructions arotherm 0020147164_07 9 air inlet temperature sensor 10 electronic expansion valve 11 main pcb 12 coding resistance 13 diagnosis software connection 14 fan 1 15 fan 2 (for vwl 155/2 only) 16 fan pcb 17 crankcase heating 18 drain pan electrica...

Page 21

Start-up 6 0020147164_07 arotherm installation instructions 21 6 start-up 6.1 run the start-up 1. Before starting up the product, read through the operat- ing instructions. 2. Check that the electrical partition is installed. 3. Check that the hydraulic and electric connections are correctly designe...

Page 22

6 start-up 22 installation instructions arotherm 0020147164_07 ▶ to purge the heating circuit, open the heating circuit's purging valve (1) by a 1/4 rotation (b) using an open-end spanner. ▶ increase the operating pressure in the heat pump heat- ing circuit. – operating pressure: 0.15 … 0.2 mpa (1.5...

Page 23

Start-up 6 0020147164_07 arotherm installation instructions 23 caution. Risk of material damage if the heating water is treated with unsuitable additives. Unsuitable additives may cause changes in the components, noises in heating mode and possibly subsequent damage. ▶ do not use any unsuitable fros...

Page 24

6 start-up 24 installation instructions arotherm 0020147164_07 6.11 operating noises "hhmmm..." (*) "ttsheeh...!" "eeee..." “clink!" "chug, chug, chug,..." "whirr..." (*) 1 2 3 4 5 6 * permanent operating noises the noises listed do not constitute a fault with the heat pump. In various operating mod...

Page 25

Maintenance 7 0020147164_07 arotherm installation instructions 25 you can read the flow rate directly from the controller. De- pending on the type of liquid in the heating circuit, the flow rate displayed on the controller may be exaggerated. Example: if you use a 30% mixture of propylene glycol and...

Page 26

7 maintenance 26 installation instructions arotherm 0020147164_07 7.2 preparing for maintenance 7.2.1 procuring spare parts the original components of the unit were also certified as part of the ce declaration of conformity. Information about available vaillant genuine spare parts is available by co...

Page 27

Troubleshooting 8 0020147164_07 arotherm installation instructions 27 1 2 3 1. Remove the side casing. (→ page 14) 2. Remove both screws (1). 3. Lift off the cover. 4. Remove the four screws (2) and remove the mesh (3). 5. Clean the product. 7.6 draining the product conditions: sw10 open-end spanner...

Page 28

9 decommissioning 28 installation instructions arotherm 0020147164_07 8.3 carrying out the actuator test menu → installer level → test menu → sensor/actuator test you can check that the components of the heating installa- tion are functioning correctly using the sensor/actuator test. Display test pr...

Page 29

Disposal 11 0020147164_07 arotherm installation instructions 29 11.2 arranging disposal of coolant warning. Risk of damage to the environment. This heat pump contains r 410 a coolant. The coolant must not be allowed to escape into the atmosphere. R 410 a is a fluorinated greenhouse gas covered by th...

Page 30

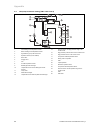

Appendix 30 installation instructions arotherm 0020147164_07 appendix a heat pump schematic a.1 heat pump schematic drawing (vwl 55/2 a 230 v) pzhh - ti - tce ti - ti - pt - ti - ti - ti - ti - 7 9 8 23 22 18 15 16 17 14 12 6 1 4 5 13 19 21 24 10 25 11 20 + 2 3 1 flow heating circuit temperature sen...

Page 31

Appendix 0020147164_07 arotherm installation instructions 31 a.2 heat pump schematic drawing (vwl 85/2 a 230 v) pzhh - ti - tce ti - ti - pt - ti - ti - ti - ti - 7 9 8 23 22 18 15 16 17 14 12 6 1 4 5 13 19 21 24 10 25 11 20 + 2 26 3 1 flow heating circuit temperature sensor 2 return heating circuit...

Page 32

Appendix 32 installation instructions arotherm 0020147164_07 a.3 heat pump schematic drawing (vwl 115/2 a 230 v) pzhh - ti - tce ti - ti - pt - ti - ti - ti - ti - 7 9 8 23 22 18 15 16 17 14 12 6 1 4 5 13 19 21 24 10 25 11 20 + 2 3 1 flow heating circuit temperature sensor 2 return heating circuit t...

Page 33

Appendix 0020147164_07 arotherm installation instructions 33 a.4 heat pump schematic drawing (vwl 155/2 a 230 v) pzhh - ti - tce ti - ti - pt - ti - ti - ti - ti - 7 9 8 23 22 18 15 16 17 14 12 6 1 3 4 5 13 19 21 24 10 25 11 20 + 2 1 flow heating circuit temperature sensor 2 return heating circuit t...

Page 34

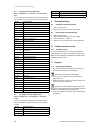

Appendix 34 installation instructions arotherm 0020147164_07 parameter explanation default setting adjustment range own setting language select the required language here. 02 english 01 deutsch 02 english 03 français 04 italiano 05 dansk 07 castellano 08 türkçe 09 magyar 11 Українська 15 svenska 16 ...

Page 35

Appendix 0020147164_07 arotherm installation instructions 35 status description 518 pump operated by remote control (auxiliary) 519 compressor's oil temperature too low for opera- tion 530 pump pre-run before cooling mode 531 pump pre-run correct in cooling mode 532 water temperature/compatibility t...

Page 36

Appendix 36 installation instructions arotherm 0020147164_07 status description 581 communication error with inverter 582 fault: compressor overcurrent 584 fault: electronic expansion valve 585 fan speed too low 588 coding resistance fault 589 fault: underfloor protective circuit 590 fault: 4-way va...

Page 37

Appendix 0020147164_07 arotherm installation instructions 37 vwl 55/2 a 230 v vwl 85/2 a 230 v vwl 115/2 a 230 v vwl 155/2 a 230 v sound power level for a7w45 according to en 12102 and en iso 9614-1 59 db(a) 60 db(a) 65 db(a) 65 db(a) sound power level for a7w55 according to en 12102 and en iso 9614...

Page 38

Appendix 38 installation instructions arotherm 0020147164_07 vwl 55/2 a 230 v vwl 85/2 a 230 v vwl 115/2 a 230 v vwl 155/2 a 230 v power consumption ef- fective at a7/w35 1.10 kw 1.80 kw 2.50 kw 3.40 kw input current at a7/w35 4.80 a 7.80 a 10.90 a 14.80 a a7/w45 heating output 4.40 kw 7.80 kw 10.20...

Page 39

Appendix 0020147164_07 arotherm installation instructions 39 code meaning cause f.532 building circuit: flow rate too low – heating circuit not fully purged – dirt filter in the heating circuit return is missing or blocked – low water pressure – pressure loss in the heating circuit too high – pump c...

Page 40

Appendix 40 installation instructions arotherm 0020147164_07 code meaning cause f.752 fault: inverter – the "max. Duration power supply cut-off" parameter has been set poorly (see the "heat pump setting parameters" section in the appendix). – inverter box damaged – the cooler inverter box is blocked...

Page 41

Appendix 0020147164_07 arotherm installation instructions 41 f commissioning checklist this commissioning checklist is to be completed in full by the competent person who commissioned the heat pump and associated equipment as a means of demonstrating compliance with the appropriate building regulati...

Page 42

Appendix 42 installation instructions arotherm 0020147164_07 it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service interval record below, please ensure you have carrie...

Page 43

Index 0020147164_07 arotherm installation instructions 43 index a actuator test ........................................................................ 28 b back cleaning......................................................................... 26 c cable duct ..........................................

Page 44

0020147164_07 06.05.2016 vaillant ltd. Nottingham road belper derbyshire de56 1jt telephone 0330 100 3461 info@vaillant.Co.Uk www.Vaillant.Co.Uk © these instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with the manufacturer's written consent. We re...