- DL manuals

- Vaillant

- Boiler

- atmocraft

- Installation And Maintenance Instructions Manual

Vaillant atmocraft Installation And Maintenance Instructions Manual

Summary of atmocraft

Page 1

Vk 654/9 - 1654/9 atmocraft de; at; gb.

Page 3

For the heating engineer vk 654/9 – 1654/9 installation and maintenance instructions atmocraft gas heating boiler gb.

Page 4

2 contents installation and maintenance instructions atmocraft contents 1 notes on the documentation . . . . . . . . . . . . 3 1.1 storage of the documents . . . . . . . . . . . . . . . . . . 3 1.2 symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 description of the applianc...

Page 5

3 installation and maintenance manual atmocraft gb notes on the documentation 1 description of the appliance 2 2 description of the appliance 2.1 identification plate the identification plate is mounted on the back of the electronic box. 1 4 3 2 fig. 2.1 identification plate the following informatio...

Page 6

4 installation and maintenance manual atmocraft 2.2 ce label ce labelling shows that the appliances comply with the basic requirements of the following directives: - gas appliances directive (90/396/eec) - electromagnetic compatibility directive with threshold class b (89/336/eec) - low voltage dire...

Page 7

5 installation and maintenance manual atmocraft gb 2.6 type overview the vaillant atmocraft gas boilers are supplied with the following capacities: appliance type nominal heat capacity p (kw) designated country (designation in accordance with iso 3166) approval category type of gas vk 654/9 vk 754/9...

Page 8

6 installation and maintenance manual atmocraft 2.7 functional and operating elements 13 12 15 14 3 4 1 6 5 2 10 9 8 7 11 fig. 2.1 overview of the functional elements key: 1 electronic box 2 gas fitting 3 burner 4 boiler filling and drain cock 5 immersion sleeve 6 safety temperature limiter stl oper...

Page 9

7 installation and maintenance manual atmocraft gb 3 safety instructions and regulations 3.1 safety instructions assembly the combustion air fed to the unit must be free of chemicals which contain, e.G. Fluorine, chlorine or sulphur. Sprays, solvents or cleaning agents, paints and adhesives can cont...

Page 10

8 installation and maintenance manual atmocraft there is danger of being injured or scalded by the boiler and by all components carrying water. Only carry out work on these components once they have cooled down. Troubleshooting disconnect the unit from the mains before starting to work. Close the ga...

Page 11

9 installation and maintenance manual atmocraft gb 4 assembly 4.1 installation site 4.1.1 regulations concerning installation site the approval of the relevant building regulations authority must be obtained for the selection of the installation site and for the characteristics of the ventilation an...

Page 12

10 installation and maintenance manual atmocraft 4.2 dimensions 1 2 3 64 69 0 66 5 56 5 32 0 Ød b c 1100 114 5 a 4 4 min. 100 100 690 4 fig. 4.1 dimensions for vk in mm key: 1 heating feed 2 gas connection 3 heating return 4 flue gas connection boiler type a b c ∅ d heating feed/ heating return gas ...

Page 13

11 installation and maintenance manual atmocraft gb 3 f e h d 500 b c 1 2 Ø Ø d 4 4 4 66 5 56 5 32 0 69 0 min. 550 g 114 5 d a 64 Ø k 3 1 2 100 d 690 fig. 4.2 dimensions for vkm in mm key: 1 heating feed 2 gas connection 3 heating return 4 flue gas connection boiler type a b c ∅ d ∅ d a f g h r exha...

Page 14

12 installation and maintenance manual atmocraft 4.3 recommended minimum distance for installation 1000 500 100 b a 500 2200 fig. 4.3 minimum clearances when installing the boiler, the minimum clearances shown in fig. 4.3 must be maintained to ensure unhindered access to the boiler. The height of th...

Page 15

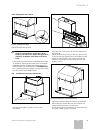

13 installation and maintenance manual atmocraft gb 4.4 boiler block, pre-assembled note! Here you will find the scope of supply of the pre-assembled boiler block. For additional installation see chapter 4.5. 4.4.1 scope of supply, boiler block, pre-assembled check the scope of supply in accordance ...

Page 16

14 installation and maintenance manual atmocraft 4.4.2 scope of supply, cladding check the scope of supply in accordance with the adjacent illustration and table for completeness and lack of damage. A a a c d h b b e e g f fig. 4.5 scope of supply cladding description back wall plates (1 x large, 2 ...

Page 17

15 installation and maintenance manual atmocraft gb 4.4.4 aligning the boiler block 1 fig. 4.7 aligning boiler block the boiler block must be level. Note! Under no circumstances should there be an incline to the side of the plug in the upper boss, otherwise air bubbles could form in the boiler block...

Page 18

16 installation and maintenance manual atmocraft 2 3 1 fig. 4.11 fitting the intermediate plate and side plates • fix one side plate (1) to the baseframe front and back with two screws. • screw the intermediate plate (2) in front of the boiler. The intermediate plate is placed on the brackets and sc...

Page 19

17 installation and maintenance manual atmocraft gb 11 2 fig. 4.15 inserting the temperature sensor into the immersion sleeve • insert the temperature sensor into the lower immersion sleeve (1) on the left of the boiler. • stick the enclosed identification plate (2) to the top left of the intermedia...

Page 20

18 installation and maintenance manual atmocraft 4.7 connection of the electrical cable fig. 4.19 connecting the gas valves and the stl • connect the connection cable to the electronic box as shown in the electrical schematic drawing, see 5.4.3 and 5.4.4. 4.8 completing the boiler 1 2 4 5 3 3 fig. 4...

Page 21

19 installation and maintenance manual atmocraft gb 1 2 3 fig. 4.23 fitting the cover plate • place the cover plate (1) in position. The braces (3) of the cover plate should be inserted into the slots in the side plates (2). Then push the cover plate back until the front edge of the cover plate is i...

Page 22

20 installation and maintenance manual atmocraft 5 installation 5.1 general instructions for heating system caution! Flush the heating system thoroughly before connecting the appliance! By doing that, residue such as welds, cinder, hemp, putty, rust, rough dust and similar substances are removed fro...

Page 23

21 installation and maintenance manual atmocraft gb 5.4.2 connecting the mains feed fig. 5.1 connecting the mains supply the nominal voltage of the mains must be 230 v; if the mains voltage is more than 253 v and below 190 v functional impairment is possible. Caution! The electronics can be destroye...

Page 24

22 installation and maintenance manual atmocraft 5.4.4 electrical connection plan with system pro e charging pump heating circuit pump option external controller/room thermostat 230v contact option external controller /room thermostat 7-8-9, 24v, digital or analogue option installation thermostat fe...

Page 25

23 installation and maintenance manual atmocraft gb charging pump heating circuit pump option external controller/room thermostat 230v contact option external controller /room thermostat 7-8-9, 24v, digital or analogue option installation thermostat feed/return sensor (option) dcf connection externa...

Page 26

24 installation and maintenance manual atmocraft 5.4.5 connection of external accessories and control units when connecting accessories, the existing bridge on the relevant plug must be removed. Take especial care that the bridge is removed when incorporating an installation thermostat. Controller c...

Page 27

25 installation and maintenance manual atmocraft gb 5.4.6 connecting external sensors, control units (accessories) fig. 5.5 connecting the sensors • push the sensor for water storage tank onto the plug (white plug) on the sensor wiring harness. • connect the outer sensor to the edge plug x8 (when us...

Page 28

26 installation and maintenance manual atmocraft caution! Do not add frost or corrosion preventative to the heating water! If frost or corrosion preventative is added to the heating water this can cause changes in the seals and can cause noises to be created during the heating process. Vaillant assu...

Page 29

27 installation and maintenance manual atmocraft gb the permissible range for the connection flow pressure is: 17.0 to 25.0 mbar - 2nd gas family (natural gases) 35.0 to 45.0 mbar - 3rd gas family (liquid gases) caution! If the connection pressure is outside the quoted range, the cause of the deviat...

Page 30

28 installation and maintenance manual atmocraft 6.2.4 gas setting tables type of gas nozzle designation corresponds to the nozzle pressure diameter ø in 1/100 mm nozzle pressure nominal output (2nd stage) partial output (1st. Stage and starting gas pressure) natural gas 2e, 2h ws = 15.0 kwh/m 3 260...

Page 31

29 installation and maintenance manual atmocraft gb 6.2.5 function check to complete the gas setting it is necessary to carry out a function check as follows: • open the gas-cock and start up the boiler as shown in chapter 6. • check the boiler and heating system for tightness. Caution! Also make su...

Page 32

30 installation and maintenance manual atmocraft 6.2.7 changeover from liquid gas p to natural gas changing the nozzles 1 2 fig. 6.5 changing the nozzles • turn the boiler off. • replace the ignition burner nozzle (1x24) (1) by the nozzle for natural gas e(h) (2x27). • unscrew the burner nozzles for...

Page 33

31 installation and maintenance manual atmocraft gb • point out to the user the correct (economical) settings for temperatures, regulators and thermostat valves. • instruct the owner on the need for regular inspection and maintenance of the system. Recommend a inspection/maintenance contract to the ...

Page 34

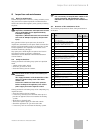

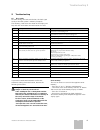

32 installation and maintenance manual atmocraft 7.2 overview of the adjustable installation parameters the following parameters can be adjusted to match the unit to the heating system and to the requirements of the customer: note! In the last column you can enter your settings after you have set th...

Page 35

33 installation and maintenance manual atmocraft gb 8 inspection and maintenance 8.1 notes for maintenance permanent operational readiness, safety, reliability and a long service life require inspections and maintenance work to be carried out regularly every year by a heating engineer. Danger! Inspe...

Page 36

34 installation and maintenance manual atmocraft 8.3.1 checking the safety temperature limiter 1 2 abb. 8.1 release button, button fault reset key 1 stl release button with cover cap 2 button fault reset • switch on the mains switch. • turn the heating circuit off. • set the unit to maximum feed tem...

Page 37

35 installation and maintenance manual atmocraft gb 8.4 maintenance tasks 8.4.1 cleaning the burner caution! If possible, do not use any chemical cleaning agents, otherwise deposits could build up on the monitoring and ignition electrodes. The unit may switch to fault condition. If you do use chemic...

Page 38

36 installation and maintenance manual atmocraft fig. 8.5 fitting the burner if it is necessary to also clean the heat exchanger, proceed as per section 8.4.2. Cleaning the heat exchanger. Otherwise re-fit the burner. Proceed as follows: • replace all the seals with original new ones. Slide the burn...

Page 39

37 installation and maintenance manual atmocraft gb 9 troubleshooting 9.1 error codes for fault finding and fault rectification, the fault signal facility of the dia system is normally adequate. The following fault codes are shown in the display and help with the localisation and rectification of a ...

Page 40

38 installation and maintenance manual atmocraft 9.2 resetting the interlock after switch-off by the safety temperature limiter (stl) 1 2 fig. 9.1 resetting the interlock after switch-off by the stl if the fault code “f.20”is displayed, the safety temperature limiter (stl) has automatically switched...

Page 41

39 installation and maintenance manual atmocraft gb display meaning display value/adjustable value d.00 test operation on 1st burner stage for gas setting (only for 2-stage boilers) 0 = normal operation (both stages) 1 = after starting switching back to the 1st stage 2 = full output (2nd stage) d.01...

Page 42

40 installation and maintenance manual atmocraft 10 vaillant service to ensure efficient and reliable operation of your boiler it is recommended that regular servicing is carried out by your service provider. Vaillant applied system sales vaillant ltd., unit d1 lowfields business park, elland. West ...

Page 43

41 installation and maintenance manual atmocraft gb 12 technical data technical data unit vk 654/9 vk 754/9 vk 854/9 vk 1054/9 vk 1154/9 vk 1304/9 vk 1504/9 vk 1654/9 nominal heat output kw 65 75 85 105 115 130 150 165 nominal heat loading kw 70.7 81.5 92.4 114 125 141.3 163 179.3 minimum heat outpu...

Page 44

83 5 5 5 3_0 2 dea t gb 09 2 006.