- DL manuals

- Vaillant

- Boiler

- eco TEC plus 415

- Instructions Manual

Vaillant eco TEC plus 415 Instructions Manual

Summary of eco TEC plus 415

Page 1

For the installer instructions for installation and servicing ecotec plus gb wall hung open vent condensing boiler supplied by heatingspares247.Com.

Page 2

Installation and servicing ecotec plus 2 contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 notes on the documentation . . . . . . . . . . . . 4 1.1.1 other instructions supplied with this appliance . . . . . . . . . . . . . . . . . . . . . 4 1.1.2 retention of docum...

Page 3

Installation and servicing ecotec plus 3 contents page contents 9 combustion analysis . . . . . . . . . . . . . . . . . . . 37 9.1 check co 2 content. . . . . . . . . . . . . . . . . . . . . 37 10 trouble shooting . . . . . . . . . . . . . . . . . . . . . . . 38 10.1 logical fault finding procedure....

Page 4

Installation and servicing ecotec plus 4 1.1 notes on the documentation. To ensure clarity of information in instructions a new european standard of advice and symbols is being introduced. To ensure compliance with this new standard the following details are included. The following information is in...

Page 5

Installation and servicing ecotec plus 5 1.4 general information thank you for choosing a vaillant boiler. The information given in this booklet will enable you to obtain the best performance from your boiler. The benchmark logbook should be completed by the installer and/or commissioning engineer a...

Page 6

Installation and servicing ecotec plus 6 1.4.13 protection against freezing the boiler has a built in frost protection programme as long as the electricity and gas are left switched on. This device operates the burner and system pump when the temperature inside the boiler falls to 3°c. Any other exp...

Page 7

Installation and servicing ecotec plus 7 1.5 statutory requirements the appliance is suitable only for installation in gb and ie and should be installed in accordance with the rules in force. In gb the installation of the boiler must be carried out by a competent person as described in the following...

Page 8

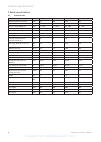

Installation and servicing ecotec plus 8 2 boiler specifications 2 boiler specifications 2.1 technical data description unit ecotec plus 415 ecotec plus 418 ecotec plus 428 ecotec plus 438 maximum ch heat input (net) kw 15.3 18.9 28.6 38.4 ch heat output (80/60 °c) kw 5.0 - 15.0 5.0 - 18.6 5.3 - 28....

Page 9

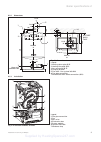

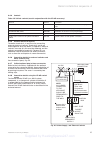

Installation and servicing ecotec plus 9 48 26 33 176 160 340 113 375 133 30 15mm gas connection 53 161 6 10 1 2 3 7 4 5 6 outside wall face boiler cl flue cl flue cl flue cl flue cl boiler cl 56 2.1.2 dimensions boiler specifications 2 legend: 1 heating return pipe Ø 22 2 heating flow pipe Ø 22 3 g...

Page 10

Installation and servicing ecotec plus 10 3 general requirements 3 general requirements 3.1 preliminary remarks for room sealed appliances this appliance should only be installed with a vaillant flue system. Install the flue system as detailed in the separate flue installation instructions supplied ...

Page 11

Installation and servicing ecotec plus 11 65 13 30 405 - 610 48 general requirements 3 3.4 gas supply the gas supplier should ensure the availability of an adequate supply of gas. A gas meter may only be connected to the service pipe by the supplier of gas or their contractor. An existing meter shou...

Page 12

Installation and servicing ecotec plus 12 3 general requirements 3.5.1 flue termination the following details refer to both flue systems. A. The terminal must be located where the combustible substances can escape freely at all times. B. A plume of water vapour will sometimes be visible from the flu...

Page 13

Installation and servicing ecotec plus 13 general requirements 3 3.8 domestic hot water cylinder caution! Single feed indirect cylinders are not suitable. The domestic hot water cylinder must be of the double feed fully indirect coil type. It must be suitable for working at a gauge pressure of 0.35 ...

Page 14

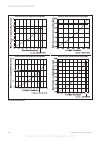

Installation and servicing ecotec plus 14 3 general requirements ecotec plus 415 pressure loss graph ecotec plus 428 pressure loss graph ecotec plus 418 pressure loss graph ecotec plus 438 pressure loss graph fig. 3.8 pressure loss supplied by heatingspares247.Com.

Page 15

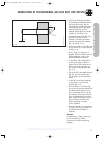

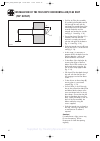

Installation and servicing ecotec plus 15 general requirements 3 fig. 3.9 open vented system 3.16 open vented heating system the boiler must be supplied from an unrestricted water supply taken from a feed and expansion cistern situated at a maximum height of 27 metres (90ft) above the boiler. The co...

Page 16

Installation and servicing ecotec plus 16 3 general requirements fig. 3.10 typical installation 3.17 sealed water systems the installation must comply with the appropriate requirements of the current issue of bs4814, bs5449, bs6759, bs6798 and bs7074 part 1 and 2. For ie your attention is drawn to t...

Page 17

Installation and servicing ecotec plus 17 boiler installation sequence 4 4 boiler installation sequence 4.1 boiler location note! This boiler is not suitable for outdoor installation. This boiler may be installed in any room, although particular attention is drawn to the installation of a boiler in ...

Page 18

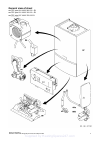

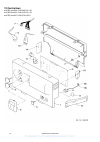

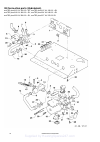

Installation and servicing ecotec plus 18 4.1.4 contents included with delivery the vaillant ecotec plus is delivered pre-mounted in a package unit. Check that all the parts have been delivered intact (see fig. 4.2 and table 4.1. Do not remove the boiler from the polystyrene base at this stage. Plac...

Page 19

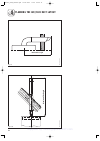

Installation and servicing ecotec plus 19 160 fig. 4.3 boiler hanging bracket boiler installation sequence 4 fig. 4.4 removing front casing retaining dowel (2 off) front casing screw (2 off) 4.3 fitting the boiler hanging bracket reposition the wall template over the flue hole ensuring the template ...

Page 20

Installation and servicing ecotec plus 20 4 boiler installation sequence 4.3.3 gas connection danger! The gas connection may only be made by a competent person. The legal directives and the local regulations for gas supply companies must be observed. Caution! Ensure a stress-relief assembly of the g...

Page 21

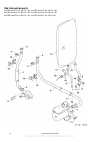

Installation and servicing ecotec plus 21 coupling fig. 4.5 gas and condense connections 22mm compression is the recommended fixing for servicing. Fig. 4.6 water connections 4.4 electrical connections danger! This appliance must be earthed. Electrocution caused by touching live parts can be fatal. B...

Page 22

Installation and servicing ecotec plus 22 fig. 4.8 mains supply connection fig. 4.7 mains supply connection 4.4.1 connection to the main supply • lower the electronics box, see fig. 4.7. Opening the electronics box • unclip the bottom of the electronics box cover and hinge back to reveal the connect...

Page 23

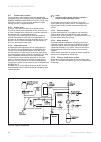

Installation and servicing ecotec plus 23 fig. 4.9 connection wiring x20 x2 - + bus 24v 230v 7 8 9 l n 3 4 5 x40 x41 x31 caution: do not connect supply voltage! Risk of damage to electronics! Room thermostat 24v: connection 7, 8 and 9 no bi-directional interface (analogue only) mains supply: 230v / ...

Page 24

Installation and servicing ecotec plus 24 fig. 4.10 mains supply connection ntc flow x 20/8 blue x 20/16 blue (earth) green/yellow fuse t2e 250 volts green/yellow green/yellow x 20/18 red (24 vdc) x 20/9 blue (earth) x 20/4 grey(pwm) x 20/3 black (hall signal) x 20/17 red (24 vdc) black link x 20/5 ...

Page 25

Installation and servicing ecotec plus 25 4.4.4 controls table 4.2 vaillant controls (used in conjunction with the vr 65 accessory) controls item no. Connection vrc 400 (1-circuit controller, weather-controlled) 00 2001 0843 installation in electronics box or wall-mounted (plug-and play) vrt 360 (ro...

Page 26

Installation and servicing ecotec plus 26 5 commissioning (part i) 5 commissioning (part i) please ensure the “benchmark” commissioning check list is completed and left with the user. 5.1 preliminaries - all systems a competent person should carry out commissioning, in accordance with the current is...

Page 27

Installation and servicing ecotec plus 27 1 3 2 4 pressure test point electrical plug gas control valve throttle offset adjustment fig. 5.3 gas control valve 5 commissioning (part i) 5.1.2 initial lighting the lighting procedure of the boiler is fully automated. To prepare the boiler for initial lig...

Page 28

Installation and servicing ecotec plus 28 6 natural gas to lpg conversion 6 natural gas to lpg conversion the ecotec plus is able to be field adjusted for use on lpg – propane g31 gas. To enable conversion the use of a combustion analyser is necessary. Caution! After converting from natural gas to l...

Page 29

Installation and servicing ecotec plus 29 7 functional checks commissioning (part ii) commissioning and service log. 7 functional checks commissioning (part ii) functional checks procedure: after installing and checking the gas supply pressure, perform a function check before commissioning the appli...

Page 30

Installation and servicing ecotec plus 30 7.1.3 final flush of the heating system (hot) • operate the appliance until the heating system is up to temperature. • check the heating system for leaks. • connect a hose to the drain valve located at the lowest position of the heating system. • shut off th...

Page 31

Installation and servicing ecotec plus 31 8 inspection and maintenance 8.1 initial inspection to ensure the continued safe and efficient operation of the boiler it is recommended that it is checked and serviced as necessary at regular intervals. The frequency of servicing will depend upon the partic...

Page 32

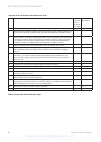

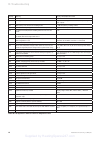

Installation and servicing ecotec plus 32 no. Activity column 1 inspection must be carried out once a year column 2 maintenance 1 check the air/ gas flue system and ensure it is not blocked, damaged and is fitted correctly. X 2 measure the gas rate during operation (see table 5.1. Inside section 5 c...

Page 33

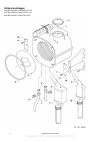

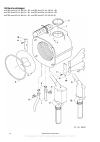

Installation and servicing ecotec plus 33 8.1.4 general all routine servicing requirements can be achieved by the removal of the front casing, inner case and chassis panel only. Remove the two screws on the underside of the front casing and lift off. Remove the two screws on the front of inner case ...

Page 34

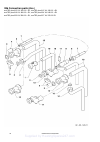

Installation and servicing ecotec plus 34 fig. 8.5 gas service cock fig. 8.4 gas service cock 8 inspection and maintenance 8.1.5 spark electrode disconnect the ignition lead and earth lead from the igniter unit and two securing screws at the spark electrode. Withdraw the spark electrode carefully fr...

Page 35

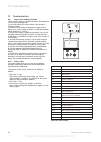

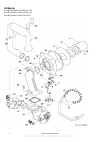

Installation and servicing ecotec plus 35 8 inspection and maintenance fig. 8.6 fan, gas valve and burner note! If the burner has to be removed it will require a new gasket when refitted. Note! When replacing ensure that the sealing grommet, situated below the gas valve is correctly re-seated. 8.1.7...

Page 36

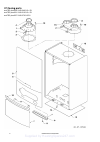

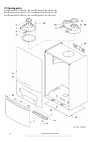

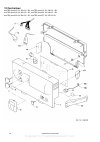

Installation and servicing ecotec plus 36 fig. 8.8 insulation fig. 8.9 panels 8 inspection and maintenance inner casing seal front casing 8.1.8 condensate drain the condense drain does not normally need removing during servicing. To flush the condense drain carefully pour water into the heat exchang...

Page 37

Installation and servicing ecotec plus 37 combustion analysis 9 9 combustion analysis note! The boiler is fitted with a combustion analysis test point. A suitable combustion analyser can be connected to this point to establish the combustion performance of the boiler. 9.1 check co 2 content refer to...

Page 38

Installation and servicing ecotec plus 38 10 troubleshooting 10 troubleshooting 10.1 logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section 4 ‘wiring system’). 2. Check that the external el...

Page 39

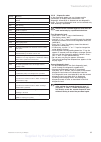

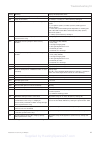

Installation and servicing ecotec plus 39 troubleshooting 10 display meaning charge hot water cylinder (when accessories are fitted): s.20 warmstart demand s.21 fan running s.22 pump running s.23 ignition sequence s.24 burner ignited s.25 fan and water pump running s.26 fan over run s.27 pump over r...

Page 40

Installation and servicing ecotec plus 40 display meaning display value/adjustable value d. 0 heating part load adjustable heating part load in kw (factory setting: max. Output) d. 1 water pump over run time for heating mode 2 - 60 min (factory setting: 5 min) d. 2 max. Burner anti cycling period at...

Page 41

Installation and servicing ecotec plus 41 display meaning display value/adjustable value d.17 heating flow/return regulation change over 0 = flow, 1 = return (factory setting: 0) d.18 pump mode (return) 0 = return, 1 = nonstop, 2 = winter (factory setting: 0) d.19 operating modes of the two-speed he...

Page 42

Installation and servicing ecotec plus 42 table 10.3 diagnostics codes of the second diagnostic level (continued) code meaning cause f. 0 flow–ntc open circuit ntc broken, ntc cable broken, defective connection at ntc, defective connection at electronics f. 1 return–ntc open circuit ntc broken, ntc ...

Page 43

Installation and servicing ecotec plus 43 code meaning cause f.27 incorrect sensing of flame flame detector defective f.28 appliance does not start: attempts to ignite during start failed faults in the gas supply such as:- - gas meter or gas pressure detector defective - air in gas- gas flow pressur...

Page 44

Installation and servicing ecotec plus 44 10.2 test programs special functions can be triggered on the appliances by activating various test programs. These programs are given in detail in the table 10.5. • the test programs p.0 to p.6 will be started when “power on” is turned on and the “+” key is ...

Page 45

Installation and servicing ecotec plus 45 parts replacement 11 note! The ecotec plus 428 and 438 fan is secured through an extension piece with two securing screws, check and replace any seals or gaskets if necessary. 11.5 replacing the heat exchanger for access refer to section 8.1.4. Remove the ga...

Page 46

Installation and servicing ecotec plus 46 fig. 11.3 condense trap spigot bung (remove and discard) spigot adapter condense trap float screw 12 recycling and disposal the design of all vaillant products takes into account the subsequent recycling and/or eventual safe scrapping of each component used....

Page 47

Installation and servicing ecotec plus 47 appendix 14 supplied by heatingspares247.Com.

Page 48

Installation and servicing ecotec plus 48 supplied by heatingspares247.Com.

Page 49

Installation and servicing ecotec plus 49 supplied by heatingspares247.Com.

Page 50

Installation and servicing ecotec plus 50 notes supplied by heatingspares247.Com.

Page 51

Installation and servicing ecotec plus 51 notes supplied by heatingspares247.Com.

Page 52

00 2 00 2 08 2 8_0 2 gb /08 /2 006 · s u b je ct t o a lt e ra ti o n supplied by heatingspares247.Com.

Page 53

For the installer flue installation instructions ecomax 613/2 e ecomax 618/2 e ecomax 622/2 e ecomax 635/ e ecomax 824/2 e ecomax 828/2 e ecomax 835/ e ecomax pro 18 e ecomax pro 28 e ecotec plus 415 ecotec plus 418 ecotec plus 428 ecotec plus 438 ecotec plus 612 ecotec plus 615 ecotec plus 618 ecot...

Page 54

834449_09gb_082006.Qxd 10.08.2006 12:20 seite 2 supplied by heatingspares247.Com.

Page 55: Overview

Overview par t 2 concentric 80/125 part 1 pages 4 - 36 standard concentric systems Ø 60/100 (galvanized steel air duct/plastic flue duct) part 2 pages 37 - 59 optional concentric system Ø 80/125 (galvanized steel air duct/plastic flue duct) par t 2 concentric 80/125 par t 1 concentric 60/100 834449_...

Page 56: Requirements

4 contents: part 1 concentric 60/100 page the air/flue duct must be installed by a suitably qualified service provider, which is responsible for observing the relevant specifications, regulations and standards. Requirements planning the air/flue duct layout regulations and standards to be observed 5...

Page 57: Par

5 par t 1 concentric 60/100 requirements regulations and standards to be observed ¤ ☞ vaillant ecomax/ecotec boilers are certified as heating boilers with corresponding flue systems according to ec directive 90/396/eec on gas-fired devi- ces. This installation manual is covered by this certification...

Page 58

X x x x x x x x x x x x x x x x x x x x 303 936 optional connection accessories telescopic offset section telescopic extension 440 mm - 690 mm Ø 60/100 6 planning the air/flue duct layout alternative termination accessories available air/flue duct extensions, concentric 470 mm - Ø 60/100 air/flue du...

Page 59: Par

7 par t 1 concentric 60/100 planning the air/flue duct layout fig. 1.1: extensions, Ø 60/100 13 65 fig. 1.3: elbow joints, Ø 60/100 elbow, 87°, Ø 60/100 only part of: vaillant accy. No.: 303 933 vaillant accy. No.: 303 936 18 27 18 27 18 27 fig. 1.2: elbow joints, Ø 60/100 elbow, 87°, Ø 60/100 vaill...

Page 60

8 planning the air/flue duct layout 155 fig. 1.8: sliding sleeve, Ø 60/100 sliding sleeve (pp), Ø 60/100 vaillant accy. No.: 303 915 290 – 374 33 – 56 fig. 1.7: offset section, Ø 60/100 offset section, Ø 60/100 vaillant accy. No.: 303 919 303919_iax 440 – 690 fig. 1.6: telescopic extension, Ø 60/100...

Page 61: Par

9 153 130 390 fig. 1.11: flat roof penetration collar flat roof penetration collar vaillant accy. No.: 009 056 498 132 255 fig. 1.9: adjustable roof tile for pitched roof adjustable roof tile for pitched roof vaillant accy. No.: 009 076 (black) gu_laz 41/0 planning the air/flue duct layout fig. 1.12...

Page 62

10 planning the air/flue duct layout fig. 1.16: 45° bend 45° bend for variable termination kit - black vaillant accy. No.: 303 945 45° bend for variable termination kit - white vaillant accy. No.: 303 948 fig. 1.15: 87° elbow 87° elbow for variable termination kit - black including 1 support clip va...

Page 63: Par

11 fig. 1.17: flue support clip, Ø 60 mm 60 flue support clip, Ø 60 mm delivered with kits maximum flue lengths for use with ecomax planning the air/flue duct layout vertical flue systems 303 900 max. Permitted concentric flue length fig. 1.18 12.0 m 10.0 m 7.0 m 10.0 m 9.0 m variable termination ki...

Page 64

Max. Permitted concentric flue length fig. 1.19 12.0 m 12.0 m 12.0 m 8.0 m 12.0 m 12 planning the air/flue duct layout variable termination kit 303 942 303 946 only in combina- tion with 303 933 max. Permitted concentric flue length fig. 1.20 accessories accy. No. Horizontal flue systems 303 933 max...

Page 65: Par

13 par t 1 concentric 60/100 maximum flue length maximum flue length las euro b/s 074/0 las euro b/s 074/0 fig. 1.18: horizontal flue systems fig. 1.19: vertical flue systems planning the air/flue duct layout concentric flue length flue length outside fig. 1.20: horizontal flue system installed with...

Page 66: Installing The

14 installing the air/flue duct sliding sleeve fig. 2.0: installing the sliding sleeve 1 3 4 6 7 5 2 schiebemuffe_neu installing the air/flue duct sliding sleeve ☞ note: for installations where there is in- sufficient movement to allow fitting of the flue into flue outlet, a slid- ing sleeve (accy. ...

Page 67: Preparation

15 installation of the horizontal air/flue duct horizontal air/flue duct accy no.: 303 933 (length 0.75 m) contents of the accessory: • horizontal air/flue duct • 87° elbow • 1 x 48 mm air duct clamp • 1 x 30 mm air duct clamp • internal trim ring Ø 100 • external wall seal. Fig. 3.7: horizontal air...

Page 68

16 installation of the horizontal air/flue duct (top outlet) • once the position of the flue exit hole has been determined, the hole should be cut through the wall using a core drill of 125 mm diameter. Note: if access can be gained to the proposed flue exit point from outside the dwelling, the hole...

Page 69: Par

17 installation of the horizontal air/flue duct (top outlet) • push the air/flue duct assembly ( 1 ) including the flexible external seal through the wall until the seal clears the outside face of the wall and pull air/flue duct back towards the boiler until the external seal touches the outside wal...

Page 70: Preparation

18 installation of the telescopic horizontal air/flue duct horizontal telescopic air/flue duct accy no.: 303 936 (length 0.4 - 0.61 m) contents of the accessory: • horizontal telescopic air/flue duct • 87° elbow • 1 x 48 mm air duct clamp • 1 x 30 mm air duct clamp • internal trim ring Ø 100 • exter...

Page 71: (Top Outlet)

19 installation of the telescopic horizontal air/flue duct (top outlet) • once the position of the flue exit hole has been determined, the hole should be cut through the wall using a core drill of 125 mm diameter. Note: if access can be gained to the proposed flue exit point from outside the dwellin...

Page 72: (Top Outlet)

20 installation of the telescopic horizontal air/flue duct (top outlet) • push the air/flue duct assembly ( 1 ) including the flexible external seal through the wall until the seal clears the outside face of the wall and pull air/flue duct back towards the boiler until the external seal touches the ...

Page 73: Par

21 par t 1 concentric 60/100 installation of the black terminal kit black terminal kit accy. No.: 303 934 contents of the accessory: • black terminal • external wall seal fig. 3.19: black kit assembly before installing the flue duct • use an 8 mm screwdriver to bend the catches inwards (fig. 3.20). ...

Page 74: Assembly

22 installation of the black terminal kit fig. 3.24: locking the catch fig. 3.23: flue duct assembly after installing the flue duct danger! Before starting work, shut down the appliance and prevent it from being switched on unintentionally. • remove the wall seal from the terminal. • use an 8 mm scr...

Page 75: Par

23 par t 1 concentric 60/100 installation of the variable termination kit variable termination kit accy. No.: 303 942 (black) 303 946 (white) contents of the kit: • variable terminal • 2 x 1m pipe • 3 x pipe support clips • 87° bend with bird protection grille important : the flue outlet of the vari...

Page 76: Assembly

24 • unlock the catch between the terminal and the flue duct by twisting them against each other (fig. 4.5). • pull the terminal out of the flue duct. • push the variable terminal onto the flue duct. ☞ please note: the catch on the top of the variable terminal must lock firmly into the notch in the ...

Page 77: Par

25 par t 1 concentric 60/100 installation of the variable termination kit • fit the pipes and bends, working from the variable terminal to the selected location for the flue exit using support clips supplied fig 4.8, 4.9, 4.10 or 4.11. Caution! Pipe extensions must be fixed to the wall using pipe cl...

Page 78

26 fig. 4.11: installation of basic kit with two additional 45° bends showing position of support clips installation of the variable termination kit fig. 4.10: installation of basic kit with two additional 87° bends showing position of support clips 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 26 s...

Page 79: Par

27 par t 1 concentric 60/100 routing around roof eaves when routing the variable termination kit around the roof eaves, additional lengths of m8 threaded bar will be required for the support brackets. Threaded bar can be purchased from most local merchants. • change the bird protection grille from t...

Page 80

28 40 1435 550 880 vertical air/flue duct accy. No.: 303 900 (black) contents of the accessory: • vertical air/flue duct and terminal assembly • 40 mm air duct clamp • fixing bracket ☞ see page 6 et seq. For details of air/flue duct elements. ☞ observe the maximum flue lengths as detailed in table o...

Page 81: Pitched Roof Installation

29 installation of the vertical air/flue duct pitched roof installation • determine the point where the vertical air/flue duct and terminal assembly will penetrate the roof. • fit the flexible pitched roof (accy. No. 303 980) tile ( 1 ). • working from above, insert the vertical roof duct ( 5 ) thro...

Page 82: Flat-Roof Installation

30 installation of the vertical air/flue duct 885 warm roof cold roof 550 Ø100 120 2 1 6 7 750 5 7 4 100- 110 fig. 5.3: fitting the appliance and vertical flue duct to a building with a flat roof flat-roof installation • determine the point where the vertical air/flue duct and terminal assembly will...

Page 83: Par

31 par t 1 concentric 60/100 fitting air/flue duct extensions how to add extensions use a saw, tin-snips, etc. To cut tubes to size. ☞ no tools are required when separating extensions for cutting to size air and flue tubes separately. When doing so, the flue conduit should be twisted into a position...

Page 84: How to Install

32 how to install 2x 87° elbows • when using 2 x 87° elbows follow fig. 6.1 to fig. 6.3 to avoid obstructions on outer wall. Note: the elbows must be correctly aligned to avoid undue stress on the joints and risk of leakage. The elbow fitted to the top of the boiler (1) should be twisted by 3° to en...

Page 85: Par

33 par t 1 concentric 60/100 1 2 max. 5 m max. 5 m * = 3 * 90 1 max. 5 m max. 5 m 90 fig. 6.4: long flue runs – using 87° elbow fig. 6.5: long flue elbow – using 45° elbows fitting air/flue duct extensions • when using elbows for long flue runs in a corner follow fig. 6.4 and fig. 6.5 to avoid obtrs...

Page 86: How to Install 87° Elbows

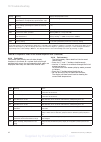

34 fitting air/flue duct extensions offset length of [in mm] air conduit [in mm] offset length of [in mm] air conduit [in mm] offset length of [in mm] air conduit [in mm] 630 420 635 425 640 430 645 435 650 440 655 445 660 450 665 455 670 460 675 465 680 470 685 475 690 480 695 485 700 490 705 495 7...

Page 87: How to Install 45° Elbows

35 fitting air/flue duct extensions 90 0 210 95 0 215 100 0 220 > 105 to not possible 160 86 280 165 93 285 170 100 290 175 107 295 180 115 300 185 122 305 190 129 310 195 136 315 200 143 320 205 150 325 210 157 330 215 164 335 220 171 340 225 178 345 230 185 350 235 192 355 240 199 360 245 206 365 ...

Page 88

36 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 36 supplied by heatingspares247.Com.

Page 89: Par

37 par t 1 concentric 60/100 contents: part 2 concentric 80/125 page the air/flue duct must be installed by a suitably qualified service provider, which is responsible for observing the relevant specifications, regulations and standards. Requirements planning the air/flue duct layout regulations and...

Page 90: Requirements

38 requirements regulations and standards to be observed ¤ ☞ vaillant ecomax/ecotec boilers are certified as heating boilers with corresponding flue systems according to ec directive 90/396/eec on gas-fired devices. This installation manual is covered by this certification and is referred to in the ...

Page 91: Par

39 par t 2 concentric 80/125 planning the air/flue duct layout alternative termination accessories available 303 200 = vertical air/flue duct (black) 303 209 = horizontal air/flue duct 303 926 = appliance connection piece optional connection accessories accy. No. 303 200 air/flue duct extensions (pp...

Page 92

40 planning the air/flue duct layout fig. 1.2: extensions, Ø 80/125 fig. 1.4: flue support clips, Ø 125 or Ø 80 flue support clips, Ø 125 (pack of 5) vaillant accy. No.: 303 616 ☞ use one clip per extension to support the air/flue duct. 15 25 15 25 15 25 fig. 1.3: elbow joints, Ø 80/125 elbow (pps),...

Page 93: Par

41 par t 2 concentric 80/125 planning the air/flue duct layout 498 132 255 fig. 1.6: adjustable roof tile for pitched roof adjustable roof tiles for pitched roof vaillant accy. No.: 009 076 (black) gu_laz 41/0 164 120 fig. 1.5: sliding sleeve, Ø 80/125 sliding sleeve (pps), Ø 80/125 vaillant accy. N...

Page 94

42 planning the air/flue duct layout maximum flue lengths for use with ecomax accessories accy. No. Vertical flue systems 303 200 max. Permitted concentric flue length horizontal flue systems 303 209 max. Permitted concentric flue length 14.0 m 13.0 m incl. 1 elbow 87° 31.0 m 20.0 m 30.0 m incl. 1 e...

Page 95: Par

43 planning the air/flue duct layout maximum flue lengths for use with ecotec par t 2 concentric 80/125 accessories accy. No. Vertical flue systems 303 200 max. Permitted concentric flue length horizontal flue systems 303 209 max. Permitted concentric flue length 14.0 m 13.0 m incl. 1 elbow 87° 27.0...

Page 96

44 planning the air/flue duct layout maximum flue length maximum flue length las euro b/s 074/0 las euro b/s 074/0 fig. 1.10 fig. 1.9 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 44 supplied by heatingspares247.Com.

Page 97: Installation

45 changing the appliance connection-piece 1 2 fig. 2.0: fitting the appliance connection-piece installation accy no.: 303 926 the appliance is supplied ready-fitted with the connection-piece for the 60/100 air/flue duct system. • loosen the four screws ( 2 ) and pull the appliance connection- piece...

Page 98: Installing The

46 installation of the sliding sleeve fig. 3.0: installing the sliding sleeve 1 3 4 6 7 5 2 schiebemuffe_neu installing the air/flue duct sliding sleeve ☞ note: for installations where there is in- sufficient movement to allow fitting of the flue into flue outlet, a slid- ing sleeve (accy. No. 303 2...

Page 99: Par

47 installation of the horizontal air/flue duct ☞ observe the maximum flue lengths as detailed in table on page 42. 70 1103 70 15 horizontal air/flue duct vaillant accy no.: 303 209 contents of the accessory: • horizontal air/flue duct • 87° elbow • 2 x 70 mm air duct clamps • 1 x internal plastic r...

Page 100: Side Flue Installations

48 side flue installations • for installations where the air/flue duct is to be installed to the side, the position of the flue exit hole can be determined as follows: • identify the correct measurement as shown in fig. 4.3, carefully measure the distance from the bottom centre of the boiler hanging...

Page 101: Extensions

49 installation of the horizontal air/flue duct Ø 80/125 with extensions • taking each extension to be used, fit the flue duct into the air duct and secure using the 3 screws provided. • for ease of measuring and marking the air/flue duct extensions, assemble them loosely together with the air/flue ...

Page 102: Extensions

50 220 15 3 1 fig. 4.8: installing the horizontal wall duct lgu_laz 384/0_it • push the assembled air/flue duct and terminal assembly through the flue exit hole until it protrudes 220 mm out from the outside wall. • ensure that the terminal is correctly positioned with the air inlet grille at the bo...

Page 103: Indirect Installation

51 installation of the horizontal air/flue duct (80/125 Ø) 8 82 - 90 253 7 4 2 3 6 750 fig. 4.9: indirect installation indirect installation • fit the wall mounting ( 2 ). • install the appliance ( 3 ) with reference to the installation and servicing instructions supplied with the boiler. • change t...

Page 104

52 1530 880 70 650 vertical air/flue duct accy. No.: 303 200 (black) contents of the accessory: • vertical air/flue duct and terminal assembly • adapter (air) for Ø 110/125 • 70 mm air duct clamp • fixing bracket ☞ see page 41 et seq. For details of air/flue duct elements. ☞ observe the maximum flue...

Page 105: Pitched Roof Installation

53 installation of the vertical air/flue duct 750 2 3 790 740 Ø125 20 – 50 5 6 8 * 7 1 0 - 5 8 4 82 - 90 fig. 5.2: fitting the appliance and the vertical roof duct to a building with a pitched roof pitched roof installation • determine the point where the vertical air/flue duct and terminal assembly...

Page 106: Flat-Roof Installation

54 installation of the vertical air/flue duct 880 warm roof cold roof 650 Ø125 120 2 1 5 6 7 750 7 4 82 - 90 fig. 5.3: fitting the appliance and vertical flue duct to a building with a flat roof flat-roof installation • determine the point where the vertical air/flue duct and terminal assembly will ...

Page 107: How to Add Extensions

55 fitting air/flue duct extensions how to add extensions use a saw, tin-snips, etc. To cut tubes to size. ☞ no tools are required when removing previously-fitted extensions for cutting to size air and flue tubes separately. When doing so, the flue conduit should be twisted into a position where the...

Page 108: How to Install

56 how to install 2x 87° elbows • when using 2 x 87° elbows follow fig. 6.1 to fig. 6.3 to avoid obstructions on outer wall. Note: the elbows must be correctly aligned to avoid undue stress on the joints and risk of leakage. The elbow fitted to the top of the boiler (1) should be twisted by 3° to en...

Page 109: Par

57 1 2 max. 5 m max. 5 m * = 3 * 90 1 max. 5 m max. 5 m 90 fig. 6.4: long flue runs – using 87° elbow fig. 6.5: long flue elbow – using 45° elbows fitting air/flue duct extensions par t 2 concentric 80/125 • when using elbows for long flue runs in a corner follow fig. 6.4 and fig. 6.5 to avoid obtrs...

Page 110: How to Install 87° Elbows

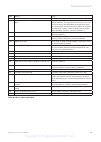

58 fitting air/flue duct extensions offset length of [in mm] air conduit [in mm] offset length of [in mm] air conduit [in mm] offset length of [in mm] air conduit [in mm] 730 520 735 525 740 530 745 535 750 540 755 545 760 550 765 555 770 560 775 565 780 570 785 575 790 580 795 585 800 590 805 595 8...

Page 111: How to Install 45° Elbows

59 90 0 210 95 0 215 100 0 220 > 100 to not possible 170 100 290 175 108 295 180 115 300 185 122 305 190 129 310 195 136 315 200 143 320 205 150 325 210 157 330 215 164 335 220 171 340 225 178 345 230 185 350 235 192 355 240 199 360 245 207 365 250 214 370 255 221 375 260 228 380 265 235 385 270 242...

Page 112

60 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 60 supplied by heatingspares247.Com.

Page 113

61 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 61 supplied by heatingspares247.Com.

Page 114

62 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 62 supplied by heatingspares247.Com.

Page 115

63 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 63 supplied by heatingspares247.Com.

Page 116

83444 9_09 gb 08 2 006 834449_09gb_082006.Qxd 10.08.2006 12:20 seite 64 supplied by heatingspares247.Com.

Page 117

Spare part catalogue 0020010870.01 gb 03/2006 wall-hung boilers ecotec plus 824, 831, 837, 612, 615, 618, 624, 630, 637 vuw 246/3-5 vuw 246/3-5 r1 vuw 316/3-5 vuw 316/3-5 r1 vuw 376/3-5 r1 vu 126/3-5 vu 126/3-5 r1 vu 156/3-5 vu 156/3-5 r1 vu 186/3-5 vu 186/3-5 r1 vu 246/3-5 vu 246/3-5 r1 vu 306/3-5 ...

Page 118

Supplied by heatingspares247.Com.

Page 119

Content general view of sheet ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 page 3 04 burner page 4 06 heat exchanger page 6 07 casing parts page 8 08 connection parts (hydroblock) page 10 08a connection parts page 14 08b connection parts (acc.) pag...

Page 120

0020010870.01 gb 03/2006 2 supplied by heatingspares247.Com.

Page 121: General View of Sheet

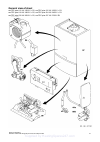

General view of sheet ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 02-00-077 subject to alteration ! Attention: please take the gross price from the valid price list ! 3 supplied by heatingspares247.Com.

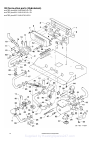

Page 122: 04 Burner

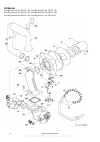

04 burner ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 4 supplied by heatingspares247.Com.

Page 123: 04 Burner

04 burner ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-04-038 00 0020010641 conversion set h -> p (not shown) 00 0020010642 conversion set p -> h (not shown) 01 049324 burner vuw 246/3-5, with parts 02, 03 01 049324 ...

Page 124: 06 Heat Exchanger

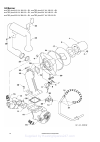

06 heat exchanger ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 6 supplied by heatingspares247.Com.

Page 125: 06 Heat Exchanger

06 heat exchanger ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-06-046 01 103409 heat exchanger vuw 246/3-5, with parts 02, 03, 04, 05, 06 01 0020018181 heat exchanger vuw 246/3-5 r1, with parts 02, 03, 04, 05, 06 01 ...

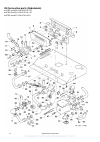

Page 126: 07 Casing Parts

07 casing parts ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 8 supplied by heatingspares247.Com.

Page 127: 07 Casing Parts

07 casing parts ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-07-073 01 180932 flue adapter 60/100 with parts 02, 03, 04 02 147392 cap (set of 5) 03 981232 packingring 04 981233 packingring 05 180935 covering, cpl. Vu...

Page 128

08 connection parts (hydroblock) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 10 supplied by heatingspares247.Com.

Page 129

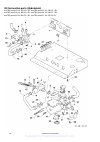

08 connection parts (hydroblock) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-08-115 01 178965 support with parts 02, 03, 04, 05, 07, 08, 10, 19, 22, 26, 44 02 178969 packingring (set of 10) 03 193535 packingring (se...

Page 130

08 connection parts (hydroblock) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 12 supplied by heatingspares247.Com.

Page 131

08 connection parts (hydroblock) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-08-115 35 - - not available as spare part, see pos. 34 36 981165 packingring (set of 10) 37 980765 grommet 38 509120 packingring (set of 1...

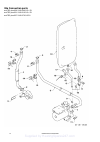

Page 132: 08A Connection Parts

08a connection parts ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 14 supplied by heatingspares247.Com.

Page 133: 08A Connection Parts

08a connection parts ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-08-120 01 180946 connection tube, cpl. With parts 02, 03 02 193537 packingring (set of 10) 03 103415 packingring (set of 10) 04 103417 clip (set of 10...

Page 134: 08B Connection Parts (Acc.)

08b connection parts (acc.) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 16 supplied by heatingspares247.Com.

Page 135: 08B Connection Parts (Acc.)

08b connection parts (acc.) ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-08-125 01 082782 gas shut-off valve, cpl. Vuw 246/3-5 01 082782 gas shut-off valve, cpl. Vuw 246/3-5 r1 01 082782 gas shut-off valve, cpl. Vuw ...

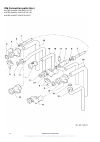

Page 136: 12 Control Box

12 control box ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 0020010870.01 gb 03/2006 18 supplied by heatingspares247.Com.

Page 137: 12 Control Box

12 control box ecotec plus 824 vuw 246/3-5 + r1 ecotec plus 831 vuw 316/3-5 + r1 ecotec plus 837 vuw 376/3-5 r1 pos. Art.-no part type, note 02-12-046 01 193582 casing, cpl. 02 251955 fuse 2.0 at (set of 10) 2.0 at 03 117319 knobs, cpl. Grey (3 knobs) 04 0020028736 printed circuit board with part 02...

Page 138

0020010870.01 gb 03/2006 20 supplied by heatingspares247.Com.

Page 139: General View of Sheet

General view of sheet ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 02-00-077 subject to alteration ! Attention: please take the gross price from the val...

Page 140: 04 Burner

04 burner ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 22 supplied by heatingspares247.Com.

Page 141: 04 Burner

04 burner ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-04-038 00 0020010641 conversion set h -> p (not shown) 00 0020010...

Page 142: 04 Burner

04 burner ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 24 supplied by heatingspares247.Com.

Page 143: 04 Burner

04 burner ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-04-038 20 193597 screw, cpl. (set of 10) 21 0020025929 sealing ga...

Page 144: 06 Heat Exchanger

06 heat exchanger ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 26 supplied by heatingspares247.Com.

Page 145: 06 Heat Exchanger

06 heat exchanger ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-06-046 01 103409 heat exchanger vu 126/3-5, with parts 02...

Page 146: 07 Casing Parts

07 casing parts ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 28 supplied by heatingspares247.Com.

Page 147: 07 Casing Parts

07 casing parts ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-07-073 01 180932 flue adapter 60/100 with parts 02, 03, 04 ...

Page 148

08 connection parts (hydroblock) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 30 supplied by heatingspares247.Com.

Page 149

08 connection parts (hydroblock) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-08-121 01 509142 support with parts 02, 03...

Page 150

08 connection parts (hydroblock) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 32 supplied by heatingspares247.Com.

Page 151

08 connection parts (hydroblock) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-08-121 30 193589 harness vu 126/3-5 30 193...

Page 152: 08A Connection Parts

08a connection parts ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 34 supplied by heatingspares247.Com.

Page 153: 08A Connection Parts

08a connection parts ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-08-120 01 180946 connection tube, cpl. Vu 126/3-5, wit...

Page 154: 08B Connection Parts (Acc.)

08b connection parts (acc.) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 36 supplied by heatingspares247.Com.

Page 155: 08B Connection Parts (Acc.)

08b connection parts (acc.) ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-08-125 01 082782 gas shut-off valve, cpl. Vu 12...

Page 156: 12 Control Box

12 control box ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 0020010870.01 gb 03/2006 38 supplied by heatingspares247.Com.

Page 157: 12 Control Box

12 control box ecotec plus 612 vu 126/3-5 + r1, ecotec plus 615 vu 156/3-5 + r1 ecotec plus 618 vu 186/3-5 + r1, ecotec plus 624 vu 246/3-5 + r1 ecotec plus 630 vu 306/3-5 + r1, ecotec plus 637 vu 376/3-5 r1 pos. Art.-no part type, note 02-12-046 01 193582 casing, cpl. 02 251955 fuse 2.0 at (set of ...

Page 158: Notes

Notes 0020010870.01 gb 03/2006 40 supplied by heatingspares247.Com.

Page 159

Supplied by heatingspares247.Com.

Page 160

0020010870.01 gb 03/200 6 subject to alteration ! / attention: please take the gross price from the valid price list ! Supplied by heatingspares247.Com.

Page 161

For the owner instructions for use ecotec plus wall hung open vent condensing boiler gb supplied by heatingspares247.Com.

Page 162

Instructions for use, installation and servicing ecotec plus 2 contents appliance characteristics appliance characteristics . . . . . . . . . . . . . . . . . . . . . 2 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.1 notes on the documentation . . . . . . . . . . . . . ...

Page 163

Instructions for use ecotec plus 3 1.1 notes on the documentation to ensure clarity of information in instructions a new european standard of advice and symbols is being introduced. To ensure compliance with this new standard the following details are included. The following information is intended ...

Page 164

Instructions for use ecotec plus 4 2.3 safety instructions always observe the following safety instructions and regulations. Danger! Inflammable mixtures of gas and air may explode. Do not use or store explosive or easily flammable substances such as petrol or paint in the same room as the appliance...

Page 165

Instructions for use ecotec plus 5 3 information on installation and operation 3.1 factory guarantee 3.1.1 two year guarantee for ecotec plus appliances vaillant undertakes to rectify any manufacturing defect that occurs within twenty-four months of the installation date. For the 2nd year of the gua...

Page 166

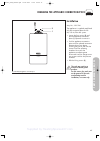

Instructions for use ecotec plus 6 4 operation 4 operation 4.1 overview of controls on ecotec plus fig. 4.1 ecotec plus controls for access to the controls open the front flap by pulling at the centre of the case strip. 1 display indicating the current heating flow temperature, the operating mode or...

Page 167

Instructions for use ecotec plus 7 operation 4 1 2 2 3 4.2 initial checks before turning on 4.2.1 opening the gas service valve • ensure the gas service valve is open. • ensure the electrical supply to the boiler is turned on. 4.4 domestic hot water the control of domestic hot water is only availabl...

Page 168

Instructions for use ecotec plus 8 2 1 4 operation 2 1 2 1 4.5.1 setting the maximum radiator temperature control fig. 4.6 setting the maximum radiator temperature control when you adjust the temperature, the set value is shown in the display (2). After five seconds the display returns to standard m...

Page 169

Instructions for use ecotec plus 9 operation 4 pump running display meaning displays during heating operation s. 0 s. 1 s. 3 s. 4 s. 6 s. 7 s. 8 s.30 s.31 s.34 s.20 s.24 no heat required ignition sequence (heating operation) burner ignited fan and pump overrun pump overrun anti cycling mode (after h...

Page 170

Instructions for use ecotec plus 10 4.10 frost protection the frost protection feature only protects the boiler. Any other parts of the system liable to frost damage should be protected accordingly. Caution! The boiler frost protection and monitoring systems are only active when the electrical suppl...

Page 171

Instructions for use ecotec plus 11 supplied by heatingspares247.Com.

Page 172

00 2 00 2 08 2 9_0 2 gb /08 /2 006 · s u b je ct t o a lt e ra ti o n supplied by heatingspares247.Com.