- DL manuals

- Vaillant

- Boiler

- ecoMAX 635

- Instructions For Installation And Servicing

Vaillant ecoMAX 635 Instructions For Installation And Servicing

Summary of ecoMAX 635

Page 1

For the installer ecomax 635 gb instructions for installation and servicing ecomax wall hung room sealed fan assisted condensing boilers 80020014605_00gb_032006 22.02.2006 21:35 uhr seite 1.

Page 2

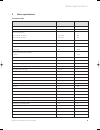

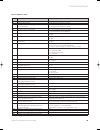

2 table of contents instructions for installation and servicing ecomax 2 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 general notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 ec design...

Page 3

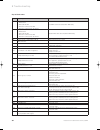

3 table of contents instructions for installation and servicing ecomax 3 9.3 replacement of fan . . . . . . . . . . . . . . . . . . . . . . 36 9.4 replacement of gas valve . . . . . . . . . . . . . . . . . 36 9.5 replacement of central heating expansion vessel . . . . . . . . . . . . . . . . . . . ....

Page 4

4 1 introduction instructions for installation and servicing ecomax 4 1 introduction 1.1 introduction note! This boiler must be installed and serviced by a competent person in accordance with the gas safety (installation and use) regulations 1998. In the uk ‘corgi’ registered installers underta- ke ...

Page 5

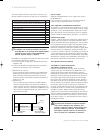

5 boiler specification 2 instructions for installation and servicing ecomax 5 2 boiler specification 2.1 technical data ecomax 635 units maximum ch heat input (g 20) (net) 34.9 kw maximum ch heat input (g 31) (net) 34.9 kw ch heat output range 80 °c flow/60 °c return 10.5 - 34.9 kw 50 °c flow/30 °c ...

Page 6

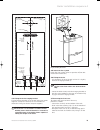

6 2 boiler specification instructions for installation and servicing ecomax 6 2.2 dimensions fig. 2.1 2 hanging bracket 3 heating–system return 5 gas connection 7 heating–system flow 2.3 boiler connections 2.2 boiler connections 2.4 functional diagram fig. 2.3 functional diagram ecomax 635 1 air duc...

Page 7

7 boiler specification 2 instructions for installation and servicing ecomax 7 2.5 design fig. 2.4 functioning elements, ecomax 635 configuration 1 expansion vessel 2 air suction pipe 3 burner assembly 4 ignition electrode 8 electronic box 9 circulating pump 10 gas valve assembly 11 auto air vent 12 ...

Page 8

8 3 general requirements instructions for installation and servicing ecomax 8 3 general requirements 3.1 preliminary remarks for roomsealed appliances this appliance should only be installed in conjunction with either a vaillant flue system or an alternative ap- proved system (details of flue approv...

Page 9

9 general requirements 3 instructions for installation and servicing ecomax 9 3.4 boiler location the location chosen for the boiler must permit the provi- sion of a satisfactory flue termination. The location must also provide adequate space for servicing and air circu- lation around the boiler. Th...

Page 10

10 3 general requirements instructions for installation and servicing ecomax 10 the flue assembly shall be so placed or sheilded as to prevent ignition or damage to any pary of the building. Terminal position mm a directly below an opening, above an opening or horizontal to an opening, air brick, op...

Page 11

11 general requirements 3 instructions for installation and servicing ecomax 11 this cleansing must take place prior to the fitting of the new boiler and be in accordance with bs 7593. For advice on the application of system cleansers contact sentinel, betz dearborn ltd. Widnes, cheshire, wa8 8ud. T...

Page 12

12 4 boiler installation sequence instructions for installation and servicing ecomax 12 4 boiler installation sequence 4.1 general fig. 4.1 the boiler should be mounted on a flat and vertical area of wall of sufficient area for the boiler plus the required clearances for installation and servicing (...

Page 13

Fig. 4.2 using boiler template 4.4 fitting the boiler hanging bracket fix the hanging bracket (2) to the wall using the screws supplied. (it may be necessary to use additional or alternative fixings to ensure adequate support). Note! If the boiler is to be fitted in a timber framed building ensure t...

Page 14

14 3 general requirements instructions for installation and servicing ecomax 14 fig. 4.4 removing/refitting the case 4.8 gas supply fig. 4.5 fitting the gas connection • connect the compression gas service cock and 15 mm copper outlet tail as supplied with the appliance and tighten. • connect a gas ...

Page 15

15 general requirements 3 instructions for installation and servicing ecomax 15 fig. 4.7 fitting the pressure relief valve 4.11 condensate drain (fig. 4.8) fig. 4.8 connect the boiler condensate drain (1) to the condensate discharge pipe (2) the condensate discharge pipe should be minimum of 19mm in...

Page 16

16 4 boiler installation sequence instructions for installation and servicing ecomax 16 4.12 connection to a unistor cylinder • for connecting a vaillant unistor cylinder please refer to the unistor installation instructions provided with the cylinder. 4.13 connect the flue system to the boiler • re...

Page 17

17 boiler installation sequence 4 instructions for installation and servicing ecomax 17 4.14.3 electronic board layout fig. 4.12: connection wiring 9 8 7 5 4 3 n l n l pump 2. Pump c o nt act therm l n 2 4v i 23 0 v rt 2 4 v 23 0 v r t 2 3 0v x 4 x 10 x 7 x 8 x 2 13 x 6 1 1 1 1 1 c oding r e sis tan...

Page 18

18 4 boiler installation sequence instructions for installation and servicing ecomax 18 4.14.3 electronic board layout fig. 4.13: connection wiring ecomax 635 fan unit ignition electrode pump ntc flow gas valve assembly ntc backflow x 2/4 red x 2/10 white x 2/15 blue plug-in coupling electronic cont...

Page 19

19 boiler installation sequence 4 instructions for installation and servicing ecomax 19 4.14.4 connection details for programmable thermostats fig. 4.14 l n 2 3 4 l n 3 4 1 acl drayton lyfestyle pt271, pt371 acl drayton digistat 2, 3, 4 acl drayton digistat rf - scr receiver danfoss randall tp4, tp5...

Page 20

20 4 boiler installation sequence instructions for installation and servicing ecomax 20 4.16 thermostatic radiator valves the boiler has a built in automatic bypass valve making it ideal for use in systems with thermostatic radiator val- ves (no separate system bypass is required). For opti- mum fue...

Page 21

21 boiler installation sequence 4 instructions for installation and servicing ecomax 21 fig. 4.16 fig. 4.17 connection details for control systems utilising 2 x 2 port motorised valves via external wiring centre/junction box diagram only applies to the specific controls mentioned l n l n 3 4 5 n l c...

Page 22

22 4 boiler installation sequence instructions for installation and servicing ecomax 22 fig. 4.18 n l 2 3 4 5 3 not used 7 6 1 not used lifestyle lp241, lp 522, lp 722 tempus 6, tempus 7 danfoss randall cp 715, fp715 note: *earth not required danfoss randall set 2e, set 3e note: *earth not required,...

Page 23

23 commissioning part i 5 instructions for installation and servicing ecomax 23 5 commissioning part i 5.1 preliminary electrical checks check the electrical installation by carrying out short circuit, earth continuity and resistance to earth tests and a check for correct polarity. 5.2 gas supply th...

Page 24

24 5 commissioning part i instructions for installation and servicing ecomax 24 1 press the ”i” and ”+” buttons below the display simul- taneously. The display will now show ”d.0”. Use the ”+” button to scroll up to ”d.14”. 2 press the ”i”–button to display the diagnostic informa- tion (e. G. Factor...

Page 25

25 commissioning part i 5 instructions for installation and servicing ecomax 25 • turn off the appliance, remove u gauge. • tighten the test point screw and test for soundness. • record appliance working gas inlet pressure (mbar) in the benchmark gas boiler commissioning checklist. 5.8.3 check gas r...

Page 26

26 5 commissioning part i 6 functional checks (commissioning part ii) instructions for installation and servicing ecomax 26 4 use the ”+” and ”–” buttons to increase or decrease the value in steps of 1 kw. The displayed value will flash while the adjustment procedure is being carried out. The availa...

Page 27

27 functional checks (commissioning part ii) 4 instructions for installation and servicing ecomax 27 6.1.3 final system flush (”hot”) • turn on the boiler for central heating and allow the boiler and system to reach temperature. • check that the heating system is watertight. • turn the boiler off an...

Page 28

28 7 servicing instructions for installation and servicing ecomax 28 7 servicing 7.1 inspection and servicing to ensure the continued safe and efficient operation of the boiler it is recommended that it is checked and ser- viced as necessary at regular intervals. The frequency of servicing will depe...

Page 29

29 servicing 7 instructions for installation and servicing ecomax 29 fig. 7.1 removing the compact thermal module remove burner assembly • remove screw (1) and disconnect air inlet pipe (2). • disconnect gas supply from gas valve by undoing union (4). Fig. 7.2 disconnecting gas supply from the gas v...

Page 30

7.2.4 refitting the compact thermal module • renew the silicone gaskets (1) (see fig 7.3) • loosely position the burner, fan and gas valve assemb- ly in place and reconnect the two electrical connec- tions to the fan. • refit the burner, fan and gas valve assembly. Ensure that the burner manifold ga...

Page 31

31 instructions for installation and servicing ecomax 31 7.4 test carry out the following checks once the maintenance tasks have been completed: • start the unit up according to the instructions supplied with the appliance. • check the unit for any signs of escaping gas or water leaks. • check the a...

Page 32

32 8 troubleshooting instructions for installation and servicing ecomax 32 8 troubleshooting 8.1 logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section ‘preliminary electrical checks’). 2.C...

Page 33

33 troubleshooting 8 instructions for installation and servicing ecomax 33 key to diagnosis codes code meaning displayed/adjustable values d.0 part load setting adjustable values in kw d.1 water pump over run 1 – 60 min (factory–adjusted to 5 min) d.2 maximum burner anti cycling period at 20 °c flow...

Page 34

34 8 troubleshooting instructions for installation and servicing ecomax 34 key to fault codes code meaning cause f.0 flow–ntc: – ntc broken – ntc cable broken flow–ntc cable defective/broken ntc faulty – defective connection at ntc – defective connection at electronics f.1 return–ntc: – ntc broken –...

Page 35

35 troubleshooting 8 instructions for installation and servicing ecomax 35 8.1.3 fault codes fault codes take priority over all other display functions in the event of a system fault occurring (table 8.3). If multiple faults occur, the corresponding fault codes are displayed alternately for about tw...

Page 36

36 9 parts replacement instructions for installation and servicing ecomax 36 9 parts replacement ensure that all regulations are observed. 9.1 safety instructions the following safety instructions are to be followed when installing replacement parts! Note! Before starting any maintenance work: isola...

Page 37

37 parts replacement 9 instructions for installation and servicing ecomax 37 • remove 2 screws (3) securing gas valve to fan. • disconnect gas inlet supply connection from gas valve by removing four screws. Refit the gas inlet supply connection to the new gas valve using the new sealing gasket suppl...

Page 38

38 9 parts replacement instructions for installation and servicing ecomax 9.6 replacement of main heat exchanger • turn off boiler. • remove front casing. • lower control box. • drain boiler as previously described. • remove burner, gas valve and fan assembly as pre- viously detailed. • disconnect c...

Page 39

39 parts replacement 9 instructions for installation and servicing ecomax fig. 9.6 carrying out measurement of co2 levels, preparing for air–ratio adjustment natural gas: adjust in steps of no more than 1/8 of a turn, and wait for each new value to stabilise (about one minute). Lpg: adjust in small ...

Page 40

40 40 10 recycling and eventual scrapping instructions for installation and servicing ecomax 10 recycling and eventual scrapping the design of all vaillant products takes into account the subsequent recycling and/or eventual safe scrapping of each component used. Vaillant’s in–house rules set strict...

Page 41

80020014605_00gb_032006 22.02.2006 21:36 uhr seite 41.

Page 42

80020014605_00gb_032006 22.02.2006 21:36 uhr seite 42.

Page 43

80020014605_00gb_032006 22.02.2006 21:36 uhr seite 43.

Page 44

00 2 0014605_00gb 0 3 2 006 s ubject t o alt er ation 80020014605_00gb_032006 22.02.2006 21:36 uhr seite 44.