- DL manuals

- Vaillant

- Boiler

- ecoMAX pro SERIES

- Instructions for use installation and servicing

Vaillant ecoMAX pro SERIES Instructions for use installation and servicing

Summary of ecoMAX pro SERIES

Page 1

To be left with the user instructions for use, installation and servicing ecomax pro wall hung condensing boilers for traditional open vented systems gb 18 e 28 e.

Page 2

Table of contents instructions for installation and servicing ecomax pro 2 page 1 list of contents . . . . . . . . . . . . . . . . . . . . . . . . . 4 contents included with ecomax pro boiler . . . 4 2 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.1 general information . ....

Page 3

Table of contents instructions for installation and servicing ecomax pro 3 page 14 servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 14.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 14.2 spark electrode . . . . . . . . . . . . . . . . . . . . . ....

Page 4

1 list of contents instructions for installation and servicing ecomax pro 4 1 list of contents 1.1 contents included with ecomax pro boiler ensure that all contents are included before commen- cing installation. Fig. 1.1: items supplied with unit (ecomax pro) 1 2 3 4 5 6 7 8 item quantity descriptio...

Page 5

Important information 2 instructions for installation and servicing ecomax pro 5 2 introduction 2.1 general information thank you for choosing a vaillant boiler. The information given in this booklet will enable you to obtain the best performance from your boiler. The benchmark logbook should be com...

Page 6

2 important information 2.12 boiler casing do not remove or adjust the casing in any way, as incorrect fitting may result in incorrect operation or failure to operate at all. 2.13 condensate drain the condensate drain, see section 10.3, must not be modified or blocked. 2.14 pluming from flue termina...

Page 7

2 important information operating the boiler 3 instructions for installation and servicing ecomax pro 7 3.2 all systems check that the electrical supply to the boiler is on at the external isolator. Set any remote heating system controls as required. 3.3 user controls slide the on / off control down...

Page 8

4 general information instructions for installation and servicing ecomax pro 8 3.4 to turn the boiler off normally the boiler will be turned off by the heating system controls. The mains on / off control may be used to switch off the boiler, however it is preferable to leave the electrical supply on...

Page 9

4 general information water system 5 instructions for installation and servicing ecomax pro 9 4.5 electrical supply the boiler must be earthed. All system components shall be of an approved type and all wiring to current i.E.E. Wiring regulations. The boiler must be connected to a permanent 230 v ac...

Page 10

Water system 5 instructions for installation and servicing ecomax pro 10 5.5 inhibitor attention is drawn to the current issue of bs 5449 and bs 7593 on the use of inhibitors in central heating systems. If an existing system is to be reused take special care to drain the entire system, including the...

Page 11

Water system 5 instructions for installation and servicing ecomax pro 11 5.9.3 pressure gauge a pressure gauge with a set pointer and covering at least 0 to 4 bar (0 to 60 lb/in2) shall be fitted perma- nently to the system in a position where it can be seen when filling the system. 5.9.4 domestic h...

Page 12

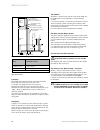

6 boiler location and ventilation instructions for installation and servicing ecomax pro 12 fig. 6.1 * * * * increase to 25mm clearance from comb ustible material. † minimum clearance from permanent surfaces † a removable compartment door can be placed at least 5mm in front of the appliance. 5 5 600...

Page 13

Flue 7 instructions for installation and servicing ecomax pro 13 7.2 flue termination the following details refer to both flue systems. A. The terminal must be positioned such that the pro- ducts of combustion can disperse freely at all times. B. In certain weather conditions a plume of water vapour...

Page 14

7 flue installation preparation 8 instructions for installation and servicing ecomax pro 14 1) in addition, the terminal should not be nearer than 150mm to an opening in the building fabric formed for the purpose of accommodating a built-in element such as a window. 2) dimension b,c and d; these cle...

Page 15

8 installation preparation boiler fixing 9 instructions for installation and servicing ecomax pro 15 fig. 8.3 to allow for the flue passing through the wall at this angle a 127 mm hole should be drilled irrespective of internal or external installation. If necessary remove the template whilst drilli...

Page 16

10 gas, water and condensate connections instructions for installation and servicing ecomax pro 16 10 gas, water and condensate connections 10.1 gas connection before connection check the supply of local gas. The gas supply can be connected from below, or through the wall at the rear of the boiler. ...

Page 17

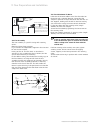

Flue preparation and installation 11 instructions for installation and servicing ecomax pro 17 11.2 extension pipes refer to figs. 11.3 and 11.4. Note maximum permitted flue lengths. When extension pipes are required please note the length of the extensions, which should be taken into account when c...

Page 18

11 flue preparation and installation instructions for installation and servicing ecomax pro 18 11.4 flue attachment to boiler lubricate the internal rubber seal of the flue outlet on the boiler with a suitable lubricant. Secure the flue adapter in position on top of the boiler with the four scr- ews...

Page 19

Electrical connections 12 instructions for installation and servicing ecomax pro 19 disconnect and remove the test cable from the terminal strip and discard. Connect both the mains supply and switched live from the external controls (room thermostat and, if applica- ble, frost thermostat) into the m...

Page 20

13 commissioning instructions for installation and servicing ecomax pro 20 13 commissioning 13.1 preliminaries - all systems a competent person in accordance with the current issue of bs 6798 should carry out commissioning. Preliminary electrical checks check the electrical installation by carrying ...

Page 21

Commissioning 13 instructions for installation and servicing ecomax pro 21 the boiler will then continue to fire until the user con- trols are satisfied. Note: after the first power up the firing sequence chan- ges. After one minute stabilisation time the boiler will ramp slowly to full rate rather ...

Page 22

14 servicing instructions for installation and servicing ecomax pro 22 14 servicing 14.1 general measurement of the products of combustion can be achieved by connection of a probe to the combustion analyser test point on the flue adaptor, see fig. 14.4. Refer to section 14.7 and data table. Before c...

Page 23

Servicing 14 instructions for installation and servicing ecomax pro 23 fig. 14.4 fig. 14.5 gently remove the fan, gas control valve and burner assembly from the combustion chamber complete with the gas pipe bracket and seal. Clean the burner with a soft brush taking great care not to damage the fron...

Page 24

14 servicing instructions for installation and servicing ecomax pro 24 fig. 14.6 fig. 14.7 seal front casing panel inner casing panel cap seal siphon adapter condense trap float screw.

Page 25

Fault finding 15 instructions for installation and servicing ecomax pro 25 15 fault finding fig. 15.1.

Page 26

15 fault finding instructions for installation and servicing ecomax pro 26 15 fault finding logical fault finding procedure these checks must be carried out before attempting to use the fault finding guide. 1. Carry out electrical safety checks (see section ‘preliminary electrical checks’ 13.1) 2. C...

Page 27

Short spare parts 16 instructions for installation and servicing ecomax pro 27 16 short spare parts key no. Part no. Description 1 190260 fan assembly 2 090750 spark electrode 3 091258 igniter unit 4 053574 gas control valve 5 101771 heating flow & return ntc (2) 6 101191 overheat stat 7 130837 cont...

Page 28

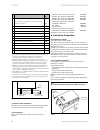

17 boiler specification ecomax pro ecomax pro 18 e 28 e units maximum ch heat input (net) 18.6 28.6 kw ch heat output (80/60 °c) 5.0 - 18.3 5.3 - 28.2 kw ch heat output (50/30 °c) 5.3 - 20.0 5.7 - 30.6 kw maximum dhw heat input (net) 20.02 30.58 kw sedbuk band a a sap seasonal efficiency 90.4 90.6 %...