- DL manuals

- Vaillant

- Boiler

- ecoMAX SERIES

- Instructions For Installation And Servicing

Vaillant ecoMAX SERIES Instructions For Installation And Servicing

Summary of ecoMAX SERIES

Page 1

For the installer ecomax 613/2 e ecomax 618/2 e ecomax 622/2 e ecomax 635 e ecomax 824/2 e ecomax 828/2 e ecomax 835 e gb instructions for installation and servicing ecomax wall hung room sealed fan assisted condensing boilers 83 41 77_12 gb04.04.Qxd 22.09.2004 12:34 uhr seite 1.

Page 2

2 table of contents instructions for installation and servicing ecomax 2 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 general notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 ec design...

Page 3

3 table of contents instructions for installation and servicing ecomax 3 7 servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 7.1 inspection and maintenance . . . . . . . . . . . . . . . 41 7.2 initial inspection . . . . . . . . . . . . . . . . . . . . . . . . 41 7.2.1 removing the c...

Page 4

4 1 introduction instructions for installation and servicing ecomax 4 1 introduction 1.1 introduction note: this boiler must be installed and serviced by a competent person in accordance with the gas safety (installation and use) regulations 1998. In the uk ‘corgi’ registered installers under take t...

Page 5

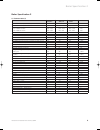

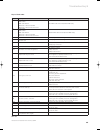

5 boiler specification 2 instructions for installation and servicing ecomax 5 boiler specification 2 2.1 technical data (1) ecomax ecomax ecomax units 824/2 e 828/2 e 835 e maximum ch heat input (g 20) (net) 18.4 22.4 27.0 kw maximum ch heat input (g 31) (net) 18.4 22.4 27.0 kw ch heat output range ...

Page 6

2.2 dimensions fig. 2.1 2 hanging bracket 3 heating–system return 4 cold–water inlet (ecomax 800/2 only) 5 gas connection 6 hot–water outlet (ecomax 800/2 only) 7 heating–system flow 70 190 480 800 2 100 380* 7 Ø 20 100 100 Ø 20 5 3 7 Ø 20 20 r 1 /2 180 4 6 *(ecomax 635, 835: 450) 6 2 boiler specifi...

Page 7

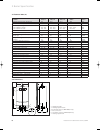

7 boiler specification 2 instructions for installation and servicing ecomax 7 2.3 boiler connections fig. 2.2 2.4 scale drawing and fitting dimensions dimensions when combined with a Øb c* the following system comp.: with 87° elbow air/flue system Ø 60/100 235 60/100 _ air/flue system Ø 80/125 253 8...

Page 8

8 2 boiler specification instructions for installation and servicing ecomax 8 2.5 functional diagrams fig. 2.4 functional diagram ecomax 800/2, 835 1 air duct 2 main heat exchanger 3 burner 4 condensate trap 5 temperature sensor (ntc 1) 6 temperature sensor (ntc 2) 7 automatic air vent 8 circulating...

Page 9

9 boiler specification 2 instructions for installation and servicing ecomax 9 2.6 design fig. 2.6 functioning elements, ecomax 800/2 configuration 1 expansion vessel 2 air suction pipe 3 burner assembly 4 ignition electrode 5 diverter valve 6 dhw heat exchanger 7 aqua sensor 8 electronic box 9 circu...

Page 10

10 2 boiler specification 3 general requirements instructions for installation and servicing ecomax 10 2.7 identification plate the identification plate of the vaillant ecomax is sup- plied ready–attached to the bottom of the unit. Fig. 2.8 identification plate (example) 3 general requirements 3.1 p...

Page 11

11 general requirements 3 instructions for installation and servicing ecomax 11 3.3 contents included with boiler (ecomax 800/2) ensure that all contents are included before commen- cing installation. Fig. 3.1 items supplied with unit (ecomax 800) do not remove the boiler from the polystyrene base a...

Page 12

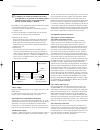

12 3 general requirements instructions for installation and servicing ecomax 12 3.5 boiler location the location chosen for the boiler must permit the provi- sion of a satisfactory flue termination. The location must also provide adequate space for servicing and air circu- lation around the boiler. ...

Page 13

Fig. 3.5 art.–no. 303 209 fig. 3.6 art.–no. 303 200 3.8 flue termination the following details refer to both flue systems. A. The terminal must be positioned such that the produc- ts of combustion can disperse freely at all times. B. A plume of water vapour will sometimes be visible from the flue te...

Page 14

14 3 general requirements instructions for installation and servicing ecomax 14 note: in addition, the terminal should not be nearer than 150 mm to an opening in the building fabric formed for the purpose of accommodating a built–in element such as a window. Bs 5440–1 it is recommended that the fann...

Page 15

15 general requirements 3 instructions for installation and servicing ecomax 15 3.11.4 pressure gauge this is factory fitted to the boiler and indicates the pri- mary circuit pressure to facilitate filling and testing. 3.11.5 expansion vessel ecomax boilers incorporate a 10 litre expansion vessel wh...

Page 16

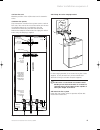

16 4 boiler installation sequence instructions for installation and servicing ecomax 16 4 boiler installation sequence 4.1 general fig. 4.1 the boiler should be mounted on a flat and vertical area of wall of sufficient area for the boiler plus the required clearances for installation and servicing (...

Page 17

17 boiler installation sequence 4 instructions for installation and servicing ecomax 17 4.2 rear flue exit mark the position of the air/flue duct and its circumfe- rence. 4.3 other flue options flue instructions for other flue systems such as vertical rsf flues, flues run to the side of the boiler a...

Page 18

18 4 boiler installation sequence instructions for installation and servicing ecomax 18 4.6 fitting the boiler • lift the boiler (3) up to the wall so that it is slightly above the hanging bracket (1). Note: lift the boiler from either side at the bottom edge. • lower the boiler slowly onto the hang...

Page 19

19 boiler installation sequence 4 instructions for installation and servicing ecomax 19 4.9 gas supply fig. 4.6 fitting the gas connection ecomax 800 (picture shows ecomax 800) • connect the compression gas service cock and 15 mm copper outlet tail as supplied with the appliance and tighten. • conne...

Page 20

20 4 boiler installation sequence instructions for installation and servicing ecomax 20 4.11 pressure relief valve (ecomax 800) fig. 4.8 fitting the pressure relief valve (ecomax 800) the pressure relief valve and filling loop connection is provided within the boiler cardboard box and should be asse...

Page 21

21 boiler installation sequence 4 instructions for installation and servicing ecomax 21 4.13 condensate drain (fig. 4.10) connect the boiler condensate drain (1) to the condensa- te discharge pipe (2) the condensate discharge pipe should be minimum of 19mm internal diameter (22mm external diameter f...

Page 22

22 4 boiler installation sequence instructions for installation and servicing ecomax 22 4.16 electrical installation 4.16.1 general requirements all electrical work shall be carried out by a competent person and shall comply with bs7671 (iee regulations). In ie, reference should be made to the curre...

Page 23

23 boiler installation sequence 4 instructions for installation and servicing ecomax 23 4.16.3 electronic board layout4.16.3 electronic board layou fig. 4.14: connection wiring ecomax 613/2, 618/2, 622/2, 824/2, 828/2 9 8 7 5 4 3 n l n l pump c o nt act therm 2 4v i 23 0 v rt 2 4 v 23 0 v r t 2 3 0v...

Page 24

24 4 boiler installation sequence instructions for installation and servicing ecomax 24 4.16.3 electronic board layout (continued) fig. 4.15: connection wiring ecomax 635, 835 9 8 7 5 4 3 n l n l pump 2. Pump c o nt act therm l n 2 4v i 23 0 v rt 2 4 v 23 0 v r t 2 3 0v x 4 x 10 x 7 x 8 x 2 13 x 6 1...

Page 25

25 boiler installation sequence 4 instructions for installation and servicing ecomax 25 4.16.3 electronic board layout (continued) fig. 4.16 connection wiring ecomax 824/2, 828/2 electronic control box aqua sensor ntc hot water outlet fan unit ignition electrode ntc flow priority reversing valve gas...

Page 26

26 4 boiler installation sequence instructions for installation and servicing ecomax 26 4.16.3 electronic board layout (continued) fig. 4.17: connection wiring ecomax 835 aqua sensor ntc hot water outlet fan unit ignition electrode pump ntc flow priority reversing valve gas valve assembly ntc backfl...

Page 27

27 boiler installation sequence 4 instructions for installation and servicing ecomax 27 4.16.3 electronic board layout (continued) fig. 4.18 connection wiring ecomax 613/2, 618/2, 622/2 fan unit ignition electrode ntc flow gas valve assembly ntc backflow x 2/4 red x 2/10 white x 2/15 blue plug-in co...

Page 28

28 4 boiler installation sequence instructions for installation and servicing ecomax 28 4.16.3 electronic board layout (continued) fig. 4.19: connection wiring ecomax 635 fan unit ignition electrode pump ntc flow gas valve assembly ntc backflow x 2/4 red x 2/10 white x 2/15 blue plug-in coupling ele...

Page 29

29 boiler installation sequence 4 instructions for installation and servicing ecomax 29 4.16.4 connection details for programmable thermostats fig. 4.20 l n 2 3 4 l n 3 4 1 acl drayton lyfestyle pt271, pt371 acl drayton digistat 2, 3, 4 acl drayton digistat rf - scr receiver danfoss randall tp4, tp5...

Page 30

Fig. 4.22 3 9 8 7 mains supply 230 v 50 hz l l l n n n n 20 vdc (do not use 7, 8, 9 in uk!) 3 a fuse switch contacts room thermostat clock 4 5 30 4 boiler installation sequence instructions for installation and servicing ecomax 30 4.17.4 connection details for time switch fig. 4.21 l n 2 3 4 l n 3 4...

Page 31

31 instructions for installation and servicing ecomax 31 4.17.5 connection details for external time switches and boiler terminal strip fig. 4.20 shows the connection details where a time switch is used without a room thermostat to control the boiler. Important: the arrowed numbers indicate connecti...

Page 32

32 4 boiler installation sequence instructions for installation and servicing ecomax 32 fig. 4.23 fig. 4.24 n l 2 3 4 5 3 8 7 6 1 not used lifestyle lp241, lp 522, lp 722 tempus 6, tempus 7 danfoss randall cp 715, fp715 note: *earth not required danfoss randall set 2e, set 3e note: *earth not requir...

Page 33

33 boiler installation sequence 4 instructions for installation and servicing ecomax 33 fig. 4.25 fig. 4.26 n l 2 3 4 5 3 not used 7 6 1 not used lifestyle lp241, lp 522, lp 722 tempus 6, tempus 7 danfoss randall cp 715, fp715 note: *earth not required danfoss randall set 2e, set 3e note: *earth not...

Page 34

34 5 commissioning part i instructions for installation and servicing ecomax 34 5 commissioning part i 5.1 preliminary electrical checks check the electrical installation by carrying out short circuit, earth continuity and resistance to earth tests and a check for correct polarity. 5.2 gas supply th...

Page 35

35 commissioning part i 5 instructions for installation and servicing ecomax 35 5.9 adjusting pump speed 5.9.1 ecomax 613/2, 618/2, 622/2, ecomax 824/2, 828/2 the units are fitted with a two–speed pump. The pump is delivered with the switch (1) set to position iii. Important note (ecomax 824/828 onl...

Page 36

36 5 commissioning part i instructions for installation and servicing ecomax 36 when altering values the display will flash. 4 press and hold the ”i”–button to save the required value to memory. When the value is saved, the display will stop flashing. 5 diagnostic mode is cancelled as follows: press...

Page 37

37 commissioning part i 5 instructions for installation and servicing ecomax 37 5.10 checking the gas supply settings 5.10.1 factory–adjusted gas settings caution: before operating the boiler check the data badge and ensure that the correct gas type appliance has been installed. The boiler is suppli...

Page 38

38 5 commissioning part i instructions for installation and servicing ecomax 38 5.11 refitting the case note: ensure that the front panel retaining cords are positioned such that they will not become trap- ped in the casing. • hook the top of the front casing (4) over the lip on the top of the boile...

Page 39

39 commissioning part i 5 functional checks (commissioning part ii) 6 instructions for installation and servicing ecomax 39 5 finally, keep the ”i” button pressed for about five seconds, or until the display stops flashing. The value is now saved to memory. The display will now return to its normal ...

Page 40

40 6 functional checks (commissioning part ii) instructions for installation and servicing ecomax 40 6.1.2 hot–water supply (ecomax 800) • switch the unit on. • fully open one of the hot water taps in the system. • press the ”i” button status code ”s.14” appears on the display to indicate that the h...

Page 41

41 servicing 7 instructions for installation and servicing ecomax 41 7. Servicing 7.1 inspection and servicing to ensure the continued safe and efficient operation of the boiler it is recommended that it is checked and ser- viced as necessary at regular intervals. The frequency of servicing will dep...

Page 42

42 7 servicing instructions for installation and servicing ecomax 42 fig. 7.1 removing the compact thermal module remove burner assembly • remove screw (1) and disconnect air inlet pipe (2). • disconnect gas supply from gas valve by undoing union (4). Fig. 7.2 disconnecting gas supply from the gas v...

Page 43

43 servicing 7 instructions for installation and servicing ecomax 43 7.2.4 refitting the compact thermal module • renew the silicone gaskets (1) (see fig 7.3) • loosely position the burner, fan and gas valve assemb- ly in place and reconnect the two electrical connec- tions to the fan. • refit the b...

Page 44

44 7 servicing 8 troubleshooting instructions for installation and servicing ecomax 44 7.3 recommissioning the boiler • carry out electrical safety checks. • turn on the electrical supply. • open the boiler ch service valves. • carry out function checks of boiler operation as pre- viously detailed. ...

Page 45

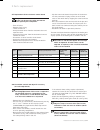

45 troubleshooting 8 instructions for installation and servicing ecomax 45 key to status codes code meaning ecomax 600 ecomax 800 s.0 no heat demand (heating operation) x x s.1 pump running (heating operation) x x s.2 pump running – pre ignition (heating operation) x x s.3 ignition sequence (heating...

Page 46

46 8 troubleshooting instructions for installation and servicing ecomax 46 8.1.2 diagnosis modes in order to assist with the pinpointing of a particular fault it is possible to use the boiler display in a diagno- stic mode to interrogate the boiler about the status of certain components (table 8.2)....

Page 47

47 troubleshooting 8 47 key to diagnosis codes code meaning displayed/adjustable values d.0 part load setting adjustable values in kw d.1 water pump over run 1 – 60 min (factory–adjusted to 5 min) d.2 maximum burner anti cycling period at 20 °c flow temperature 2 – 60 min (factory–adjusted to 20 min...

Page 48

48 8 troubleshooting instructions for installation and servicing ecomax 48 8.1.3 fault codes fault codes take priority over all other display functions in the event of a system fault occurring (table 8.3). If multiple faults occur, the corresponding fault codes are displayed alternately for about tw...

Page 49

49 troubleshooting 8 instructions for installation and servicing ecomax 49 key to fault codes code meaning cause f.0 flow–ntc: – ntc broken – ntc cable broken flow–ntc cable defective/broken ntc faulty – defective connection at ntc – defective connection at electronics f.1 return–ntc: – ntc broken –...

Page 50

50 8 troubleshooting instructions for installation and servicing ecomax 50 8.2 test programs the use of different test programs permits the activati- on of a range of special unit functions. Please refer to table 8.4 (below) for detailed information. • test programs p.1 to p.6 are activated by opera...

Page 51

51 parts replacement 9 instructions for installation and servicing ecomax 51 9 parts replacement ensure that all regulations are observed. 9.1 safety instructions the following safety instructions are to be followed when installing replacement parts! Important: before starting any maintenance work: ...

Page 52

52 9 parts replacement instructions for installation and servicing ecomax 52 9.4 replacement of gas valve • turn off boiler. • remove front casing. • lower control box. • remove burner, gas valve and fan assembly as pre- viously detailed. • remove 4 screws (1). • separate gas valve and fan assembly ...

Page 53

53 parts replacement 9 instructions for installation and servicing ecomax 53 9.6 replacement of main heat exchanger • turn off boiler. • remove front casing. • lower control box. • drain boiler as previously described. • remove burner, gas valve and fan assembly as pre- viously detailed. • disconnec...

Page 54

54 9 parts replacement instructions for installation and servicing ecomax 54 9.7 replacement of the electronic control board danger: ensure you observe the safety precautions when replacing this component. • turn off boiler. • remove front casing. • lower control box. • unclip the back cover from th...

Page 55

55 instructions for installation and servicing ecomax 55 • turn anti–clockwise to increase level of co 2 content. • turn clockwise to reduce level of co 2 content. • once the adjustment procedure is complete, swivel the air suction pipe upwards and back into position. • re–check the level of co 2 co...

Page 56

83 4 1 7 7_12 gb 10 2 004 s ubject t o alt er ation 83 41 77_12 gb04.04.Qxd 22.09.2004 12:34 uhr seite 56.