- DL manuals

- Vaillant

- Boiler

- ecoTEC plus 1006 VU GB 1006/5-5

- Installation And Maintenance Instructions Manual

Vaillant ecoTEC plus 1006 VU GB 1006/5-5 Installation And Maintenance Instructions Manual

Summary of ecoTEC plus 1006 VU GB 1006/5-5

Page 1

For the competent person installation and maintenance instructions ecotec plus vu gb .../5 ‑ 5 gb, ie installation and maintenance instructions publisher/manufacturer vaillant gmbh berghauser str. 40 d-42859 remscheid tel. +49 21 91 18 ‑ 0 fax +49 21 91 18 ‑ 2810 info@vaillant.De www.Vaillant.De.

Page 2

Contents 2 installation and maintenance instructions ecotec plus 0020134823_04 contents 1 safety .................................................................... 4 1.1 action-related warnings ......................................... 4 1.2 intended use ..............................................

Page 3

Contents 0020134823_04 ecotec plus installation and maintenance instructions 3 d status codes – overview .................................. 41 e overview of fault codes .................................... 42 f connection diagram .......................................... 44 g initial start-up check...

Page 4

1 safety 4 installation and maintenance instructions ecotec plus 0020134823_04 1 safety 1.1 action-related warnings classification of action-related warnings the action-related warnings are classified in accordance with the severity of the possible danger using the following warning signs and signal...

Page 5

Safety 1 0020134823_04 ecotec plus installation and maintenance instructions 5 1.3.5 danger caused by improper operation improper operation may present a danger to you and others, and cause material damage. ▶ carefully read the enclosed instructions and all other applicable documents, par- ticularly...

Page 6

1 safety 6 installation and maintenance instructions ecotec plus 0020134823_04 1.3.14 risk of material damage caused by frost ▶ do not install the product in rooms prone to frost. 1.3.15 risk of corrosion damage due to unsuitable combustion and room air sprays, solvents, chlorinated cleaning agents,...

Page 7

Notes on the documentation 2 0020134823_04 ecotec plus installation and maintenance instructions 7 2 notes on the documentation 2.1 observing other applicable documents ▶ you must observe all the operating and installation in- structions included with the system components. 2.2 storing documents ▶ p...

Page 8

4 installation 8 installation and maintenance instructions ecotec plus 0020134823_04 3.1.2 functional element (1006/5 ‑ 5 and 1206/5 ‑ 5) 1 2 3 6 7 5 4 8 10 9 12 13 14 15 16 11 1 connection for the flue pipe 2 fan 3 gas valve 4 supply air connector 5 flue gas pressure cartridge 6 return temperature ...

Page 9

Installation 4 0020134823_04 ecotec plus installation and maintenance instructions 9 4.3 product dimensions and connection dimensions 28 7 190 67 3 60 3 480 17 5 138 172 172 70 22 48 2 Ø2 5 49 g 1 1/ 4 96 0 47 7 680 ,5 1 2 3 4 5 6 7 1 wall duct for flue pipe 2 flue pipe connection 3 hanging bracket ...

Page 10

4 installation 10 installation and maintenance instructions ecotec plus 0020134823_04 4.7 wall-mounting the product conditions : the load-bearing capacity of the wall is sufficient, the fixing material may be used for the wall ▶ wall-mount the product as described. Conditions : the load-bearing capa...

Page 11

Installation 5 0020134823_04 ecotec plus installation and maintenance instructions 11 4.10 removing/installing the side section (as required) 4.10.1 removing the side section caution. Risk of material damage caused by mech- anical deformation. Removing both side sections may cause mechanical distort...

Page 12

5 installation 12 installation and maintenance instructions ecotec plus 0020134823_04 ▶ remove the residues from the gas line by blowing through the gas line beforehand. ▶ make sure that the existing gas meter is capable of passing the rate of gas supply required. ▶ install an approved gas isolator ...

Page 13

Installation 5 0020134823_04 ecotec plus installation and maintenance instructions 13 5.2.2 installing an expansion vessel 1 ▶ install an expansion vessel on the connection (1) in the return. – connection to the pump group: 1/2 ″ conditions : using a system separation – large expansion vessel: ≥ 10 ...

Page 14

5 installation 14 installation and maintenance instructions ecotec plus 0020134823_04 5.2.5 connecting the condensate drain pipework min. 180 2 1 3 ▶ when making the condensate pipe connections ensure that there is adequate branch ventilation and that there can be no backflow of water into the boile...

Page 15

Installation 5 0020134823_04 ecotec plus installation and maintenance instructions 15 danger! Risk of personal injury and material dam- age due to unapproved air/flue pipes. Vaillant boilers are certified only with vaillant original air/flue pipes. The use of other ac- cessories may cause personal i...

Page 16

5 installation 16 installation and maintenance instructions ecotec plus 0020134823_04 5.4.3 carrying out the wiring caution. Risk of material damage caused by incor- rect installation. Mains voltage at the incorrect plug terminals on the proe system may destroy the elec- tronics. ▶ do not connect an...

Page 17

Operation 6 0020134823_04 ecotec plus installation and maintenance instructions 17 5.4.7 connecting additional components you can use the multi-functional module to actuate two addi- tional components. The following components can be actuated: – circulation pump – external pump – cylinder charge pum...

Page 18

7 start-up 18 installation and maintenance instructions ecotec plus 0020134823_04 7 start-up 7.1 auxiliary service equipment: the following test and measuring equipment is required for start-up: – co 2 measuring instrument – digital or u tube manometer – flat blade screwdriver, small – 2.5 mm allen ...

Page 19

Start-up 7 0020134823_04 ecotec plus installation and maintenance instructions 19 ▶ inform the operator about the measures required for frost protection. 7.4 switching on the product ▶ press the on/off button on the product. ◁ the basic display appears on the display. 7.5 running the installation as...

Page 20

7 start-up 20 installation and maintenance instructions ecotec plus 0020134823_04 display meaning p.02 minimum load check programme: after successful ignition, the product is operated at minimum heat input. P.06 filling mode check programme: the burner and pump are switched off (to fill or drain the...

Page 21

Start-up 7 0020134823_04 ecotec plus installation and maintenance instructions 21 18. If there is still too much air in the heating installation at the end of the check programme p.00 , restart the check programme. 19. Check all connections and the entire system for leak- tightness. 7.12 flushing th...

Page 22

7 start-up 22 installation and maintenance instructions ecotec plus 0020134823_04 conditions : the product design is compatible with the local gas group ▶ proceed as described below. 7.14.2 checking the leak-tightness of the flue gas system and for flue gas recirculation 1. Check that the flue gas s...

Page 23

Start-up 7 0020134823_04 ecotec plus installation and maintenance instructions 23 – permissible gas flow pressure for operation with g20 natural gas: 1.6 … 2.3 kpa (16.0 … 23.0 mbar) 9. Should the pressure recorded at the reference test point in the boiler be lower than indicated check if there is a...

Page 24

7 start-up 24 installation and maintenance instructions ecotec plus 0020134823_04 conditions : the co ₂ content must be adjusted 1 1 806/5-5 1006/5-5 1206/5-5 caution. Risk of poisoning due to an incorrectly installed gas valve. If the gas flow pressure is outside the per- missible ranges in the tab...

Page 25

Adapting the unit to the heating installation 8 0020134823_04 ecotec plus installation and maintenance instructions 25 6. Fill the heating system again with water as de- scribed in "filling and purging the heating installation" ( → page 20). 7. Re-fill the system until the system design pressure of ...

Page 26

9 inspection and maintenance 26 installation and maintenance instructions ecotec plus 0020134823_04 8.6 burner anti-cycling time 8.6.1 setting the burner anti-cycling time to prevent frequent switching on and off of the burner and thus prevent energy losses, an electronic restart lockout is activate...

Page 27

Inspection and maintenance 9 0020134823_04 ecotec plus installation and maintenance instructions 27 9.1 observing inspection and maintenance intervals warning. Risk of injury and a risk of material dam- age caused by negligent inspection and maintenance work. Negligence in inspection and maintenance...

Page 28

9 inspection and maintenance 28 installation and maintenance instructions ecotec plus 0020134823_04 9.4 carrying out electronics self-tests menu → installer level → test programs → electronics self-test you can use the electronics self-test to check the pcb in advance. 9.5 removing the gas-air mixtu...

Page 29

Inspection and maintenance 9 0020134823_04 ecotec plus installation and maintenance instructions 29 8 9 10 11 13 5 6 7 12 11 8 10 12 5 6 7 9 13 806/5-5 1006/5-5 1206/5-5 danger! Risk of poisoning and fire caused by es- caping gas! The gas pipe may become damaged. ▶ ensure that you do not damage the ...

Page 30

9 inspection and maintenance 30 installation and maintenance instructions ecotec plus 0020134823_04 9.7 checking the burner 1 2 5 3 4 1. Check the surface of the burner for damage. If you no- tice any damage, replace the burner and seal, see "re- placing the burner ( → page 33)"). 2. Check the insul...

Page 31

Troubleshooting 10 0020134823_04 ecotec plus installation and maintenance instructions 31 8 9 10 11 13 5 6 7 12 11 8 10 12 5 6 7 9 13 806/5-5 1006/5-5 1206/5-5 4 4 4. Connect the gas-air mixture unit (5) to the heat ex- changer (7) . 5. Tighten the screws (6) in a cross-wise pattern until the burner...

Page 32

10 troubleshooting 32 installation and maintenance instructions ecotec plus 0020134823_04 10.1 contacting your service partner if you contact your vaillant service partner, if possible, please mention – the fault code that is displayed ( f.Xx ), – the product status ( s.Xx ) that is displayed on the...

Page 33

Troubleshooting 10 0020134823_04 ecotec plus installation and maintenance instructions 33 10.10 replacing defective components 10.10.1 replacing the gas valve 2 2 806/5-5 1006/5-5 1206/5-5 1 1 1. Remove the gas pipe (1) from the gas valve. 2. Unscrew the screws (2) from the fan and remove the gas va...

Page 34

10 troubleshooting 34 installation and maintenance instructions ecotec plus 0020134823_04 16. Install the ignition and monitoring electrodes. Use new seals for this. – torque: 2.8 nm 17. Install the gas-air mixture unit. ( → page 30) 18. Check that the product functions correctly and check the leak-...

Page 35

Decommissioning 11 0020134823_04 ecotec plus installation and maintenance instructions 35 1. Disconnect the unit from the power mains and secure it against being switched back on again. Conditions : replacing the display or pcb ▶ replace the pcb or display according to the assembly and installation ...

Page 36

Appendix 36 installation and maintenance instructions ecotec plus 0020134823_04 appendix a installer level menu structure – overview menu installer level reset burner off time information back select appliance config. Test programs installer level fault list back select test programs gas type check ...

Page 37

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 37 target flow temp. Appliance config. Dhw temperature comfort mode back select comfort mode comfort on cancel ok appliance config. Test programs diagnosis menu installer level back select appliance config. Start inst. Assi...

Page 38

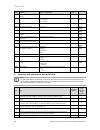

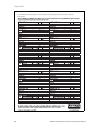

Appendix 38 installation and maintenance instructions ecotec plus 0020134823_04 b overview of diagnostics codes code parameter values or explanations default setting own setting d.000 heating partial load adjustable heating partial load in kw auto: product automatically adjusts max. Partial load to ...

Page 39

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 39 code parameter values or explanations default setting own setting d.027 switching of relay 1 on the vr 40 "2 in 7" multi-functional module 1 = circulation pump 2 = external pump 3 = cylinder charging pump 4 = extractor h...

Page 40

Appendix 40 installation and maintenance instructions ecotec plus 0020134823_04 code parameter values or explanations default setting own setting d.072 internal pump overrun after cylinder charging adjustable from 0 to 10 mins 2 min d.076 device specific number 82 = vu 806 81 = vu 1006 80 = vu 1206 ...

Page 41

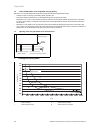

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 41 no. Work inspection (annual) mainten- ance (at least every 2 years) 8 check, and if necessary correct, the charge pressure of the expansion vessel. X 9 remove the gas-air mixture unit (burner door with fan and gas valve)...

Page 42

Appendix 42 installation and maintenance instructions ecotec plus 0020134823_04 status code meaning s.32 waiting period because of fan speed deviation s.34 frost protection mode active s.36 target value of the ebus controller is s.37 fan waiting period: fan failure in operation s.39 "burner off cont...

Page 43

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 43 code meaning cause f.34 safety switch-off: pressure monitoring exhaust gas pressure switch: cable break, blocked flue gas route water pressure switch: hydraulic leakage, air in the heating circuit f.35 fault: air/flue pi...

Page 44

Appendix 44 installation and maintenance instructions ecotec plus 0020134823_04 f connection diagram pump pwm signal gas valve water pressure sensor cylinder sensor (optional) cylinder contact “c1-c2“ flow sensor flow sensor flue gas dd safety cut-out safety cut-out remote control circulation pump e...

Page 45

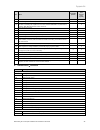

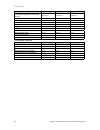

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 45 g initial start-up checklist location competent person customer service tech- nician name street/house number postcode town/city telephone start-up date serial number hydraulic scheme g.1 initial start-up checklist yes n...

Page 46

Appendix 46 installation and maintenance instructions ecotec plus 0020134823_04 yes no values unit low loss header if yes, which type? Number of mixers cylinder – buffer cylinder (if yes, which type?) – domestic hot water cylinder (if yes, which type?) l pumps – secondary circuit (if yes, which type...

Page 47

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 47 yes no values unit other heat generators solar system, heat pump, solid fuel boiler? If yes, which type? Control system vaillant controller if yes, which type? Third-party controller if yes, which type? Room thermostat, ...

Page 48: Www.Centralheating.Co.Uk

Appendix 48 installation and maintenance instructions ecotec plus 0020134823_04 h commissioning checklist © heating and hotwater industry council (hhic) www.Centralheating.Co.Uk benchmark commissioning and servicing section it is a requirement that the boiler is installed and commissioned to the com...

Page 49

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 49 this commissioning checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating compliance with the appropriate building regulations and then handed to the customer...

Page 50

Appendix 50 installation and maintenance instructions ecotec plus 0020134823_04 it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider service record service 01 and ² % and ² % service 02 and ² % and ² % servic...

Page 51

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 51 i opening of the flue pipe g n n m m a ii o h h c b l j q q q q q k p d, e f i s r t i.1 positioning of the opening of a fan-supported flue gas guiding installation site minimum dimen- sions a directly below an opening, ...

Page 52

Appendix 52 installation and maintenance instructions ecotec plus 0020134823_04 i.2 text from bs 5440-1 on fan-supported flue gas guiding bs 5440 – 1: it is recommended that the fanned flue gas system terminal is positioned as follows: – at least 2 m from an opening in the building directly opposite...

Page 53

Appendix 0020134823_04 ecotec plus installation and maintenance instructions 53 k technical data technical data – output 806 (vu gb 806/5 ‑ 5) 1006 (vu gb 1006/5 ‑ 5) 1206 (vu gb 1206/5 ‑ 5) nominal heat output range at 50/30 °c 16.5 … 82.3 kw 20.74 … 102.8 kw 24.7 … 123.4 kw nominal heat output ran...

Page 54

Appendix 54 installation and maintenance instructions ecotec plus 0020134823_04 806 (vu gb 806/5 ‑ 5) 1006 (vu gb 1006/5 ‑ 5) 1206 (vu gb 1206/5 ‑ 5) permitted pressure difference in the flue pipe for installation type b23p as cascade opera- tion max. 50 pa (0.00050 bar) 50 pa (0.00050 bar) 50 pa (0...

Page 55

Index 0020134823_04 ecotec plus installation and maintenance instructions 55 index a air index setting................................................................... 23 air/flue pipe ......................................................................... 14 air/flue pipe, installed ..............

Page 56

Index 56 installation and maintenance instructions ecotec plus 0020134823_04 self-test ............................................................................... 27 service message................................................................. 32 service partner .................................

Page 60

0020134823_04 18.02.2016 vaillant ltd. Nottingham road belper derbyshire de56 1jt telephone 0330 100 3461 info@vaillant.Co.Uk www.Vaillant.Co.Uk © these instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with the manufacturer's written consent. We re...