- DL manuals

- Vaillant

- Boiler

- ecoTEC pro

- Installation And Maintenance Instructions Manual

Vaillant ecoTEC pro Installation And Maintenance Instructions Manual

Summary of ecoTEC pro

Page 1

Installation and maintenance instructions for the competent person gb, ie installation and maintenance instructions ecotec pro vuw.

Page 2

Table of contents 2 installation and maintenance instructions ecotec pro 0020129672_03 table of contents 1 notes on the documentation .....................................4 1.1 storing documents ..........................................................4 1.2 symbols used ...............................

Page 3

Table of contents 3 installation and maintenance instructions ecotec pro 0020129672_03 10.10 carrying out a full function test.................................36 10.10.1 checking the heating mode ........................................37 10.10.2 checking the hot water generation ......................

Page 4

Notes on the documentation 4 installation and maintenance instructions ecotec pro 0020129672_03 1 1 notes on the documentation the following instructions are intended to guide you throughout the entire documentation. Further documents apply in combination with these installation and mainte- nance in...

Page 5

Notes on the documentation installation and maintenance instructions ecotec pro 0020129672_03 5 1 1.6 benchmark vaillant ltd. Supports the benchmark initiative. You will find the benchmark logbook on the last pages of this instruction manual. It is very important that this docu- ment be filled out p...

Page 6

6 installation and maintenance instructions ecotec pro 0020129672_03 a safety a 2 2 safety 2.1 safety and warning information > when installing the ecotec pro, take account of the general safety instructions and the warning notes that appear before all of the actions. 2.1.1 classification of warning...

Page 7

Installation and maintenance instructions ecotec pro 0020129672_03 7 a safety a 2 the current etci regulations for installing electrical equip- ment must also be observed. Installation and settings in the following cases, the boiler must be operated only with the front casing fitted and closed and w...

Page 8

8 installation and maintenance instructions ecotec pro 0020129672_03 a safety a 2 attention shall be paid to (but not restricted to) the following: – gas safety (installation and use) regulations. – all building regulations 2000 for england and wales, (as amended). – (includes approved codes of prac...

Page 9

Installation and maintenance instructions ecotec pro 0020129672_03 9 a safety a 2 > please ensure that the boiler is room sealed or in a sepa- rate installation room if – the combustion air supply contains the aforemen- tioned substances, – you install the boiler in hairdresser salons, painter's or ...

Page 10

10 installation and maintenance instructions ecotec pro 0020129672_03 a safety a 2 risk of damage if the heating water is treated with unsuitable frost or corrosion protection agents. Frost and corrosion protection agents can cause changes to seals, noise during heating mode and may lead to other co...

Page 11

Description of the appliance installation and maintenance instructions ecotec pro 0020129672_03 11 3 3 description of the appliance design 5 6 7 8 11 9 10 12 13 15 4 3 1 2 18 17 16 14 3.1 functional elements key 1 gas valve 2 water pressure sensor 3 heat exchanger 4 connection for the air/flue gas d...

Page 12

Installation 12 installation and maintenance instructions ecotec pro 0020129672_03 4 4 installation i before proceeding - ensure boiler is correct for gas group supplied! The work described in this section must only be carried out by a competent person. 4.1 accessories 4.1.1 controller to control th...

Page 13

Installation installation and maintenance instructions ecotec pro 0020129672_03 13 4 item qty description 1 1 wall bracket 2 1 boiler 3 2 connectors (hot water, expansion relief valve) 4 4 service valves 5 1 installation template 6 1 enclosure documentation 7 3 bags with parts incl. Electrical plug ...

Page 14

Installation 14 installation and maintenance instructions ecotec pro 0020129672_03 4 > ensure safe lifting techniques are used – keep back straight – bend using legs. > keep load as close to body as possible. > always use assistance if required. > it is assumed safe access, flooring and adequate lig...

Page 15

Installation installation and maintenance instructions ecotec pro 0020129672_03 15 4 > ensure safe lifting techniques are used - keep back straight – bend using legs - when lifting load from floor level. > do not twist – reposition feet instead. > keep boiler as close as possible to body throughout ...

Page 16

Installation 16 installation and maintenance instructions ecotec pro 0020129672_03 4 4.5 dimension drawing and connection measurements 72 0 20 35 35 62 4 33 5 18 0 12 5 12 5 10 0 10 0 4 4 0 a 2 1 8 3 4 5 6 7 7 9 10 6 3 4 5 11 4.3 connection measurements in mm key 1 wall breakthrough for air/flue gas...

Page 17

Installation installation and maintenance instructions ecotec pro 0020129672_03 17 4 4.6 wall-mounting the boiler a danger! Risk of death if the load-bearing capacity of the fixing elements used is insuffi- cient! If the fixing elements or wall do not have sufficient load-bearing capacity, the boile...

Page 18

Installation 18 installation and maintenance instructions ecotec pro 0020129672_03 4 4.8 removing/fitting the side panel you can also remove a side panel for installation or mainte- nance purposes. B caution. Risk of damage caused by mechanical tension. Removing both side panels may cause mechanical...

Page 19

Installation and maintenance instructions ecotec pro 0020129672_03 19 5 gas installation 5 gas installation the work described in this section must only be carried out by a competent person. 5.1 preparing for installation a danger! Risk of death from incorrectly installed gas system! An incorrect ga...

Page 20

Hydraulic installation 20 installation and maintenance instructions ecotec pro 0020129672_03 6 6 hydraulic installation the work described in this section must only be carried out by a competent person. 6.1 preparing for installation a danger! Risk of death caused by an incorrectly installed system!...

Page 21

Hydraulic installation installation and maintenance instructions ecotec pro 0020129672_03 21 6 6.2 connecting the hot and cold water 1 2 3 4 5 6 7 6.1 fitting the hot and cold water connection > make the domestic hot and cold water connections as shown. > ensure correct water pressure and flow requi...

Page 22

Hydraulic installation 22 installation and maintenance instructions ecotec pro 0020129672_03 6 > connect the condensate discharge (1) of the boiler to a condensate discharge pipework (3) which has a minimum internal diameter of 19 mm (22 mm outside diameter for all external pipes) and is made from a...

Page 23

Flue gas installation installation and maintenance instructions ecotec pro 0020129672_03 23 7 7 flue gas installation 7.1 air/flue gas duct a danger! Risk of death and risk of damage from use of non-approved air/flue gas ducts! Vaillant boilers are certified only with gen- uine vaillant air/flue gas...

Page 24

Flue gas installation 24 installation and maintenance instructions ecotec pro 0020129672_03 7 7.2 flue termination the following details refer to all flue systems. A. The terminal must be positioned such that the prod- ucts of combustion can disperse freely at all times. B. A plume of water vapour w...

Page 25

Flue gas installation installation and maintenance instructions ecotec pro 0020129672_03 25 7 location minimum dimensions a directly below an opening, air brick, opening win- dows, etc. 300 mm b above an opening, air brick, opening window, etc. 300 mm c horizontally to an opening, air brick, opening...

Page 26

Electrical installation 26 installation and maintenance instructions ecotec pro 0020129672_03 8 8 electrical installation 8.1 preparing for installation e danger! Risk of death from electric shock! Touching live connections can cause seri- ous personal injury. > switch off the power supply. > secure...

Page 27

Electrical installation installation and maintenance instructions ecotec pro 0020129672_03 27 8 b caution. Risk of damage caused by incorrect installation. A mains voltage at the incorrect plug termi- nals on the proe system can destroy the electronics. > only connect the mains connection cable to t...

Page 28

Electrical installation 28 installation and maintenance instructions ecotec pro 0020129672_03 8 8.4.2 connecting controllers to the electronic system b caution. Risk of damage caused by incorrect installation. Connecting wires that have been stripped too far can cause short circuits and damage the e...

Page 29

Electrical installation installation and maintenance instructions ecotec pro 0020129672_03 29 8 8.6 connection wiring diagram circulat ion pump remot e cont rol 1 dcf connect ion eart h eart h ext ernal sensor flow sensor (opt ional) 6 ignit ion t rans- former bus connect ion (cont roller/ room t h....

Page 30

Operation 30 installation and maintenance instructions ecotec pro 0020129672_03 9 9 operation the vaillant ecotec pro boiler is fitted with a digital infor- mation and analysis system (dia). You can use the dia to display the current status of your boiler (live monitor) and fault codes, to view and ...

Page 31

Commissioning installation and maintenance instructions ecotec pro 0020129672_03 31 10 10 commissioning at the time of commissioning, complete all relevant sec- tions of the benchmark checklist found within the back pages of this document. Ensure that the filling and purging programs p.06 and p.00 h...

Page 32

Commissioning 32 installation and maintenance instructions ecotec pro 0020129672_03 10 i if the boiler is in error condition, you cannot start any test programs. You can detect an error condition by the fault symbol shown in the left bottom corner of the display (¬ fig. 10.1). You must first reset. ...

Page 33

Commissioning installation and maintenance instructions ecotec pro 0020129672_03 33 10 i if the water pressure in the heating system is too low, the display switches between fault mes- sage f.22 and the display of the current pressure when the boiler is switched on. > purge the lowest radiator until...

Page 34

Commissioning 34 installation and maintenance instructions ecotec pro 0020129672_03 10 1 10.3 filling the condensate trap > remove the lower part (1) of the condensate trap by turning the bayonet fitting anti-clockwise. > fill the lower section with water until about 10 mm below the upper edge. > re...

Page 35

Commissioning installation and maintenance instructions ecotec pro 0020129672_03 35 10 1 2 10.4 flue gas and air measure points legend: 1 flue gas measure point 2 air measure point for checking the system for recirculation use the air meas- ure point (2). > use the flue gas analyser. > if you detect...

Page 36

Commissioning 36 installation and maintenance instructions ecotec pro 0020129672_03 10 > undo the sealing screw of the measuring nipple (1) (left- hand screw) at the gas valve using a screwdriver. > connect a digital pressure gauge or u-tube manometer (2) to the measuring nipple (1). > open the gas ...

Page 37

Commissioning installation and maintenance instructions ecotec pro 0020129672_03 37 10 you can display the current operating condition of the boiler in the "live monitor" on the boiler display (¬ sec- tion 13.2.1). 10.10.1 checking the heating mode > switch on the boiler. > make sure that there is a...

Page 38

Adapting the boiler to the heating installation 38 installation and maintenance instructions ecotec pro 0020129672_03 11 11 adapting the boiler to the heating installation you can find all setting options in the diagnostic codes in the installer level (¬ section 9.2). 11.1 diagnosis codes – overview...

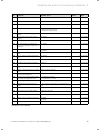

Page 39

Adapting the boiler to the heating installation installation and maintenance instructions ecotec pro 0020129672_03 39 11 code parameters adjustable values factory setting your own setting d.000 heating partial load adjustable heating partial load in kw auto: boiler automatically adjusts max. Partial...

Page 40

Adapting the boiler to the heating installation 40 installation and maintenance instructions ecotec pro 0020129672_03 11 code parameters adjustable values factory setting your own setting d.027 switching of relay 1 on the "2 in 7" multi-functional module vr 40 1 = circulation pump 2 = external pump ...

Page 41

Adapting the boiler to the heating installation installation and maintenance instructions ecotec pro 0020129672_03 41 11 code parameters adjustable values factory setting your own setting d.067 remaining burner anti-cycling time in minutes not adjustable d.068 unsuccessful ignitions at 1st attempt n...

Page 42

Adapting the boiler to the heating installation 42 installation and maintenance instructions ecotec pro 0020129672_03 11 11.1.1 setting the heating partial load the heating partial load of the vaillant ecotec pro boiler is factory-set to "auto". This means that the boiler independ- ently determines ...

Page 43

Adapting the boiler to the heating installation installation and maintenance instructions ecotec pro 0020129672_03 43 11 t feed (target) [°c] set maximum burner anti-cycling time [min] 1 5 10 15 20 25 30 35 40 45 50 55 60 20 2.0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0 50.0 55.0 60.0 25 2.0 4.5 9...

Page 44

Adapting the boiler to the heating installation 44 installation and maintenance instructions ecotec pro 0020129672_03 11 > regulate the pressure using the setting screw (1). Position of the setting screw pressure in mpa (mbar) notes/application right-hand stop (turned all the way down) 35.0 (350) if...

Page 45

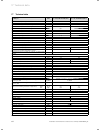

Inspection and maintenance installation and maintenance instructions ecotec pro 0020129672_03 45 12 12 inspection and maintenance after servicing, complete the relevant service record sec- tion of the benchmark checklist located on the inside back pages of this document. 12.1 inspection and maintena...

Page 46

Inspection and maintenance 46 installation and maintenance instructions ecotec pro 0020129672_03 12 12.1.1 general inspection and maintenance instructions to ensure the faultless operation, long term availability of all functions and long working life of your vaillant boiler and to prevent modificat...

Page 47

Inspection and maintenance installation and maintenance instructions ecotec pro 0020129672_03 47 12 1 12.1 measuring the co 2 concentration i the boiler is fitted with a flue gas analysis point (1). A suitable flue gas analyser can be con- nected to this point to establish the combustion performance...

Page 48

Inspection and maintenance 48 installation and maintenance instructions ecotec pro 0020129672_03 12 settings unit natural gas (h) propane co 2 after 5 minutes full load mode with boiler front casing fitted vol.–% 9.2 +/- 1.0 10.2 +/- 0.5 co 2 after 5 minutes full load mode with boiler front casing r...

Page 49

Inspection and maintenance installation and maintenance instructions ecotec pro 0020129672_03 49 12 12.2 inspection and maintenance work steps no. Activity column 1 inspection must be carried out each year column 2 maintenance must be car- ried out at reg- ular intervals 1 check the air flue gas ins...

Page 50

Inspection and maintenance 50 installation and maintenance instructions ecotec pro 0020129672_03 12 12.2.1 filling the boiler and the heating installation a description of how to fill the boiler and the heating instal- lation is provided in ¬ section 10.5. 12.2.2 draining the boiler > close the serv...

Page 51

Inspection and maintenance installation and maintenance instructions ecotec pro 0020129672_03 51 12 1 2 3 7 5 4 6 12.4 removing the compact thermal module i the plug on the fan motor has a latching lug with which it engages in the slot. You have to release the latching lug by pushing it in to pull o...

Page 52

Inspection and maintenance 52 installation and maintenance instructions ecotec pro 0020129672_03 12 as the burner (1) is maintenance-free, it does not require cleaning. > check the surface of the burner for damage. > if necessary, replace the burner. 12.3.4 cleaning the condensate trap a danger! Ris...

Page 53

Inspection and maintenance installation and maintenance instructions ecotec pro 0020129672_03 53 12 12.3.6 installing the compact thermal module a danger! Risk of death and risk of damage caused by hot flue gas! If you do not renew the seal and the self- locking nuts on the burner door, hot flue gas...

Page 54

Inspection and maintenance 54 installation and maintenance instructions ecotec pro 0020129672_03 12 ing installation, ideally with nitrogen, otherwise with air. Ensure drain valve on boiler is open during topping up. > if water escapes from the measuring stub pipes (1) of the expansion vessel, you m...

Page 55

Troubleshooting installation and maintenance instructions ecotec pro 0020129672_03 55 13 13 troubleshooting 13.1 contact vaillant service solutions (0870 6060 777) > if you contact vaillant service solutions (0870 6060 777) or your vaillant service partner, if possible, please mention – the fault co...

Page 56

Troubleshooting 56 installation and maintenance instructions ecotec pro 0020129672_03 13 13.2.4 service messages if the "open-end spanner" maintenance symbol appears on the display, a service message is present. The mainte- nance symbol appears if you have set a maintenance inter- val, for example, ...

Page 57

Troubleshooting installation and maintenance instructions ecotec pro 0020129672_03 57 13 13.2.9 overview of fault codes code meaning cause f.00 flow temperature sensor interruption ntc plug not plugged in or has come loose, multiple plug on the pcb not plugged in correctly, interruption in cable har...

Page 58

Troubleshooting 58 installation and maintenance instructions ecotec pro 0020129672_03 13 code meaning cause f.68 unstable flame signal fault air in gas, gas flow pressure too low, wrong air ratio, condensate route blocked, wrong gas restrictor, ionisation flow interruption (cables, elec- trodes), fl...

Page 59

Replacing components installation and maintenance instructions ecotec pro 0020129672_03 59 14 14 replacing components the work described in this section must only be carried out by a competent person. > only use genuine vaillant spare parts for repairs . An overview of the available genuine vaillant...

Page 60

Replacing components 60 installation and maintenance instructions ecotec pro 0020129672_03 14 14.3 replacing the fan or the gas valve 6 7 8 3 1 4 5 2 14.2 removing/refitting the fan/gas valve unit > remove the air intake pipe (¬ section 12.3.1). > remove the plug from the gas valve (7, ¬ fig. 14.2)....

Page 61

Replacing components installation and maintenance instructions ecotec pro 0020129672_03 61 14 1 2 3 4 14.5 replacing the expansion vessel > loosen the screw connection (4) at the water connec- tion on the underside of the expansion vessel. > remove both screws (1) on the support plate (2). > remove ...

Page 62

Replacing components 62 installation and maintenance instructions ecotec pro 0020129672_03 14 b caution. Risk of damage to the boiler. Mineral oil-based lubricants may damage the seals. The seals should therefore not be lubricated. > only use water or commercially available soft soap, if necessary, ...

Page 63

Decommissioning installation and maintenance instructions ecotec pro 0020129672_03 63 15 15 decommissioning 15.1 temporarily shutting down the boiler b caution. Risk of frost damage due to incorrect shutdown. If you switch off the boiler using the on/off switch or disconnect it from the power mains,...

Page 64

Technical data 64 installation and maintenance instructions ecotec pro 0020129672_03 17 17 technical data ecotec pro unit pro 24 (vuw gb 246/5-3) pro 28 (vuw gb 286/5-3) nominal heat output range p at 50/30 °c kw 5.7 - 19.9 6.9 - 25.7 nominal heat output range p at 80/60 °c kw 5.2 - 18.9 6.2 - 24.4 ...

Page 65

Glossary installation and maintenance instructions ecotec pro 0020129672_03 65 18 18 glossary air/flue gas duct an air/flue gas duct is a line system with two separate flow channels. The flue gas is routed into separate chambers at the same time as the required combustion air is pumped to the boiler...

Page 66

Appendix 66 installation and maintenance instructions ecotec pro 0020129672_03 19 19 appendix installation, commissioning and service record.

Page 67

Benchmark log book installation and maintenance instructions ecotec pro 0020129672_03 67 20 20 benchmark log book.

Page 68

Benchmark log book 68 installation and maintenance instructions ecotec pro 0020129672_03 20 it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below . Before completing the appropriate service interval record below, please e...

Page 69

Ec declaration of conformity installation and maintenance instructions ecotec pro 0020129672_03 69 21 21 ec declaration of conformity.

Page 70

Index 70 installation and maintenance instructions ecotec pro 0020129672_03 index a accessories.................................................................................... 12 air/flue gas duct .................................................................. 23, 65 air/flue system ............

Page 71

Index 71 installation and maintenance instructions ecotec pro 0020129672_03 m mains connection ........................................................................ 26 manufacturer’s guarantee ........................................................ 63 minimum clearance .............................

Page 72

00 2 012 9 6 7 2_0 3 gbie 0 7 2 012 – s ubject t o change manufacturer supplier.