- DL manuals

- Vaillant

- Boiler

- ecoTEC VU

- Installation And Maintenance Instructions Manual

Vaillant ecoTEC VU Installation And Maintenance Instructions Manual

Summary of ecoTEC VU

Page 1

Installation and maintenance instructions for the competent person channel islands installation and maintenance instructions ecotec vu, vuw.

Page 2

Table of contents 2 installation and maintenance instructions ecotec 0020173113_01 table of contents 1 notes on the documentation .....................................4 1.1 storing documents ..........................................................4 1.2 symbols used ...................................

Page 3

Table of contents 3 installation and maintenance instructions ecotec 0020173113_01 10.13 carrying out a full function test..................................41 10.13.1 checking the heating mode ....................................... 42 10.13.2 checking the hot water generation (vuw boilers only) ......

Page 4

Notes on the documentation 4 installation and maintenance instructions ecotec 0020173113_01 1 1 notes on the documentation the following instructions are intended to guide you throughout the entire documentation. Further documents apply in combination with these installation and mainte- nance instru...

Page 5

Notes on the documentation installation and maintenance instructions ecotec 0020173113_01 5 1 1.7 type overview unit type ecotec designated coun- try (designation in accordance with iso 3166) approval category 22 (vu gb 226/5-3) gb (great britain) ie (ireland) ii 2h3p 26 (vuw gb 266/5-3) gb (great b...

Page 6

6 installation and maintenance instructions ecotec 0020173113_01 a safety a 2 2 safety 2.1 safety and warning information > when installing the ecotec, take account of the general safety instructions and the warning notes that appear before all of the actions. 2.1.1 classification of warnings the wa...

Page 7

Installation and maintenance instructions ecotec 0020173113_01 7 a safety a 2 the current etci regulations for installing electrical equip- ment must also be observed. Installation and settings in the following cases, the boiler must be operated only with the front casing fitted and closed and with ...

Page 8

8 installation and maintenance instructions ecotec 0020173113_01 a safety a 2 – bs 6981 installation of low pressure gas pipework of up to 35 mm in domestic premises. – bs 4814 specification for: expansion vessels using an internal diaphragm, for sealed hot water and heating sys- tems. – bs 7074 app...

Page 9

Installation and maintenance instructions ecotec 0020173113_01 9 a safety a 2 – ige/up /1b for systems up to 0.035 m 3 capacity – for larger systems ige/up/1a and – for lpg installations refer to bs 5482 - 1 or – ige/up1 edition 2 for larger volume installations. 2.4.4 air supply detailed recommenda...

Page 10

10 installation and maintenance instructions ecotec 0020173113_01 a safety a 2 additives intended to remain permanently in the system – fernox f1 – fernox f2 – sentinel x 100 – sentinel x 200 additives for frost protection intended to remain permanently in the system – fernox antifreeze alphi 11 – s...

Page 11

Description of the appliance installation and maintenance instructions ecotec 0020173113_01 11 3 3 description of the appliance design 5 6 7 8 11 9 10 12 14 4 3 1 2 15 13 3.1 functional elements of the vu system boiler key 1 gas valve 2 water pressure sensor 3 heat exchanger 4 connection for the air...

Page 12

Installation 12 installation and maintenance instructions ecotec 0020173113_01 4 4 installation i before proceeding - ensure boiler is correct for gas group supplied! The work described in this section must only be carried out by a competent person. 4.1 accessories 4.1.1 controller to control the ec...

Page 13

Installation installation and maintenance instructions ecotec 0020173113_01 13 4 item qty description 1 1 wall bracket 2 1 boiler 3 1 flow restrictor 4 4 supply pipes (gas, heating, expansion relief valve) 5 3 service valves 6 1 montageschablone 7 1 enclosure documentation 8 2 bags with parts 4.2 sc...

Page 14

Installation 14 installation and maintenance instructions ecotec 0020173113_01 4 > if removing boiler from truck straddle the load and tilt forwards to facilitate secure grip. > ensure safe lifting techniques are used – keep back straight – bend using legs. > do not twist – reposition feet instead. ...

Page 15

Installation installation and maintenance instructions ecotec 0020173113_01 15 4 > always use assistance if required. > recommend wear suitable cut resistant gloves with good grip to protect against sharp edges and ensure good grip when handling appliance. Positioning of appliance for final installa...

Page 16

Installation 16 installation and maintenance instructions ecotec 0020173113_01 4 – the position of the connections. – the position of the wall breakthrough of the air/flue gas duct. Position the installation template vertically over the instal- lation site. > attach the template to the wall, using t...

Page 17

Installation installation and maintenance instructions ecotec 0020173113_01 17 4 4.5 dimension drawing and connection measurements 72 0 20 35 35 6 24 3 35 180 125 125 100 100 440 a 2 1 8 3 4 5 6 7 7 9 10 6 3 4 5 11 4.4 connection measurements in mm key 1 wall breakthrough for air/flue gas duct 2 han...

Page 18

Installation 18 installation and maintenance instructions ecotec 0020173113_01 4 4.6 wall-mounting the boiler a danger! Risk of death if the load-bearing capacity of the fixing elements used is insuffi- cient! If the fixing elements or wall do not have sufficient load-bearing capacity, the boiler ca...

Page 19

Installation and maintenance instructions ecotec 0020173113_01 19 4 installation 4.8 removing/fitting the side panel you can also remove a side panel for installation or mainte- nance purposes. B caution. Risk of damage caused by mechanical tension. Removing both side panels may cause mechanical dis...

Page 20

Gas installation 20 installation and maintenance instructions ecotec 0020173113_01 5 5 gas installation the work described in this section must only be carried out by a competent person. 5.1 preparing for installation a danger! Risk of death from incorrectly installed gas system! An incorrect gas in...

Page 21

Hydraulic installation installation and maintenance instructions ecotec 0020173113_01 21 6 6 hydraulic installation the work described in this section must only be carried out by a competent person. 6.1 preparing for installation a danger! Risk of death caused by an incorrectly installed system! Hea...

Page 22

Hydraulic installation 22 installation and maintenance instructions ecotec 0020173113_01 6 6.2 connecting the hot and cold water (vuw boiler) 6.1 fitting the hot and cold water connection > make the domestic hot and cold water connections as shown. > ensure correct water pressure and flow requiremen...

Page 23

Hydraulic installation installation and maintenance instructions ecotec 0020173113_01 23 6 6.5 low loss header a low loss header disconnects the boiler from the heating system. The system is no longer dependent on the remain- ing feed head of the boiler. In conjunction with the heating pump, the low...

Page 24

Hydraulic installation 24 installation and maintenance instructions ecotec 0020173113_01 6 min. 180 1 2 3 6.5 fit the discharge pipe on the expansion relief valve (exam- ple: vuw boiler) > insert a seal (1) in the cap nut (2). > screw the discharge pipe (3) onto the expansion relief valve. > make th...

Page 25

Flue gas installation installation and maintenance instructions ecotec 0020173113_01 25 7 7 flue gas installation 7.1 air/flue gas duct a danger! Risk of death and risk of damage from use of non-approved air/flue gas ducts! Vaillant boilers are certified only with gen- uine vaillant air/flue gas duc...

Page 26

Flue gas installation 26 installation and maintenance instructions ecotec 0020173113_01 7 143 0 70 7.4 scope of delivery for the vertical air/flue gas duct article number 303200 7.2 flue termination the following details refer to all flue systems. A. The terminal must be positioned such that the pro...

Page 27

Flue gas installation installation and maintenance instructions ecotec 0020173113_01 27 7 g n n m m a ii o h h c b l j q q q q q k p d, e f i s r t 7.5 termination of the air/flue gas duct location minimum dimensions a directly below an opening, air brick, opening win- dows, etc. 300 mm b above an o...

Page 28

Flue gas installation 28 installation and maintenance instructions ecotec 0020173113_01 7 7.6 termination of air/flue gas duct under balcony or eaves.

Page 29

Electrical installation installation and maintenance instructions ecotec 0020173113_01 29 8 8 electrical installation 8.1 preparing for installation e danger! Risk of death from electric shock! Touching live connections can cause seri- ous personal injury. > switch off the power supply. > secure the...

Page 30

Electrical installation 30 installation and maintenance instructions ecotec 0020173113_01 8 b caution. Risk of damage caused by incorrect installation. A mains voltage at the incorrect plug termi- nals on the proe system can destroy the electronics. > only connect the mains connection cable to the t...

Page 31

Electrical installation installation and maintenance instructions ecotec 0020173113_01 31 8 8.4.2 connecting controllers to the electronic system b caution. Risk of damage caused by incorrect installation. Connecting wires that have been stripped too far can cause short circuits and damage the elect...

Page 32

Electrical installation 32 installation and maintenance instructions ecotec 0020173113_01 8 8.6 connection wiring diagrams circulation pump remote control 1 dcf connection earth earth external sensor flow sensor (optional) 6 ignition trans- former bus connection (controller/room th. Digital) m x2 8 ...

Page 33

Electrical installation installation and maintenance instructions ecotec 0020173113_01 33 8 circulation pump remote control 1 dcf connection earth earth external sensor flow sensor (optional) 6 ignition trans- former bus connection (controller/room th. Digital) x2 8 17 7 18 14 13 4 12 5 7 7 16 4 3 1...

Page 34

Operation 34 installation and maintenance instructions ecotec 0020173113_01 9 9 operation the vaillant ecotec pro boiler is fitted with a digital infor- mation and analysis system (dia). You can use the dia to display the current status of your boiler (live monitor) and fault codes, to view and chan...

Page 35

Commissioning installation and maintenance instructions ecotec 0020173113_01 35 10 10 commissioning at the time of commissioning, complete all relevant sec- tions of the benchmark checklist found within the back pages of this document. Ensure that the filling and purging programs p.06 and p.00 have ...

Page 36

Commissioning 36 installation and maintenance instructions ecotec 0020173113_01 10 p.00 1,0 bar 10.1 boiler in error condition i if the boiler is in error condition, you cannot start any test programs. You can detect an error condition by the fault symbol shown in the left bottom corner of the displ...

Page 37

Commissioning installation and maintenance instructions ecotec 0020173113_01 37 10 > in order to fill the heating installation, first open the cold water valve. > open all thermostatic radiator valves. > check that both service valves on the boiler are open. > slowly open the stop valve on the filli...

Page 38

Commissioning 38 installation and maintenance instructions ecotec 0020173113_01 10 10.8 filling the condensate trap a danger! Risk of poisoning from escaping flue gas! An empty or insufficiently filled condensate trap may allow flue gas to escape into the room air. > fill the condensate trap with wa...

Page 39

Commissioning installation and maintenance instructions ecotec 0020173113_01 39 10 10.10 adjusting the boiler to the gas used on the channel islands the gas ratio can only be correctly set if the gas flow pres- sure is within the permissible tolerances at the same time. For this reason, the two meas...

Page 40

Commissioning 40 installation and maintenance instructions ecotec 0020173113_01 10 boiler gas used on the channel islands minimum pressure at reference test point in kpa (mbar) maximum pressure at reference test point in kpa (mbar) 22 1.0 (10) 1.7 (17) 26 1.0 (10) 1.7 (17) 10.2 gas inlet working pre...

Page 41

Commissioning installation and maintenance instructions ecotec 0020173113_01 41 10 1 2 10.8 flue gas and air measure points legend: 1 flue gas measure point 2 air measure point for checking the system for recirculation use the air meas- ure point (2). > use the flue gas analyser. > if you detect any...

Page 42

Commissioning 42 installation and maintenance instructions ecotec 0020173113_01 10 you can display the current operating condition of the boiler in the "live monitor" on the boiler display (¬ sec- tion 13.2.1). 10.13.1 checking the heating mode > switch on the boiler. > make sure that there is a hea...

Page 43

Adapting the boiler to the heating installation installation and maintenance instructions ecotec 0020173113_01 43 11 11 adapting the boiler to the heating installation you can find all setting options in the diagnostic codes in the installer level (¬ section 9.2). 11.1 diagnosis codes – overview you...

Page 44

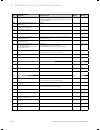

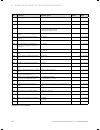

Adapting the boiler to the heating installation 44 installation and maintenance instructions ecotec 0020173113_01 11 code parameters adjustable values factory setting your own setting d.000 heating partial load adjustable heating partial load in kw auto: boiler automatically adjusts max. Partial loa...

Page 45

Adapting the boiler to the heating installation installation and maintenance instructions ecotec 0020173113_01 45 11 code parameters adjustable values factory setting your own setting d.027 switching of relay 1 on the "2 in 7" multi-functional module vr 40 1 = circulation pump 2 = external pump 3 = ...

Page 46

Adapting the boiler to the heating installation 46 installation and maintenance instructions ecotec 0020173113_01 11 code parameters adjustable values factory setting your own setting d.067 remaining burner anti-cycling time in minutes not adjustable d.068 unsuccessful ignitions at 1st attempt numbe...

Page 47

Adapting the boiler to the heating installation installation and maintenance instructions ecotec 0020173113_01 47 11 11.1.1 setting the heating partial load the heating partial load of the vaillant ecotec boiler is fac- tory-set to "auto". This means that the boiler independently determines the opti...

Page 48

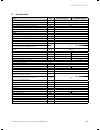

Adapting the boiler to the heating installation 48 installation and maintenance instructions ecotec 0020173113_01 11 t feed (target) [°c] set maximum burner anti-cycling time [min] 1 5 10 15 20 25 30 35 40 45 50 55 60 20 2.0 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0 50.0 55.0 60.0 25 2.0 4.5 9.2 1...

Page 49

Adapting the boiler to the heating installation installation and maintenance instructions ecotec 0020173113_01 49 11 > regulate the pressure using the setting screw (1). Position of the setting screw pressure in mpa (mbar) notes/application right-hand stop (turned all the way down) 35.0 (350) if the...

Page 50

Inspection and maintenance 50 installation and maintenance instructions ecotec 0020173113_01 12 12 inspection and maintenance after servicing, complete the relevant service record sec- tion of the benchmark checklist located on the inside back pages of this document. 12.1 inspection and maintenance ...

Page 51

Inspection and maintenance installation and maintenance instructions ecotec 0020173113_01 51 12 for an overview of the available original vaillant spare parts, contact the vaillant sales office on 0870 6060 777. During any inspection and maintenance or after change of parts of the combustion circuit...

Page 52

Inspection and maintenance 52 installation and maintenance instructions ecotec 0020173113_01 12 1 12.1 measuring the co 2 concentration i the boiler is fitted with a flue gas analysis point (1). A suitable flue gas analyser can be con- nected to this point to establish the combustion performance of ...

Page 53

Inspection and maintenance installation and maintenance instructions ecotec 0020173113_01 53 12 settings unit gas used on the channel islands co 2 after 5 minutes full load mode with boiler front casing fitted vol.–% 10.4 +/ - 0.3 co 2 after 5 minutes full load mode with boiler front casing removed ...

Page 54

Inspection and maintenance 54 installation and maintenance instructions ecotec 0020173113_01 12 12.2 inspection and maintenance work steps no. Activity column 1 inspection must be carried out each year column 2 maintenance must be car- ried out at reg- ular intervals 1 check the air flue gas install...

Page 55

Inspection and maintenance installation and maintenance instructions ecotec 0020173113_01 55 12 12.2.1 filling the boiler and the heating installation a description of how to fill the boiler and the heating instal- lation is provided in ¬ section 10.5. 12.2.2 draining the boiler > close the service ...

Page 56

Inspection and maintenance 56 installation and maintenance instructions ecotec 0020173113_01 12 1 2 3 7 5 4 6 12.4 removing the compact thermal module i the plug on the fan motor has a latching lug with which it engages in the slot. You have to release the latching lug by pushing it in to pull off t...

Page 57

Inspection and maintenance installation and maintenance instructions ecotec 0020173113_01 57 12 as the burner (1) is maintenance-free, it does not require cleaning. > check the surface of the burner for damage. > if necessary, replace the burner. 12.3.4 cleaning the condensate trap a danger! Risk of...

Page 58

Inspection and maintenance 58 installation and maintenance instructions ecotec 0020173113_01 12 12.3.6 installing the compact thermal module a danger! Risk of death and risk of damage caused by hot flue gas! If you do not renew the seal and the self- locking nuts on the burner door, hot flue gases m...

Page 59

Inspection and maintenance installation and maintenance instructions ecotec 0020173113_01 59 12 ing installation, ideally with nitrogen, otherwise with air. Ensure drain valve on boiler is open during topping up. > if water escapes from the measuring stub pipes (1) of the expansion vessel, you must ...

Page 60

Troubleshooting 60 installation and maintenance instructions ecotec 0020173113_01 13 13 troubleshooting 13.1 contact vaillant service solutions (0870 6060 777) > if you contact vaillant service solutions (0870 6060 777) or your vaillant service partner, if possible, please mention – the fault code d...

Page 61

Troubleshooting installation and maintenance instructions ecotec 0020173113_01 61 13 13.2.4 service messages if the "open-end spanner" maintenance symbol appears on the display, a service message is present. The mainte- nance symbol appears if you have set a maintenance inter- val, for example, (¬ s...

Page 62

Troubleshooting 62 installation and maintenance instructions ecotec 0020173113_01 13 13.2.9 overview of fault codes code meaning cause f.00 flow temperature sensor interruption ntc plug not plugged in or has come loose, multiple plug on the pcb not plugged in correctly, interruption in cable harness...

Page 63

Troubleshooting installation and maintenance instructions ecotec 0020173113_01 63 13 code meaning cause f.68 unstable flame signal fault air in gas, gas flow pressure too low, wrong air ratio, condensate route blocked, wrong gas restrictor, ionisation flow interruption (cables, elec- trodes), flue g...

Page 64

Replacing components 64 installation and maintenance instructions ecotec 0020173113_01 14 14 replacing components the work described in this section must only be carried out by a competent person. > only use genuine vaillant spare parts for repairs . For an overview of the available original vaillan...

Page 65

Replacing components installation and maintenance instructions ecotec 0020173113_01 65 14 > remove the plug from the gas valve (7, ¬ fig. 14.2). I the plug on the fan motor has a latching lug with which it engages in the slot. You have to release the latching lug by pushing it in to pull off the plu...

Page 66

Replacing components 66 installation and maintenance instructions ecotec 0020173113_01 14 > fill and purge the boiler and, if necessary, the system after installing the new expansion vessel (¬ sec- tion 10.5). > on completion of the work, check for water leaks. 14.5 replacing the heat exchanger b ca...

Page 67

Replacing components installation and maintenance instructions ecotec 0020173113_01 67 14 14.6 replacing the pcb and/or the display e danger! Risk of death from electric shock! Mains connection terminals l and n remain live even if the continuous voltage on/off switch is turned off. > before carryin...

Page 68

Decommissioning 68 installation and maintenance instructions ecotec 0020173113_01 15 15 decommissioning 15.1 temporarily shutting down the boiler b caution. Risk of frost damage due to incorrect shutdown. If you switch off the boiler using the on/off switch or disconnect it from the power mains, thi...

Page 69

Technical data installation and maintenance instructions ecotec 0020173113_01 69 17 17 technical data ecotec unit 22 (vu gb 226/5-3) 26 (vuw gb 266/5-3) nominal heat output range p at 50/30 °c kw 7.1 - 23.8 nominal heat output range p at 80/60 °c kw 6.4 - 22.4 maximum heat output for hot water gener...

Page 70

Glossary 70 installation and maintenance instructions ecotec 0020173113_01 18 18 glossary air/flue gas duct an air/flue gas duct is a line system with two separate flow channels. The flue gas is routed into separate chambers at the same time as the required combustion air is pumped to the boiler. Th...

Page 71

Appendix installation and maintenance instructions ecotec 0020173113_01 71 19 19 appendix installation, commissioning and service record.

Page 72

Appendix 72 installation and maintenance instructions ecotec 0020173113_01 20 please affix the label from the rear cover of the control box over this area..

Page 73: Service Interval Record

Installation and maintenance instructions ecotec 0020173113_01 73 21 service interval record it is recommended that your heating system is serviced regularly and that you complete the appropriate service interval record below . Service provider. Before completing the appropriate service interval rec...

Page 74

Index 74 installation and maintenance instructions ecotec 0020173113_01 index a accessories.................................................................................... 12 air/flue gas duct .................................................................. 25, 70 air/flue system ................

Page 75

Index 75 installation and maintenance instructions ecotec 0020173113_01 o overview inspection and maintenance work .................................... 54 parameters ............................................................... 44, 45, 46 read-off and setting options .................................

Page 76

00 2 017 3 113_01 channel islands 08 2 013 – s ubject t o change manufacturer supplier.