- DL manuals

- Vaillant

- Thermostat

- VRC 700/2

- Installation Instructions Manual

Vaillant VRC 700/2 Installation Instructions Manual

Summary of VRC 700/2

Page 1

For the competent person installation instructions vrc 700/2 vrc 700/2 gb, ie installation instructions publisher/manufacturer vaillant gmbh berghauser str. 40 d-42859 remscheid tel. +49 21 91 18‑0 fax +49 21 91 18‑28 10 info@vaillant.De www.Vaillant.De.

Page 2

Contents 2 contents 1 safety .................................................................... 3 1.1 general safety information .................................... 3 1.2 requirements for lines........................................... 3 1.3 regulations (directives, laws, standards) ...............

Page 3

Safety 1 3 1 safety 1.1 general safety information 1.1.1 risk caused by inadequate qualifications assembly and disassembly, installation, start- up, maintenance, repairs and decommission- ing must only be carried out by a compet- ent person who is sufficiently qualified to ob- serve all of the instr...

Page 4

2 notes on the documentation 4 2 notes on the documentation 2.1 observing other applicable documents ▶ you must observe all the operating and installation in- structions included with the system components. 2.2 storing documents ▶ pass these instructions and all other applicable docu- ments on to th...

Page 5

Installation 4 5 3. Carefully push the controller into the wall socket. 4.2 installing the controller in the heat generator note if you have installed a system with a hybrid heat pump, you must install the controller in the living area. Conditions: the heat generator is not connected to the ebus via...

Page 6

5 electrical installation 6 2. Alternatives 2 / 2 conditions: vrc 9535 outside temperature sensor 2 4 5 3 1 2 3 ▶ drill holes in line with the mounting holes (1). 3. Route the connection cable (3) in accordance with the illustration. 4. Remove the housing cover (5). 5. Undo the cap nut (2) and slide...

Page 7

Start-up 6 7 2. Alternatives 2 / 2 conditions: vrc 9535 outside temperature sensor 1 2 ▶ connect the connection cable to the terminal block on the outside temperature sensor (1). 3. Connect the connection cable to the 6‑pin edge con- nector on the heat generator (2). 4. Route the connection cable wi...

Page 8

8 operating and display functions 8 – you can use this function to read the heating installa- tion's operating mode. Standby: the heating installation does not report any energy requirement. Heat. Mode: the heating installation is in heating mode for the heating circuits. Cooling: the heating instal...

Page 9

Operating and display functions 8 9 to do this, the controller must be installed in the living area and assigned to a zone. The thermostat function must be activated. 8.2.14 defining the hybrid manager menu → installer level → system configuration [system -- --] → hybrid manager – you can use this f...

Page 10

8 operating and display functions 10 8.2.22 reading the system flow temperature menu → installer level → system configuration [system -- --] → system flow temp. – you can use this function to read the current temperature of the low loss header, for example. 8.2.23 setting the offset for the buffer c...

Page 11

Operating and display functions 8 11 8.5 heat exchanger 1 8.5.1 reading the status menu → installer level → system configuration [heat gen- erator 1 ----] → status – you can use this function to read which requirement the controller reports to the heat generator. Off: the controller does not report ...

Page 12

8 operating and display functions 12 8.6.9 reading the current temperature menu → installer level → system configuration → [heat- ing1 ----] → current temperature – you can use this function to read the current temperature of the heating circuit. 8.6.10 setting the excess temperature menu → installe...

Page 13

Operating and display functions 8 13 a b c d 18 22 20 0.4 70 60 50 40 30 15 10 5 0 -5 -10 -15 -20 a outside temperature °c b target flow temperature °c c target room temperat- ure °c d axis a if the heating curve 0.4 is selected and 21 °c is specified for the target room temperature, the heating cur...

Page 14

8 operating and display functions 14 8.7 zone1 8.7.1 deactivating the zone menu → installer level → system configuration → [zone1 ----] → zone activated – you can use this function to deactivate the zone that you do not require. All available zones appear in the display if the existing heat- ing cir...

Page 15

Operating and display functions 8 15 – you can use this function to define whether the anti-le- gionella function is carried out daily or on a specific day. When the anti-legionella function is activated, the respective cylinder and the corresponding hot water pipes are heated up to a temperature of...

Page 16

8 operating and display functions 16 8.9 buffer cylinder 8.9.1 reading the top cylinder temperature in the buffer cylinder menu → installer level → system configuration [buffer cylinder ----] → cyl. Temp.: top – you can use this function to read the current temperature in the upper section of the bu...

Page 17

Operating and display functions 8 17 the solar pump is switched on for 15 seconds (solar pump boost) if the temperature at the collector temperature sensor has risen by 2 k/hour. This transports the heated solar fluid to the point of measurement more quickly. 8.10.8 setting the solar circuit protect...

Page 18

8 operating and display functions 18 – you can use this function to define a differential value for stopping the temperature difference control, such as solar heating support. If the difference between temperature difference sensor 1 and temperature difference sensor 2 falls below the specified swit...

Page 19

Fault messages and faults 9 19 days after starting the func- tion target flow temperature for this day [°c] 4 40 5 45 6 - 12 45 13 40 14 35 15 30 16 25 17 - 23 10 (frost protection function, pump in operation) 24 30 25 35 26 40 27 45 28 35 29 25 the display shows the current day and the target flow ...

Page 20

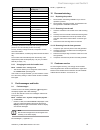

Appendix 20 appendix a overview of the setting options a.1 installation assistant setting values increment, select default setting min. Max. Language languages available for se- lection deutsch system diagram 1 13 1 1 config.: vr70, addr. 1 1 12 1 1 system configuration 1) 1) you can use the ok butt...

Page 21

Appendix 21 setting level values unit increment, select default setting min. Max. Energy supplier hp off, bh off, hp&bh off, heat- ing off, cooling off, ht./cl. Off hp off auxiliary heater for inactive, heating, dhw, dhw+heat. Dhw+heat. System flow temp. Current value ℃ 1 pv buffer cylinder offset 0...

Page 22

Appendix 22 setting level values unit increment, select default setting min. Max. Set-back temp. 5 30 ℃ 0.5 15 room temperature current value ℃ zone assignment without, vrc700, vr91 ad.1 none zone valve status current value closed, open dhw circuit ---- cylinder active, inactive active flow temp. Se...

Page 23

Appendix 23 setting level values unit increment, select default setting min. Max. Switch-on diff. 1 20 K 1 5 switch-off diff. 1 20 K 1 5 minimum temperature 0 99 ℃ 1 0 maximum temperature 0 99 ℃ 1 99 td1 sensor current value ℃ td2 sensor current value ℃ td output off, on off ventilation ---- air qua...

Page 24

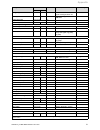

Appendix 24 available function setting the type of circuit function heating pool circuit fixed value circuit increase in return flow dhw circuit direct cir- cuit mixing cir- cuit setting the heating curve x x – – – – setting the minimum flow temperature for the heating circuit x x – – – – setting th...

Page 25

Appendix 25 legp: legionella protection pump solar yield: solar yield pwm: start-up signal for the solar pump unit or the feedback signal b.2 configuring the inputs and outputs of the vr 70 set value r1 r2 r3/r4 r5/r6 s1 s2 s3 s4 s5 s6 s7 1 hc1p hc2p ma hc2op/ hc2cl dhw1/ bufbt dem1 dem2 sysflow fs2...

Page 26

Appendix 26 c overview of the fault messages and faults c.1 fault messages in column 1 in the table, a $ symbol is displayed after the sensor. The $ symbol is a placeholder for the sensor number. The % symbol after various components is a placeholder for the address of the component. In both cases, ...

Page 27

Appendix 27 message possible cause measure incorrect configuration: ma2 vwz‑ai incorrectly connected vr 71 module 1. Connect the vr 71 module to the appropriate system dia- gram. Vr70/vr71 combination not perm. Vr 70 and vr 71 are connec- ted in combination 1. Connect either the vr 70 or the vr 71. ...

Page 28

Index 28 index a activating automatic cooling.................................................. 8 activating cooling ................................................................ 13 activating room temperature control ................................... 13 activating the adaptive heating curve......

Page 29

Index 29 reading the software version................................................ 8 reading the status ............................................................ 11 circulation pump............................................................ 14 cylinder charging pump..............................

Page 32

0020200781_01 20.05.2015 vaillant ltd. Nottingham road belper derbyshire de56 1jt telephone 03 30 100‑34 61 telephone (renewables) 02 07 022‑09 28 vaillant service solutions 03 30 100‑31 43 spares technical enquiries 177 359 66 15 info@vaillant.Co.Uk technicalspares@groupservice.Co.Uk www.Vaillant.C...