- DL manuals

- Valentin

- Printer

- Pica 104/8

- Operating Manual

Valentin Pica 104/8 Operating Manual

Summary of Pica 104/8

Page 1

Operating manual – english thermal transfer printer pica series 79.28.055 • may 2005 all rights reserved. Carl valentin gmbh • neckarstraße 78 – 80 & 94 • 78056 villingen-schwenningen support@valentin-carl.De • www.Valentin-carl.De.

Page 3

Table of contents 1 printer driver installation ....................................................................................... 1 windows 95, windows 98 and windows me ...........................................................................................................1 windows nt .......

Page 4

Table of contents 2 options .............................................................................................................................. 22 dispenser operating modes........................................................................................................................

Page 5

Manual 1 printer driver installation windows 95, windows 98 and windows me start the computer and wait until the operating system is ready. Click the button. Place the cursor first on settings and then on printers (see illustration below). The following window appears: double click add printer and t...

Page 6

Manual 2 double click driver and then select one of the available languages. At the moment you can either chose german or english . Depending on your operating system select win95 , win98 or winme . The open dialog box should appear as illustrated below. Confirm the selection with ok and the followi...

Page 7

Manual 3 windows nt start your computer and wait until the operating system is ready. Click the button. Place the cursor first on settings and then on printers (see illustration below). The following window appears: double click add printer and the first dialog of the add printer wizard appears. Sel...

Page 8

Manual 4 double click driver and then select one of the available languages. At the moment you can either chose german or english . Select winnt and the locate file dialog should appear as illustrated below double click the oemsetup.Inf file and the following dialog appears. Click again the ok butto...

Page 9

Manual 5 windows 2000 professional start your computer and wait until the operating system is ready. Click the button. Place the cursor first on settings and then on printers (see illustration below). Following dialog box appears: double click the add printer icon and the add printer wizard appears....

Page 10

Manual 6 from the list of available ports, select the one you want the printer to use and confirm your selection with next . The next page of the add printer wizard appears. Insert the installation cd, then click the have disk button. Click the browse button and the locate file dialog appears. Doubl...

Page 11

Manual 7 initial operation turn on the power switch at the rear of the printer. Load label material and if required transfer ribbon. Start measuring by pressing the keys and one after the other. Make sure that the printer is in online mode (green led lights up). With the key it is possible to change...

Page 12

Manual 8 printer rear 1 = ethernet interface (option) 2 = centronics interface 3 = serial interface 4 = primary fuse 5 = slots for cooling system 6 = input/output (option) 7 = connection for external unwinder 8 = power supply with on/off switch.

Page 13

Manual 9 loading of print material loading of labels in standard mode open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Remove the outside label mounting plate (c). Load the label roll (g) with inner winding onto the unwinding roll (d) and attach again ...

Page 14

Manual 10 loading of labels in rewinding mode rewinder behind open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Remove the outside label mounting plate (c). Load the label roll with inner winding onto the unwinding roll (d) and attach again the label mo...

Page 15

Manual 11 rewinder in front open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Remove the outside label mounting plate (c). Load the label roll with inner winding onto the unwinding roll (d) and attach again the label mounting plate (c). Lead the label m...

Page 16

Manual 12 loading of labels in cutter mode open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Remove the outside label mounting plate (c). Load the label roll with inner winding onto the unwinding roll (d) and attack again the label mounting plate (c). L...

Page 17

Manual 13 loading of labels in peel-off mode open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Remove the outside label mounting plate (c). Load the label roll with inner winding onto the unwinding roll (d) and attach again the label mounting plate (c)....

Page 18

Manual 14 loading of fan-fold material open the printer cover. Open printhead (a) by turning the lever (b) against clockwise direction. Load the fan-fold material from the back in the corresponding guiding (f). Lead the fan-fold material (c) through the photocell (e). To move the printhead (a) down,...

Page 19

Manual 15 loading of transfer ribbon note: as for the electrostatic unloading the thin coating of the thermal printhead or other electronic parts can be damaged, the transfer ribbon should be antistatic. The use of wrong materials can lead to printer malfunctions and the guarantee can expire. Note: ...

Page 20

Manual 16 technical data pica 104/8 pica 108/12 print max. Material width min. Label width min. Label height print width max. Print height resolution print speed printhead 110 mm 15 mm 6 mm 104 mm 750 mm (without ethernet) 650 mm (with ethernet 200 dpi 50-80 mm/s flat type 110 mm 15 mm 6 mm 108 mm 5...

Page 21

Manual 17 tear-off in case the printer is not equipped with a cutter or a dispenser, then it has as default an integrated tear-off edge. After a print order you can lead the labels together with the supporting paper over the tear-off edge to tear them off. Standard labels are suitable when using the...

Page 22

Manual 18 cleaning of cutter caution: unplug the machine! Danger of injury while working at the cutter! Use a cotton stick (or similar) with special label remover (here available) and clean the cutter blade by leading the stick from the left to the right side. Repeat this procedure as long as the co...

Page 23

Manual 19 operating and display elements led signals of the printer green led lights up printer is in online mode green led flashes printer is in offline mode red led lights up error signal red led flashes stopped print order key printer status function online and offline mode change from online to ...

Page 24

Manual 20 functions print make sure before printing that the printer is in online mode. Send the print order via serial or parallel interface. After transmission of the corresponding data the label is printed automatically. It is possible to discontinue and then again continue the print order by mea...

Page 25

Manual 21 rewinding unit pr28 1 it is possible to use the external rewinding unit pr28 for: • rewinding the labels onto roll • rewinding the supporting paper in dispensing mode rewind labels onto roll the rewinding unit is mounted at the front side of the printer without the enclosed return pulley. ...

Page 26

Manual 22 options dispenser operating modes it is possible to select the desired operating mode either by corresponding printer driver or label design software. The printer supports the following operating modes: off it is printed without the labels are dispensed. I/o static: the input signal is ana...

Page 27

Manual 23 cutter operating modes it is possible to select the desired operating mode either via the corresponding printer driver or the label design software. The printer supports the following operating modes: off it is printed without cutting the labels. Without backfeed a cut is effected after ea...

Page 28

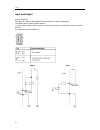

Manual 24 input and output (9-term. Dsup pin) this option is not part of the standard version and has to be ordered separately. The signal output is lead via optical couplers. In case a control output is active, then the corresponding output is to strain with a maximum current of 20ma. Pin equipment...

Page 29

Manual 25 error correction in case an error occurs, the printer stops, i.E. The print order is interrupted. Press the key to print the error code and at the same time the corresponding text. Recover the error, and then press the key to bring the printer again into operation. An active print order is...

Page 30

Manual 26 error table error no. Possible causes possible error correction 1 line rises up completely or partly over the upper edge of label. Move line down (increase y value). Check rotation and font. 2 line rises up completely or partly over the bottom edge of label. Move line up (decrease y value)...

Page 31

Manual 27 error no. Possible causes possible error rectification 15 invalid length of received mask statement. Check sent data. Check connection pc – printer. 16 transferred mask statement invalid. Check set data. Check connection pc – printer. 17 no end of data found. Check set data. Check connecti...

Page 32

Manual 28 error no. Possible causes possible error rectification 32 real time clock function is selected but the battery is empty. Defective rtc. Change or recharge battery. Change rtc component. 34 no print memory found. Check memory assembly on cpu. 35 at start of a print order the printhead is up...

Page 33

Manual 29 error no. Possible causes possible error rectification 53 drive full delete files which are no longer used from the card. 54 file/directory exists check the file name and rename it. 55 file too large 57 invalid graphic file the selected file does not contain graphic data. Check the file na...

Page 34

Manual 30 error no. Possible causes possible error rectification 79 faulty definition of shift times (overlapping times). Check definition of shift times. 80 rss bar code error. Check definition and parameter of rss bar code. 81 rss bar code error. Check sent data. 82 printing creation was still act...

Page 35

Manual 31 operating conditions before initial operation and during operation these operating conditions have to be observed to guarantee save and interference-free service of our printers. Therefore please carefully read these operating conditions. In case of questions referring to the practical han...

Page 36

Manual 32 stray radiation and immunity from disturbance • stray radiation according to: din en 50081-2 *din en 55011 / 12.98 *din en 55022 7 4.98 • stray radiation according to en 50082-2 electromagnetic fields according to din en 61000-4-3 / 8.97 discharge of static electricity according to din en ...

Page 37

Manual 33 limit values protection according to ip: 20 ambient temperature °c (operation): min. +5 max. +35 ambient temperature °c (storage): min. − 20 max. +60 relative air humidity % (operation): max. 80 relative air humidity % (storage): max. 80 (bedewing the printers not allowed) guarantee we do ...

Page 39

Index 35 index a air convection ................................................................................................................................................ 32 allowable lines............................................................................................................

Page 40

Index 36 o operating conditions air convection ............................................................................................................................................ 32 connecting lines to external machines ..........................................................................