- DL manuals

- Valeo

- Heating System

- spheros thermo 230

- Workshop Manual

Valeo spheros thermo 230 Workshop Manual

Summary of spheros thermo 230

Page 1

Rev. 05/2017 id.No. 9003656c thermo 230 thermo 300 thermo 350 with control unit 1572 model .30 and up thermo 230 thermo 300 thermo 350 with control unit 1572d model .30 and up thermo 231 thermo 301 model .01 and up thermo rail workshop manual heating systems.

Page 2: 1 Table of Contents

I thermo 230 / 231 / 300 / 301 / 350 1 table of contents table of contents 1 introduction 101 1.1 content and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 1.2 effectivity of the workshop manual . . . . . . . . . . . ....

Page 3: 1 Table of Contents

Ii thermo 230 / 231 / 300 / 301 / 350 1 table of contents 6 functional checkouts 601 6.1 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601 6.2 adjustments . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4: 1 Table of Contents

Iii thermo 230 / 231 / 300 / 301 / 350 1 table of contents 9.2.7 high pressure nozzle, replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 908 9.2.8 igniter box, replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: 1 Introduction

101 thermo 230 / 231 / 300 / 301 / 350 1 introduction 1 introduction 1.1 content and purpose this workshop manual is used during maintenance and repair of water heaters (further referred to as heaters) thermo 230, 231, 300, 301 and 350. Attention: work on the heater may only be performed by briefed ...

Page 6: 1 Introduction

102 thermo 230 / 231 / 300 / 301 / 350 1 introduction 1.7 suggestions for improvement and change please direct any complaints, improvement or modifica- tion suggestions regarding this manual to: service@spheros.De.

Page 7: 2 General Description

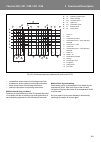

201 thermo 230 / 231 / 300 / 301 / 350 2 general description 2 general description the water heaters spheros thermo 230, 231, 300, 301 and 350 are used in combination with the vehicle’s own heating installation to – heat the passenger compartment – defrost the windscreen – preheat water-cooled engin...

Page 8: 2 General Description

202 thermo 230 / 231 / 300 / 301 / 350 2 general description 2.1 combustion air fan the combustion air fan supplies the air required for combustion from the combustion air inlet to the combus- tion chamber. The fan consists of a fan motor with fan wheel. Air is taken in through a splash protection c...

Page 9: 2 General Description

203 thermo 230 / 231 / 300 / 301 / 350 2 general description 2.2.1 nozzle block preheater at extremely low temperatures malfunctions may occur without a nozzle block preheater. At a temperature of heater cartridge in the nozzle block. The heating period depends on the heat reflected within the combu...

Page 10: 2 General Description

204 thermo 230 / 231 / 300 / 301 / 350 2 general description 2.8 temperature sensor the temperature sensor senses the coolant temperature at the heat exchanger outlet as an electrical resistance. This signal is supplied to the control unit for processing. 2.9 temperature limiter the temperature limi...

Page 11: 2 General Description

205 thermo 230 / 231 / 300 / 301 / 350 2 general description 2.11.1 aquavent 5000 (u4814) and aquavent 5000s (u4854) circulating pumps the aquavent 5000 (u4814) and 5000s (u4854) circula- ting pumps are equipped with a brush motor. Note aquavent 5000 (u4814) with floating-ring type shaft seal. Aquav...

Page 12: 2 General Description

206 thermo 230 / 231 / 300 / 301 / 350 2 general description 2.12 fuel filter at compact devices of the series 230/300/350.126 and .190 rail an optional heatable fuel filter is provided, as an additional option also for .124 and . 155 rail . If the electrical filter heating is hooked-up, the tempera...

Page 13: 3 Functional Description

301 thermo 230 / 231 / 300 / 301 / 350 3 functional description 3 functional description activation and deactivation is by means of a • switch • timer • air conditioning dependent on the type of installation. For monitoring operation at least an operating indicator light is provided. Switch off rele...

Page 14: 3 Functional Description

302 thermo 230 / 231 / 300 / 301 / 350 3 functional description switching thresholds for thermo xxx raill 3.1 switch on upon switch on the operating indicator light goes on. Combustion air fan, fuel pump and circulation pump start operation. (if fitted and temperature is preheater is also activated)...

Page 15: 3 Functional Description

303 thermo 230 / 231 / 300 / 301 / 350 3 functional description heaters with control unit 1572d only gradient evaluation in case of low coolant flow or poor coolant circuit venting the temperature quickly increases in heating operation. If gradient evaluation exists, the control unit recognises the ...

Page 16: 3 Functional Description

304 thermo 230 / 231 / 300 / 301 / 350 3 functional description – temperature sensor short circuit during control idle. – temperature sensor open circuit during combustion. – flame sensor short circuit during combustion. – solenoid valve short circuit during combustion. Malfunctions during run-down:...

Page 17: 3 Functional Description

305 thermo 230 / 231 / 300 / 301 / 350 3 functional description 3.8 switch-off upon failure (heaters with control unit 1572d) the heater switches off automatically when detecting one of the following malfunctions. Several subsequent switch-offs due to a malfunction will cause the heater to enter an ...

Page 18: 3 Functional Description

306 thermo 230 / 231 / 300 / 301 / 350 3 functional description malfunctions during run-down: detection of a flame after more than 30 seconds after start of run-down with the circulation pump and combustion air fan only maintaining operation for the follo- wing 90 seconds. Malfunctions by overheatin...

Page 19: 4 Technical Data

401 thermo 230 / 231 / 300 / 301 / 350 4 technical data 4 technical data where no threshold values are specified technical data are understood to include standard tolerances for heater units of ± 10% at ambient temperature of + 20 °c and at nominal voltage. 4.1 electrical components control unit, fa...

Page 20: 4 Technical Data

402 thermo 230 / 231 / 300 / 301 / 350 4 technical data optional fuel filter heater heater thermo 230 thermo 231 thermo 300 thermo 301 thermo 350 type thermo 230 thermo 231 thermo 300 thermo 301 thermo 350 mark of conformity up to 4/03 ~ s230 ~ s327 ~ s229 ~ s328 ~ s228 ec type approval number e1*20...

Page 21: 5 Troubleshooting

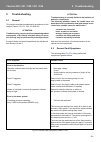

501 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5 troubleshooting 5.1 general this section describes troubleshooting procedures for the heaters thermo 230, 231, 300, 301 and 350 . Attention: troubleshooting requires profound knowledge about components of the heater and their theory of opera...

Page 22: 5 Troubleshooting

502 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting heater stops as the connected heat exchangers provides insufficient heat. Flow rate too small, because • air in the heater, heat exchangers or in system sections. • taps/valves (flow controllers) throttled, contaminated, closed. • contaminatio...

Page 23: 5 Troubleshooting

503 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3 fault symptoms during functional checkouts and error code output or tests with diagnostic computer, components tester or pc heater diagnosis 5.3.1 general error code output note: only heaters with a control unit 1572d provide an error code...

Page 24: 5 Troubleshooting

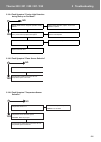

504 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3.2 fault symptoms 5.3.2.1 fault symptom "no start" note heaters with control unit 1572d: if the heater performs 8 subsequent attempts to start due to a malfunction, the heater enters an error lockout and stops any further attempts to start....

Page 25: 5 Troubleshooting

505 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3.2.2 fault symptom "flame-out" note: heaters with control unit 1572d: if the heater performs 5 subsequent attempts to start due to a malfunction, the heater enters an error lockout and stops any further attempts to start. This error lockout...

Page 26: 5 Troubleshooting

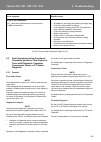

506 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3.2.4 fault symptom "foreign light detection during run-up or run-down" 5.3.2.5 fault symptom "flame sensor defective" 5.3.2.6 fault symptom "temperature sensor defective" no yes has the heater been in long time operation shortly before? All...

Page 27: 5 Troubleshooting

507 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3.2.7 fault symptom "solenoid valve defective" no yes is the solenoid valve supplied with electrical power? Has the safety thermostat responded? (thermo 231/301 only) investigate the reason for the response (e.G.Check the exhaust system) rep...

Page 28: 5 Troubleshooting

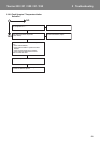

508 thermo 230 / 231 / 300 / 301 / 350 5 troubleshooting 5.3.2.8 fault symptom "temperature limiter defective" is electrical power supply to components o.K.? Yes no has temperature limiter responded (reset limiter)? Determine why temperature limiter has responded, e.G.: • check shut-off elements, • ...

Page 29: 6 Functional Checkouts

601 thermo 230 / 231 / 300 / 301 / 350 6 functional checkouts 6 functional checkouts 6.1 general this section describes the tests and adjustments on the heater in installed and removed condition to prove its serviceability. The heater must not be operated in closed areas like garages or workshops wi...

Page 30: 6 Functional Checkouts

602 thermo 230 / 231 / 300 / 301 / 350 6 functional checkouts 6.3 components testing 6.3.1 temperature sensor resistance check when checking the temperature sensor with a digital multimeter the values of the following diagram must be obtained. Resistance checking is preferably performed at ambient t...

Page 31: 6 Functional Checkouts

603 thermo 230 / 231 / 300 / 301 / 350 6 functional checkouts 6.3.5 fuel pump check 6.3.5.1 fuel pump check on heaters with control unit 1572 a pressure test gauge with a display range from 0 to 15 bar as well as a bleeding feature is required (see fig. Below). The pressure test gauge can be obtaine...

Page 32: 6 Functional Checkouts

604 thermo 230 / 231 / 300 / 301 / 350 6 functional checkouts – screw on the test gauge with bleeding feature. – follow the instructions in the menu component test of the pc heater diagnosis. – open the bleed port at the pressure test gauge until some fuel escapes, collect it e.G. With a cloth. Clos...

Page 33: 7 Circuit Diagrams

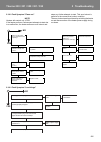

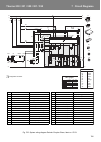

701 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams 7 circuit diagrams 7.1 general the circuit diagrams (fig. 701 and 702) show possible heater circuits for thermo 230, 300 and 350 with control unit 1572 and with – switch – timer 1529 (triple timer) the circuit diagrams (fig. 703 and 704) show...

Page 34: 7 Circuit Diagrams

702 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 701: automatic control circuit with control unit 1572 and switch item nomenclature remark a1 heater not grounded a2 control unit sg 1572 b1 flame sensor b2 temperature sensor b3 temperature limiter b4 thermostat open at t > 8 °c e1 heati...

Page 35: 7 Circuit Diagrams

703 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 702: automatic control circuit with control unit 1572 and timer (triple timer) item nomenclature remark a1 heater not grounded a2 control unit sg 1572 b1 flame sensor b2 temperature sensor b3 temperature limiter b4 thermostat open at t >...

Page 36: 7 Circuit Diagrams

704 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 703: automatic control circuit with control unit 1572d and switch item nomenclature remark a1 heater not grounded a2 control unit sg 1572 b1 flame sensor observe polarity b2 temperature sensor polarity optional b3 temperature limiter b4 ...

Page 37: 7 Circuit Diagrams

705 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 704: automatic control circuit with control unit 1572d and standard timer bl br ge gn gr or rt sw vi ws wire colors blue brown yellow green gray orange red black violet white wire gauges 7,5 - 15 m 0,75 mm 2 1,0 mm 2 1,5 mm 2 2,5 mm 2 4,...

Page 38: 7 Circuit Diagrams

706 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 705: system wiring diagram daimler chrysler citaro, ident no. 67131 3 5 2 6 4 rt/ws br rt m1 b4 a1 e1 u2 u1 se - + m 3 1 1 5 4 3 3 2 2 1 1 4 b2 y1 ϑ sw a2 x1 a d h2 s3 s4 s1 b1 f1 f2 30 30 c w1 31 31 d 4 3 2 1 a 6 5 4 3 2 1 deutsch 2 4 ϑ...

Page 39: 7 Circuit Diagrams

707 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 706: system wiring diagram van hool, ident no. 89401 3 3 1 1 5 2 2 6 4 4 3 8 2 6 1 5 4 b2 y1 br gr or gn ϑ rt/ws bl or br br sw rt sw a2 a d x2 c k2 k1 m1 h2 b4 s2 s3 s4 s1 a1 b1 e1 u2 u1 se - + m f3 f2 30 30 w1 h1 1 3 m2 m 7 10 16 15 -3...

Page 40: 7 Circuit Diagrams

708 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 707: system wiring diagram o405 / o407 / o408, ident no. 91292 3 3 5 1 1 5 6 2 2 6 1 2 4 4 4 3 3 2 2 1 1 4 f1 b2 y1 br gr or gn ϑ ϑ rt/ws bl or br br sw rt sw a2 x1 a x3 d x2 c k2 k1 m1 m2 h2 h1 b3 b4 s2 s3 s4 s1 a1 b1 e1 u2 u1 se - + m ...

Page 41: 7 Circuit Diagrams

709 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 708: system wiring diagram man, ident no. 89404 3 6 2 6 1 2 4 rt/ws bl br sw rt c m1 m2 h1 b4 a1 e1 u2 u1 se - + m m 3 5 1 1 5 4 3 3 2 2 1 1 4 b2 y1 ϑ or sw a2 x1 a x2 d h2 s2 s3 s4 s1 b1 f1 f2 30 30 c w1 w2 31 31 2 7 4 ϑ b3 2 1 1 3 2 1 ...

Page 42: 7 Circuit Diagrams

710 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 709: system wiring diagram setra, ident no. 90972 3 5 2 6 4 rt/ws br rt m1 b4 a1 e1 u2 u1 se - + m 3 1 1 5 3 3 2 2 1 1 4 b2 y1 ϑ sw a2 x1 a h2 s4 b1 f1 f2 30 30 c w1 -31 -31 d 4 3 2 1 a 6 5 4 3 2 1 deutsch 2 4 2 1 1 3 2 4 61 61 x3 d+ fa ...

Page 43: 7 Circuit Diagrams

711 thermo 230 / 231 / 300 / 301 / 350 7 circuit diagrams fig. 710: automatic control circuit rail with control unit 1572d, standard timer and filter heating 1 diagnostic connector 2 timer p: with plus to connection 10 = continuous operating during immediate heating terminal 10 not connected = durat...

Page 44: 8 Servicing

801 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8 servicing 8.1 general this section describes the servicing procedures allowed on the heater when installed. 8.2 heater servicing as long as the heater is in operation or in run-down the battery main power supply must not be disconnected to prevent...

Page 45: 8 Servicing

802 thermo 230 / 231 / 300 / 301 / 350 8 servicing inspection and attachment note: the exhaust muffler must always be secured with a sheet metal screw. Drill a hole with a diameter of 2.5 mm into the exhaust end pipe and muffler and arrest muffler with a sheet metal screw b 3.9 x 25 (see figure). 1....

Page 46: 8 Servicing

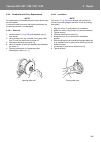

803 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8.5.2 burner head opening and closing the igniter box operates with high voltage. Prior to opening the burner head the connectors of the cable harness in the vehicle have to be disconnected to prevent lethal injuries. After closing burner head, reco...

Page 47: 8 Servicing

804 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8.6 visual inspections and regulations for installation 8.6.1 connection to vehicle cooling system the installation of the heater should be in a location as low as possible to ensure self-venting of the heater and circu- lation pump. This applies in...

Page 48: 8 Servicing

805 thermo 230 / 231 / 300 / 301 / 350 8 servicing fig. 802 example of a heater installation in a passenger bus 4 8 3 1 1 1 1 2 7 5 6 water heating circuit – sidewall radiators and roof duct heating 1 sidewall radiator with fan 2 heat exchanger, entrance 3 heater unit 4 circulation pump 5 heat excha...

Page 49: 8 Servicing

806 thermo 230 / 231 / 300 / 301 / 350 8 servicing when installing a shut-off device in the return line a clearly visible information label must be provided. Attention: operation with the return line shut off causes damage to the fuel pump. Fuel may escape. Danger of fire. Loose fuel lines must be s...

Page 50: 8 Servicing

807 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8.6.4 exhaust line observe official regulations concerning the installa- tion (see 1.6 ). Attention: the exhaust pipe outlet opening must not point in the direction of motion. The exhaust pipe outlet opening must be located so as not to expect clogg...

Page 51: 8 Servicing

808 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8.7.4 burner, replacement note: the replacement procedure for the burner is identical with the heater installed or removed. Perform replacement in accordance with 9.2.3 . The igniter box operates on high voltage. Prior to re- placement of burner dis...

Page 52: 8 Servicing

809 thermo 230 / 231 / 300 / 301 / 350 8 servicing 8.8.2 fuel supply system, bleeding the whole fuel supply system including the fuel filter must completely filled with fuel before initial start-up. Note: never use the fuel pump to fill / bleed the fuel system! Attention: in the event no fuel comes ...

Page 53: 9 Repair

901 thermo 230 / 231 / 300 / 301 / 350 9 repair 9 repair 9.1 general this section describes the repairs that may be performed on the heaters thermo 230, 300 and 350 when removed. Any further disassembly will void the warranty. For re-assembly only components of the proper spare part kits are to be u...

Page 54: 9 Repair

902 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.1.1 work on components after disassembly attention: all gaskets located between disassembled com- ponents must always be replaced and discarded. 9.1.1.1 visual inspection, general • examine all components for damages (cracks, deformation, wear, etc.)...

Page 55: 9 Repair

903 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.1.2.1 installation of control unit 1572d as substitute for control unit 1572 general due to the progress in the development of processors control unit 1572 can no longer be supplied. The retrofit of control unit 1572d is performed according to the fo...

Page 56: 9 Repair

904 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2 disassembly and assembly 9.2.1 temperature limiter, replacement 9.2.1.1 removal 1. Disconnect electrical connection to temperature limiter. 2. Withdraw rubber cap. Using screw driver lever off retaining spring and remove temperature limiter (1, fig...

Page 57: 9 Repair

905 thermo 230 / 231 / 300 / 301 / 350 9 repair fig. 901 temperature limiter, temperature sensor and burner, replacement rubber cap temperature retaining clip 8 7 6 5 4 3 2 1 1 temperature limiter 2 temperature sensor 3 connector 4 coolant outlet 5 cotter pin 6 nut (2) 7 hinge bolt (2) 8 burner limi...

Page 58: 9 Repair

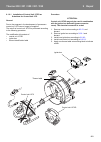

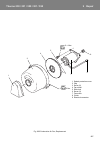

906 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2.4 combustion air fan, replacement note: for replacement of the combustion air fan the burner may be left installed. In removed condition ensure that igniter electrodes are not bent and nozzle is not damaged. 9.2.4.1 removal 1. Loosen screws (3, fig...

Page 59: 9 Repair

907 thermo 230 / 231 / 300 / 301 / 350 9 repair fig. 902 combustion air fan, replacement 1 2 3 4 5 6 7 8 9 1 splash protection cover 2 cap 3 screw (2) 4 fan wheel 5 slide lock 6 screw (3) 7 fan motor 8 clutch 9 electrical connector 5 +1 nm 2 nm.

Page 60: 9 Repair

908 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2.5 control unit, replacement note: for replacement of the control unit the burner head may be left installed and must only be swung open for disconnection of electrical connector (8, fig. 904 ). In removed condition ensure that igniter electrodes ar...

Page 61: 9 Repair

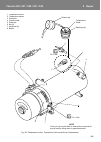

909 thermo 230 / 231 / 300 / 301 / 350 9 repair fig. 903 control unit and fuel pump, replacement 1 igniter box 2 screw (2) 3 igniter electrodes 4 high pressure nozzle 5 viewing glass 6 disk 7 solenoid valve 8 electrical connector 9 screw (3) 10 fuel pump 11 filter screen 12 o-ring (2) 13 rotating ri...

Page 62: 9 Repair

910 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2.8.1 removal 1. Remove burner if required (refer to 9.2.3.1 ). 2. Using screw driver lever off igniter electrodes ( fig. 904 ) from igniter box and remove. 3. Remove disk (6). 4. Remove combination screws (2). 5. Withdraw igniter box (1) and remove....

Page 63: 9 Repair

911 thermo 230 / 231 / 300 / 301 / 350 9 repair fig. 904 igniter box and flame sensor, replacement (sheet 2 of 2) 1 igniter box 2 screw (2) 3 igniter electrodes 4 high pressure nozzle 5 viewing glass 6 disk 7 solenoid valve 8 electrical connector 9 screw (3) 10 fuel pump 11 filter screen 12 o-ring (...

Page 64: 9 Repair

912 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2.10 heat exchanger, replacement 9.2.10.1 removal 1. Remove temperature limiter (refer to 9.2.1.1 ). 2. Remove temperature sensor (refer to 9.2.2.1 ). 3. Remove burner (refer to 9.2.3.1 ). 4. Withdraw combustion chamber (1, fig. 905 ) from heat excha...

Page 65: 9 Repair

913 thermo 230 / 231 / 300 / 301 / 350 9 repair 9.2.11.2 installation attention: when replacing the combustion chamber, ensure that the new combustion chamber corresponds to the heating capacity class of your heating appliance. 1. Slide combustion chamber (1, fig. 905 ) fully into the heat exchanger...

Page 66: Packaging, Storage and

1001 thermo 230 / 231 / 300 / 301 / 350 10 packaging, storage and shipping 10 packaging, storage and shipping 10.1 general the heater or its components shipped to webasto thermosysteme gmbh for testing or repair must be cleaned and packaged so that they are protected against damage during handling, ...

Page 67

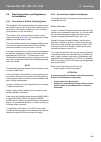

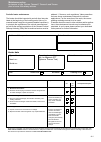

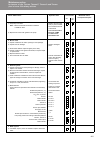

A-1 maintenance plan for heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles periodic heater maintenance the heater should be inspected in periodic time intervals, latest at the beginning of the heating period (time of in- creased heater usage due to present weat...

Page 68

A-2 maintenance plan for heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles check / maintenance important notes check result measured values, accomplished repairs ok not ok c) fuel pump / fuel lines note: observe technical information if biodiesel or fame is use...

Page 69

A-3 maintenance plan for heaters of type thermo, thermo e, thermo s and thermo plus in buses und railway vehicles 7. Functional check a) if available, open shut-off valve of the fuel return line and water line. B) check fault memory, clear it as needed using the diagnostic tool (stt). C) check heate...

Page 70

Memos.

Page 71

Valeo thermal commercial vehicles germany gmbh postfach 1371 - 82198 gilching - germany - tel. +49 (0)8105 7721-0 - fax +49 (0)8105 7721-889 www.Valeo-thermalbus.Com - service-valeobus@valeo.Com.