- DL manuals

- Valeo

- Heating System

- THERMO DC 200

- Installation And Operation Instructions Manual

Valeo THERMO DC 200 Installation And Operation Instructions Manual

Summary of THERMO DC 200

Page 1

Rev. 01/2017 id.No. 11118910a thermo dc 200 heating systems installation and operating instructions bus.

Page 2

Ii thermo dc 200 note: subject to modification. In multilingual versions the german language is binding. The latest version of this document is provided for download on www.Spheros.De . Highlighted words like warning!, caution!, attention: and note: in these installation and operating instructions s...

Page 3: Table of Contents

Thermo dc 200 iii table of contents 1 statutory regulations governing installation 1 1.1 statutory regulations governing installation 1 1.2 model plate 2 2 safety regulations 3 3 use / version 4 3.1 installation example 5 4 operating and maintenance instructions 6 5 installation 7 5.1 grounding, add...

Page 4

Iv thermo dc 200

Page 5

Thermo dc 200 statutory regulations governing installation 1 1 statutory regulations governing installation 1.1. Statutory regulations governing installation for the heater exists a type approval according to the ece regulations r10 (emc) no. 04 6641 and r122 (heater) no. 00 0377. Installation is go...

Page 6

Statutory regulations governing installation thermo dc 200 2 applicable local regulations, laws and standards for electrical in- stallations, in particular the provisions of ece regulation r100 are to be observed by the vehicle manufacturer and should be appro- priately implemented. Attention: failu...

Page 7

Thermo dc 200 safety regulations 3 2 safety regulations installation, maintenance and repairs may only be carried out when the vehicle's engine is not running and the high voltage supply is switched off. Before starting the work at the heater, it is to make voltageless acc. To din vde 0105-100 and t...

Page 8

Use / version thermo dc 200 4 3 use / version the fully electrical water heater thermo dc operates independently of the vehicle engine and is connected to the vehicle’s cooling and electrical systems. The electrical heater can be used in a depot for pre-heating purposes. For this it is connected sta...

Page 9

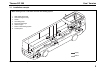

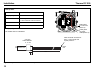

Thermo dc 200 use / version 5 3.1. Installation example figure 2: installation example for the heater 1 wall heater with blower 2 heat exchanger at entry 3 heater 4 circulating pump 5 roof heat exchanger 6 vehicle engine 7 driver’s seat heating system 8 control panel water heating circuit – wall hea...

Page 10

Operating and maintenance instructions thermo dc 200 6 4 operating and maintenance instructions the thermo dc heating appliance may not be operated at temperatures of more than +85°c. Amount of antifreeze in the water circuit - see technical data. Attention: the heaters may be only used in closed ve...

Page 11

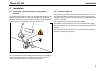

Thermo dc 200 installation 7 5 installation 5.1. Grounding, additional protective equipotential bonding a grounding cable, at least 1x4 mm² cu, should be attached to the posi- tion on the housing which is marked and provided for it. Ideally this should be carried out with a ring cable lug for fasten...

Page 12

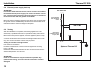

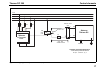

Installation thermo dc 200 8 figure 4: connecting schematic with integrated dc-dc converter (thermo dc compact distributor board) 4mm², gr, 180mm, radox 3 gkw 12545290 0,75mm², rt, 200mm, flry schütz siemens 3tc4417/0ab4 2,5mm², r t, 250mm 2,5mm², r t, 250mm quint/ps/ 3ac/ 24dc radox 3 gkw 12545290 ...

Page 13

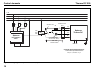

Thermo dc 200 installation 9 figure 5: connecting schematic without integrated dc-dc converter (thermo dc compact distributor board) + - ϑ 68 .. 75°c ϑ 125°c 1l1 + l- 2t1 a1 24+ a2 24- 0,75mm², sw, 130mm, flry 15 16 19 6mm², gr, 220mm,radox 3 gkw 12548127 1 2 3 4 rd br bu bk 12 10 11 12 6mm², gr, 18...

Page 14

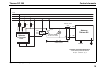

Installation thermo dc 200 10 figure 6: preparation of the cables and hook-up hook-up data: cord grip range: 9 - 17 mm use suitable tools for installation! Contactor connections stripping length 11 - 13 mm kind of wire single wire or wire strand or wire strand with cable end sleeves cable cross sect...

Page 15

Thermo dc 200 installation 11 5.3. Overcurrent protection / insulation monitoring device attention: the power supply circuit is to be protected through an all pole overcurrent protection device that allows a max. Current of 35a. If the overcurrent device has been triggered, the heater is to be switc...

Page 16

Installation thermo dc 200 12 5.4. External power supply hook-up attention: it should be noted that with vehicles, which are to be connected to the earthed external power supply unit via the conductive connec- tion, a device must be present by which the galvanic connection of the electrical earth wi...

Page 17

Thermo dc 200 maintenance 13 6 maintenance – maintenance work on the electrical equipment may only be car- ried out by a qualified electrician. – the appliance must be disconnected from the power supply pri- or to any maintenance work and in particular prior to repair work (see 2 safety regulations)...

Page 18

Faults, troubleshooting, repairs thermo dc 200 14 7 faults, troubleshooting, repairs attention: if a safety switch has been triggered, this should only be reset after a qualified electrician has determined the cause of the fault and eliminated the error. The opening of the appliance, troubleshooting...

Page 19

Thermo dc 200 control elements 15 8 control elements the control line should be kept as short as possible so that the voltage drop is not too great. Max. Length: 10 meters and at least 2.5mm². If greater lengths have to be bridged, a relay must be used to split the power circuits and limit the lengt...

Page 20

Control elements thermo dc 200 16 8.2. Pre-selection timer if the spheros pre-selection timer is used as an operational element, a 24v vehicle relay (switching current >1.5a), with a current consumption smaller than 400ma, must be used in accordance with the following circuit diagrams. When using a ...

Page 21

Thermo dc 200 control elements 17 figure 13: wiring diagram with pre-selection timer, 2 pole 5a 1 10 11 12 4 5a 5a 2 0, 75mm ² 0, 75mm ² 0, 75mm ² external control input t. 58 t. 15 t. 30 t. 31 max. Max. 10m at least 2.5mm 2 2 1 rd spheros thermo dc 24v rd 690v dc 24v dc 1.5 a 5a 0.4a consider presc...

Page 22

Control elements thermo dc 200 18 figure 14: wiring diagram with pre-selection timer, 4 pole bk rd rd/ 1 2 wh bn 4 3 - - + + 5a 1 10 11 12 4 5a 5a 2 0, 75mm ² 0, 75mm ² 0, 75mm ² max. 10m 690v dc spheros thermo dc t. 58 t. 15 t. 30 t. 31 max. 24v 0.4a 24v dc 1.5a operation indicator 24v dc max. 250m...

Page 23

Thermo dc 200 control elements 19 figure 15: wiring diagram with pre-selection timer, without dc-dc converter 5a 1 10 11 12 4 5a 5a 2 8 0, 75mm ² 0, 75mm ² 0, 75mm ² bn 2 1 bk t. 58 t. 15 t. 30 t. 31 max. Spheros thermo dc 24v 690v dc at least 30v dc 0.4a 1,5 a max. 10m 24v dc max. 250ma consider pr...

Page 24

Control elements thermo dc 200 20 attention: never connect the timer directly to the heating appliance. This will damage the timer. You can use the following relay: id: 98559a (fa. Wehrle, 29 201 045). The pre-selection timer enables you to preset the start of the heater operation up to 7 days in ad...

Page 25

Thermo dc 200 control elements 21 recalling/erasing preset times repeatedly press the button until the desired memory location is displayed. To erase the preset time, press the button several times until the time of the day is displayed instead of the memory location. Programming duration of operati...

Page 26

Circulation pump thermo dc 200 22 9 circulation pump attention: for a correct switching on of the heating appliance an adequate circulation of the cooling medium must be ensured before swit- ching on. The heating appliance is preferably to be equipped with spheros circu- lation pumps, refer to techn...

Page 27

Thermo dc 200 installation of the heater - fitting of important assemblies 23 11 installation of the heater - fitting of important assemblies 11.1. Installation attention: – the legal regulations for the installation are to be observed. – if the operation of the water heating appliance is to be part...

Page 28

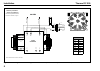

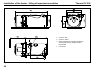

Installation of the heater - fitting of important assemblies thermo dc 200 24 figure 17: dimensions of the heating appliance thermo dc 1 2 3 4 1 coolant - inlet 2 coolant - outlet 3 space required for removal of the electric components and the cartridge heaters hlp20x300 4 vent screw.

Page 29

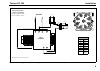

Thermo dc 200 installation of the heater - fitting of important assemblies 25 figure 18: installation position and hole pattern thermo dc 10.8 welded nut m8 - din 929 1 attachment variant 1 4x screw m8 (15nm +5nm) 2 attachment variant 2 4x screw m8 (through going) + 4x hexagonal nut m8 (15nm +5nm)+ ...

Page 30

Installation of the heater - fitting of important assemblies thermo dc 200 26 11.2. Connection to the vehicle's cooling system the heating appliance is connected to the vehicle's cooling system according to figure 17. The volume of coolant fluid present in the circuit must be at least 35 liters. The...

Page 31

Thermo dc 200 installation of the heater - fitting of important assemblies 27 11.3. Installation of the circulation pump consider the information regarding the installation provided in the documentation of your circulation pump. Note the installation position! Note: the pump ports and connection lin...

Page 32

Installation of the heater - fitting of important assemblies thermo dc 200 28 11.4. Tightening torques figure 19: tightening torques grounding screw cable gland cable gland control power supply cable (m12x1.5): (m10x1): bleed screw 20 ±1 nm 1.5 -0.3 nm 8 -1 nm 16 +1 nm (m25x1.5): cable.

Page 33

Thermo dc 200 technical data 29 12 technical data unless limit values are given, the technical data below is understood to be subject to the usual tolerances for heating appliances of +/-10% at an ambient temperature of +20°c and at nominal voltage. Note: the allocation of the circulation pumps to t...

Page 34

Technical data thermo dc 200 30 for notes:.

Page 35

Memos.

Page 36: Heating Systems

Heating systems valeo thermal commercial vehicles germany gmbh postfach 1371 - 82198 gilching - germany - tel. +49 (0)8105 7721-0 - fax +49 (0)8105 7721-889 www.Valeo-thermalbus.Com - service-valeobus@valeo.Com.