- DL manuals

- Valor

- Indoor Fireplace

- 1100IN

- Installation & Owner's Manual

Valor 1100IN Installation & Owner's Manual

H5 S

ERIES

DV ZC Gas Fireplace

1100IN (NG) & 1100IP (LPG)

1150ILN (NG) & 1150ILP (LPG)

4003682-02

©2014, Miles Industries Ltd.

Ce guide est disponible en français sur demande.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

INSTALLER

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

Please read this manual

BEFORE installing and

operating this appliance.

This manual contains instructions to install the

ENGINE ONLY. A trim kit is REQUIRED to

complete the installation. A barrier screen is

provided with the trim kit. Refer to the manual

supplied with the trim for installation.

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

DANGER

!

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and shall be

installed for the protection of children and other at-risk

individuals.

Installation & Owner’s Manual

— Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

ƒ Do not try to light any appliance.

ƒ Do not touch any electrical switch; do

not use any phone in your building.

ƒ Leave the building immediately.

ƒ Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

ƒ If you cannot reach your gas supplier,

call the re department.

— Installation and service must be

performed by a quali ed installer, service

agency or the gas supplier.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

Summary of 1100IN

Page 1

H5 s eries dv zc gas fireplace 1100in (ng) & 1100ip (lpg) 1150iln (ng) & 1150ilp (lpg) 4003682-02 ©2014, miles industries ltd. Ce guide est disponible en français sur demande. This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use...

Page 2

2 table of contents designed and manufactured by / for miles industries ltd. 190–2255 dollarton highway, north vancouver, bc, canada v7h 3b1 tel. 604-984-3496 fax 604-984-0246 www.Valor replaces.Com the information contained in this installation manual is believed to be correct at the time of prin...

Page 3: Safety Precautions

3 safety precautions ! Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be ...

Page 4: Safety And Your Fireplace

4 safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with a hot glass surface can ca...

Page 5

5 operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the full height of the fi ...

Page 6

6 warning do not touch the glass while it is hot! Let the fi replace cool fi rst before cleaning it. ! Spring loaded window levers warning choking hazard! Ensure that the fi replace area is clear of fi reglass or shale particles as these could be ingested by small children. Vacuum thoroughly around ...

Page 7

7 warning for safety purpose, ensure the barrier screen is re-installed on the replace front after maintenance. ! Window frame bottom railing convection baf e or heatshield trim barrier screen’s top tabs coming through slots in baf e/heatshield (behind the face of the trim) to re t the window:...

Page 8

8 warning do not attempt to change the batter- ies while the fireplace is still hot! Let the fi replace cool fi rst before touching it. Caution do not use a screwdriver or other metallic object to remove the batteries from the receiver or the handset! This could cause a short circuit. ! 1100 driftwo...

Page 9

9 warning do not attempt to touch the informa- tion card while the fireplace is still hot! Let the fi replace cool fi rst before touching it. Wall switch (optional) remote control handset am thermostatic remote control wall switch (optional) ! On: parallel to pipe off: perpendicular to pipe 3. Slide...

Page 10

10 gas valve on receiver gas valve how to ensure your fireplace cannot be turned on inadvertently you can use one of the two following methods to ensure that your fi replace will not turn on when you don’t want it on. First, ensure your replace is turned off—including the pilot—and cold before g...

Page 11

11 remote control operation setti deactivating or activating functions choosing one-button or two-button ignition ng celsius or fahrenheit on am pm off to change between °c and °f, press and buttons simultaneously. Note: choosing °f results in a 12 hour clock. Choosing °c results in a 24 hour clock....

Page 12

12 remote control operation manual mode (handset)) to turn on fire w on am pm off handset one-button operation (default setting) ƒ ƒ main ƒ handset automatically goes into man- ual mode after main burner ignition. Notice to change from one-button to two-button ignition operation, go to page 1 for in...

Page 13

13 remote control operation program mode note: the set temperature for thermostatic mode is the tem- perature for the on time in program mode. Changing the thermostatic mode set temperature also changes the on time temperature in program mode. On am pm off on: press button. , or , on or off displaye...

Page 14

14 eco mode am on: press button. Displayed. Off: press button. Disappears. On am pm off temperature setting: 1. Press button and hold until . And set temperature (set- ting in thermostatic mode) displayed. 2. To continue press button or wait. , displayed, temperature flashes. 3. S elect off temperat...

Page 15

15 remote control operation automatic turn down 3 hour no communication function ƒ receiver overheating rqo\lirswlrqdoflufxodwlqjidqfrqwuroprgxohlvfrqqhfwhg ƒ automatic shut off countdown timer ƒ low battery receiver ƒ five day shut off ƒ $whqgrifrxqwgrzqwlphshulrgwkhiluhwxuqvrii7kh &rxqwgrzq7lphurq...

Page 16

16 options required kits fuel beds (choose one)—1100 units only 1101dwk driftwood kit 1103dgm murano glass kit 1104dgs decorative glass set ceramic liners (choose one)—1100 and 1150 units 1110vrl valor red liner 1115lsl ledgestone liner 1125fbl fluted black liner trims (choose one)—1100 and 1150 ...

Page 17

17 lighting instructions for your safety, read before lighting warning: if you do not follow these instructions exactly, a re or explosion may result causing property damage, personal injury or loss of life. A. This appliance has a pilot which must be lighted by hand, remote control, or wall switc...

Page 18

18 state of massachusetts carbon monoxide detector/vent terminal signage requirements for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth...

Page 19

19 (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identifi es “special venting systems”, the following requirements s...

Page 20

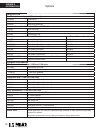

20 x ratings model 1100in 1100ip gas natural propane altitude (ft.)* 0-4,500 feet* input maximum (btu/h) 28,000 28,000 input minimum (btu/h) 13,000 13,000 manifold pressure (in w.C.) 3.5” 9” minimum supply pressure (in w.C.) 5” 11” maximum supply pressure (in w.C.) 10” 14” main burner injector marki...

Page 21

21 overview mantel—see mantel & hearth clearances non-combustible hearth— see hearth requirements t t t tr i i i im m w it it it h h h b b barr i i ier s s s screen (required) miniimal trim (1130mtb) installs at framing sttage and allows non- com mbustible wall nish to nish up to it. All other...

Page 22

22 m in. 41-1/2” t o t o p o f c em en t b o ar d 40 ” electrical inlet point 1270rbk duct kit inlet (remove plate) 1270rbk duct kit inlet (remove plate) gas line access point zero clearance stand-offs header center line 6-5/8” dia. Venting field- convertible from top to rear outlet center of vent h...

Page 23

23 bottom of unit 0 2” 1” 4” 6” 8” 10” 12” do not put furniture or objects within 36” (914 mm) of front of appliance mantel projection (from face of cement board) mantel height (from bottom of unit) ceiling 24” m in. To c eiling 49” 47” 45” 43” 41” 4” minimum to combustible floor or hearth. See hear...

Page 24

24 34” fireplace opening wall min. 8” to wall 3” face of finished wall shading denotes allowable location for combustible mantel legs fireplace depth 1” 2” 3” 4” 5” 6” or greater clearance 3” 4” 5” 6” 7” 8” note right side clearances are the same combustible sidewall / mantel leg—top view mantel & ...

Page 25

25 hearth requirements top of finished hearth must be flush with bottom of heater to accommodate most optional mantels and trims. The 1140 four- sided trim extends 1-1/2” below the bottom of the appliance. See option section at the beginning of this manual for optional accessories. Note: unit will n...

Page 26

26 hearth requirements unit raised above combustible hearth or floor face of cement board top face of combustible floor or carpet 4” min. Base of fireplace combustible floor rules 1. A hearth is not required. However, any hearth/fl oor in front of fi replace within 4 inches vertically of the bottom...

Page 27

27 front of fireplace (surface of cement board) min. Hearth projection required to protect combustible floor surface of combustible floor or carpet bottom of fireplace when using optional trims and mantels, surface of finished hearth must be flush with bottom of fireplace (otherwise, optional trims ...

Page 28

28 40” 38” 40” * * between underside of header and base of heater. Base of heater must be at finished hearth height. Increase cavity height accordingly. 29” between underside of non-combustible board and base of heater 1/2” thick non-combustible board required above engine (not supplied). See page ....

Page 29

29 min. 39-1/2” (1003 mm) m in. 12” (305 mm) non-combustible board required thickness: 1/2 inch (13 mm) framing requirements minimum non-combustible board dimensions minimum coverage area of non-combustible board. Any wall fi nish applied to shaded area must be non- combustible. We recommend extendi...

Page 30: Partial Shelf, Top Outlet

30 40” (1016 mm) t o underside of c ombustible ca vit y min. 1” (25.4 mm) clearance to combustibles around vertical vent pipe approx. 9-1/4” (235 mm) from back surface of wall finish to front surface of appliance case w/no vent offset 13-3/4” (349 mm) partial shelf, top outlet 1/2” thick non-combust...

Page 31

31 * appr ox . 49 -3 /4 ” ( 12 66 m m ) w it h 1 2” v en t p ip e 40” (1016 mm) t o underside of c ombustible ca vit y min 1” (25.4 mm) required clearance to vertical pipe affects cavity depth 12” pipe section a p p ro x. 3 9- 1/ 4” (9 97 m m ) stand-off fireplace - left side view 40” (1016 mm) t o ...

Page 32: Er Sealing & Vapor Barriers

32 10” (254 mm) 10” (254 mm) align the vent cen- ter to the center of the frame venting top or rear outlet this unit is supplied with a 45 degrees top vent outlet which can be fi eld-converted to a rear vent outlet. See installation section for more information. Vent material this unit is approved...

Page 33

33 horizontal termination 2-piece wall thimble pipe length horizontal termination 2-piece wall thimble pipe length pipe length pipe length pipe length 90˚ elbow 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination co-axial venting typical co-ax...

Page 34

34 2 4 6 8 10 12 14 16 18 20 vertical rise (ft) horizontal run (ft) 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 4 x 90º elbows maximum (or equivalent) v2 v1 v3 h2 h1 45° elbow take-off supplied with unit max. 12” pipe length with no vertical rise 1” min. All around vertical pipe 3” min...

Page 35

35 position #1 position #2 position #3 position #4 install here restrictors the restrictors are not required when less than 1’-0” vertical rise in vent system. Install the restrictors in the roof of the fi rebox behind the top liner panel. Adjust the restrictors before installation of the top liner ...

Page 36

36 v g a min. 72” max. 72” alcove detail (open on one side) normal ceiling/soffi t clearances apply. Key vent terminal locations - minimum distances minimum clearance inches cm a clearance above grade, verandah, porch, deck or balcony 12 30 b clearance to window or door that may be opened 12 30 c cl...

Page 37

37 roof pitch minimum "h" (feet) flat to 7/12 1' over 7/12 to 8/12 1.5' over 8/12 to 9/12 2’ over 9/12 to 10/12 2.5’ over 10/12 to 11/12 3.25’ over 11/12 to 12/12 4’ over 12/12 to 14/12 5’ overhang should not extend beyond vent if within 48” of termination cap horizontal overhang vertical wall min. ...

Page 38

38 8-5/8” 38” 25-1/4” 29” 16-1/4” 9-3/8” 11-11/16” 3” exhaust collar 1-1/2” 4” exhaust collar adapter front rear 1156cla co-linear vent adapter 4” dimensions with co-linear adapter dimensions shown are with valor 1156 co-linear adapter. Installation for installation of the adapter to the appliance, ...

Page 39

39 only quali ed licensed or trained personnel should install this appliance. Installer—read this first 1. You need to know from the homeowner: - the height of the unit and hearth if used; - the thickness and type of the wall nish around the rebox opening; - what accessories (trim, decorative ...

Page 40

40 1/2” (13mm) thick non-combustible cement board gypsum board up to perimeter of non-combustible board min. 12” (305 mm) min. 39-1/2” (1003 mm) plan wall finish non-combustible cement board the h5 fi replace requires a 1/2” (13 mm) thick non-combustible cement board or equivalent, to be used as a w...

Page 41

41 cracking if a clean fi nish with no tile, etc. Is desired, joints in the non-combustible board and the transition to gypsum board will require special attention if future cracking is to be controlled. Shrinkage and differential movement of the framing and non-combustible wall board can transmit c...

Page 42

42 fold lines remove top outlet (6 screws) remove heat shield (3 screws) convert from top to rear outlet (if required) this unit is supplied with a top vent outlet which can be fi eld-converted to a rear vent outlet. Please note that the rear outlet requires the installation of the heat shield on to...

Page 43

43 section views window frame bottom railing installation remove window the window is held in place by a spring-loaded lever on each side. 1. To remove the window, locate the levers on each side of the window towards the top. Using your fi nger, pull the lever towards you and unhook it from the wind...

Page 44

44 1130mtb minimal trim kit rear take-off 16-1/2” top take-off 17-1/2” x x installation • the 1130 installs to the appliance during the framing stage and the appliance’s position is fi xed in the framing. Wall fi nishes are then applied over top of the fl anges and butted up to the frame of the 11...

Page 45

45 combustible floor base of heater non-combustible material gap for air flow (must be free at all time) trim’s removable panel max. 1” total thickness of hearth 1/2” micore board (provided) non-combustible hearth with 1130 minimal trim—cross-section gap for air- ow 1130mtb minimal trim kit insta...

Page 46

46 installation 1. Unpack the 1130 kit checking that you have all the pieces on hand. 2. On the top of the appliance’s case in front of the stand-offs, remove the positioning brackets (2 screws each); they are not used with this kit. 3. At the bottom of the appliance case, install the valve cover pr...

Page 47

47 1135 3-sided trims 1140 4-sided trims 1147cms cast mantel 1149edv edge- mont double-door kiit • the 3 and 4-sided trims are adjustable to accomodate up to an additional 3/4” of tile or other over top of the 1/2” non-combustible wall board. • the appliance’s position within the framing cavity may ...

Page 48

48 1135 3-sided trims 1140 4-sided trims 1147cms cast mantel 1149edv edgemont double-door kiit install appliance for 3 or 4-sided trims and fronts the 3-sided trims 1135, 4-sided trims 1140, double doors 1149 and cast mantel 1147 are fi tted to the appliance once it’s installation and the wall fi ni...

Page 49

49 installation fit appliance to framing 1. Install stud brackets on each side of the appliance (2 screws per bracket). Use the hole or the slot according to the thickness of the wall fi nish—see page 47. 2. Taking great care not to cut your hands on the sheet metal edges, lift the appliance out of ...

Page 50

50 electrical wiring through the left hand side of the appliance case install electrical wiring (for optional fan or power adapter kit) this section provides information to install the electric pre-wiring required for use with the 1195cfk circulat- ing fan kit or gv60pak power adapter kit. All wirin...

Page 51

51 x 1-7/16” (36 mm) 4-5/16” (110 mm) gas line access hole 1-1/2” (38 mm) diam. Connect gas supply the gas supply inlet connection is a 3/8” npt male connector located on the right hand side of the fi rebox. The unit is supplied with a stainless steel fl ex line to allow the appliance to be disconne...

Page 52

52 top underside ( re side) rear ceramic panel re ective panel (optional) with 1105rgl— re ective panel top underside ( re side) rear ceramic panel without 1105rgl— re ective panel install liners the following guidelines apply for all liners. 1. Inside the fi rebox, on the top of each side, r...

Page 53

53 install driftwood kit 1101dwk (1100 models) material required • long beach driftwood kit, which contains: • 3 logs • 5 pebbles • 1 x 1.5 lb bag of 3/4” grey/black shale • gloves, if desired installation logs carefully unpack the kit. Each log has pegs to help you locate them on the ceramic burner...

Page 54

54 warning choking hazard! Ensure that the fi replace area is clear of shale particles as these could be ingested by small children. Vacuum area after installation. Installation 4. Carefully spread shale in the cavity of the ceramic burner. You can also add some shale on the edge outside of the burn...

Page 55

55 warning choking hazard! Ensure that the fi replace area is clear fi reglass particles as these could be ingested by small children. Vacuum area after installation. Installation install decorative glass murano 1103dgm (1100 models) material required • decorative glass murano kit, which contains: •...

Page 56

56 install decorative glass set 1104dgs (1100 models) material required • decorative glass set, which contains: • 1 metal tray • 1 pilot cover • 3 bags of clear 1/2” fi reglass • gloves (recommended to manipulate glass) installation carefully unpack the kit. Wear gloves to handle the fi reglass. 1. ...

Page 57

57 installation install traditional logs (1150 models) material required • log set included with the appliance, which contains: • 8 logs • gloves, if desired installation unpack the ceramic logs very carefully to avoid damaging them. Each log has keys to help you locate them on the ceramic burner pl...

Page 58

58 installation 3. Place the right-hand middle log locating its notch on the key in the ember bed as indicated. 4. Place the left-hand base log on the platform locating it on the key as indicated. 5. Place the center base log locating its notch on the key in the ember bed as indicated. 6. Place the ...

Page 59

59 installation 7. Place the left-hand cross log locating its notch on the key on the top of the rear log as indicated. Rest the front end of the log on top of the left base log as indicated. 8. Place the right-hand cross log locating its notch on the key on the top of the rear log as indicated. Res...

Page 60

60 section views window frame bottom railing re t and check window 1. To refi t the window, place it in its bottom railing and push its top against the fi rebox. Ensure there is no glass or shale particles in the bottom railing. 2. While you hold it, pull the side levers back into the window bracke...

Page 61

61 remote control initial pairing the receiver and the handset of the remote control sys- tem must be initially paired before the fi rst use. 1. Insert two 1.5 v aaa alkaline batteries in the handset. 2. Locate the reset button on the front side of the receiver. 3. With a sharp object, press and hol...

Page 62

62 screw wing nut below wing nut below air shutter close open install trim and barrier screen install the trim chosen by the customer for their fi replace. Install as well the barrier screen which is provided with the trim. Show the customer how to remove the barrier screen to access the controls. F...

Page 63

63 install remote control handset wall holder the remote control kit for this fi replace comes complete with a wall-mounted holder. This holder is not required in all installations but is provided as an optional feature for those customers who wish to mount the remote handset to the wall. To install...

Page 64

64 wiring diagram optional wall switch kit 1265wsk connector man-knob interruptor block thermocouple electrode cable receiver combination control valve gv60 wiring diagram button “reset: battery compartment 4 aa batteries optional fan 1195cfk control module yellow spark spark sw pilot thermocurrent ...

Page 65

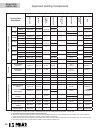

65 approved venting components approved direct vent suppliers for valor models 1100, 1150, 1200 5 , 1500, 1600 5 and 1700 6 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm termina...

Page 66

66 approved venting components venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — 94610606 bla...

Page 67

67 warr ant y p rog ram warr ant y p rog ram va lor co m fo r t va lor co m fo r t va lor co m fo r t warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the ...

Page 68

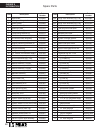

68 spare parts code description part number 1 heat shield 4004460 2 45 degrees fl anged elbow 0945jm 3 elbow gasket 4002999 4 top stand-offs (2) 4004469 5 restrictor plate 4001222 6 take-off cover (2) 4003046 7 frame fi xing brackets (2) 4003703 8 lh window latch assembly 4003681 9 rh window latch a...

Page 69

69 spare parts code description part number 74 refl ective glass liner - 1100 1105rgl 75 liner panels - complete sets valor red brick liners 1110vrl ledgestone liner set 1115lsl fluted black liner set 1125fbl 76 rear panel valor red brick 4003264 ledgestone 4003246 fluted black 4003258 77 lh side pa...

Page 70

70 30 31 32 33 34 35 36a 36b 36c 36d 38 spare parts 45 46 1 2 3 4 4 5 6 6 7 7 8 9 10 11 11 12 13 14 74 16 17 18 18 19a 19b 19c 19d 20 21 22 23a 23b 23c 24 25a 25b 26 27 28a 28b 29 37 39 40 41 42 43 44 47 48 49 50 51 52 53 54 55 56 57 58 59 60 60 61 62 63 64 65 66 67 68 69 70 71 72 73 75 79 76 77 78 ...

Page 71

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed installer. Please ll in the information below. The information provided will be used for customer records only. Online warranty registration at www....

Page 72

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valor replaces.Com.