- DL manuals

- Valor

- Indoor Fireplace

- 1200EAN (NG)

- Installation And Owner's Manual

Valor 1200EAN (NG) Installation And Owner's Manual

V

ENTANA

Ce guide est disponible en français sur demande.

4001272-23

©2012, Miles Industries Ltd.

Direct Vent ZC Fireplace

1200EAN (NG) & 1200EAP (LPG)

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light the appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

Manufactured by

MILES INDUSTRIES LTD.,

British Columbia, Canada

www.valorfi replaces.com

Installation & Owner’s Manual

Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity

of this or any other appliance.

Installation and service must be performed

by a qualifi ed installer, service agency or the

gas supplier.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

I N S TA L L E R

L e a v e t h i s m a n u a l

w i t h t h e a p p l i a n c e .

C O N S U M E R

R e t a i n t h i s m a n u a l

f o r f u t u r e r e f e r e n c e .

Massachusetts: The piping and fi nal

gas connection must be performed by a

licensed plumber or gas fi tter in the State of

Massachusetts. Also, see Carbon Monoxide

Detector requirements on page 16.

Please read this manual BEFORE installing

and operating this appliance.

HOT GLASS

WILL

CAUSE BURNS.

DO NOT TOUCH

GLASS

UNTIL COOLED.

NEVER

ALLOW CHILDREN

TO TOUCH GLASS.

Summary of 1200EAN (NG)

Page 1

V entana ce guide est disponible en français sur demande. 4001272-23 ©2012, miles industries ltd. Direct vent zc fireplace 1200ean (ng) & 1200eap (lpg) warning: if the information in these instructions is not followed exactly, a fi re or explosion may result causing property damage, personal injury ...

Page 2

2 designed and manufactured by / for miles industries ltd. 190–2255 dollarton highway, north vancouver, bc, canada v7h 3b1 tel. 604-984-3496 fax 604-984-0246 www.Valorfi replaces.Com © copyright miles industries ltd., 2012 for the owner for the qualified installer the information contained in this i...

Page 3: Safety Precautions

3 safety precautions ! Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be ...

Page 4: Safety And Your Fireplace

4 safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with a hot glass surface can ca...

Page 5: Do Not Put

5 operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the full height of the fi ...

Page 6

6 cleaning important - glass cleaning - mineral deposits one of the by-products of the combustion process in a gas appliance is a mineral which can show up as a white fi lm on the ceramic glass of the viewing door. The composition of the deposit varies widely from various locations and also from tim...

Page 7

7 light fi xture without glass cover 100w halogen light bulb (119mm) checks a periodic check of the pilot and burner fl ames should be made. Check after the fi re has been on for at least 30 minutes. The pilot fl ame must cover the tip of the thermocouple probe. The main burner fl ame pattern will v...

Page 8

8 owner’s information if the antenna was unhooked when replacing batteries, hook it back to its clip. Note: it must not touch the ignition wire! Antenna ignition wire ! Caution do not use a screwdriver or other metallic object to remove the batteries from the receiver or the handset! This could caus...

Page 9

9 owner’s information wall switch (optional) manual on/off switch on off thermostatic remote control wall switch manual on/off switch remote control handset fireplace control devices there are three ways to control your fi replace. 1. Thermostatic remote control; 2. Wall switch; 3. Manual on/off swi...

Page 10

10 remote control operation when the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position). St...

Page 11

11 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance a...

Page 12

12 remote control operation setting the on / off temperatures • briefl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temperatur...

Page 13

13 setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the icon indicates the end of t...

Page 14

14 remote control operation options ceramic liners (required) 1245vrl—victorian red liner pack 1250fsl—frontera liner pack 1255ibl—inca slab liner pack 1260bsl—black slab liner pack doors and surrounds (optional) 1210dka—alhambra door kit 1215fdv—fenderfire double door kit 1220fsv—fenderfire single ...

Page 15

15 lighting instructions warning : if you do not follow these instructions exactly d¿uhruh[sorvlrqpd\uhvxowfdxvlqj surshuw\gdpdjhshuvrqdolqmxu\ruorvvriolih )lj )lj )lj$ for your safety, read before lighting a. This appliance has a pilot which must be lighted by hand or by remote control. Follow thes...

Page 16

16 state of massachusetts carbon monoxide detector/vent terminal signage requirements for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth...

Page 17

17 (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identifi es “special venting systems”, the following requirements s...

Page 18

18 ratings model n p gas natural propane altitude (ft.)* 0-4,500 feet* input maximum (btu/h) 36,000 31,000 input minimum (btu/h) 15,000 15,000 manifold pressure (in w.C.) 3.6” 10.5” minimum supply pressure (in w.C.) 5” 11” maximum supply pressure (in w.C.) 10” 14” main burner injector marking cat # ...

Page 19

19 overview fire on/off wall switch (optional) mantel—see mantel clearances non-combustible hearth— see hearth requirements decorative light dimmer switch (not provided) optional doors and plates—see options 1200ea combustible floor framing—see framing cement board—combustible wall fi nish may butt ...

Page 20

20 dimensions location 18” 43” 32-1/2” 33” 28” 24” 7-1/8 ” 8-1 /2 ” 51-1/2” t o to p o f c ement boar d 50 ” to u n d er si d e of he ad e r electrical (for ambient light only) electrical (for ambient light only) zero clearance to stand-offs at top gas x x 6-5/8” dia. Venting center line 66” 46-3/4”...

Page 21: Left Side View

21 combustible mantel—left side view mantel clearances bottom of unit face of cement board 0 2” 4” 6” 8” 10” 12” 50” 45” 43” 41” 39” 36” 33” 28” mantel projection (from face of cement board) combustible wall finish allowed above cement board mantel height (from bottom of unit) fireplace opening fire...

Page 22: Top View

22 2” 1” 4” 5” 3” 2” 1” 4” 5” 3” 32-1/2” fireplace opening wall min. 6” between edge of opening and wall face of finished wall note right side clearances are the same shading denotes allowable location for combustible mantel legs combustible sidewall / mantel leg—top view mantel clearances fireplace...

Page 23

23 hearth requirements general hearth considerations top of finished hearth must be flush with bottom of heater to accommodate some optional mantels and trims. See option section at the beginning of this manual for optional accessories. Note: • unit will need to be raised in almost every case to acc...

Page 24

24 hearth requirements unit raised above combustible hearth or floor face of cement board top face of combustible floor or carpet 4” min. Base of fireplace combustible floor rules 1. Any hearth/fl oor in front of fi replace within 4 inches of the bottom of the unit must be non-combustible and projec...

Page 25

25 unit with site-built non-combustible hearth extending using 616/617stk stone trim kits front of fireplace (surface of cement board) min. Hearth projection required to protect combustible floor surface of combustible floor or carpet bottom of fireplace when using optional trims and mantels, surfac...

Page 26: Cover Cement Board

26 framing 24” 50” 43-1/2” 1/2” thick cement board required above and on each side of engine (supplied w/engine) - combustible wall finish may butt up to but not cover cement board framing dimensions between underside of header and base of heater. Note: may increase if raising heater further. See he...

Page 27

27 venting vent material this unit is approved for installation using 4 x 6-5/8 inches co-axial direct vent pipe and accessories as listed in the approved venting components section on pages 46–47 of this manual. Follow the installation instructions supplied with the individual venting accessories. ...

Page 28: Vapor Barriers

28 co-axial venting horizontal termination 2-piece wall thimble pipe length pipe length pipe length pipe length 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination important installer notice – weather sealing & vapor barriers it is the install...

Page 29: Allowable Vent

29 how to read the venting chart the chart below applies to roof or wall termination. 1. The total length of the vent pipe cannot exceed 40 feet (12.2 m). 2. The minimum vertical height with roof termination is 6 feet (1.83 m). 3. Any combination of rise and run can be used as long as they are withi...

Page 30

30 restrictor many installations require a restrictor for improved fl ame picture and performance, this unit is supplied with one restrictor having four different positions or settings. The level of restriction required depends on the vertical rise in the venting system and, to a lesser degree, the ...

Page 31

31 vent termination • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airfl ow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be maintained when...

Page 32

32 flashing 2 x 3” liners 3” min. Bend radius co-linear adapter 2 x 3” liners co-linear adapter vogue engine approved co-linear termination or approved co-linear adapter and approved co-axial termination co-axial venting 10-1/2” (267 mm) 3” (76 mm) 7-1/2” (191 mm) 7-1/8” (181 mm) conversion to co-li...

Page 33

33 installation planning installer—read this first 1. You need to know from the homeowner: - the height of the fl oor or hearth fi nish; - the thickness and type of the wall fi nish around the fi rebox opening; - what accessories (surround, door, etc.) will be installed with this fi replace if any; ...

Page 34

34 appliance preparation unpacking the appliance to assist you, we have included the cement and hearth insulation boards required in the installation. The boards need to be removed and reinstalled with care. Two of the boards are fi xed temporarily to the back of the appliance for transportation pur...

Page 35

35 appliance preparation fixing the appliance to the fl oor 1. Remove the front bottom overlay panel by removing 2 screws on each side and slide the panel out from under the fi rebox. 2. Screw the appliance to the fl oor with 4 countersunk wood or cement screws (not provided). 3. Reinstall the overl...

Page 36

36 appliance preparation window removal the window is held in place by a spring-loaded lever on each side. 1. To remove the window, locate the levers on each side of the window towards the top. Using your fi nger, pull the lever towards you and unhook it from the window frame bracket. 2. Gently pull...

Page 37

37 supply gas installation the unit is supplied with a stainless steel fl ex line to allow the appliance to be disconnected for service. The fl ex line is supplied loose to avoid damage during shipping. Connect the fl ex to the appliance valve as shown below. An individual shut-off valve (not suppli...

Page 38

38 ceramic bricks installation the following guidelines apply for all brick liners. 1. Inside the fi rebox, on the top of each side, release the screw of the side brick anchors (one per side). 2. Place the rear panel against the back of the fi rebox, behind the retainer at bottom. 3. Hold the left h...

Page 39

39 ceramic logs installation the ceramic logs are supplied in two packages. Unpack them very carefully to avoid damaging the fragile material. Install the logs as shown below. Please note that the position of the logs is critical to insure proper performance of the appliance. 1. Place the rear log o...

Page 40

40 ceramic logs installation 7. Place the top right log on the right pin of the rear log with its narrow end resting on the middle and the middle right logs. 6. Place the top left log on the left pin of the rear log with its end resting on the middle left and front logs. 4. Place the narrow end of t...

Page 41

41 window refi tting 2. While you hold it, pull the side levers back into the window brackets on each side. 3. Pull out the top of the window and release it to insure the springs return it. 4. Apply light hand pressure against the window frame sides to bed-in the window seal.To refi t the window, pl...

Page 42

42 decorative lighting electrical installation wall dimmer switch the electrical installation must be performed by a qualifi ed installer and must be electrically wired and grounded in accordance with local codes, or, in the absence of local codes, with the national electrical code, ansi/nfpa 70 or ...

Page 43

43 operation check & aeration settings adjustment air shutter in open position air shutter in closed position air shutter operation check turn the fi replace fl ame up and down using the remote control to confi rm that the full range of inputs is achieved—see the remote control operation instruction...

Page 44

44 remote control handset wall holder installation the remote control kit for this fi replace comes complete with a wall-mounted holder. This holder is not required in all installations but is provided as an optional feature for those customers who wish to mount the remote handset to the wall. To in...

Page 45

45 wiring diagram optional wall switch kit 1265wsk connector red yellow gv60 wiring diagram qualified installer.

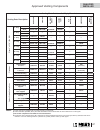

Page 46

46 approved direct vent suppliers for valor models 1200, 1300 and 1500 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries t ermination caps horizontal co-axial kit, 26” long — — — — — — ...

Page 47

47 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — black 46dva-06b 4dt-06(b) tc-4dl6b sv4lb6 7” lo...

Page 48: Lor

48 warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in ma...

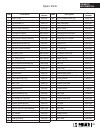

Page 49

49 code description part number 1 intake collar 4000925 2 intake collar gasket 4000942 3 top standoff (2) 4001373 4 firebox 5 air inlet duct assembly 4001246 6 rear log support 4001280by 7 front brick support 4001265by 8 side brick anchor (2) 4001283 9 lh explosion relief assembly 4001286 10 rh expl...

Page 50

50 spare parts code description part number 67 rear panel a victorian red brick 4001226 b frontera stone 4001321 c inca slab 4001322 d black slab 4001480 68 rh panel a victorian red brick 4001225 b frontera stone 4001325 c inca slab 4001326 d black slab 4001479 69 overlay (to cover front bottom fp) ...

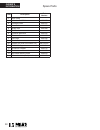

Page 51

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 11 56 55 63 69 72 19a,19b pilot assy 20a to 27 28a, 28b 31a, 31b 33 module plate gaskets 34 to 37 39 40 42 42a 43 59 60 61 62 38a, 38b 44 71 72 47a, 47b 48 49 50 51 52 53a, 53b 54 64 65 67 66 68 51 spare parts 73 owner’s information.

Page 53

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed installer. Please fi ll in the information below. The information provided will be used for customer records only. Online warranty registration at www...

Page 54

Tape shut thank you for choosing a valor product postage needed were you given all documentation and manuals for your product? Yes no miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.