530 direct vent gas fireplace heater installation booklet 600b121-4 manufactured by miles industries ltd. British columbia, canada vous pouvez vous procurer un exemplaire en langue française de cette brochure chez votre marchand. • safety information • options • location • supply gas • pack contents...

1. Safety information ...................................................................................................................................................................2 2. Options..........................................................................................................

Manufactured by miles industries ltd., british columbia, canada 2 1. Safety information warning: do not operate the appliance with the glass front removed, cracked or broken. Replacement of the glass should be done by a licensed or qualified service person. (the whole window unit may be temporarily ...

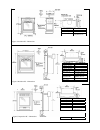

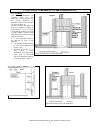

Manufactured by miles industries ltd., british columbia, canada 3 2. Options heater engine unit #530ean is used with all installations. 2.1. Appliance styles president fs free standing cast iron stove. (see figure 1), black textured - kit #531csb. Black enameled – kit #532esb. Green enameled – kit #...

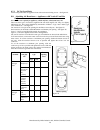

Manufactured by miles industries ltd., british columbia, canada 4 figure 1 president fs – dimensions mantle leg projection “d” min clearance from appliance side “e” up to 8” 1” more than 8” 6” figure 2 president zc – dimensions figure 3 impression zc – dimensions mantle leg projection “d” min cleara...

Manufactured by miles industries ltd., british columbia, canada 5 3. General 3.1. Approvals & codes this appliance is certified by international approval services for use in canada and the usa. The appliance is for installation directly venting through an outside wall or through the roof. This appli...

Manufactured by miles industries ltd., british columbia, canada 6 4. Location – president fs 4.1. Wall & floor fixing the president fs can be installed against a wall or in the room away from walls. The appliance is designed to be fixed to the floor. The appliance can additionally or alternatively b...

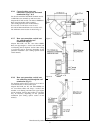

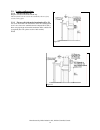

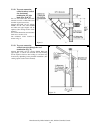

Manufactured by miles industries ltd., british columbia, canada 7 4.2.3. Rear vent connection, vertical vent rise with horizontal termination (fig. 7) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura...

4.2.6. Corner location, rear vent connection, vertical rise, horizontal termination (figs 7 & 9) manufactured by miles industries ltd., british columbia, canada 8 can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #9...

4.2.9. Rear vent connection, installed to fireplace chimney with co-linear liners (fig.12) only for use when retro fitting a non-combustible fireplace and chimney. The appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance. Requires adapter #817vak, co- axi...

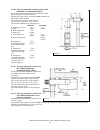

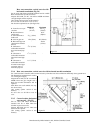

4.2.10. Top vent connection, vertical vent rise with horizontal rear termination (fig.13) manufactured by miles industries ltd., british columbia, canada 10 can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, one 90° vent elbow #990b and...

Figure 15 4.2.13. Top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (figs 13 & 15) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, one 90° elbow #990b, one 45° elbow #945b and dura-vent pipe l...

4.2.16. Top vent connection, vertical vent rise with offset and through the roof termination (fig.18) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, two 45° vent elbows #984, wall straps, a vertical vent terminal, roof flashing and ...

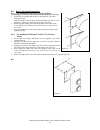

Manufactured by miles industries ltd., british columbia, canada 13 5. Location – president zc and impression zc 5.1. Framing the framing dimensions for appliances with rear vent connection are shown in figure 19. The framing dimensions for appliances with top vent connection are shown in figure 20. ...

5.2. Venting configurations figure 22 5.2.1. Flat on wall (fig. 22) requires standard vent kit #551dvk only. The horizontal vent run can not be extended by the use of any vent accessory pipes. 5.2.2. Flat on wall with snorkel termination (fig. 23) for use on horizontal vent installations where the o...

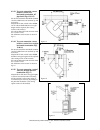

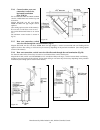

Manufactured by miles industries ltd., british columbia, canada 15 rear vent connection, vertical vent rise with horizontal termination (fig. 24) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura- ven...

Manufactured by miles industries ltd., british columbia, canada 16 5.2.6. Corner location, rear vent connection, vertical rise, horizontal termination (figs 24 & 26) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows...

5.2.9. Top vent connection, vertical vent rise with horizontal rear termination (fig.29) figure 29 can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 45° elbows #945b, one 90° vent elbow #990b and dura-vent pipe lengths will be requ...

Manufactured by miles industries ltd., british columbia, canada 18 5.2.12. Top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (figs 29 & 31) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two ...

5.2.14. Top vent connection, vertical vent rise with offset and through the roof termination (fig.33) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, four 45° vent elbows #984, wall straps, a vertical vent terminal, roof flashing and...

Vent location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airflow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be maintained when locate...

Manufactured by miles industries ltd., british columbia, canada 21 6. Supply gas all appliances are supplied for installation with natural gas. The supply pressure must be between the limits shown in section 3.2 of this manual. The supply connection is 3 / 8 ’’npt. The opening for the gas supply lin...

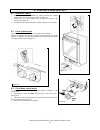

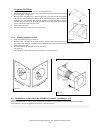

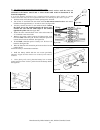

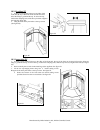

Manufactured by miles industries ltd., british columbia, canada 22 8. Appliance preparation 8.1. Detach the window 1. Release the top of the window by pulling forward and rotating outwards the two bars at the top corners. See figure 35. Figure 35 2. Unscrew the two spring loaded bolts securing the b...

8.4. Top vent outlet positioning manufactured by miles industries ltd., british columbia, canada 23 if installing with rear vent outlet go to next step. 1. Remove the top plate and seal by unscrewing 12 screws. (see figure 38). Keep the seal, plate and screws for fitting to the back. 2. Remove the r...

8.5. Rear vent outlet preparation 8.5.1. For installations with dura-vent dv gs pipes manufactured by miles industries ltd., british columbia, canada 24 if installing flat on wall with valor terminal kit #551dvk, ignore this step : 1. Fit the dura-vent adapter #817vak over the appliance vent collars...

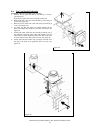

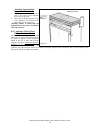

Attaching stand-off spacers manufactured by miles industries ltd., british columbia, canada 25 figure 45 8.6.1. For president fs only these spacers need not be fitted if the rear of the appliance is more than 1 1 / 4 ” (32mm) from any combustible material and if the installer can be absolutely certa...

8.7.3. Fit the front plinth fit the front plinth under the appliance front with two thread forming screws – see figure 46. Manufactured by miles industries ltd., british columbia, canada 26 8.8. Attaching air restrictors – appliances with vertical vent rise only no restrictors are required for appli...

8.9. Attaching top air deflector fit the top air deflector under the top panel of the appliance case. Secure with two thread forming screws. See figure 49. Figure 49 8.10. Attaching outer surround - zc models only manufactured by miles industries ltd., british columbia, canada 27 1. Locate the surro...

Manufactured by miles industries ltd., british columbia, canada 28 attaching top insulation layers –zc models only 1. For top vent outlet appliances cut out a circle at the center of the insulation layers for the vent collar. 2. Place both the insulation layers on top of the appliance case inboard o...

9. Installations with horizontal termination – installing to wall see sections 4 & 5 for full range of horizontal termination applications. 9.1. Installations except with valor #551dvk terminal – vent pipe fitting fit all the required dura-vent dv gs pipes and elbows securely twist locking each sect...

Manufactured by miles industries ltd., british columbia, canada 30 preparing wall plates the wall plates are not used for 7” hole in non-combustible walls. 1. Bend the wall shields and screw to the inside of the wall plates with 6 thread cutting screws per plate. See figure 53. 2. Bend the inner wal...

Manufactured by miles industries ltd., british columbia, canada 31 10. Installations with through the roof vertical termination 10.1. All co-axial vent installations 1. Check the roof pitch to determine which roof flashing will be needed - see vent accessories section 2.4. 2. The distance from the r...

Manufactured by miles industries ltd., british columbia, canada 32 11. Installing to frame & fitting switch– zc appliances 1. Secure the appliance to the framing by fixing to the studding through the bent tabs in the outer surround. 2. Refit the burner module using the 11 screws previously removed (...

Manufactured by miles industries ltd., british columbia, canada 33 d) for active remote control with active appliance switch caution! Don’t connect the batteries in the remote control receiver until the wires are connected to the burner control unit. A short circuit could result in destruction of th...

12. Fitting sides & switch – fs models 1. A) for active appliance side switch as only active switch figure 63 • snap fit the switch into the opening in the switch mounting bracket.See figure 63 • fit the two wire clips to the right side of the case. • route the switch wires round the back of the val...

Manufactured by miles industries ltd., british columbia, canada 35 13. Gas supply installation 1. The appliance is supplied for supply gas connection at the rear left corner of the case. An adapter is included in the pack that must be fitted to the appliance inlet pipe. Supply line connection to the...

Manufactured by miles industries ltd., british columbia, canada 36 14. Aeration setting check the burner is equipped with an adjustable shutter to control primary aeration. See figure 68. The shutter is factory set at an aeration gap which will give optimum performance for the vast majority of insta...

Manufactured by miles industries ltd., british columbia, canada 37 15. Ceramic fuel bed installation 15.1. Ceramic walls installation figure 71 figure 72 1. Locate the ceramic rear wall in the channel at back of the firebox and flat against the back of the firebox. See figure 69. 2. Locate the side ...

15.2. Ceramic logs installation (see section 15.3 for ceramic coals) 1. Place the base log on the supports in the firebox and against the firebox back. See figure 72. 2. Place the rear log over the base log. Locate the holes in the top log into the pegs in the base log. See figure 73. 3. Place the f...

Figure 77 15.3. Ceramic coals installation (see section 15.2 for ceramic logs) 1. Place the base coal on the supports in the firebox and against the firebox back. See figure 77. 2. Place the left front coal in position behind the metal lip at the front of the firebox. The side projection on this coa...

16. Window refitting & checking 1. Place the window centrally against the engine unit and resting on the support at bottom front of the engine. 2. Pull the clamping bars forward and rotate inwards to secure the top of the window. See figure 82 3. Fit the two spring loaded bolts through the bottom of...

Manufactured by miles industries ltd., british columbia, canada 41 17. Operation checks 1. Check ignition, pilot stability , burner flames and the full range of the thermostat using the rotary switch inside the appliance and all other controls (appliance rocker switch, wall switch, remote hand unit)...

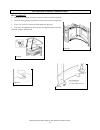

18. Installation completion 18.1. President fs 1. Hang the front casting by the hooks at the four corners as shown in figure 85. 2. Fit the top casting making sure that the corners locate as shown in figure 86. Figure 85 3. If rear vent connection: fit the top infill casting. See figure 87. 4. If ne...

18.2. President zc 1. If tiling is to be applied right up to the sides of the front unit, the top of the front can be moved forward to allow the tiling to go behind the top. To move the top, slacken the clamping bolts, slide the top forward, retighten the bolts (see figure 89). Figure 89 2. Hang the...