Model 530san model 530sap direct vent gas fireplace heater (with logs or coals) please read this manual before installing and operating this heater this manual should remain with the homeowner - do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other a...

2 contents 1. Safety information ........................................................................................................................................................................ 3 2. Options.........................................................................................

3 1. Safety information warning: do not operate the appliance with the glass front removed, cracked or broken. Replacement of the glass should be done by a licensed or qualified service person. (the whole window unit may be temporarily removed by the owner for cleaning the interior of the firebox, e...

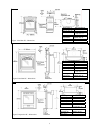

4 2. Options heater engine unit #530san is used with all natural gas installations. Heater engine unit #530sap is used with all propane installations. 2.1. Appliance styles president fs free standing cast iron stove. (see figure 1), black textured - kit #531csb. Black enameled – kit #532esb. Green e...

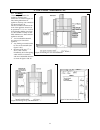

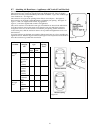

5 figure 1 president fs – dimensions figure 2 president zc – dimensions figure 3 impression zc – dimensions mantle depth “a” min. Clearance“b” up to 7” 4” above 7” up to 8” 5” above 8” up to 9” 7” above 9” up to10” 8” above 10” up to 12” 9” more than 12” 9”+extra 1” for every 1” depth above 12” mant...

6 3. General 3.1. Approvals & codes this appliance is certified by international approval services for use in canada and the usa. The appliance is for installation directly venting through an outside wall or through the roof. The appliance complies with cga p.4.1, testing method for measuring annual...

7 4. Location – president fs 4.1. Wall & floor fixing the president fs can be installed against a wall or in the room away from walls. The appliance is designed to be fixed to the floor. The appliance can additionally or alternatively be fixed to a rear wall. The fixing positions are shown in figure...

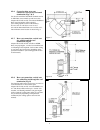

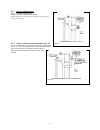

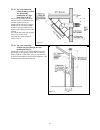

8 4.2.3. Rear vent connection, vertical vent rise with horizontal termination (fig. 7) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura-vent pipe lengths will be required. (see venting options sectio...

9 4.2.6. Corner location, rear vent connection, vertical rise, horizontal termination (figs 7 & 9) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura-vent pipe lengths will be required. (see venting op...

10 4.2.9. Rear vent connection, installed to fireplace chimney with co-linear liners (fig.12) only for use when retro fitting a non-combustible fireplace and chimney. The appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance. Requires adapter #817vak, co- ...

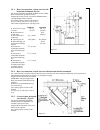

11 4.2.10. Top vent connection, vertical vent rise with horizontal rear termination (fig.13) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, one 90° vent elbow #990b and dura-vent pipe lengths will be required. (see venting options s...

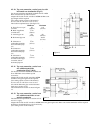

12 4.2.13. Top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (figs 13 & 15) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, one 90° elbow #990b, one 45° elbow #945b and dura-vent pipe lengths ...

13 4.2.16. Top vent connection, vertical vent rise with offset and through the roof termination (fig.18) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, two 45° vent elbows #984, wall straps, a vertical vent terminal, roof flashing a...

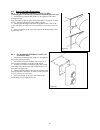

14 5. Location – president zc 5.1. Framing the framing dimensions for appliances with rear vent connection are shown in figure 19. The framing dimensions for appliances with top vent connection are shown in figure 20. The zero clearance unit allows the front of the appliance surround to be positione...

15 5.2. Venting configurations 5.2.1. Flat on wall (fig. 22) requires standard vent kit #551dvk only. The horizontal vent run can not be extended by the use of any vent accessory pipes. 5.2.2. Flat on wall with snorkel termination (fig. 23) for use on horizontal vent installations where the outside ...

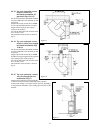

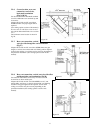

16 5.2.3. Rear vent connection, vertical vent rise with horizontal termination (fig. 24) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura- vent pipe lengths will be required. (see venting options sec...

17 5.2.6. Corner location, rear vent connection, vertical rise, horizontal termination (figs 24 & 26) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 90° vent elbows #990b and dura-vent pipe lengths will be required. (see venting...

18 5.2.9. Top vent connection, vertical vent rise with horizontal rear termination (fig.29) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 45° elbows #945b, one 90° vent elbow #990b and dura-vent pipe lengths will be required. (...

19 5.2.12. Top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (figs 29 & 31) can be used with either #551dvk standard vent kit or #984 dura-vent terminal cap and accessories. Adapter #817vak, two 45° elbows #945b, one 90° vent elbow #990b and dura-vent pipe le...

20 5.2.14. Top vent connection, vertical vent rise with offset and through the roof termination (fig.33) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, four 45° vent elbows #984, wall straps, a vertical vent terminal, roof flashing ...

21 5.3. Vent location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airflow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be maintained whe...

22 6. Supply gas heater engine 530san is used on natural gas installations. Heater engine 530sap is used on propane installations. The supply pressure must be between the limits shown in section 3.2 of this manual. The supply connection is 3 / 8 ’’npt. The opening for the gas supply line is at the r...

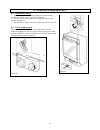

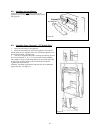

23 8. Appliance preparation 8.1. Detach the window 1. Release the top of the window by pulling forward and rotating outwards the two bars at the top corners. See figure 35. 2. Unscrew the two spring loaded bolts securing the bottom of the window. See figure 35. 3. Carefully lift the window. Keep the...

24 8.3. Top vent outlet positioning if installing with rear vent outlet go to next step. 1. Remove the top plate and seal by unscrewing 12 screws. (see figure 37). Keep the seal, plate and screws for fitting to the back. 2. Remove the rear outer vent collar and seal by unscrewing 12 screws (see figu...

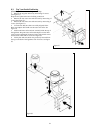

25 8.4. Rear vent outlet preparation 8.4.1. For installations with dura-vent dv gs pipes if installing flat on wall with valor terminal kit #551dvk, ignore this step : 1. Fit the dura-vent adapter #817vak over the appliance vent collars pushing on firmly. Align the adapter so that the seam on horizo...

26 8.5. Attaching stand-off spacers 8.5.1. For president fs only these spacers need not be fitted if the rear of the appliance is more than 1 1 / 4 ” (32mm) from any combustible material and if the installer can be absolutely certain that no combustible construction will be added at a future date – ...

27 8.7. Attaching air restrictors – appliances with vertical vent rise only no restrictors are required for appliances, which only have a horizontal vent, run. There are three types of restrictor supplied with each #530 engine unit. They are slightly different in size. They can be identified by the ...

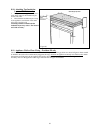

28 8.8. Attaching top air deflector fit the top air deflector under the top panel of the appliance case. Secure with two thread forming screws. See figure 48. 8.9. Attaching outer surround - zc models only 1. Locate the surround over the appliance. 2. Secure the surround to the sides of the applianc...

29 8.10. Attaching top insulation layers –zc models only 1. For top vent outlet appliances cut out a circle at the center of the insulation layers for the vent collar. 2. Place both the insulation layers on top of the appliance case inboard of the stand- off spacers. See figure 50. !Warning: failure...

30 9. Installations with horizontal termination – installing to wall see sections 4 & 5 for full range of horizontal termination applications. 9.1. Installations except with valor #551dvk terminal – vent pipe fitting fit all the required dura-vent dv gs pipes and elbows securely twist locking each s...

31 9.4. Preparing wall plates the wall plates are not used for 7” hole in non-combustible walls. 1. Bend the wall shields and screw to the inside of the wall plates with 6 thread cutting screws per plate. See figure 52. 2. Bend the inner wall plate tab as shown in figure 53 so that the seam on the t...

32 10. Installations with through the roof vertical termination 10.1. All co-axial vent installations 1. Check the roof pitch to determine which roof flashing will be needed - see vent accessories section 2.4. 2. The distance from the roof to the lowest terminal discharge opening (“h” in fig. 55) de...

33 11. Remote control installation caution! Don’t connect the batteries to the remote control receiver until the wires are connected to the burner control unit, as short circuit could result in destruction of the electrical components. When installing the remote please refer to figures 57 and 58 bel...

34 12. Gas supply installation 1. The appliance is supplied for supply gas connection at the rear left corner of the case. An adapter is included in the pack that must be fitted to the appliance inlet pipe. Supply line connection to the adapter is 3 / 8 ”npt. Alternatively, the appliance inlet pipe ...

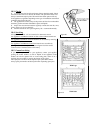

35 13. Aeration setting check the burner is equipped with an adjustable shutter to control primary aeration. See figure 60. The shutter is factory set at an aeration gap which will give optimum performance for the vast majority of installations. In a few unusual installations performance may be impr...

36 14.2. Ceramic logs installation (see section 14.3 for ceramic coals) 1. Place the base log on the supports in the firebox and against the firebox back. See figure 64. 2. Place the rear log over the base log. Locate the holes in the top log into the pegs in the base log. See figure 65. 3. Place th...

37 14.3. Ceramic coals installation (see section 14.2 for ceramic logs) 1. Place the base coal on the supports in the firebox and against the firebox back. See figure 69. 2. Place the left front coal in position behind the metal lip at the front of the firebox. The side projection on this coal shoul...

38 15. Window refitting & checking 1. Place the window centrally against the engine unit and resting on the support at bottom front of the engine. 2. Pull the clamping bars forward and rotate inwards to secure the top of the window. See figure 74 3. Fit the two spring loaded bolts through the bottom...

39 17. Installation completion 17.1. President fs 1. Hang the front casting by the hooks at the four corners as shown in figure 77. 2. Fit the top casting making sure that the corners locate as shown in figure 78. 3. If rear vent connection: fit the top infill casting. See figure 79. 4. If necessary...

40 17.2. President zc 1. If tiling is to be applied right up to the sides of the front unit, the top of the front can be moved forward to allow the tiling to go behind the top. To move the top, slacken the clamping bolts, slide the top forward, retighten the bolts (see figure 81). 2. Hang the front ...

41 18. Owners information please read the safety information and notes on page 3. 18.1. Operating your fire the operating instructions are also on a chained plate inside the control access door. 1. For your safety this appliance is fitted with a flame supervision device which will shut off the gas s...

42 figure 84 18.2. Cleaning 1. It will be necessary to clean the glass periodically. During startup, condensation, which is normal, forms on the inside of the glass and causes dust, lint etc. To cling to the glass surface. Initially paint, while curing, may deposit a slight film on the glass. We the...

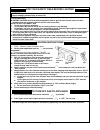

43 for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance has a pilot, which must be lighted by hand. When lighting the pilot, follow these instructions ...

44 18.3. Checks 1. A periodic check of the pilot and burner flames should be made. Check after the fire has been on for at least 30 minutes. The pilot flame must cover the tip of the thermocouple probe. The main burner flame pattern will vary from appliance to appliance depending on the type of inst...