- DL manuals

- Valor

- Indoor Fireplace

- 530XAN

- Installation And Owner's Manual

Valor 530XAN Installation And Owner's Manual

Model 530XAN/XAP

Model 530XCN/XCP

Direct Vent Gas Fireplace Heater

(With Logs or Coals)

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

PLEASE READ THIS MANUAL BEFORE

INSTALLING AND OPERATING THIS HEATER.

- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

-

WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch: do not

use any phone in your building.

•

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

•

If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

This appliance may be installed in an

aftermarket permanently located,

manufactured (mobile) home, where not

prohibited by local codes.

This appliance is only for use with the type of

gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purpose such as drying clothes etc.

B-Vent Installations

If this appliance is intended to be installed with a

B-Vent instead of direct vent, use this manual in

conjunction with the manual supplied with the B-

Vent adapter kit #552BVK.

This appliance is suitable for installation in a

bedroom or bed sitting room.

Manufactured by

MILES INDUSTRIES LTD.

British Columbia, Canada

4000305-10

Installation and Owner’s Manual

WARNING: If the information in these

instructions is not followed exactly, a

fire or explosion may result causing

property damage, personal injury or

loss of life.

Massachusetts: The piping and final gas

connection must be performed by a licensed

plumber or gas fitter in the State of

Massachusetts. Also, see Carbon Monoxide

detector requirements under “Safety and

Warning Information” on page 4.

Summary of 530XAN

Page 1

Model 530xan/xap model 530xcn/xcp direct vent gas fireplace heater (with logs or coals) installer: leave this manual with the appliance. Consumer: retain this manual for future reference. Please read this manual before installing and operating this heater. - do not store or use gasoline or other fla...

Page 2

2 of 50 contents 1. Safety information ....................................................................................................................... 3 2. Options....................................................................................................................................

Page 3

3 of 50 1.0 safety information warning: do not operate the appliance with the glass front removed, cracked or broken. Replacement of the glass should be done by a licensed or qualified service person. (the whole window unit may be temporarily removed by the owner for cleaning the interior of the fir...

Page 4

4 of 50 state of california. Proposition 65 warning. Fuels used in gas, wood-burning or oil fired appliances, and the products of combustion of such fuels, contain chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. California health & safety code s...

Page 5

5 of 50 1. Detailed instructions for the installation of the venting system design or the venting system components; and 2. A complete parts list for the venting system design or venting system. (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a pro...

Page 6

6 of 50 2.0 options heater engine unit # 530 x is available in either natural gas or lpg and comes equipped with either a simulated log or coal fuel bed in either fuel. The 530x engine unit is supplied standard with a rear vent d.V outlet and may be converted to a top outlet d.V with no extra parts ...

Page 7

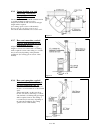

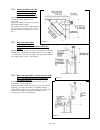

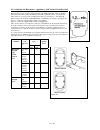

7 of 50 figure 1. Model 531 president free standing – dimensions figure 2. Model 536 recessed president – dimensions figure 3. Model 539 windsor arch. With backplate - dimensions mantle depth “a” min. Clearance“b” up to 7” 4” above 7” up to 8” 5” above 8” up to 9” 7” above 9” up to10” 8” above 10” u...

Page 8

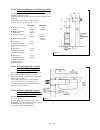

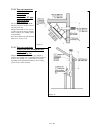

8 of 50 fig 4. 549 windsor arch without backplate. Note – this option is intended for insert applications only and does not include the stand-offs and insulation pads required for zero clearance applications. Most recessed 530 insert applications will also require a 556 cla co-linear adapter fig 5. ...

Page 9

9 of 50 3.0 general 3.1 approvals & codes this appliance is certified by international approval services for use in canada and the usa. The appliance complies with cga p.4.1, testing method for measuring annual fireplace efficiencies. The installation must conform with local codes or, in the absence...

Page 10

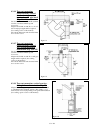

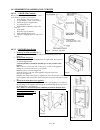

10 of 50 4.0 location – president free standing 4.1 wall & floor fixing the president fs can be installed against a wall or in the room away from walls. The appliance is designed to be fixed to the floor. The appliance can additionally or alternatively be fixed to a rear wall. The fixing positions a...

Page 11

11 of 50 4.2.3 rear vent connection, vertical vent rise with horizontal termination (fig. 9) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, two 90° vent elbows and pipe lengths will be required. (see venting options section of this manual)...

Page 12

12 of 50 4.2.6 corner location, rear vent connection, vertical rise, horizontal termination (figs 9 & 11) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, two 90° vent elbows and pipe lengths will be required. (see venting options section of...

Page 13

13 of 50 4.2.9 rear vent connection, installed to fireplace chimney with co- linear liners (fig.14) only for use when retrofitting a non-combustible fireplace and chimney. The appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance. Requires 556 cla co-axial...

Page 14

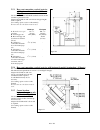

14 of 50 4.2.11 top vent connection, vertical vent rise with horizontal rear termination (fig.16) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, one 90° vent elbow and pipe lengths will be required. (see venting options section of this man...

Page 15

15 of 50 4.2.14 top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (figs 16 & 18) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, one 90° elbow, one 45° elbow and pipe lengths will be required. (see v...

Page 16

16 of 50 4.2.17 top vent connection, vertical vent rise with offset and through the roof termination (fig.21) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, two 45° vent elbows, wall straps, a vertical vent terminal, roof flashing a...

Page 17

17 of 50 5.0 location –zero clearance 5.1 framing -general the framing dimensions vary with the different cast iron fronts and with different vent configurations, allowing for elbows etc. Read framing drawings carefully. 5.2 finishing- general the president 536 and bolero 541 fronts come supplied wi...

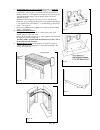

Page 18

18 of 50 5.4 windsor arch 539 front – zero clearance ( note – 549 version of the windsor arch front (without the backplate) does not come with zero clearance items and is intended for insert applications only) combustible wall finish may be used behind the cast iron plate up to the extent of the fra...

Page 19

19 of 50 5.5 z.C venting configurations ( all fronts) 5.5.1 flat on wall (fig. 28) requires standard vent kit #551dvk only. The horizontal vent run cannot be extended by the use of any vent accessory pipes. 5.5.2 flat on wall with snorkel termination (all fronts) (fig. 29) for use on horizontal vent...

Page 20

20 of 50 5.5.3 rear vent connection, vertical vent rise with horizontal termination (all fronts) (fig. 30) can be used with either #551dvk standard vent kit another terminal cap and accessories. Adapter #817vak, two 90° vent elbows and pipe lengths will be required. (see venting options section of t...

Page 21

21 of 50 5.5.6 corner location, rear vent connection, vertical rise, horizontal termination (all fronts) (figs 30 & 32) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, two 90° vent elbows and pipe lengths will be required. (see venting opti...

Page 22

22 of 50 5.5.9 top vent connection, vertical vent rise with horizontal rear termination(all fronts)(fig.35) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, two 45° elbows, one 90° vent elbow and pipe lengths will be required. (see venting o...

Page 23

23 of 50 5.5.12 top vent connection, corner location, vertical rise, horizontal termination, 45° pipe bend (all fronts) (figs 35 & 37) can be used with either #551dvk standard vent kit or another terminal cap and accessories. Adapter #817vak, two 45° elbows, one 90° vent elbow and pipe lengths will ...

Page 24

24 of 50 5.5.14 top vent connection, vertical vent rise with offset and through the roof termination (all fronts)(fig.39) for situations where offset is necessary in an attic to avoid obstructions or allow useful space. Adapter #817vak, four 45° vent elbows, wall straps, a vertical vent terminal, ro...

Page 25

25 of 50 923 gk termination 3336 cp closure plate ( 536 & 541 fronts) 6.0 recessed insert applications 6.0 rear or top outlet conversion to co-linear liners using 556 cla co-linear adapter. ( all fronts ) ( simpson duravent 923 gcl may also be used as an alternate to the 556 cla) only for use when r...

Page 26

26 of 50 7.0 direct vent location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airflow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be ma...

Page 27

27 of 50 8.0 pack contents( heater/engine & accessories) #530 engine unit (either log or coal version supplied) 1 appliance engine unit fitted with window 2 restrictor plates type #1 for log versions 2 restrictor plates type #2 for log versions 2 restrictor plates type #3 for log versions 2 restrict...

Page 28

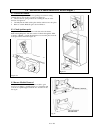

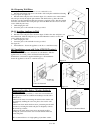

28 of 50 9.0 appliance preparation( heater/engine ) 9.1 detach the window 1. Release the top of the window by pulling forward and rotating outwards the two bars at the top corners. See figure 41. 2. Unscrew the two spring loaded bolts securing the bottom of the window. See figure 41. 3. Carefully li...

Page 29

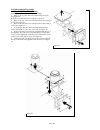

29 of 50 9.4 conversion to top outlet for solid direct vent piping if installing with rear vent outlet go to next step. 1. Remove the top plate and seal by unscrewing 12 screws. (see figure 44). Keep the seal, plate and screws for fitting to the back. 2. Remove the rear outer vent collar and seal by...

Page 30

30 of 50 figure 48 9.5 rear vent outlet preparation for installations using if installing straight off the back venting with valor terminal kit #551dv only, ignore this step: 1. Fit the adapter #817vak over the appliance vent collars pushing on firmly. Align the adapter so that the seam on horizonta...

Page 31

31 of 50 9.8 attaching air restrictors – appliances with vertical vent rise only no restrictors are required for appliances, which only have a horizontal vent, run. There are three types of restrictor supplied with each #530 engine unit. They are slightly different in size. They can be identified by...

Page 32

32 of 50 10.0 installations with horizontal termination – installing to wall see sections 4 & 5 for full range of horizontal termination applications. 10.1 installations except with valor #551dvk terminal – vent pipe fitting fit all the required pipes and elbows securely twist locking each section. ...

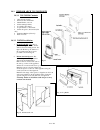

Page 33

33 of 50 10.4 preparing wall plates the wall plates are not used for 7” hole in non-combustible walls. 1. Bend the wall shields and screw to the inside of the wall plates with 6 thread cutting screws per plate. See figure 52. 2. Bend the inner wall plate tab as shown in figure 53 so that the seam on...

Page 34

34 of 50 11.0 installations with through the roof vertical termination 11.1 all co-axial vent installations 1. Check the roof pitch to determine which roof flashing will be needed - see vent accessories section 2.4. 2. The distance from the roof to the lowest terminal discharge opening (“h” in fig. ...

Page 35

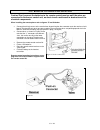

35 of 50 12.0 remote control installation caution! Don’t connect the batteries to the remote control receiver until the wires are connected to the burner control unit, as short circuit could result in destruction of the electrical components. When installing the remote please refer to figures 57 and...

Page 36

36 of 50 13.0 gas supply installation 1. The appliance is supplied for supply gas connection at the rear left corner of the case. Supply line connection to the inlet pipe of the appliance is 3 / 8 ”npt ( female). Alternatively, the appliance inlet pipe may be removed and the supply line routed direc...

Page 37

37 of 50 14.0 aeration setting check the burner is equipped with an adjustable shutter to control primary aeration. See figure 60. The shutter is factory set at an aeration gap, which will give optimum performance for the vast majority of installations. In a few unusual installations performance may...

Page 38

38 of 50 15.2 ceramic log installation (see section 15.3 for ceramic coal) 1. Place the base log on the supports in the firebox and against the support at the firebox back. See figure 64. 2. Locate the rear upper log on the two ceramic pins at the rear of the base log. See figure 65. 3. Place the fr...

Page 39

39 of 50 15.3 ceramic coals installation (see section 15.2 for ceramic logs) 1. Place the base coal on the supports in the firebox and against the firebox back. See figure 69. 2. Place the left front coal in position behind the metal lip at the front of the firebox. The side projection on this coal ...

Page 40

40 of 50 16.0 window refitting & checking 1. Place the window centrally against the engine unit and resting on the support at bottom front of the engine. 2. Pull the clamping bars forward and rotate inwards to secure the top of the window. See figure 74 3. Fit the two spring loaded bolts through the...

Page 41

41 of 50 18.0 installation of fronts and components 18.1 president 531 fs front 18.1.1 531 kit contents top pack ( box 1) 1 top casting 1 top infill plate side’s pack ( box 2) 1 front casting unit 2 side casting units 1 top air deflector 2 wall spacer brackets 2 self cutting screws 4 machine screws ...

Page 42

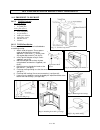

42 of 50 18.2 president 536 / bolero 541 z.C fronts 18.2.1 536/541 kit contents kits are identical other than items marked “ 536 or 541” which are specific to each version. 1 front casting ( 536 or 541 version) 1 top air deflector ( 536 or 541 version) 2 stand-off spacers (supplied flat) 2 top insul...

Page 43

43 of 50 4. Install plinth and rear support channel below firebox (optional) the purpose of the plinth is to allow the appliance to be placed on a rough subfloor, such as plywood, without regard for the additional thickness of tile etc. As the appliance bottom must otherwise be placed at the finishe...

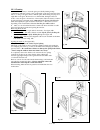

Page 44

44 of 50 18.3 windsor arch 539 / 549 fronts 18.3.1 539 / 549 kit contents 1 outer cast iron arch 1 inner cast iron arch infill 1 hearth fender, cast iron 2 side mounting brackets 1 top baffle, sheet metal 1 top air deflector, sheet metal 2 stand-off spacers, sheet metal (539 only) 2 insulation blank...

Page 45

45 of 50 3. Locate side mounting brackets as shown in fig. 96 and line up the mounting holes in the side of the heater body (note either channel may be fitted to either side). Secure the side channels to the heater using the screws provided – 2 per side. 4. Locate top insulation blanket. For top ven...

Page 46

46 of 50 19.0 owners information please read the safety information and notes on page 3. 19.1 operating your fire the operating instructions are also on a chained plate inside the control access door. 1. For your safety this appliance is fitted with a flame supervision device which will shut off the...

Page 47

47 of 50 fig.101 19.3 cleaning 1. It will be necessary to clean the glass periodically. During startup, condensation, which is normal, forms on the inside of the glass and causes dust, lint etc. To cling to the glass surface. Initially paint, while curing, may deposit a slight film on the glass. We ...

Page 48

48 of 50 19.4 checks 1. A periodic check of the pilot and burner flames should be made. Check after the fire has been on for at least 30 minutes. The pilot flame must cover the tip of the thermocouple probe. The main burner flame pattern will vary from appliance to appliance depending on the type of...

Page 49

49 of 50 for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A.This appliance has a pilot which must be lighted by hand. When lighting , follow these instructions exact...

Page 50

50 of 50 21. Approved vent suppliers approved alternative vent suppliers for 530, 534, 535 and 739 models venting parts code / availability by manufacturer venting parts description si m p s o n d urav e n t se lk irk se c u re ve n t rl h in dus tr ie s mil e s in dus tr ie s co-axial kit, 26" long...

Page 51

51 of 50 venting parts code / availability by manufacturer venting parts description simp son du raven t se lk ir k secur e ven t rl h industr ies mi les industr ies galvanized 945 black 945b sv4ebr45 galvanized swivel 945g 4dt-el45 sv4e45 dv 4 5 ° e l bow s black swivel 945bg 4dt-el45(b) sv4eb45 ga...

Page 52

52 of 50 22. Miles industries ltd. Warranty for valor brand products if you have a problem with this unit, please contact your dealer or supplier immediately. Under no circumstances should you attempt to service the unit in any way by yourself. The warranties in paragraphs 1 and 2 are provided only ...