4005130-03 © 2016, miles industries ltd. All rights reserved. Installation & owner’s manual this manual contains instructions to install the en- gine only. A front trim kit is required to install the engine as it affects the framing cavity and posi- tion of the engine. A barrier screen is provided w...

22 table of contents designed and manufactured by / for miles industries ltd. 190–2255 dollarton highway, north vancouver, bc, canada v7h 3b1 tel. 604-984-3496 fax 604-984-0246 www.Valor fi replaces.Com © copyright miles industries ltd., 2016 the information contained in this installation manual is ...

33 safety precautions ! Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be...

44 safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with a hot glass surface can c...

55 operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the full height of the fi...

66 cleaning your fireplace important - glass cleaning - mineral deposits one of the by-products of the combustion process in a gas appliance is a mineral which can show up as a white fi lm on the ceramic glass viewing door. The composition of the deposit varies widely with loca- tion and time. It be...

77 rock fuel bed a black discoloration may form over time at the front bottom of the 6-rock original fuel bed; this deposit can be burned off by running the fi replace on a low to medium setting fi re for 30 to 45 minutes. This discoloration is unavoidable and will re-form again. Owner’s information...

88 owner’s information caution do not use a screwdriver or other metallic object to remove the batteries from the receiver or the handset! This could cause a short circuit to the receiver. Warning do not attempt to change the batter- ies while the fireplace is still hot! Let the fi replace cool fi r...

99 owner’s information gas valve gas valve under window as well, familiarize yourself with the gas shut-off valve location in your house. As indicated below, the gas is running when the handle is parallel with the pipe. The gas is off when the handle is perpendicular with the pipe. How to ensure you...

10 10 remote control operation when the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position)....

11 11 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the applianc...

12 12 remote control operation setting the on / off temperatures • brie fl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temper...

13 13 setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the icon indicates the end o...

14 14 remote control operation wall switch operation automatic turn down automatic shut off low battery indication handset / receiver match remote handset: the battery icon will show when the battery needs to be replaced. Replace with one 9 v alkaline battery. Receiver: frequent ‘beeps’ for 3 second...

15 15 options required kits* fuel beds (choose one) 534lsk log set 534rsk rock set liners (choose one) 618rgl re fl ective glass liners 620fbl fluted black liners 621vrl valor red brick liners 622lsl ledgestone liners surrounds (choose one) 660lsv landscape surround vintage iron 660lsb landscape sur...

16 16 lighting instructions for your safety, read before lighting warning: if you do not follow these instructions exactly, a fi re or explosion may result causing property damage, personal injury or loss of life. A. This appliance has a pilot which must be lighted by hand, remote control, or wall s...

17 17 state of massachusetts carbon monoxide detector/vent terminal signage requirements for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwea...

18 18 (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identi fi es “special venting systems”, the following requiremen...

19 19 speci fi cations approvals & codes these appliances are certi fi ed by ansi z21.88-2014/ csa 2.33-2014 american national standard / csa standard for vented gas fireplace heaters for use in canada and usa. These appliances are for installation directly venting through an outside wall or through...

20 20 overview fire on/off wall switch (supplied, recommended) hearth (if used) may be combustible material. Minimum 1/2” (13 mm) gap required below backing plate to surface of hearth or fl oor in front for air fl ow. Raise enrtire unit accordingly. Note: unit projects forward of fi nished wall. All...

21 21 mantel depth “a” 0–2” (0–51 mm) 2–4” (51–102 mm) 4–6” (102–152 mm) 6–8” (152–203 mm) 8–10” (203–254 mm) 10–12” (254–305 mm) mantel height “b” 31-1/4” (794 mm) 34” (864 mm) 35” (889 mm) 36” (914 mm) 37” (940 mm) 38” (965 mm) dimensions mantel 36” (914 mm) min. See table stand-off stand-off see ...

22 22 • a non-combustible hearth is not necessary in front of this appliance. • note that the unit is installed at the framing stage and fi xed to framing using support angles. See page 32. The wall fi nish is then installed over the support angles up to the front frame on the unit, on the sides and...

23 23 location venting vent material this unit is approved for installation using 4 x 6-5/8 inches approved co-axial direct vent pipes and acces- sories listed on pages 46–47 of this guide. Follow the installation instructions supplied with the individual venting accessories. This unit may also be c...

24 24 horizontal termination 2-piece wall thimble pipe length pipe length pipe length 817vak 817vak pipe length 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination typical co-axial venting components co-axial venting qualified installer.

25 25 co-axial venting important installer notice – weather sealing & vapor barriers it is the installer’s responsibility to ensure that vent installations through exterior walls are caulked and weatherproofed in such a manner as to: • prevent rain water from entering the wall from the weather side ...

26 26 co-axial venting horizontal vent termination location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed air fl ow hits the outside vent terminal from any direction. • the minimum clearances from t...

27 27 example 1 v value = v1 (6’) + v2 (6’) + v3 (2’)= 14’ h value = h1 (3’) + h2 (3’) = 6’ co-axial venting min. 6” rise for top outlet 817vak adapter required for top or rear outlet max. 24” before elbow min. 12” rise 45° elbow directly on flue collar is allowed with min. 6” pipe between elbows 1”...

28 28 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 2 4 6 8 10 12 14 16 rear outlet top outlet 1 1 2 4 6 8 10 12 14 16 1 3 5 3 5 0.5 1 2 3 1 2 3 0.5 1 2 3 1 2 3 how to read the venting chart the chart below applies to co-axial roof or...

29 29 ‘h’ horizontal overhang vertical wall termination cap storm collar roof flashing plumber’s tape fixed to wall strap wall strap ceiling firestop ceiling support offset elbows min. 18” overhang should not extend beyond vent if within 48” of termination cap min. 24” (unvented soffit) min. 36” (ve...

30 30 co-linear vent installations • the fi replace dimensions are shown in the dimensions section of this manual. • place the appliance ( fi tted with the co-linear adapter) near the fi replace opening but allow space for manipulating the chimney liners on to the appliance. • drop the 3-inch diamet...

31 31 installation remove window 1. Turn the top two spring-loaded window bolts through 90 degrees to release the window from the fi rebox. 2. Remove the bottom two spring-loaded window bolts. 3. Carefully lift the window away. Keep the window and bolts in a safe place. Convert to rear vent outlet (...

32 32 installation install top stand-off and support angles the distance from the support angles to the front face of the heater case is adjustable to allow for a range of wall fi nish material thickness (e.G. Tile, etc.). 1. Check the wall fi nish requirements with the homeowner. 2. Secure the side...

33 33 re-install rear log support re fi t the rear log support in place (5 screws). Adjustable piece air restrictor assembly vent terminal appliance vent outlet vertical vent pipe run use restrictor setting horizontal through wall with vertical rise top or rear less than 6’ (183 cm) from 6’ (1.83 m)...

34 34 connect gas supply • the gas supply pipe should enter the appliance case through the opening at the left side. The supply pipe should be connected to the appliance gas inlet pipe situated at the left side of the control valve. Supply line connection to the inlet pipe is 3/8 inch npt ( female)....

35 35 installation install liner panels all liner panels can be installed as indicated below except the 618rgl—re fl ective glass liners —see instructions supplied with the liners. Unpack the liners carefully to avoid scratching or damaging them. 1. Place the rear panel against the back of the fi re...

36 36 installation install 534lsk ceramic logs unpack the ceramic logs very carefully to avoid damaging their fragile material. Install the logs as shown below. Please note that the position of the logs is critical to insure the good performance of the appliance. 1. Place the rear log on the sheet m...

37 37 installation 6. Place the lower end of the center right log onto the pin on the front right log. Rest the narrow end in the notch into the rear log. 7. Pour some ceramic loose coals on each side of the logs to hide the sheet metal work. Do not put any coal into the pilot area. Notch in rear lo...

38 38 to p bottom 1. Install the front support platform in the fi rebox carefully sliding it down between the burner and the front bottom edge for the fi rebox while avoiding scraping the side ceramic panels. 2. Place the rock ceramic base on the log support behind the burner. The front bottom of th...

39 39 4. The underside of each ceramic rock is identi- fi ed by a number and a speci fi c protruding positioning triangle. Install the six rocks from left to right starting with rock no. 1. Note: the ceramic base may need to be slightly adjusted side-to-side to allow stones to fi t within the platfo...

40 40 (appliance shown without its front frame and baf fl es for clarity) rear view detail—window assembly with window baf fl e hooked on frame appliance front view window baf fl e installation re fi t and check window, install window baf fl e 1. Slide the window inside the appliance case and rest i...

41 41 safety warning plate installation 7. If the hot glass warning plate has been removed from the front lower corner of the window, reinstall it by sliding it between the glass and the frame as indicated below. Qualified installer.

42 42 caution do not use a screwdriver or other metallic object to remove the batteries from the receiver or the handset! This could cause a short circuit to the receiver. Caution to avoid short-circuit to the receiver, position the antenna so that it does not touch the ignition wire. Installation i...

43 43 open open close close ng flashback shield (for lpg only) lpg air shutter slider open close lpg ng air shutter slider & cover check operation turn the fi replace fl ame up and down using the remote control to con fi rm that the full range of inputs is achieved—see the remote control operation i...

44 44 install front, trim and barrier screen install the front or trim chosen by the customer for their fi replace. Install as well the barrier screen which is provided with the front or trim. Show the customer how to access the controls when the front or trim are installed and how to remove them. F...

45 45 wiring diagram wall switch kit connector gv60 wiring diagram qualified installer.

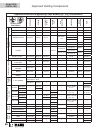

46 46 approved direct vent suppliers for valor models 530 6 , 534, 650 and mf28 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm termination caps horizontal standard co-axial 46dva...

47 47 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — 94610606 black 46dva-06b 4dt-06(b) tc-4d...

48 48 warranty warr an ty pr og ram warr an ty pr og ram va lor co m fo r t va lor co m fo r t va lor co m fo r t 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial owner for the r...

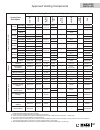

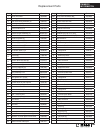

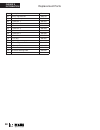

49 49 replacement parts key description part no. 1 outer vent collar 330a888 2 blanking plate 330a964 3 side frame fi xing brackets (2) 3000255 4 rear log support 4001999 5 burner module ng 4001952 burner module lpg 4001953 6 window assembly 3000389s 6a window screw assembly (2) 000b214s 7 window ba...

50 50 replacement parts key description part no. 61 12-inch top stand-off 4002121 62 rock set complete 534rsk 63 rock no. 1 4001821 64 rock no. 2 4001822 65 rock no. 3 4001823 66 rock no. 4 4001824 67 rock no. 5 4001825 68 rock no. 6 4001826 69 rock base 4001792 70 lh twig 4001827 71 rh twig 4001828...

51 51 75 61 63 64 65 66 67 68 69 62 70 71 72 73 74 41a ng lpg 15 17 22 23 24 25 26 18 19 20 21 16 36 35 4 34 3 3 9 14 2 8 13 50 51 52 1 5 6 7 28 27 33 32 29 30 31 43 49 46 45 44 40a, 40b 41 47 42 12a 12b 11a 11b replacement parts 53 54 55 58 56 59 57 60 48 6a owner’s information.

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a quali fi ed installer. Please fi ll in the information below. The information provided will be used for customer records only. Online warranty registration at ww...

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valor fi replaces.Com.