- DL manuals

- Valor

- Indoor Fireplace

- 762

- Installer And Owner Manual

Valor 762 Installer And Owner Manual

5136065/06

Model 762

Inset live fuel effect gas fire for assembly with;

Blakely fascia

©

GDC Group Ltd. 2013

INSTALLER AND OWNER GUIDE

Please keep me in a safe place for future use.

We trust that this guide gives sufficient details to enable this appliance to be

installed, operated and maintained satisfactorily. However, if further information is

required, our Valor Technical Helpline will be pleased to help.

Telephone 0844 879 35 88 (National call rates apply in the United Kingdom).

In the Republic of Ireland Telephone 01 842 8222.

DO

N’T

FOR

GET

To re

giste

r your

guar

antee

!

Call

0800

597 8

500

Summary of 762

Page 1

5136065/06 model 762 inset live fuel effect gas fire for assembly with; blakely fascia © gdc group ltd. 2013 installer and owner guide please keep me in a safe place for future use. We trust that this guide gives sufficient details to enable this appliance to be installed, operated and maintained sa...

Page 2

© gdc group ltd. All rights reserved. No part of this publication may be reproduced in any material form (including photocopying), stored in any medium by electronic means (including in any retrieval system or database) or transmitted, in any form or by any means, whether electronic, mechanical, rec...

Page 3

Safety first. Valor fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. All valor fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso 9001 quality system accepted by the br...

Page 4

© gdc group ltd. 2013 page 4 installer guide for owner guide see pages 41 to 58 installer guide.

Page 5

Contents section page installer guide 5 - 40 owner guide 41 - 58 1. Image 7 2. Safety 8 3. Accessories 9 4. Appliance data, efficiency and nox 9 4.1 general information. 9 4.2 efficiency. 10 4.3 nox 10 5. General installation requirements 10 5.1 regulations, standards and law. 10 5.2 ventilation req...

Page 6

13. Burner and supply pipe installation 27 13.1 burner installation. 27 13.2 supply pipe installation. 27 13.3 burner checks. 27 13.3.1 lighting the fire. 27 13.3.2 adjusting flame height. 28 13.3.3 adjusting to pilot only setting. 28 13.3.4 turning off. 28 13.4 check inlet pressure. 29 14. Fitting ...

Page 7

1. Image © gdc group ltd. 2013 page 7 installer guide blakely fascia.

Page 8: Installer

2. Safety installer before continuing any further with the installation of this appliance please read the following guide to manual handling. - the lifting weight of this appliance (kg) is as below: model heat engine (without ceramics) fascia fascia blakely 22.14 6.62 (fret) 8.54 (frame) this fire a...

Page 9

3. Accessories accessory part number lpg conversion kit 0595271 4. Appliance data, efficiency and no x 4.1 general information. * when converted using kit 0595271. The appliance information label is located under the burner on the right hand side of the fire. This can be seen by removing the fascia....

Page 10

The gross calorific value of the fuel has been used for this efficiency calculation. The test data from which it has been calculated has been certified by advantica certification services (0087). The efficiency value may be used in the uk government's standard assessment procedure (sap) for energy r...

Page 11

- in scotland, the current edition of the building standards (scotland) regulations issued by the scottish executive. - in northern ireland, the current edition of the building regulations (northern ireland) issued by the department of the environment for northern ireland. - in the republic of irela...

Page 12

5.6 chimney preparation. 5.6.1 if the appliance is intended to be installed to a chimney that was previously used for solid fuel, the flue must be swept clean prior to installation. All flues should be inspected for soundness and freedom from blockages. 5.6.2 any chimney damper or restrictor should ...

Page 13

5.8 the hearth. The appliance must be mounted behind a non-combustible hearth unless the conditions of section 4.10.2 are met (n.B. Conglomerate marble hearths are considered as non-combustible). The appliance can be fitted to a purpose made proprietary class “o”-150°c surround. The hearth material ...

Page 14

© gdc group ltd. 2013 page 14 5.9.2 blakely fascia - the minimum allowable distance from the outside of the appliance fascia to a corner wall having combustible material or any other combustible surface which projects beyond the front of the appliance is shown in figure 3. A 10mm access clearance fr...

Page 15

5.10 installation options. In the united kingdom, as supplied, the appliance can be installed in the following situations: 5.10.1 conventional fireplace and hearth.- to a fireplace opening and hearth as shown in figure 4 and complying with bs1251 after removal of the fireback and sufficient material...

Page 16

© gdc group ltd. 2013 page 16 5.11 flues. 1. Suitable flues and minimum flue sizes are as follows: - it should be noted that, as with many appliances, sharp bends or horizontal runs in metal flues at the top of the system can be a cause of problems in these types of installation. - 225mm x 225mm con...

Page 17

6. Unpacking 1. The ceramic fuel effect is packed inside the convector box. The window panel is secured at the bottom with two clamps. To release the clamps, hold at the rear and pull down (see figure 6). 2. With both clamps released, gently pull the base of the window panel forward. Hold the window...

Page 18

7. Pack contents the items required for this appliance are packed in sections. The ceramic walls are fragile. They are packed inside the top fitment as you open the carton. Section 1 - fire unit contains: 1 burner and convection box unit. 2 lengths of self adhesive foam seal. 2 cable clamps. 2 fire ...

Page 19

© gdc group ltd. 2013 page 19 installer guide figure 8. Pack contents (items are not to scale).

Page 20

Note: the blakely appliance is supplied with a flue restrictor, this should be fitted if the flue height is greater than 4.3m (14ft), with a good draught present. Generally we recommend the flue restrictor is not fitted to precast flues or metal flue box installations. There may be circumstances whe...

Page 21

1) by fixing to the fireplace front. 2) using concealed tension cables fixed to the rear of the fireplace opening together with secondary fixing to the fireplace floor. The methods are detailed in section 12 of this manual. Before selecting the retention method, consult with the customer. Method 2 i...

Page 22

© gdc group ltd. 2013 page 22 9.3 setting the handset and receiver relationship. The receiver will have to be set to learn the handset / remote code. Do this as below: place the ‘on/off’ switch to the ‘-’ (on position). This is on the right hand front of the appliance. Press and hold the reset butto...

Page 23

© gdc group ltd. 2013 page 23 important before continuing with the installation of this gas fire the aeration setting on the burner must be checked. The aeration is factory set and should not require adjustment. See section 19.1 (servicing and parts replacement). 2. It is important that the grommet ...

Page 24

3. Mark the fireplace front surround through the seven fixing holes in the side flanges of the convection box (see figure 15). 4. Remove the convection box. Drill four holes in the fireplace front surround at the marked positions using a suitably sized masonry drill for the fibre / wooden plugs supp...

Page 25

Always screw the base into position before applying tension to the cables. This will ensure a tight seal between the top of the convection box and wall. 8. The convection box has two slots at each side of the flue outlet. Loop one end of each cable and pass the loop into the slots (see figure 18). G...

Page 26

Cables in position. Apply tension to the cables by turning the hexagonal adjusters by hand (see figure 20). 13. Inspect the installation of the convection box against the fireplace surround. If the convection box is aligned squarely and the sealing is satisfactory, fully tighten the cable retainers....

Page 27

13. Burner and supply pipe installation 13.1 burner installation. 1. Remove the ‘aeration checking’ reminder label from the top of the burner. 2. Refit the burner unit to the convection box with the six screws removed previously. 13.2 supply pipe installation. 1. A nut and olive is provided for an 8...

Page 28

Simultaneously press and hold the ‘off’ and (large flame) buttons until a short acoustic signal confirms the start sequence has begun; release buttons. Continuing signals confirms the ignition is in progress. There will be a slight delay and several sparks should be seen between the electrode and pi...

Page 29

13.4 check inlet pressure. The appliance is pre-set to give the correct heat input at the inlet pressure shown in section 4 of this guide. No adjustment is necessary. 1. Ensure that the fire is off then fit a pressure gauge at the test point. The test point is on the inlet ‘t’ connector (see figure ...

Page 30

14.4 fitting the port cover. The port cover supplied with the fire needs to be fitted to the inner top of the convection box. Locate the port cover, being careful not to scratch the ceramic side walls, and secure with three no. 8 x 3/8” screws supplied (see figure 25). 14.5 fitting the ceramic fuel ...

Page 31

15. Full operating checks 15.1 check the burner operation. Repeat the checks conducted in section 12.3. Please note: when first turned on from cold, the flames will appear predominantly blue. When operating the fire for the first time, some vapours may be given off which could set off smoke alarms i...

Page 32

15.3 flame supervision and spillage monitoring system. This pilot unit includes a system that will automatically shut off the gas supply if the pilot flame goes out or if there is insufficient oxygen due to spillage or poor ventilation. This monitoring system must not be adjusted, bypassed or put ou...

Page 33

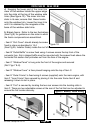

16. Fascia installation blakely fascia - refer to the two illustrations (see fig 27) for guidance on the order in which the fascia components are assemblied. - item a” port cover” should already be screw fixed in place as described in 14.4 (see fig 25) inside the roof of the fire box. - item b “outl...

Page 34

17. Final review 1. Complete the information in the warranty and service section of the owner guide (see last pages of the owner guide). 2. Visually inspect the appliance. Clean off any marks incurred during installation. 3. Advise the customer how to operate the appliance. Point out that lighting i...

Page 35

18. Servicing & parts replacement - always turn off the gas supply before commencing any servicing and allow the fire to cool completely (the appliance inlet ‘t’ connector incorporates an isolating valve). - it is recommended that, at least once a year, the appliance is disconnected and the fireplac...

Page 36

18.1 checking the aeration setting of the burner. 1. The aeration shutter is factory set. It is important to ensure that the aeration setting is correct (see figure 28). 2. If the setting is not as shown in figure 28 adjust the aeration setting. To do this loosen the two aeration shutter screws, sli...

Page 37

18.5 to remove the burner unit. 1. Complete section 18.4. 2. Isolate the gas supply at the inlet isolating ‘t’ connector. 3. Support the inlet ‘t’ connector to avoid straining the pipework and disconnect the appliance from the inlet ‘t’ connector. 4. Unscrew and remove the seven screws from the top ...

Page 38

18.7 to remove the gas valve. (see figure 32). 1. Remove the burner assembly (see section 18.6). 2. If turning the burner upside down, ensure that the work surface is suitably protected. This will avoid damage to the work surface. 3. Remove the thermocouple by unscrewing the thermocouple nut at the ...

Page 39

18.8 to remove the receiver box. 1. Slide the receiver box out of its support bracket. 2. Remove the electrode ‘spark’ lead. 3. Remove the wiring block from the side of the receiver box. 4. Unscrew and remove the yellow coded switch wire and red coded thermocouple wire. 5. Refit in reverse order. Pl...

Page 40

4. Support the elbow injector and unscrew the injector nut. 5. Lift the right hand side of the burner, slide it to the right and lift clear 6. Refit in reverse order. 18.11 to remove the burner injector. 1. Remove the burner (see section 18.11 points 1-5). 2. Unscrew the injector from the burner. 3....

Page 41

© gdc group ltd. 2013 page 41 owner guide owner guide for warranty and service information see pages 55 to 58.

Page 42

List of contents section page safety 43 gas consumption 44 appliance dimensions 45 operating your fire 46 the oxysafe flame sensing and flue blockage safety system. 46 operating the fire with the remote control handset. 46 lighting the fire. 46 adjusting the flame height. 46 adjusting to the pilot o...

Page 43

Safety do have the fire installed by a competent person. In the united kingdom, installation must be in accordance with the latest edition of the gas safety (installation & use) regulations. In the republic of ireland, installation must be in accordance with all national and local regulations in for...

Page 44

Do get advice about the suitability of any wall covering near your fire. Soft wall coverings (e.G. Embossed vinyl, etc.) which have a raised pattern are easily affected by heat. They may, therefore, scorch or become discoloured when close to a heating appliance. Please bear this in mind whenever you...

Page 45

Appliance dimensions © gdc group ltd. 2013 page 45 owner guide key description blakely model a height (mm) 680 b width (mm) 930 c depth into room (mm) 130 d minimum mandatory clearance to combustible surfaces projecting beyond the front of appliance (mm) 75 e recommended clearance to non-combustible...

Page 46

Operating your fire the oxysafe flame sensing and flue blockage safety system. For your safety, this appliance is fitted with a flue blockage safety device which is designed to shut down the appliance in the event of abnormal flue conditions. Note - this device is not a substitute for an independent...

Page 47

Signal is given, then release the button. Please note: - the flames on the n.G. Appliance will appear predominantly blue. The flames on the l.P.G. Appliance will appear predominantly yellow. - the appliance will operate to its maximum potential if the flue is primed during the first 20 – 30 minutes ...

Page 48

2. The ‘main valve knob’ is the knob on the right hand side (see figure 4). Turn this knob to the ‘off’, fully clockwise position . 3. The ‘manual knob’ is the knob on the left hand side (see figure 5). Turn this knob to the ‘off’, fully clockwise position. 4. Place the ‘on/off’ switch to the ‘o’ (o...

Page 49

8. Turn the ‘manual’ knob to the on, full counterclockwise position. The main burner will now light on the max flame setting. 9. Turn main valve knob to the full ‘on' counterclockwise position. 10. If the appliance will not operate, follow the instructions “to turn off” below and call the valor tech...

Page 50

- when lifting always keep your back straight. Bend your legs and not your back. - avoid twisting at the waist. It is better to reposition your feet. - avoid upper body/top heavy bending. Do not lean forward or sideways whilst handling the fascia. - always grip with the palm of the hand. Do not use ...

Page 51

4. Keeping the lower part of the inner trim clear of the window locate the upper edge into the slots at the top of the window side trims (see figure 10). The inner trim has slots in its rear, ensure that these locate onto the window trim. Lower the inner trim until it is retained by the magnets at t...

Page 52

This product uses fuel effect pieces, burner compartment walls and ceramic gravel containing refractory ceramic fibres (rcf), which are man-made vitreous silicate fibres. Excessive exposure to this material may cause irritation to eyes, skin and respiratory tract. Consequently, it is important to ta...

Page 53

Maintenance battery replacement. Please note: in order to ensure maximum battery life and optimal performance, we recommend that only 'long life' alkaline type replacement batteries are used. The use of non-alkaline batteries will result in limited battery life'. Handset. The remote control handset ...

Page 54

Regular maintenance. In order to achieve and maintain high levels of personal safety and performance efficiency, it is essential that the opening at the back of the fire and the flue are kept clear of any form of obstruction. It is possible that deposits of mortar or soot could fall and accumulate c...

Page 55

Warranty and service standard warranty terms & conditions the warranty is for 12 months subject to contract. In the united kingdom servicing can be carried out either by a gdc service engineer or a gas safe register engineer. Outside of the united kingdom servicing can be carried out either by a cor...

Page 56

© gdc group ltd. 2013 page 56 when calling the gdc helpline, it would be helpful if you could have the following information to hand:- 1. Fire serial number and fascia code (located on the information label - see figure 13 on page 57)*. 2. Date of installation* 3. Your installer name and address det...

Page 57

© gdc group ltd. 2013 page 57 figure 13. The following pages are to be completed by the installer: installer details (block capitals) installer name gas safe register number. Company name. Company address company telephone number company fax number owner guide.

Page 58

© gdc group ltd. 2013 page 58 model owner guide 7 6 2 d d m m y y date of installation fascia code - can be found close to the information label (block capitals) fascia name (block capitals) serial number (a label containing this information may have been placed below or can be found on the serial n...

Page 59

© gdc group ltd. 2013 page 59.

Page 60

© gdc group ltd. 2013 page 60