- DL manuals

- Valor Fires

- Indoor Fireplace

- 541 Camden

- Installer And Owner Manual

Valor Fires 541 Camden Installer And Owner Manual

©

Baxi Heating U.K. Limited 2008.

5133756/01

INSTALLER: Please leave this guide with the

owner

Model 541

ROOM SEALED RADIANT / CONVECTOR

GAS FIRE

Fitted with one of the following fascia.

Camden, Seattle, Sonnet

or

Ultimate.

(GC No. 32-032-64)

We trust that this guide gives

sufficient details to enable this

appliance to be installed and

maintained satisfactorily. However, if

further information is required, our

Valor Fires Technical Helpline will

be pleased to help.

Telephone 0844 8711 565 (National

call rates apply in the United

Kingdom).

In the Republic of Ireland

Telephone 0044 844 8711 565.

INSTALLER AND OWNER GUIDE

Summary of 541 Camden

Page 1

© baxi heating u.K. Limited 2008. 5133756/01 installer: please leave this guide with the owner model 541 room sealed radiant / convector gas fire fitted with one of the following fascia. Camden, seattle, sonnet or ultimate. (gc no. 32-032-64) we trust that this guide gives sufficient details to enab...

Page 2

© baxi heating u.K. Limited 2008. All rights reserved. No part of this publication may be reproduced in any material form (including photocopying), stored in any medium by electronic means (including in any retrieval system or database) or transmitted, in any form or by any means, whether electronic...

Page 3

Page 3 safety first. Valor fires fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. All valor fires fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso 9001 quality system...

Page 4

Page 4 © baxi heating u.K. Limited 2008. Installer guide for owner guide see pages 38 to 51 installer guide.

Page 5: Contents

Contents section heading page installer guide 4 - 37 owner guide 38 - 51 1. Safety 6 2. Appliance data 7 3. List of available kits 8 4. Appliance and recess dimensions 9 5. General installation requirements 10 6. Unpacking and preliminary checks 16 7. Gas supply connection 18 8. Wall preparation 18 ...

Page 6: 1. Safety

1. Safety installer before continuing any further with the installation of this appliance please read the following guide to manual handling: the approximate lifting weight (kg) of this appliance is as below: model heat engine fascia fire front combined weight inc. Ceramics camden 12.75 1.31 0.95 15...

Page 7: 2. Appliance Data

2. Appliance data befre continuing with the installation of this appliance please complete the information on the last pages of this guide. The appliance data label is located on a plate at the base of the fire. This can be seen by removing the lower front casting / fire front. The efficiency of thi...

Page 8: 3. List Of Available Kits

3. List of available kits description part number spacer kit (5 inch) 0595121 spacer kit (3 inch) 0595131 timber frame flue clearance kit. 0583141 this kit includes : - 1 off insulation for rear of fire. 1 off flue clearance sleeve. 1 off drip collar. 1 off external wall plate. Under no circumstance...

Page 9

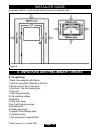

4. Appliance and recess dimensions this appliance must not be recessed into a combustible wall. Page 9 © baxi heating u.K. Limited 2008. Figure 1. Appliance dimensions and clearances (fire dimensions are subject to manufacturing deviation) fascia may differ from that shown key description model ulti...

Page 10

5. General installation requirements 5.1 the appliance can be installed into the following: a) a minimum 4.5in rebate surround or valor fires 5in. Spacer kit part no 0595121. Where either of these are mounted to a combustible wall make sure that there is no combustible material or combustible claddi...

Page 11

Under no circumstances is the fire to be recessed into timber frame constructions. For timber framed installations see section 8. 5.4 the installation must be in accordance with this guide. For the user’s protection, in the united kingdom it is the law that all gas appliances are installed by compet...

Page 12

5.6 the minimum height from the base of the fire to the underside of any shelf made from wood or other combustible materials is as follows:- • for a shelf up to 150mm deep minimum height = 780mm. • for a shelf deeper than 150mm 780mm + 12.5mm for every 25mm depth over 150mm. (see graph 1) there is n...

Page 13

For installations that are not elevated. This appliance does not require a non-combustible hearth. It can be installed on any hard surface. This surface should be level and sufficiently flat to enable the bottom of the fascia / fire front / castings to be aligned horizontally. Any unevenness (uneven...

Page 14

5.15 if the fire is to be fitted against a wall with combustible cladding, the cladding must be removed from the area shown in figure 3. 5.16 minimum allowable distances from the terminal are shown in figures 4 and 5. Page 14 © baxi heating u.K. Limited 2008. Figure 3. Area to be free of combustible...

Page 15

*in addition, the terminal should not be nearer than 300mm to an opening in the building fabric formed for the purpose of accommodating a built-in element such as a window frame or door frame (see figure 5). ** the reference to external corners does not apply to building protrusions not page 15 © ba...

Page 16

Exceeding 450mm, such as disused chimneys on external walls. 6. Unpacking and preliminary checks 6.1 unpacking. 1 main fire assembly with fascia. 1 ceramic fuel effect (packed in the fire). 1 nut & olive for 8mm inlet pipe. 1 fire front / fire front casting set. 1 flue unit. 1 wall fixing template. ...

Page 17

6.2 appliance disassembly. Fascia removal (see figure 6). Remove the two screws securing the bottom of the fascia to the sides of the convection box. Raise the fascia to allow the retaining lugs at the top to clear the slots in the convection box hood and then lift clear. Place the fascia in a safe ...

Page 18: 7. Gas Supply Connection

7. Gas supply connection a nut & olive are provided for an 8mm pipe inlet connection to the inlet ‘t’ connector at the bottom front of the appliance. This can be rotated to allow a connection from any direction and includes a valve for isolating the gas supply. The supply pipe must be rigid material...

Page 19

8.2.1 fitting a lintel. Whenever a lintel is required to support the recess in the inner leaf of a brick/blockwork building, follow the method outlined below (see figure 9). The lintel should be either steel (catnic) or reinforced precast concrete. It should be 750mm long x 75mm deep x inner leaf th...

Page 20

8.3 combustible wall materials. For brick or other non-combustible wall constructions, be sure to remove any combustible wall cladding material from the area shown in figure 2. For timber frame buildings, the back surface of the appliance case must be separated from the timber frame by 25mm of non-c...

Page 21

Pierce the template at the centre of the screw fixing holes and the flue hole and mark the positions on the wall. Remove the template. 8.4.1 core drilling. Drill a pilot hole through the wall. Inspect the hole to ensure that it is in the brickwork and not in mortar. If it is in mortar, it is advisab...

Page 22

8.6 prepare appliance fixing holes. 8.6.1 screwing case to wall. Recheck the position of the screw fixing holes relative to the flue hole. Drill the four fixing holes to a minimum depth of 42mm using a suitably sized masonry drill for the wall plugs supplied. Insert four plastic wall plugs supplied....

Page 23

Fit the two eyebolts. 9. Flue and terminal installation 9.1 cutting flue to size. For outset appliances with surround or spacer measure the total wall thickness from the outside surface of the wall to the inside face of the surround or spacer. Deduct 35mm from this measurement to obtain the correct ...

Page 24

9.2 fitting to wall. Fit the flue tubes firmly over the spigots at the rear of the fire. Make sure that the seam on the flue tube is not at the bottom. Push on until the outer (air) tube just covers the slots in the appliance outer spigot (see figure 15). Secure the flue to the fire by drilling thro...

Page 25: 10. Gas Connection

Through the wall. Pull the cables taut. Timber frame building with combustible outer leaf (e.G. Shiplap boarding): a metal or other non-combustible end plate must be fitted on the outside of the wall. The plate must be concentric with the flue and at least 254mm (10in) square or diameter (see figure...

Page 26

11. Ceramic coals installation this section is for models supplied with a ‘coal’ fuel effect only. For ‘pebble fuel effect’ see section 12 the ceramic fuel effect may cause staining / discolouration to decorative surfaces. It is therefore advisable to protect decorative surfaces. 1. Fit the ceramic ...

Page 27

3. Hold coal ‘b’ upright with the arrow pointing to the top. Locate coal ‘b’ as shown in figure 19. 4. Hold coal ‘c’ upright with the arrow pointing to the top. Locate coal ‘c’ as shown in figure 20. 5. Hold coal ‘d’ upright with the arrow pointing to the top. Locate coal ‘d’ as shown in figure 21. ...

Page 28

12. Ceramic pebbles installation this section is for models supplied with a ‘pebble’ fuel effect only. For ‘coal fuel effect’ see section 11. The ceramic fuel effect may cause staining / discolouration to decorative surfaces. It is therefore advisable to protect decorative surfaces. 1. Fit the ceram...

Page 29

3. Hold pebble ‘b’ upright with the arrow pointing to the top. Locate pebble ‘b’ as shown in figure 25. 4. Hold pebble ‘c’ upright with the arrow pointing to the top. Locate pebble ‘c’ as shown in figure 26. 5. Hold pebble ‘d’ upright with the arrow pointing to the top. Locate pebble ‘d’ as shown in...

Page 30: 13. Window Fitting

13. Window fitting fitting the window. Locate the channel at the top of the window over the top of the firebox opening. Refit the three spring loaded screws and bushes. The wide part of the bushes should be in contact with the window frame. Tighten sufficiently to seal the firebox. Pull the bottom o...

Page 31

Kept at any position enabling the customer to use the right hand control only to ignite the burner at the set flame height. After checking turn the right hand knob to off. Depress the control knob partially at the pilot position ( ), turn clockwise to off ( • ) and release the knob. If any resistanc...

Page 32: 15. Fascia Fitting

15. Fascia fitting if you have not done so already complete the information on the last pages of this guide. Remove any protective film from the fascia. Locate the two lugs at the top of the fascia in the slots in the convection box hood. Swing the bottom of the fascia sides back against the convect...

Page 33: 16. Final Review

16. Final review recheck the pilot ignition and operation of the fire through the range of settings. Visually inspect the appliance. Clean off any marks incurred during installation. Advise the customer to read their owner guide before operating the fire and to always follow the advice in the sectio...

Page 34

17. Servicing & parts replacement always turn off the gas and allow the appliance to cool completely before commencing any servicing. (the inlet ‘t’ connector on this appliance incorporates an isolating valve) always test for gas soundness after refitting the appliance. This product uses a fuel effe...

Page 35

Clear the slots in the convection box hood and then lift clear (see figure 34). 17.2 to remove window unit. Remove the fascia (see section 17.1). Unscrew and remove the three spring-loaded window- fixing screws and bushes from the base of the window frame (see figure 35). Gently swing the base of th...

Page 36

17.5 to remove the burner from the burner module. Remove the complete burner module as in section 17.4. Support the injector elbow and unscrew the pipe nut from its base. The burner bracket is secured to the front cover by four screws. Remove these screws. The burner and its bracket can now be lifte...

Page 37

17.8 to remove the gas valve. Remove the complete burner module as in section 17.4 remove the electrode lead at the pilot. Do this by holding the lead as close to the electrode as possible. This will limit the possibility of damaging the lead connection. Unscrew the thermocouple at the rear of the g...

Page 38

Page 38 owner guide © baxi heating u.K. Limited 2008. Owner guide for warranty and service information see pages 45 to 51.

Page 39: Contents

Contents section heading page safety 40 appliance dimensions 42 gas consumption 43 operating your fire 43 to light the pilot. 43 to light the main burner. 44 to turn off the main burner only. 44 to turn off the main burner and pilot. 44 cleaning your fire 44 maintenance 44 warranty and service 45 th...

Page 40: Safety

Safety do have the fire installed by a competent person. In the united kingdom, installation must be in accordance with the latest edition of the gas safety (installation & use) regulations. In the republic of ireland, installation must be in accordance with all national and local regulations in for...

Page 41

Is a heating appliance and certain parts of its surface will become hot. Do wait three minutes before attempting to relight if the fire is switched off or the flames are extinguished for any reason. Your fire is fitted with a safety device which will automatically shut off the gas supply to the fire...

Page 42: Appliance Dimensions

Appliance dimensions page 42 © baxi heating u.K. Limited 2008. Figure 1. Appliance dimensions and clearances (fire dimensions are subject to manufacturing deviation). Fascia may differ from that shown. Key description model ultimate & sonnet camden & seattle a appliance height (mm) 607 607 b applian...

Page 43: Gas Consumption

Gas consumption model 541 has a maximum natural gas input of 3.65kw (gross) has a maximum natural gas output of 2.8kw has a minimum natural gas input of 1.5kw (gross) has a minimum natural gas output of 1.13kw operating your fire the pilot may be left alight. It is advisable, however, that the pilot...

Page 44: Cleaning Your Fire

To light the main burner. Partially depress the right control knob and turn to the main burner position marked . The main burner should now light at its low position. The left-hand knob is for burner flame adjustment. Turning it anticlockwise should gradually increase the flame height and heat outpu...

Page 45: Warranty And Service

Warranty and service standard warranty terms & conditions the warranty is for 12 months subject to contract. In the united kingdom servicing can be carried out either by a heateam service engineer or a corgi registered installer. You must register your fire with heateam, the service division of baxi...

Page 46

When calling heateam, it would be helpful if you could have the following information to hand:- 1. Fire serial number and fascia code (located on the information label - see figure 4 on page 51). 2. Date of installation. 3. Your installer name and address details. 4. Fire make and model number. 5. P...

Page 47

Page 47 © baxi heating u.K. Limited 2008. Owner guide.

Page 48

© baxi heating u.K. Limited 2008. Page 48 owner guide.

Page 49

Page 49 © baxi heating u.K. Limited 2008. Owner guide.

Page 50

Page 50 © baxi heating u.K. Limited 2008. Owner guide installer details (block capitals) installer name corgi registration number. Company name. Company address company telephone number company fax number to be completed by installer:.

Page 51

Page 51 © baxi heating u.K. Limited 2008. Brand (please tick) baxi valor wonderfire other........................ D d m m y y date of installation fascia code - can be found close to the information label (block capitals) model serial number (can be found on the information label - see figure 4) a l...

Page 52

© baxi heating u.K. Limited 2008..