L egend g4 4002252-06 ©2011, miles industries ltd. Direct vent gas insert 780in (ng) & 780ip (lpg) installation and owner’s manual warning: if the information in these instructions is not followed exactly, a fi re or explosion may result causing property damage, personal injury or loss of life. What...

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed dealer. Each valor fi replace is fully tested during the production process for your safety and comfort. Your unit has been professionally installed b...

3 safety and your fireplace safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with ...

= updated content ◊ ◊ ◊ ◊ ◊ ◊ ◊ table of content safety and your fireplace .............................................................................3 safety and warning information...................................................................5 specifi cations ..................................

Safety and warning information children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others...

X x safety and warning information ratings model ng lpg gas natural propane altitude (ft.)* 0-4,500 feet* input maximum (btu/h) 30,000 28,000 input minimum (btu/h) 6,500 14,500 manifold pressure (in w.C.) 4.0 10.5 minimum supply pressure (in w.C.) 5.0 11.0 maximum supply pressure (in w.C.) 10.0 14.0...

Overview this appliance may only be installed in an existing unaltered, functioning solid-fuel burning fi replace with a working fl ue and constructed of non-combustible material. Do not install into combustible construction. This appliance is not approved for installation with a zero clearance kit....

33” (838 mm) 24” (610 mm) 15” (381 mm) 15” (381 mm) 4” (102 mm) 3” (76 mm) 3” (76 mm) 3” (76 mm) 10” (254 mm) 23” (584 mm) gas line access alternate gas line access hole. 12” (305 mm) of flex protruding from sheet metal box if using this access hole. Gas line approx. 24“ (610 mm) of flex protruding ...

9” (229 mm) a b non-combustible hearth with optional fan: depth +3” (76 mm) do not put furniture or objects within 36” (914 mm) of the front of appliance sidewall clearances minimum distance from side of appliance (liner box) to combustible wall: 9” (229 mm). Mantel projection a 1” (25 mm) 4” (101 m...

3” liners 3” min. Bend radius terminal cap flashing 2 x 3” fl ex liners—see venting table for length allowed existing fi replace and chimney typical vent installation see list of approved venting accessories on page 38 of this manual. Note: flexible co-linear vent pipes may only be installed into ex...

Installation planning installer—read this first 1. You need to know from the homeowner what accessories (surround, screen, fan/blower, etc.) will be installed with this fi replace; 2. Unpack the appliance. 3. Check that you have everything. 4. Clean cavity, chimney, ash dump, and clean-out. 5. Insta...

Unpacking the appliance beware of sharp edges! Wear gloves! 1. Unpack the appliance. 2. Unpack any loose items from around the appliance and check against the pack content list provided in the documentation package. 3. Remove the window and set aside in a safe place to avoid damage—see next page. 4....

Appliance preparation fan installation if the 795cfk circulating fan kit (blower) is to be installed, we suggest that you do it now. The fan cavity is accessible from the back of the fi rebox to facilitate its installation. If the fan is retrofi tted after the installation of the appliance, the appl...

Venting installation important: this appliance’s venting system is room sealed and therefore, does not require room air to be used in the combustion process. 1. Rough-in two 3” diameter vent liners into the existing chimney system from the roof. Be careful not to tear or damage the liners in the pro...

Supply gas installation the gas supply inlet connection is a 1/2” npt female. Gas shut-off valve supplied on the end of stainless steel fl exible connector. Flex connector is located on the left hand rear corner of the appliance. Use only new black iron or steel pipes or copper tubing if acceptable—...

Front view, left side top view, left side flex connector redirected using one elbow. Flex connector redirected using two elbows. Common fi ttings required (not supplied) 3/8” elbow + short 3/8” nipple or 3/8” street elbow(s) (where al- lowed) 1. Remove fl ex connector. 2. Remove fl ared connector. 3...

Ceramic panels installation the following guidelines apply for all brick liners. 1. Remove the rear log support (3 screws). 2. Remove the front brick support. 3. Inside the fi rebox, on the top of each side, release the screw of the side brick anchors (one per side) just enough to allow them to rota...

Ceramic panels installation 9. Reinstall the front brick support. 10. Reinstall the rear log support (3 screws). Its rear edge rests on the rear brick support ledge. Ceramic logs installation for ceramic rocks, see next section. Unpack the ceramic logs very carefully to avoid damaging the fragile ma...

Ceramic logs installation 2. Place the black glass piece on top of the burner and move it forward to rest in the grooved recess of the grate and center it. The glass should not hang over the space between the burner and the rear log. 3. Identify the left log and place it over the peg on top of the r...

6. Identify the top right log. It is the longest of the two remaining logs. Place its wider end on the front right log’s peg and rest its narrow end in the notch on the rear log. 7. Place the top left log’s wider end on the peg of the front left log and rest its narrow end in the notch on the rear l...

Ceramic rocks installation for ceramic logs, see previous section. Unpack the ceramic rocks very carefully to avoid damaging them. Install the rocks as shown. Please note that the position of some of the rocks identifi ed in the following instructions is critical to ensure proper performance of the ...

14 11 9 7 4. Each rock is embossed underneath with a number and an arrow indicating its position. The arrow points to the front of the fi replace when the rock is installed. See the image at the beginning of this section to help you identify and position the rocks. 5. Identify rocks number 1, 2, 3, ...

Window refi tting 1. To refi t the window, place it in its bottom railing and rotate its top against the fi rebox. 2. While you hold it, pull the side levers back into the window brackets on each side. 3. Pull out the top of the window and release it to ensure the springs return it. 4. Apply light h...

Remote control initial set-up the receiver and the handset of the remote control system must be initially synchronized before the fi rst use. 1. Remove the cover of the battery box (1 screw). 2. Insert alkaline batteries in the battery box and handset. 3. Refi t the cover and secure with the screw. ...

Side shrouds installation operation check & aeration settings adjustment operation check turn the fi replace fl ame up and down using the remote control to confi rm that the full range of inputs is achieved—see the remote control operation instructions on pages 30-35. Aeration settings light the fi ...

Packing contents: 1 wall bracket a 2 screws b 1 screw c 2 wall anchor d 1 spacer e (detach before assembly) 1 wall bracket f switch plate alternative 1 alternative 2 alternative 3 remote control handset wall holder installation the remote control kit for this fi replace comes complete with a wall-mo...

Cleaning important - glass cleaning - mineral deposits one of the by-products of the combustion process in a gas appliance is a mineral which can show up as a white fi lm on the ceramic glass of the viewing door. The composition of the deposit varies widely from various locations and also from time ...

Owner’s information checks a periodic check of the pilot and burner fl ames should be made. Check after the fi re has been on for at least 30 minutes. The pilot fl ame must cover the tip of the thermocouple probe. The main burner fl ame pattern will vary from appliance to appliance depending on the ...

Manual on/off switch wall switch (optional) remote control handset off on owner’s information 4. Replace the 4 aa batteries. 5. Replace the cover and screw in place. 6. Reconnect the battery box. 7. Put the battery box back in its position. 8. Reinstall the left access door. Lighting, operation and ...

When the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position). Standby mode (pilot flame) • p...

Setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance at pilot fl ame. • for fi ne ...

• - nighttime setback temperature mode (appliance must be in standby mode; pilot ignited) - the room temperature is measured and compared to the nighttime setback temperature. The fl ame height is then automati- cally adjusted to achieve the night- time setback temperature. • - timer mode (appliance...

Setting the “nighttime setback” temperature default settings: (moon), “ -- ” (off) • press (large fl ame) button to increase nighttime setback temperature. • press (small fl ame) button to decrease nighttime setback temperature. • press off or simply wait to complete programming. • briefl y press se...

• briefl y press set button to scroll to timer (moon) while the time fl ashes. • press (large fl ame) button to set the hour. • press (small fl ame) button to set the minutes. Setting p2 on time • briefl y press set to scroll to timer mode (sun) while the time fl ashes. • follow the instructions giv...

Remote control operation options venting (required) see approved venting accessories listed on page 35. Liner (required) 786lsl—ledgestone liner set 787ebl—enamel black liner set 788fbl—fluted black liner set 789vrl—valor red brick liner set fuel bed (required) 781rsk—rock set 782lsk—log set front (...

Lighting instructions warning : if you do not follow these instructions exactly a ¿re or exslosion pay result causinj sroserty dapaje sersonal inmury or loss of life )ij )ij )ij a for your safety, read before lighting a. This appliance has a pilot which must be lighted by hand or by remote control. ...

Red yellow wiring diagram remote battery box optional fan control module 4 aa batteries gv60 max wiring diagram optional wall switch kit 1265wsk connector 37 installation.

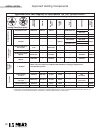

Approved direct vent suppliers for valor models 739, 780, 785 and rf24dv venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries t ermination caps v ertical standard co-axial 46dva-vc...

Warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in mater...

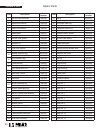

Spare parts code description part number 1 exhaust slide assembly 4002287 2 exhaust slide gasket 4000176 3 restrictor enclosure 4002330 4 metal strip 4002329 5 restrictor assembly 4002333 6 coil spring 4002605 7 rod support 4002331 8 cover 4002289 9 access panel gasket 4002664 10 access plate 400251...

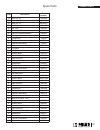

Spare parts code description part number 74 rock no. 16 4002659 75 rock no. 17 4002660 76 rock no. 18 40026461 77 lh twig 4001827 78 rh twig 4001828 79 ceramic platform—sand 4002439 80 platform support assembly 4002663 81 liner panels—complete set a ledgestone 786lsl b enamel black 787ebl c ceramic ...

Spare parts 1 2 3 - 7 8 9 10 11 12 13 14 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 - 57 79 80 81 82 83 84 85 86 87 ng lpg 15 16 - 23 24 25 26 27 - 32 33 33a 34 35 33b 38 39 36 37 25a 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 41a 42 owner’s info.

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed dealer. Please circle where appropriate - ask your installer or your dealer if in doubt. The information provided will be used for customer records on...

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.