M adrona ©2011, miles industries ltd. Engine to be installed only with the cast stove body mfcs01 or mfcs02 4001917-09 manufactured by miles industries ltd., british columbia, canada www.Valorfi replaces.Com warning: if the information in these instructions is not followed exactly, a fi re or explos...

2 the information contained in this installation manual is believed to be correct at the time of printing. Miles industries ltd. Reserves the right to change or modify any information or specifi cations without notice. Miles industries ltd. Grants no warranty, implied or stated, for the installation...

3 safety and your fireplace safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with ...

4 table of contents safety and your fireplace .............................................................................3 safety & warning information ......................................................................5 specifi cations .............................................................

5 safety & warning information children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others...

6 operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the full height of the fi ...

7 safety & warning information 1. Detailed instructions for the installation of the venting system design or the venting system components; and 2. A complete parts list for the venting system design or venting system. (d) manufacturer requirements - gas equipment venting system not provided. When th...

8 specifi cations approval & codes this appliance is certifi ed to ansi z21.88-2009/ csa 2.33-2009 american national standard / csa standard for vented gas fireplace heaters for use in canada and usa, and to cga 2.17-91 high altitude standard in canada . This appliance is for direct vent installatio...

Gas inlet position 3/8” fem. Npt x gas inlet position 3/8” fem. Npt x supplied with top vent; fi eld convertible to rear vent 9 dimensions & clearances inlet collar Ø 6-5/8” exhaust collar Ø 4” 17-7/8” 28-1/2” 23” 7-1/2” 27-1/2” 14” 30-1/2” 25-1/8” center line hearth requirements this unit is approv...

10 dimensions & clearances corner clearances wall clearances mantel / shelf clearances min. 5” between combustible wall and stove min. 5” between combustible wall and stove min. 6” between combustible wall and side of stove min. 5” between combustible wall and rear of stove 17-7/8” 28-1/2” 40-1/2” m...

11 venting top / rear outlet this unit is shipped with a top outlet collar which is fi eld-convertible to rear outlet—see page 21 for details. Vent material this unit is approved for installation using 4 by 6-5/8 inches co-axial direct vent pipe and accessories—see list of approved venting pipes and...

12 snorkel required (min. 14” high) with horizontal run through the wall (no rise) venting through wall (without vertical rise) typical venting components see list of approved venting pipes and accessories on pages 37–38. Through wall (with vertical rise) through roof maximum pipe length: 24” (strai...

5 x 90º elbows maximum restrictor 75 no restrict ors example 1 no installation no installation v3 restrictor 50 2 4 6 8 10 12 14 16 18 20 13 venting allowable vent confi gurations example 1 v value = v1 (6’) + v2 (6’) + v3 (2’)= 14’ h value = h1 (3’) + h2 (3’) = 6’ 75% restrictor required vertical r...

14 venting restrictors some installations require restrictors . For improved fl ame picture and performance, this unit is supplied with two different sets of vent restrictors. The level of restriction required depends on the vertical rise in the venting system and, to a lesser degree, the horizontal...

15 venting key vent terminal locations - minimum distances minimum clearance inches cm a clearance above grade, verandah, porch, deck or balcony 12 30 b clearance to window or door that may be opened 12 30 c clearance to permanently closed window (recommended to prevent condensation on window) 12 30...

16 installation planning fan (blower) allow for and install electrical wiring if there will be a blower to install. Ask the homeowner if you are not sure. Venting confi guration this unit is supplied with a top outlet and is fi eld convertible to a rear outlet. Plan routing of vent taking into consi...

17 appliance preparation %rowv appliance’s foot print x 4 detail window & log pack 1. Release the spring bolts at top and bottom of the window by pushing and turning 1/4 turn. 2. Lift the window and set it aside in a safe place to avoid damage. 3. Remove the log pack from inside the fi rebox and set...

18 appliance preparation detail engine flip the base upside-down. Place the engine on the base at its approximate fi nal position—see detail below. Center the engine using the holes at front of the base as guidelines. Casting side panels on the casting side panels, release the top and bottom screws....

19 appliance preparation 3/8” gas line connection 5/16” fl are fixing casting side panels & engine 1. Adjust the position of the engine to locate the top and bottom screws of the side panels into the slots of the engine’s side bracket. Tighten the top and bottom screws. 2. Adjust the engine as requi...

20 appliance preparation fasten thermal switch to underside of burner module using 2 existing screws optional fan (blower) if the circulating fan kit (blower) is to be installed, we suggest that you do it now. 1. Take the fan out of its package. 2. Remove the mounting plate from the fan and discard ...

21 appliance preparation venting outlet if the appliance is to be vented from the top, it is ready for vent installation once the engine is on the casting base. If the appliance is to be vented from the rear, it must be converted. Follow these simple steps: 1. Remove the following parts in this orde...

22 supply gas installation • the gas supply inlet connection is a 3/8 inch npt female connector. For detailed location of this connector see the drawing on page 8. If a circulating fan or isolating valve is to be installed, adjust the routing of the gas line to suit. • use only new black iron or ste...

1. Place the rear log centering it side to side in the fi rebox. Position forward until it sits against the sheet metal return behind the burner. 2. Place the front left log on top of the burner with its front edge resting slightly on the window frame. 3. Place the front right log on the top of the ...

24 window refi tting x 4 to refi t the window, place it on the fi rebox frame and hold it in place while pushing and turning its fastening studs 90 degrees. Then, apply light hand pressure against the window frame sides to bed-in the window seal. Remote control initial set-up the receiver and the ha...

25 front & top installation front installation hook the cast front to the side brackets located between the engine and the cast sides. Cast front hook details engine side bracket air shutter operation check turn the fi replace fl ame up and down using the remote control to confi rm that the full ran...

26 top casting place the top casting piece on the top of the stove ensuring the rear edge is fl ush with the rear edge of the cast side panels. Fill in the vent space with the infi ll plate if using a rear vent. To level the top casting, unscrew the levelling bolts on the top rear of each casting si...

27 owner’s information read the safety information on pages 3 and 5 of this manual. Operating your stove for your safety, this appliance is fi tted with a fl ame supervision device which will shut-off the gas supply if, for any reason, the pilot fl ame goes out. This device incorporates a fi xed pro...

28 owner’s information dust can be brushed from the ceramic logs and fi rebox walls after removing the front unit and opening the win- dow. Dust can also be removed from the burner using a soft brush after removing the ceramic logs. When cleaning, make sure that no particles are brushed into the slo...

29 owner’s information servicing if any attention is required for your appliance, contact your supplier quoting the model number. It will be helpful if the appliance serial number can also be quoted. This number is on the rating plate, which is attached to the unit. The replacement parts are shown a...

30 remote control operation when the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position). St...

31 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance a...

32 remote control operation setting the on / off temperatures • briefl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temperatur...

33 remote control operation setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the ic...

34 remote control operation options stove casing (required, choose one) mfcs01—madrona stove kit standard black mfcs02—madrona stove kit majolica brown venting 551dvk—direct vent kit, for horizontal terminations with vertical rise. See also venting accessories listed on pages 37–38. Other kits (opti...

35 lighting instructions warning : if you do not follow these instructions exactly a ¿re or exslosion pay result causinj sroserty dapaje sersonal inmury or loss of life )ij )ij )ij a for your safety, read before lighting a. This appliance has a pilot which must be lighted by hand or by remote contro...

36 wiring diagram optional wall switch kit 1265wsk connector red yellow gv60 wiring diagram installation.

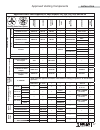

37 approved direct vent suppliers for valor models 530, 534, 535, 650, and mf28 venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries t ermination caps horizontal co-axial kit, 26” ...

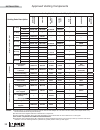

38 venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — black 46dva-06b 4dt-06(b) tc-4dl6b sv4l...

39 warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in ma...

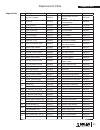

40 replacement parts 1 2 3 4 5 6 7 8 9 description part no. Description part no. Black majolica black majolica 1 base 4000926ah 4000926mj 6 fret 4000935ah 4000935mj 2 top panel 4000928ah 4000928mj 7 lh side panel 4000931ah 4000931mj 3 leg (4) 4000929ah 4000929mj 8 infi ll plate 4000927ah 4000927mj 4...

41 description part no. Description part no. 1 log set complete 4001916 32 hooked olive for pilot injector 720a196 2 rear log 4001932 33 olive nut—pilot pipe to pilot assembly 420k385 3 front left log 4001933 34 electrode 720a543 4 front right log 4001934 35 electrode retaining nut 720a200 5 right c...

1 2 3 4 5 6 7 42 replacement parts 8 9 10 11 50 75 12 13 14 16 17 20 21 66 18 22 65 ng lpg 23 24 27 25b 25a 28 37 29 31 36 32 33 34 35 38 39 40 42 41 43 44 45 46 47 48 52 53 51 54 49 55 56 64 63 62 62a 58 57 59 60 30 26a 26b 50 15 19 owner’s info.

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed dealer. Please circle where appropriate - ask your installer or your dealer if in doubt. The information provided will be used for customer records on...

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.