4001754-20 p ortrait installation & owner’s manual dv gas fireplace heater 530iln/ilp (logs), 530icn/icp (coals), 530irn/irp (rocks) this manual contains instructions to install the en- gine only. A front trim kit is required to install the engine as it affects the framing cavity and posi- tion of t...

2 table of contents designed and manufactured by / for miles industries ltd. 190–2255 dollarton highway, north vancouver, bc, canada v7h 3b1 tel. 604-984-3496 fax 604-984-0246 www.Valorfi replaces.Com the information contained in this installation manual is believed to be correct at the time of prin...

3 safety precautions ! Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and others may be ...

4 safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with a hot glass surface can ca...

5 owner’s information operating your fireplace for the first time when operating your new fi replace for the fi rst time, some vapors may be released due to the burning of curing compounds used in the manufacture of the appliance. They may cause a slight odor and could cause the fl ames to be the fu...

6 cleaning your fireplace important - glass cleaning - mineral deposits one of the by-products of the combustion process in a gas appliance is a mineral which can show up as a white fi lm on the ceramic glass of the viewing door. The composition of the deposit varies with location and time. It is be...

7 owner’s information thermocouple probe must be in flame correct fl ame appearance with logs with coals with rocks 7. If the hot glass warning plate has been removed from the front lower corner of the window, reinstall it by sliding it between the glass and the frame as indicated. 8. Reinstall the ...

8 on off wall switch (optional) manual on/off switch thermostatic remote control locating lighting, operation and rating information plate the lighting, operation and rating information is located on a plate under the fi rebox. To access the plate, remove any fret or access panel and grab the plate ...

9 remote control operation when the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position). Sta...

10 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance a...

11 remote control operation setting the on / off temperatures • briefl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temperatur...

12 remote control operation setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the ic...

13 options automatic turn down automatic shut off low battery indication handset / receiver match remote handset: the battery icon will show when the battery needs to be replaced. Replace with one 9 v alkaline battery. Receiver: three short ‘beeps’ will sound when the motor turns when the batteries ...

14 lighting instructions warning : if you do not follow these instructions exactly d¿uhruh[sorvlrqpd\uhvxowfdxvlqj surshuw\gdpdjhshuvrqdolqmxu\ruorvvriolih )lj )lj )lj$ for your safety, read before lighting a. This appliance has a pilot which must be lighted by hand or by remote control. Follow thes...

15 state of massachusetts carbon monoxide detector/vent terminal signage requirements for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth...

16 commonwealth of massachusetts (d) manufacturer requirements - gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identifi es “special venting systems”...

17 specifi cations approvals and codes this appliance is certifi ed to ansi z21.88–2014/csa 2.33–2014 american national standard/csa standard for vented gas fireplace heaters for use in canada and usa. The appliance complies with csa p4.1-09, testing method for measuring annual fi replace effi cienc...

18 dimensions, clearance and framing the dimensions, clearances and framing vary with each applications and with the front trim installed. Refer to the installation instructions of the front trim chosen for more information. Venting warning hot hearth / floor! The hearth or fl oor in front of the fi...

19 venting all horizontal pipe runs must be graded 1/4 inch per foot upwards in the direction of the exhaust fl ow. The fi nal pipe length, when terminating through the wall may be graded downwards slightly to prevent water migration. 10” (254 mm) 10” (254 mm) align the vent center to the center of ...

20 horizontal termination 2-piece wall thimble horizontal termination 2-piece wall thimble pipe length pipe length pipe length pipe length 817vak 817vak pipe length 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination typical co-axial venting c...

21 important installer notice – weather sealing & vapor barriers it is the installer’s responsibility to ensure that vent installations through exterior walls are caulked and weatherproofed in such a manner as to: • prevent rain water from entering the wall from the weather side by adequately caulki...

22 horizontal vent termination location • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airfl ow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that mus...

23 use 845tg vent guard with a vent terminal located at less than 7’ (2.13 m) above grade v1 v2 h1 h2 1” min. All around vertical pipe 3” min. Above top of horizontal pipe 1” min. Around bottom & sides of horizontal pipe 817vak adapter required for top or rear outlet 530 heater max. 24” before elbow...

24 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 2 4 6 8 10 12 14 16 top or rear outlet 1 1 3 5 how to read the venting chart the chart below applies to co-axial roof or wall termination in installations with vertical rise. See page 23 for installations with no vertical rise. 1. The total ...

25 co-axial venting attaching air restrictors—appliances with vertical vent rise only no restrictors are required for appliances which only have a horizontal vent run. If installing an appliance which has a rear vent outlet connection and no vertical vent pipe rise, ignore this stage. Two restrictor...

26 ‘h’ horizontal overhang vertical wall termination cap storm collar roof flashing plumber’s tape fixed to wall strap wall strap ceiling firestop ceiling support offset elbows min. 18” overhang should not extend beyond vent if within 48” of termination cap min. 24” (unvented soffit) min. 36” (vente...

27 co-linear venting co-linear venting into existing solid-fuel burning fireplaces and chimneys see venting accessories list on pages 41–42 for allowable components. Co-linear adapter may be installed as top or rear outlet—see page 30. • co-linear and co-axial venting may be combined in a single ven...

28 co-linear venting alternate to 556cla/559clt/559fsk conversion for vertical termination co-axial to co-linear adapter 10” 10” 3” inlet & exhaust collars 7-5/8” dia. Collar 559fsk flashing kit 559clt co-linear vertical ter- minal terminal cap co-linear to co-axial adapter flashing 720swk sidewall ...

29 convert from rear outlet to top outlet (co-axial venting) if installing with rear vent outlet, go to next step. 1. Remove the top plate and seal by unscrewing 12 screws. Keep the seal, plate and screws for fi tting to the back. 2. Remove the rear outer vent collar and seal by unscrewing 12 screws...

30 prepare vent outlet co-axial installations 1. Fit the adapter 817vak over the appliance vent collars pushing on fi rmly. Align the adapter so that the seam on horizontal pipes is not at the bottom—check by temporarily fi tting a pipe. 2. Drill through the adapter outer tube and appliance outer co...

31 installation connect gas supply • it’s preferable to rough-in the gas line at this point before proceeding with the fi rebox installation. • the appliance is supplied for supply gas connection at the control valve. Supply line connection to the control valve of the appliance is 3/8 inch npt (fema...

32 installation install ceramic walls (530il and ic only) the 530il and 530ic engines are provided with a set of reversible walls. One side shows the brick pattern and the reverse side shows a black vertical fl uted pattern. Follow the instructions below to install the wall set on the chosen side. •...

33 installation install ceramic logs (530il) 1. Place the base log on the supports in the fi rebox and against the support at the fi rebox back. 2. Locate the rear upper log on the two ceramic pins at the rear of the base log. 3. Place the front log behind the metal strip at the front of the fi rebo...

34 installation install ceramic coals (530ic) 1. Place the base coal on the supports in the fi rebox and against the fi rebox back. 2. Place the left front coal in position behind the metal lip at the front of the fi rebox. The side projection on this coal should be near the middle front of the fi r...

35 installation install ceramic walls and rocks (530ir) the ceramic rock set is packed in three cartons. Unpack each piece carefully to avoid damages. You should have in hand the following items: carton 4001879 • ceramic platform carton 4002055 • left and right side reversible brick/fl uted ceramic ...

36 installation to get the optimal fl ame effect, it is important to place the rocks in their appropriate position. Each rock is embossed underneath with letters and an arrow indicating the position of the rock. The arrows point to the front of the fi replace when the rock is installed. See the imag...

37 installation refi t and check window 1. Place the window centrally against the engine unit and resting on the support at bottom front of the engine. 2. Pull the clamping bars forward and rotate inwards to secure the top of the window. 3. Fit the two spring loaded bolts through the bottom of the w...

38 installation open open close close ng flashback shield (for lpg only) lpg air shutter slider open close lpg ng air shutter slider & cover check operation turn the fi replace fl ame up and down using the remote control to confi rm that the full range of inputs is achieved—see the remote control op...

39 packing contents: 1 wall bracket a 2 screws b 1 screw c 2 wall anchor d 1 spacer e (detach before assembly) 1 wall bracket f switch plate alternative 1 alternative 2 alternative 3 installation install remote control handset wall holder the remote control kit for this fi replace comes complete wit...

40 wiring diagram optional wall switch kit 1265wsk connector red yellow gv60 wiring diagram qualified installer.

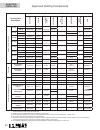

41 approved venting components approved direct vent suppliers for valor models 530 6 , 534, 650 and mf28 venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm termination caps horizonta...

42 approved venting components venting parts description venting parts code / availability by manufacturer dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries bdm pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — 94610606 black ...

43 warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in ma...

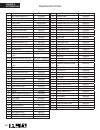

44 replacement parts code description part no. 1 side wall support (2) 330a898 2 rear wall support 320b320 4 velcro strip 4000022 5 port cover 4000828ah 6 inner vent collar 340b174 7 inner vent collar seal 620b973 8 top vent collar seal 568399 9 top vent cover plate 330a902 10 wall bracket spacer (2...

45 1 2 4 5 6 7 8 9 10 11 12 13 14 19 20 21 22a 22b 23 24 25 26 27 28 29 30 31 33 32 34 35 36 38 39 40 41 42 44 43a, 43b 45 46 47 48 41a 41b ng lpg 16a 16b 15a 15b replacement parts 44a 49 owner’s information.

46 51 52 53 54 55 56 57 58 59 60 61 62 63 50 replacement parts 64 65 66 67 69 73 71 74 72 75 76 77 78 79 80 81 70 68 for 530irn/p only for 530iln/p and icn/p owner’s information.

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed installer. Please fi ll in the information below. The information provided will be used for customer records only. Online warranty registration at www...

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.