- DL manuals

- Valor

- Indoor Fireplace

- Vogue 1300ILN

- Installation & Owner's Manual

Valor Vogue 1300ILN Installation & Owner's Manual

V

OGUE

4001746-14

©2011, Miles Industries Ltd.

Manufactured by

MILES INDUSTRIES LTD.,

British Columbia, Canada

www.valorfi replaces.com

Ce guide est disponible en français sur demande.

DV ZC Gaz Fireplace

1300ILN/P (Logs) & 1300IRN/P (Rocks)

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light the appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certifi ed kit is used.

This appliance is a domestic room-heating

appliance. It must not be used for any other

purposes such as drying clothes, etc.

This appliance is suitable for installation in a

bedroom or bed sitting room.

Installation & Owner’s Manual

Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity

of this or any other appliance.

Installation and service must be performed

by a qualifi ed installer, service agency or the

gas supplier.

This appliance may be installed in an

after-market permanently located,

manufactured (mobile) home where not

prohibited by local codes.

I N S TA L L E R

L e a v e t h i s m a n u a l

w i t h t h e a p p l i a n c e .

C O N S U M E R

R e t a i n t h i s m a n u a l

f o r f u t u r e r e f e r e n c e .

Massachusetts: The piping and fi nal

gas connection must be performed by a

licensed plumber or gas fi tter in the State of

Massachusetts. Also, see Carbon Monoxide

Detector requirements under “Safety and

Warning Information” on page 6.

Please read this manual BEFORE installing

and operating this appliance.

HOT GLASS

WILL

CAUSE BURNS.

DO NOT TOUCH

GLASS

UNTIL COOLED.

NEVER

ALLOW CHILDREN

TO TOUCH GLASS.

Summary of Vogue 1300ILN

Page 1

V ogue 4001746-14 ©2011, miles industries ltd. Manufactured by miles industries ltd., british columbia, canada www.Valorfi replaces.Com ce guide est disponible en français sur demande. Dv zc gaz fireplace 1300iln/p (logs) & 1300irn/p (rocks) warning: if the information in these instructions is not f...

Page 2: Caution—Hot! Hot! Hot!

2 caution—hot! Hot! Hot! This appliance is a heating appliance and it becomes very hot when in operation. Under any circumstances, do not place any object, furniture, draperies or other item less than 36 inches (0.9 m) in front of the fireplace. Children and pets radiant heat can heat surfaces such ...

Page 3: Safety And Your Fireplace

3 safety and your fireplace safety and your fireplace please follow these important child safety precautions and recommendations, • parts of your valor fireplace become extremely hot while in operation. • the glass viewing window temperature can exceed 500 f at full capacity. Momentary contact with ...

Page 4

4 safety and your fireplace .............................................................................3 safety and warning information...................................................................5 specifi cations .................................................................................

Page 5

5 safety and warning information children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children and othe...

Page 6

6 hot surfaces . Be aware that, although safe, some combustible materials and fi nishes, even though installed at listed clearances may, over time, shrink, discolor, warp or show cracks. The 1300i requires the installation of the cement board provided with the engine. Convective heat will exit the u...

Page 7

7 safety and warning information 1. Detailed instructions for the installation of the venting system design or the venting system components; and 2. A complete parts list for the venting system design or venting system. (d) manufacturer requirements - gas equipment venting system not provided. When ...

Page 8

8 ratings model n p gas natural propane altitude (ft.)* 0-4,500 feet* input maximum (btu/h) 30,000 28,000 input minimum (btu/h) 6,500 14,500 manifold pressure (in w.C.) 3.7” 10.5” minimum supply pressure (in w.C.) 5” 11” maximum supply pressure (in w.C.) 10” 14” main burner injector marking cat # 82...

Page 9

9 overview fire on/off wall switch (optional) mantel—see mantel clearances hearth. Non-combustible as required—see framing & hearth requirements for clearance optional decorative light dimmer switch—not provided, see your electrician s s s s s s s surrou d d d nd p p p p l l l la t t te ( ( ( ( if i...

Page 10

10 dimensions location enter c ine li x x 6-5/8” dia. Venting 21-5/8” 43” 32-1/2” 26” 2 1-1/8 ” 21” 6 -3 /8” 7 -1 /2 ” 37-1/2” t o t o p of c ement boar d 36 ” to u n d er si d e o f he ad er electrical (for optional ambient light only) electrical (for optional ambient light only) zero clearance to ...

Page 11: Left Side View

11 combustible mantel—left side view mantel clearances bottom of unit face of finished wall four-sided trims, if used - extend below bottom of unit (for dimensions, see instructions packaged with trim) 0 2” 4” 6” 8” 10” 12” 38” 36” 34” 32” 29” 26” 21-1/8” do not put furniture or objects within 36” (...

Page 12: Top View

12 2” 1” 4” 5” 3” 2” 1” 4” 5” 3” 32-1/2” fireplace opening wall min. 6” between edge of opening and wall face of finished wall note right side clearances are the same shading denotes allowable location for combustible mantel legs combustible sidewall / mantel leg—top view mantel clearances fireplace...

Page 13

13 rules 1. When using a 3-sided surround plate or no surround plate, any hearth/fl oor in front of fi replace less than 2 inches from bottom of unit must be non-combustible and project a minimum distance of 9 inches. The hearth/fl oor must have a non-combustible fi nish applied over the 1/2 inch in...

Page 14

14 framing & hearth requirements framing dimensions with hearth surface of combustible floor or carpet #1335 three-sided trim is flush with bottom of appliance. Wood is allowed directly below fireplace surface of combustible floor or carpet e-sided trim is flush bottom of appliance. Wood is allowed ...

Page 15

15 venting vent material this unit is approved for installation using 4 x 6-5/8 in co-axial direct vent pipe and accessories as listed in the approved venting components table on pages 44–45 of this manual. Follow the installation instruc- tions supplied with the individual venting accessories. This...

Page 16: Vapor Barriers

16 co-axial venting horizontal termination 2-piece wall thimble pipe length pipe length pipe length pipe length 90˚ elbow ceiling firestop attic firestop attic insulation shield flashing storm collar vertical termination important installer notice – weather sealing & vapor barriers it is the install...

Page 17: Allowable Co-Axial

17 how to read the venting chart the chart below applies to co-axial roof or wall termination. 1. The total length of the vent pipe cannot exceed 40 feet. 2. The minimum vertical height with roof termination is 6 feet. 3. Any combination of rise and run can be used as long as they are within the all...

Page 18

18 restrictor all installations require a restrictor for improved fl ame picture and performance. This unit is supplied with a pre-fi tted restrictor having four different positions or settings. The level of restriction required depends on the vertical rise in the venting system and, to a lesser deg...

Page 19

19 vent termination • the vent terminal must be located on an outside wall or through the roof. • this direct vent appliance is designed to operate when an undisturbed airfl ow hits the outside vent terminal from any direction. • the minimum clearances from this terminal that must be maintained when...

Page 20

20 co-axial venting 10-1/2” (267 mm) 3” (76 mm) 7-1/2” (191 mm) 7-1/8” (181 mm) conversion to co-linear liners using generic co-linear adapters co-linear portion of vent system may only be installed within a solid-fuel burning fi replace and chimney. The appliance must not be connected to a chimney ...

Page 21

21 installation planning installer—read this first 1. You need to know from the homeowner: - the height of the fl oor or hearth fi nish; - the thickness and type of the wall fi nish around the fi rebox opening; - what accessories (trim, decorative lighting, remote control wall switch, etc.) will be ...

Page 22

22 appliance preparation unpacking the appliance to assist you, we have included the cement that may be required in the installation. The boards may need to be removed and reinstalled. One of the boards is fi xed temporarily to the back of the appliance for transportation purpose. When disassembling...

Page 23

23 appliance preparation option 1—with 1335 or 1337 trims (narrow), appliance flush to framing • sheet metal front face of the appliance is fl ush with the framing studs. • cement board required on top and on each side of the appliance’s opening. • additional fi nishes such as tile, etc., can be but...

Page 24: No Wall Finish

24 appliance preparation fixing the appliance to the framing 1. Screw the appliance to the fl oor or wood surface with 4 countersunk wood or cement screws (not provided). 2. Screw the appliance to the side studs from the inside of the appliance case behind the side doors—1 screw each side. Note: fas...

Page 25

25 window removal the window is held in place by a spring-loaded lever on each side. 1. To remove the window, locate the levers on each side of the window towards the top. Using your fi nger, pull the lever towards you and unhook it from the window frame bracket. 2. Gently pull the top of the window...

Page 26

26 supply gas installation the unit is supplied with a stainless steel fl ex line to allow the appliance to be disconnected for service. The fl ex line is supplied loose to avoid damage during shipping. Connect the fl ex to the appliance valve as shown below. An individual shut-off valve (not suppli...

Page 27

27 ceramic liners installation the following guidelines apply to all liners. 1. Inside the fi rebox, on the top of each side, release the screw of the side brick anchors (one per side). 2. Place the rear panel against the back of the fi rebox, behind the retainer at bottom. 3. Hold the left hand sid...

Page 28

28 logs installation (1300il) please note that the position of the logs is critical to insure proper performance of the appliance. 4. Identify the right cross log; it has a hole under on of its end and it is the shortest cross log. Place it on the right pin located on the rear log. Rest its other en...

Page 29

29 1. Place the cast platform in the fi rebox locating it’s rear feet in the holes on the bottom of the fi rebox as indicated. 2. Place the ceramic rock base inside the cast platform. Make sure that it sits against the tabs behind the burner as indicated. Ceramic base to sit against tabs behind burn...

Page 30

30 3. The underside of each ceramic rock is identifi ed by a number and a specifi c protruding positioning triangle. Install the six rocks from left to right starting with rock no. 1. 4. Place the left twig across the second and third rocks from the left ; rest its end on the edge of the platform as...

Page 31

31 window refi tting 1. To refi t the window, place it in its bottom railing and push its top against the fi rebox. 2. While you hold it, pull the side levers back into the window brackets on each side. 3. Pull out the top of the window and release it to insure the springs return it. 4. Apply light ...

Page 32

32 operation check & aeration settings adjustment operation check turn the fi replace fl ame up and down using the remote control to confi rm that the full range of inputs is achieved—see the remote control operation instructions on pages 37–41. Aeration settings light the fi re and allow the unit t...

Page 33

33 owner’s information read the important safety information on pages 3 and 5 of this manual. Operating your fireplace for your safety, this appliance is fi tted with a fl ame supervision device which will shut-off the gas supply if, for any reason, the pilot fl ame goes out. This device incorporate...

Page 34

34 owner’s information pilot flame can be seen between logs (1300il) or left of the fi rst rock (1300ir) pilot flame correct flame picture— logs correct flame picture— rocks thermocouple probe must be in flame to refi t the window: 1. Place it in its bottom railing and push its top against the fi re...

Page 35

35 owner’s information batteries low battery signal: see page 41. Before changing the batteries, turn off the valve using the manual on/off switch — see instructions next page. The appliance uses four 1.5 v aa alkaline batteries for its remote control receiver and one 9 v alkaline battery for its ha...

Page 36

36 owner’s information wall switch (optional) manual on/off switch on off thermostatic remote control wall switch manual on/off switch remote control handset fireplace control devices there are three ways to control your fi replace. 1. Thermostatic remote control; 2. Wall switch (optional); 3. Manua...

Page 37

37 remote control operation when the pilot is off, it will take 2 minutes before it can be lit again. To turn on appliance to turn off appliance flame height adjustment • on the valve, turn man knob on the on, full counterclockwise position. • place on/off switch (if equipped) in i (on position). St...

Page 38

38 remote control operation setting the time setting ºc/24-hour or ºf/12-hour clock modes of operation note: manual mode can also be reached by pressing either the (large fl ame) or the (small fl ame) buttons. • press and hold (small fl ame) button to decrease fl ame height or to set the appliance a...

Page 39

39 remote control operation setting the on / off temperatures • briefl y press set button to scroll to temp (sun) mode. Hold the set button until the temp fl ashes. • press (large fl ame) button to increase the daytime set temperature. • press (small fl ame) button to decrease daytime set temperatur...

Page 40

40 remote control operation setting program timers • you can program two periods of time between 12:00 am and 11:50 pm in each 24-hour cycle. • the programs p1 and p2 must be set in the following order during a 24-hour cycle: , , and . • the icon indicates the beginning of the period (on) and the ic...

Page 41

41 options ceramic liners (required) 1340cbl—ceramic black fl uted liners 1350ebl—enamel black liners trims (required) 1335mtb—three-sided black trim 1335mtp—three-sided polished trim 1337mfb—four-sided black trim 1337mtp—four-sided polished trim 1365fsp—four-sided surround polished 1365fsb—four-sid...

Page 42

42 lighting instructions warning : if you do not follow these instructions exactly a ¿re or exslosion pay result causinj sroserty dapaje sersonal inmury or loss of life )ij )ij )ij a for your safety, read before lighting a. This appliance has a pilot which must be lighted by hand or by remote contro...

Page 43

43 wiring diagram optional wall switch kit 1265wsk connector red yellow gv60 wiring diagram installation.

Page 44

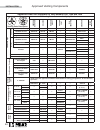

44 approved direct vent suppliers for valor models 1200, 1300 and 1500 venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries t ermination caps horizontal co-axial kit, 26” long — — ...

Page 45

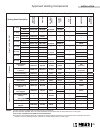

45 venting parts description venting parts code / availability by manufacturer simpson dura-vent selkirk icc excel direct secure vent rlh industries amerivent miles industries pipes 4” x 6 5/8” ( id x od ) 6” long galvanized 46dva-06 4dt-06 tc-4dl6 sv4l6 — — — black 46dva-06b 4dt-06(b) tc-4dl6b sv4l...

Page 46: Lor

46 warranty 1. Extended warranty coverage for a period of up to ten (10) years, miles industries ltd., (the “company”) or its appointed distributor will at its option pay the initial purchaser for the repair of, or will exchange the following parts or components which are found to be defective in ma...

Page 47

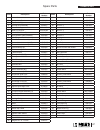

47 code description part number 1 intake collar 4000925 2 intake collar gasket 4000942 3 top standoff (2) 4001906 4 air inlet duct assembly 4002021 5 front brick support 4001849by 6 rear log support 4001854by 7 side brick anchor (2) 4001283 8 lh explosion relief assembly 4001286 9 rh explosion relie...

Page 48

1 2 3 4 5 6 7 8 9 10 53 59 36 11a,11b pilot assy 12a to 18 19a, 19b 22a, 22b 24 module plate gaskets 25 to 28 33 29 34 ng lpg 21a 21b 20a 20b 68 67 60 61 62 61 64 65 66 54 55 57 56 58 39 40 41 42 43 44 38 37 45 46 30 31 32 32a 49 50 51 52 47 48 spare parts owner’s info.

Page 49

Thank you ... For purchasing a valor by miles industries. Your new radiant gas heater is a technical appliance that must be installed by a qualifi ed dealer. Please circle where appropriate - ask your installer or your dealer if in doubt. The information provided will be used for customer records on...

Page 50

Tape shut thank you for choosing a valor product postage needed miles industries ltd. 190 - 2255 dollarton highway north vancouver, bc v7h 3b1 canada fold here online warranty registration at www.Valorfi replaces.Com.