- DL manuals

- Valtra

- Tractor

- T144

- Operator's Manual

Valtra T144 Operator's Manual

Summary of T144

Page 1

Operator's manual t series hitech ref no 39 892 21 3 ( 08/2015 ) your working machine.

Page 3

About this manual this operator's manual is for the valtra t series hitech tractors. The t series hitech models are t144 h, t154 h, t174e h, t194 h, t214 h and t234 h. The manual is meant for agricultural tractors only. If the tractor is used for other applications, it is the owner's responsibility ...

Page 4

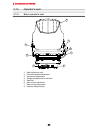

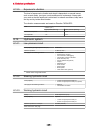

Tractor serial numbers when ordering spare parts or service, give the model indication and serial numbers and, in some cases, the engine, front axle, cab and transmission numbers. 2 5 3 1 7 6 4 guid-83fd881f-92c4-4883-87a2-fefa9521c800 1. Cab number and type plate eec • model = model indication • id...

Page 5

Contents about this manual........................................................................................1 tractor serial numbers.................................................................................2 1 safety precautions..............................................................

Page 6

2.12 air conditioning controls.....................................................................................54 2.12.1 automatic air conditioning and additional heater controls................................54 2.12.2 manual air conditioning and additional heater controls.........................

Page 7

3.7 power outlets..................................................................................................... 97 3.7.1 lighter and power outlets.................................................................................97 3.7.2 using the two-pin current socket and power switch...........

Page 8

3.10 proline instrument panel display......................................................................142 3.10.1 fixed views.....................................................................................................142 3.10.2 single-row and two-row views..................................

Page 9

3.12.13.1 using the drive balance control ............................................... 178 3.13 three-point linkage.......................................................................................... 179 3.13.1 attaching implements...............................................................

Page 10

3.21.3 hydraulic pick-up hitch................................................................................... 228 3.21.4 using the pickup hitch.................................................................................... 230 3.21.4.1 unlatching the pick-up hitch .............................

Page 11

4.7.3 weekly maintenance......................................................................................273 4.7.3.1 greasing the rear linkage......................................................... 273 4.7.3.2 checking the pick-up hitch........................................................2...

Page 12

4.7.6.4 checking the engine vibration damper..................................... 330 4.7.6.5 maintaining the air conditioning................................................ 330 4.8 checks and adjustments..................................................................................331 4.8.1 cha...

Page 13

6.5 tyres................................................................................................................383 6.5.1 wheel nut tightening torques..........................................................................383 6.5.2 wheel stud dimensions.......................................

Page 14

1 safety precautions always follow the safety precautions given when working with the tractor. The regulations given do not release the operator from statutory and other national regulations regarding traffic safety and occupational health and safety. In addition to the precautions given in this man...

Page 15

Important: after maintenance work, all replacements for parts with a safety sign on them must include also the new safety sign. 13 23 14 15 9 10 20 5 21 18 16 16 18 6 2 8 8 guid-d80034fc-c7f4-4349-8b02-554747a5597b 1. Safety precautions - 13 -.

Page 16

17 25 1 11 19 4 26 22 12 27 7 3 24 guid-64799c1a-46b6-4665-82e2-95bd37bc93d9 1 caution: instructions on avoiding injuries during startup, driving and maintenance. Located inside the cab, below the left-hand side c-pillar. 2 warning: country-specific warning concerning handling of the battery and its...

Page 17

3 sign indicating the location of emergency brake. Located inside the cab, next to the right-hand side control panels. 4 sign indicating an emergency exit. Located inside the cab on the rear window and on the right-hand side window. 5 danger: country-specific warning that the battery and its accesso...

Page 18

9 caution: during the connection of the front linkage to the shut-off valve, there must be no load on the front linkage or a rear implement connected to the same valve. The warning sign is located next to the shut-off valve at the back of the tractor. 10 country-specific warning concerning jaw locki...

Page 19: Atención

14 warning: country-specific sign indicating the standard distances related to pto driveline. Located at the back of the tractor, on the left rear wheel mudguard. “b” “c” “d” “a” 400mm (15.85 in) 400mm (15.85 in) acv0279640 400mm (15.85 in) 400mm (15.85 in) “b” “c” “d” “a” atenciÓn pueden producirse...

Page 20

16 warning: the sign warns against several dangers: • exposed fan which can crush and cut • surfaces which can be hot • exposed belt drive which can cause severe injury located under the bonnet, on both sides of the radiator. 17 country-specific notification concerning the reverse drive system. Loca...

Page 21

19 warning: country-specific sign notifying that the seat belt must be used when driving the tractor. Located behind the passenger seat. AtenciÓn use el cinturÓn de seguridad mantenga su cinturón ajustado cómodamente no salte si el tractor vuelca 39661600 20 warning against standing directly behind ...

Page 22

22 country-specific warning concerning cabin tightness. Located in the cab, on the left side of the front housing. 23 country-specific signs located at the back of the tractor, on the left rear mudguard. Danger: only approved parts in their correct position can be used for pulling. Danger: all equip...

Page 23

25 country-specific safety signs located on the front housing, next to the fire extinguisher. Brand- släckare pulverslÄckare uppluckra pulvret minst en gång per vecka. Kontrollera att manometern står på grönt. 26 country-specific notification concerning tractor approval. Located in the cab, on the f...

Page 24

• brakes • always check before driving that the brakes are working. • after attaching a trailer, check that the brakes are working. • lock the brake pedals together whenever individual wheel brakes are not required and always when driving on the road. • extensive repairs to the braking system should...

Page 25

• emergency exits familiarise yourself with the three emergency exits of the tractor cab, that is, the door, the rear window and the roof hatch. If necessary, the right-side window can be broken and used as emergency exit. The windshield is polycarbonate and cannot be easily broken. When the tractor...

Page 26

• roof hatch 3 4 5 1 2 guid-ba2c1723-eb95-4628-8964-6805ecbe1b9a 1. Direction for releasing the lock 2. Direction for detaching the spring 3. Safety sign for using the emergency exit 4. Gas springs with quick locks 5. Handle • pull open the sunshade. • turn the handle to unlock the hatch. • release ...

Page 27

• emergency brake use the emergency brake only in emergency situations if braking with brake pedals is not possible. Warning: turning the ignition switch to (off) position cannot be used as an emergency brake. The emergency brake operates only when the power is switched on. Warning: emergency brake ...

Page 28

• front linkage warning: when the front linkage is being connected to the rear valve, make sure there is no load on the front linkage or rear implement connected to the same valve. The load on the front linkage or rear valve implement discharges when the shut-off valve lever is turned. This may caus...

Page 29

• hot surfaces caution: be careful of hot surfaces during operation and service work, in particular the engine and hydraulics components. • fuel-operated heater warning: during the heating period, clean the exhaust pipe of the fuel-operated heater daily and its surroundings monthly. In dusty conditi...

Page 30

• use handrails, grab handles and steps when getting in and out. • do not use control levers as a handhold. • do not step on the pedals when getting in and out. • park the tractor carefully before you get out of the cab. • stop the tractor. • apply the parking brake and make sure that the parking br...

Page 31

Warning: when driving the tractor with an attached implement with the centre of gravity far from the tractor, the tractor may sway considerably during cornering. The tractor may tip over or the load may be displaced. 1.2.5.5 driving downhill be careful when driving downhill. • check the brakes often...

Page 32

Warning: before entering between the tractor and the implement, prevent the tractor from moving by applying the parking brake or blocking the wheels. There is a risk of accidents if the tractor or implement should move. Warning: implements attached to the linkage or the auxiliary hydraulic system mu...

Page 33

Guid-8924d3b6-ebb0-42ec-b132-a9a189e79d81 1.2.5.8 running with power take-off driven implements or machines read and follow the given instructions to use power take-off (pto) driven implements and machines safely. Danger: serious accidents may occur due to failure to use the prescribed safety device...

Page 34

1.2.5.10 towing read and follow the given instructions to tow a trailer or an implement safely. Warning: when the tractor is towing a trailer, the brake pedals must be locked together. The brakes are not to be used individually for steering. Warning: when using a trailer, make sure that the hitch la...

Page 35

• stop the engine and lower the implement to the ground when leaving the tractor. • do not let passengers ride in the tractor unless it is provided with a special seat. Other personal transport, for example on front-mounted loaders, is not permissible. • do not let passengers ride on the platform in...

Page 36

1.2.5.14 aftertreatment system the selective catalytic reduction (scr) aftertreatment system contains copper- zeolite. Copper-zeolite is not classified as hazardous. The scr aftertreatment system is installed in the muffler. The system is not hazardous to health under normal use and handling. When t...

Page 37

1.2.5.16 repair and maintenance during repair and maintenance work, all the applicable safety precautions and maintenance instructions have to be followed. The engine has to be stopped and the implements lowered before any maintenance work. Support if the maintenance work requires supporting the tra...

Page 38

2 instruments and controls 2.1 one-key locking system there is one key for locking and unlocking all the locking devices of the tractor. • ignition switch • door handle lock • fuel tank cap lock • adblue tank cap lock • engine hood lock • battery housing lock a replacement key is available from your...

Page 39

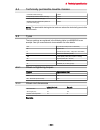

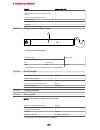

2.3 dashboard 6 11 12 13 14 10 16 17 2 3 4 5 7 8 5 20 30 40 50 0 5 0 20 25 30 1 9 15 guid-93386ada-df9c-4082-aa9e-a69b37ac3c27 1. Power shuttle lever 2. Preprogramming push button 3. Lever for adjusting steering wheel position 4. Steering wheel 5. Multifunction lever 6. Proline instrument panel 7. 3...

Page 40

2.4 control panel for a-pillar display and proline 5 20 30 40 50 0 5 0 20 25 30 1 2 3 4 5 6 guid-983cd1d6-7614-41b0-8d19-1e07fb1000a9 1. Proline instrument panel selection 2. Arrow up 3. A-pillar display selection 4. Back 5. Arrow down 6. Set / selection note: moving back in the selection menu autom...

Page 41

1. Fuel gauge 2. Coolant temperature gauge 3. Indicator lights for turn signal 4. Tachometer 5. Speedometer 6. Indicator light for the high beam 7. Proline instrument panel display the fuel gauge shows the amount of fuel left in the tank. The coolant thermometer indicates the engine temperature. The...

Page 42

Symbol function l/h avg l/h immediate fuel consumption average fuel consumption fuel consumption lower link position (%, 0-100) gearbox temperature (c/f) travel distance (m/km/miles) square area (ha) reset counters reset 2.5.2 indicator lights on the left side of the display 5 20 30 40 50 0 5 0 20 2...

Page 43

Indicator light indication guid-9ecac14d-0d4e-4140-a7e0- ef644a757258 Ʃ-indicator light (optional on models t144, t154, t174e). The light is lit continuously (yellow) when the tractor is operating in the higher power range and using pto. Guid-578f4fb0-505c-4c35-8a38- a986a78bbdaf glow indicator ligh...

Page 44

Indicator light indication guid-5e3e430f- f6c2-4c78-85f1-385620 934cd2 stop indicator light (red). The light flashes to indicate serious fault. Possible reasons: • engine oil pressure too low • engine temperature too high (gauge) • gearbox oil pressure too low • gearbox oil temperature too high impo...

Page 45

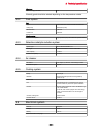

2.6 controls on the right-hand side 2.6.1 driving controls au to contr ol stop 1 2 4 6 7 8 9 10 11 12 13 14 15 3 5 16 guid-8c1cef16-6823-4d2c-a55c-ff1a3a6a4f35 1. Emergency brake button 2. Push button for ecopower (optional) 3. Switch for four-wheel drive (4wd) 4. Switch for differential lock 5. Pus...

Page 46

2.6.2 linkage 2.6.2.1 rear linkage au to contr ol stop 3 4 5 6 7 12 13 8 11 10 9 1 2 guid-03d8f571-4616-40ec-a8c8-6aa42e34a58f 1. Lowering indicator light 2. Lifting indicator light 3. Diagnostic light 4. Lowering speed selector 5. Max lifting height selector 6. Draft control selector 7. Lifting/low...

Page 47

1 guid-455cafdd-a21e-4be9-8210-17fbb7098005 1. Control lever, auxiliary hydraulics valve 4 2.6.3 power take-off 2.6.3.1 rear power take-off au to 1 2 3 4 guid-58d1863a-cea0-4bcc-8786-aa68bbaf4dc1 1. Button for rear pto automatic start/stop 2. Speed control knob for rear pto 3. Switch for rear pto wh...

Page 48

2.6.3.2 front power take-off the front power take-off (pto) is optional. Au to 1 guid-3c1bbace-be65-409b-93e7-cdb09819b187 1. Switch for front pto 2. Instruments and controls - 46 -.

Page 49

2.6.4 auxiliary hydraulics the following instruments and controls are used to control the auxiliary hydraulics. Au to 6 7 1 2 3 4 5 guid-bff32da7-7c29-4c75-a103-be2b2186d589 1. Control lever for auxiliary hydraulics rear valve 1 2. Control lever for auxiliary hydraulics rear valve 2 3. Control lever...

Page 50

2.6.5 other controls 1 2 3 4 5 6 7 8 9 10 guid-5c89bba1-a7f1-4194-bbf7-6038c3690154 1. Power outlet (optional) 2. 3-pin current socket 3. 3-pin current socket (optional) 4. Isobus terminal connector (optional) 5. Isobus bus extension connectors (behind the cover; optional) 6. Implement signal connec...

Page 51

2.7 controls on the rear side 2.7.1 rear window opening latch 1 guid-6b43c7c5-a73c-48e8-ae3a-7a8465d12a09 1. Rear window opening latch 2.7.2 additional wipers 1 2 3 guid-815ff11e-1be7-4131-828e-7f42bd38d28c 1. Rear window wiper switch (optional) 2. Side window wiper switch (optional) 3. Roof window ...

Page 52

2.7.3 rear drive pedal the rear drive pedal is optional. 1 guid-e9dfc9e1-786e-472a-93fe-ddb47f0a3543 1. Drive pedal 2.8 controls on the left-hand side the following controls are positioned on the left-hand side. 1 2 3 4 5 7 1 6 guid-cbeeb308-1f37-4109-a69a-8eabaddb4497 1. Storage compartment 2. Cool...

Page 53

2.9 controls on the right-hand side roof console the following controls are positioned on the right-hand side roof console. Ok 1 2 1 2 3 4 6 7 8 9 l r 10 5 guid-b1111944-fcc4-43fe-a805-f7a93d5177b2 1. Radio (optional) 2. Air conditioning controls 3. Tachograph (optional) 4. Mirror adjustment knob (o...

Page 54

2.10 controls on the skyview equipment right-hand side roof console the following controls are positioned on the skyview equipment right-hand side roof console. 1 2 3 4 5 6 7 9 8 guid-aa4bd9ef-08c4-43d7-a6ab-20b82efdd7fb 1. Mirror heating switch (optional) 2. Mirror adjustment knob (optional) 3. Tel...

Page 55

2.11 working light controls 1 2 3 4 5 6 7 8 9 guid-f64de483-75ff-4d51-9a29-17bda57edd55 1. Light panel on/off button 2. Front working lights 3. Front waist working lights (optional) 4. Rotary beacon light (optional) 5. Rear working lights 6. Automatic operation of the rear working lights 7. Trailer ...

Page 56

2.12 air conditioning controls 2.12.1 automatic air conditioning and additional heater controls the automatic air conditioning and additional heater system is optional. Auto auto ° c 1 2 4 5 3 6 7 guid-ddf9f4a0-689e-45e8-b4aa-5455ed35a00d 1. Fan speed control knob (selection off/auto/manual) 2. Defr...

Page 57

2.12.3 manual air conditioning the manual air conditioning system is optional. 1 2 3 guid-0913c775-1dda-46df-9676-d334471a4a4e 1. Off/fan speed control knob 2. Air conditioning on/off 3. Temperature control knob 2.12.4 heater controls 1 2 guid-dc873987-32c9-48b4-88ec-c1ce9002d57d 1. Off/fan speed co...

Page 58

2.13 operator's seat 2.13.1 basic operator's seat 4 5 1 6 2 7 3 8 guid-4ad10f3d-c4fe-4339-8312-d184f682ae7c 1. Seat belt anchor point 2. Forward/backward adjustment 3. Suspension adjustment 4. Storage compartment for manuals 5. Seat belt 6. Back rest tilt adjustment 7. Seat turning lock/release 8. O...

Page 59

2.13.2 air suspended operator's seat air suspended operator's seat is optional. Off on 2 3 4 1 6 5 7 8 9 10 11 12 guid-a31c2e34-3dbb-4e21-95e9-79f162b07db4 1. Seat depth and cushion angle adjustment 2. Headrest height adjustment and removal 3. Seat heating 4. Storage net for manuals 5. Seat turning ...

Page 60

2.14 controls on the rear mudguard on/off 1 2 guid-47c6ae52-9d4f-437a-ba5e-92a482751a34 1. Rear power take-off on/off push button (optional) 2. Lifting/lowering push button 2. Instruments and controls - 58 -.

Page 61

2.15 front end controls and connections front linkage and front quick couplings are optional. 3 4 1 5 2 guid-69fcd1f6-d695-4ebf-9a06-0554487c5e11 1. Engine bonnet lock 2. Trailer socket (optional) 3. Lifting/lowering push buttons for the front linkage (optional) 4. Front valve 1 push buttons (option...

Page 62

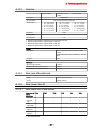

2.16 rear controls and connections outside the cab stop 1 2 3 5 7 8 9 11 12 13 14 15 16 17 18 19 20 21 22 23 24 4 25 10 6 guid-df6737df-6f37-4232-9177-b0aa92b824f6 1. Trailer coupling, duo-matic (optional) 2. Trailer coupling, 2-line system (optional) 3. Trailer coupling, 1-2-line system (optional) ...

Page 63

5. Emergency stop plug for rear power take-off (pto) 6. Front linkage shut-off valve (optional) 7. Top link 8. Top link/lower link ball storage bracket 9. Quick couplings, auxiliary hydraulics 10. Flow control adjustment (optional) 11. Auxiliary hydraulic system return coupling 12. Quick coupling fo...

Page 64

3 operation 3.1 running the tractor in the tractor is run in during the 50 first hours of use. Running the tractor in correctly gives the tractor a longer service life and makes it more economical. Before you start driving, make sure that: • you understand all the instruments and the functions of th...

Page 65

Caution: do not attempt to adjust the seat while driving. There is an increased risk of loss of control. 4 5 1 6 2 7 3 8 guid-4ad10f3d-c4fe-4339-8312-d184f682ae7c 1. Seat belt anchor point 2. Forward/backward adjustment 3. Suspension adjustment 4. Storage compartment for manuals 5. Seat belt 6. Back...

Page 66

• adjust the suspension. The operator weight display shows the settings for operators of different weights. • to increase the suspension, turn the suspension adjustment lever clockwise. • to decrease the suspension, turn the suspension adjustment lever counterclockwise. • adjust the height of the se...

Page 67

Off on 1 2 6 3 4 5 8 7 10 9 11 12 13 14 15 guid-415af9f9-7272-4394-9e91-e403fb5e4ef0 1. Armrest adjustment (air-suspended +) 2. Storage compartment (air-suspended +) or net (air-suspended) for manuals 3. Seat heating 4. Lumbar support adjustment (air-suspended +) 5. Seat depth and cushion angle adju...

Page 68

• turn the seat. • release the lock by pulling the lock/release lever upwards. • turn the seat to the desired position. The seat can be turned between 190° anti-clockwise and 90° clockwise. The seat can be locked to set positions at 10°, 20°, 80° and 90° when turning clockwise and 10°, 20°, 180° and...

Page 69

• fasten the seat belt to the anchor points on the seat. • adjust the backrest inclination. • pull the backrest inclination lever up. • set the backrest to the desired position. • adjust the armrest. • remove the cover. • change the armrest position in the mounting slot. • adjust the lumbar support....

Page 70

• set the steering wheel rake. • press the locking pedal down. • adjust the steering wheel rake to the desired position. • release the pedal. 3.2.4 adjusting standard mirrors you can adjust the position of the standard mirrors manually. 1 guid-84d4c889-6dc1-407f-86da-ffd8196a71c1 1. Locking device o...

Page 71

• adjust the mirrors. • to adjust the left mirror, turn the knob to the left and push the knob in the direction of the arrows. • to adjust the right mirror, turn the knob to the right and push the knob in the direction of the arrows. • adjust the telescopic mirrors. • to shorten/extend the left tele...

Page 72

3.2.7 using the windscreen wiper and washer 5 20 30 40 50 0 5 0 20 25 30 1 guid-50d64ecd-35d1-4cd7-a725-22439e1bbc6d 1. Multifunction lever • to use the windscreen wiper, turn the multifunction lever. The wiper has an intermittent position and two speeds. • to use the windscreen washer, push the lev...

Page 73

3.2.9 using the rear window wiper and washer the rear window wiper is extra equipment. The switch for the rear window wiper and washer is located on the c-pillar. 1 guid-c6b05d9e-0c0c-45f0-b379-df47a9625461 1. Rear window wiper switch • to use the rear window wiper, turn the switch. The wiper has an...

Page 74

3.2.11 using the window heaters windscreen and rear window heaters are optional equipment. 1 l r 2 guid-7a9e3401-c437-4b39-926d-f669934af04b 1. Windscreen heater button 2. Rear window heater button when the windscreen or rear window heater is on, the light on the button is lit. • to switch on the wi...

Page 75

3.2.12 power shuttle lever with the power shuttle lever you can change the driving direction and apply the parking brake. 1 guid-f9baa5c6-a67b-4a8f-8a35-2c4e78b77a27 1. Power shuttle lever • f (front position) = forward driving direction • n (centre position) = neutral • r (rear position) = reverse ...

Page 76

3.2.13 control stop the control stop is used when the tractor is running an implement in stationary mode (for example a compressor or pump) and the operator is not in the cab. Using the control stop reduces the risk of more serious damage to the engine or in the transmission. The control stop is ext...

Page 77

4 5 6 1 2 3 guid-3396b664-6140-46de-9a14-d68094fd1b08 1. Ignition switch 2. Ignition key 3. Off position 4. Acc position 5. Power on position 6. Start position • turn on the power by turning the ignition key from the (off) position to the (power on) position. In cold conditions, when the engine is c...

Page 78

3.2.16 main power the main power is controlled by the ignition switch. The main power is automatically turned on when you turn the ignition key to other than the (off) position. When you turn the ignition key to the (off) position, the main power is turned off after a delay. During this delay, data ...

Page 79

• if neither light is lit, the main power emergency button status is off. • if the green light is lit, the main power emergency button status is on. • if the green light is blinking, the main power is shutting down with the delay. • if the red light is blinking, the red button has been pressed while...

Page 80

1. Open the roof hatch. • slide the sun shade open by pulling it backward. • turn the handle to unlock the roof hatch. • push the roof hatch open. 2. Close the roof hatch. • pull the roof hatch closed. • turn the handle to lock the roof hatch. • slide the sun shade closed by pushing it forward. 3.3 ...

Page 81

5 20 30 40 50 0 5 0 20 25 30 1 2 3 4 5 6 guid-354237ec-2de8-4cc4-9efd-94f1a0f0a031 1. Engine oil pressure 2. Stop light (is flashing) 3. Gearbox oil pressure 4. Four-wheel drive 5. Parking brake 6. Battery charging 1. Apply the parking brake. 2. Turn the hand throttle to the low idling position. 3. ...

Page 82

9. Use the driving pedal to control the engine speed. Important: never race a cold engine. After starting a cold engine, the glow indicator light can light up again. The afterglow reduces white smoke and keeps the cold engine running smoothly. 3.3.2 starting under cold conditions to ensure a success...

Page 83

• if the temperature is below 0°c, first, warm up the engine and hydraulics oil for a while at low engine speed. Allow the engine to run for a few minutes before starting to drive or engaging the power take-off. When first starting to use hydraulic functions, use the predefined factory setting m2 to...

Page 84

3.4 using lights 3.4.1 using the light switch 5 20 30 40 50 0 5 0 20 25 30 2 3 4 5 1 6 guid-f7fda353-7370-4a14-90f4-292028a04b95 1. Rotary light switch 2. Off position 3. Parking lights 4. Headlights 5. Upper headlights 6. Multifunction lever • turn the light switch to the parking lights position to...

Page 85

• to turn on the high beams, pull the multifunction lever towards yourself. X130 1 guid-9bad42f5-6a0f-4b12-8234-9190c88a5f49 1. Connector x130 when the light switch is in the headlight position, the upper high beams (optional) operate as an additional high beams when the connector x130 (black wire 1...

Page 86

1 2 3 4 5 6 7 8 9 guid-f64de483-75ff-4d51-9a29-17bda57edd55 1. Light panel on/off button 2. Front working lights 3. Front waist working lights (optional) 4. Rotary beacon light (optional) 5. Rear working lights 6. Automatic operation of the rear working lights 7. Trailer hitch light (optional) 8. Re...

Page 87

5. Press the light panel on/off button again to switch off the light panel. The panel can be turned off also by switching off the parking lights. When the panel is turned off, the working light settings are saved and taken into use when the panel is turned on again. Note: the rotary beacon light (op...

Page 88

3.4.5 using the torch the torch (optional) is fitted in the holder in the cab's left b-pillar. 1 2 3 guid-ac92a84f-5eb5-4eff-a4ac-3c632f48ff45 1. Torch 2. Torch on/off button 3. Battery charge indicator light the magnet at the bottom of the torch allows you to attach it as a working light on differe...

Page 89

3.5 using notification devices 3.5.1 using turn signals 5 20 30 40 50 0 5 0 20 25 30 1 2 guid-425cf0c2-afb1-4410-8887-485a3207c6ba 1. Multifunction lever 2. Indicator lights for turn signals • to switch on the left-hand side turn signal, move the multifunction lever upwards. • to switch on the right...

Page 90

• to sound the horn, push the horn button. 3.5.3 using the rotary beacon light rotary beacon light is an extra equipment. 1 guid-6f8be120-48cf-48ff-aac3-af25a59c59b9 1. Button for rotary beacon light 1. Press the button for rotary beacon light to switch the beacon on or off. When on, the symbol on t...

Page 91

3.6 heating and ventilation 3.6.1 using the heater 1 2 guid-dc873987-32c9-48b4-88ec-c1ce9002d57d 1. Off/fan speed control knob 2. Temperature control knob • to regulate the speed of the fan, turn the fan speed control knob. • to regulate the temperature, turn the temperature control knob. 3.6.2 usin...

Page 92

3.6.3 using the manual air conditioning and additional heater the additional heater is optional equipment. 1 2 3 4 guid-a6f90b40-8a1f-47ee-8492-6e97052b878e 1. Off/fan speed control knob 2. Air conditioning on/off 3. Additional heater off/fan speed control knob 4. Temperature control knob 1. Press t...

Page 93

• defrost is connected • lo mode is connected • a different fan speed is selected manually 3.6.4.1 automatic air conditioning control panel and display control panel auto auto ° c 1 2 4 5 3 6 7 guid-ddf9f4a0-689e-45e8-b4aa-5455ed35a00d 1. Fan speed control knob (selection off/auto/manual) 2. Defrost...

Page 94

Displays the selected target temperature. If adjusted below 16°c, lo is displayed. If adjusted over 29°c, hi is displayed. Displays the additional heater fan status and speed (off, 1, 2, auto). Displayed when the eco mode (temperature control without the ac compressor switched on) is on. 3.6.4.2 usi...

Page 95

• to deactivate the air conditioning system, turn the fan control knob to the off position. 3.6.4.3 using eco mode use the air conditioning eco mode to regulate the cab temperature without the ac compressor. In the eco mode the system tries to achieve the target temperature by adjusting the water va...

Page 96

3.6.4.4 using the additional heater use the additional heater to blow air to the lower part of the cab. The additional heater operates automatically when the air conditioning is in the auto or eco mode. The additional heater has four modes: auto, fan speed 1, fan speed 2 and off. 1 2 3 4 auto auto °...

Page 97

• to activate defrost, press the defrost button. The led next to the button is lit. When defrost is active, the fan speed is at its maximum and the text hi is displayed. • to deactivate defrost, press the defrost button again. The defrosting button indicator led goes off, and the former air conditio...

Page 98

3.6.5.1 installing sim card to the mobile controlled heater 1 2 3 4 guid-ff2d0660-f2a9-40a4-84a5-88dadf7817bb 1. Screw 2. Gsm modem 3. Button 4. Sim card 1. Turn off the tractor power. 2. Open the cover of the electric centre. The gsm modem is fitted at the bottom of the electric centre. 3. Loosen t...

Page 99

3.7 power outlets 3.7.1 lighter and power outlets a lighter socket and power outlets provides an output of 12 v dc; 10 a at a maximum. 2 3 1 guid-47fee990-fdcd-4acb-a4f0-83a0544070f7 1. Lighter 2. Power outlet on the front console (optional) 3. Power outlet on the right-hand side (optional) 3.7.2 us...

Page 100

The 2–pin current socket on the left hand side and the power outlet at the rear end of the tractor is controlled with the power switch. • to connect the 2–pin current socket power, press down the symbol side of the switch. • to disconnect the 2–pin current socket power, press down the side of the sw...

Page 101

1 2 3 4 5 6 7 guid-61a1535a-eae5-4869-a7e2-359e3574bb25 1. Direction indicator left (yellow) 2. Ignition switch current, max. 10 a (blue) 3. Ground (white) 4. Direction indicator right (green) 5. Parking light right (brown) 6. Parking light left (black) 7. Brake light (red) socket at the front end t...

Page 102

1 guid-aa285d38-0574-4c34-a109-9a53ef8f8f00 1. Socket at the front end 3.8 driving the tractor 3.8.1 notifications about steering warning: if the engine stops while the tractor is moving (for example, the fuel has run out), do not press the clutch pedal down. When the tractor is moving and the trans...

Page 103

The operator detector prevents the shuttle engagement if you are not on the seat. If the direction is selected, the arrow of the selected direction flashes on the display panel. The selected direction does not engage until you sit on the seat and move the power shuttle lever to the parking brake pos...

Page 104

3.8.4 using the power shuttle lever 1 guid-f9baa5c6-a67b-4a8f-8a35-2c4e78b77a27 1. Power shuttle lever • f (front position) = forward driving direction • n (centre position) = neutral • r (rear position) = reverse driving direction • p = parking brake position 3. Operation - 102 -.

Page 105

• engage the parking brake: stop the tractor completely. Pull up the collar round the power shuttle lever and move the lever to the parking brake (p) position. P 2 1 guid-c8dbfd22-64c1-4bcb-b3e6-5fcfd5184ecd 1. Power shuttle lever 2. Collar the parking brake indicator light p on the instrument panel...

Page 106

3.8.5 adjusting the power shuttle engagement speed you can adjust the power shuttle engagement speed through the a-pillar display settings. The index determines how quickly the torque of the power shuttle increases to the maximum value when the clutch is engaged. The index affects both the f (forwar...

Page 107

4. Press the up arrow or the down arrow to select the index to be changed. The parameter number for power shuttle engagement speed is 30. 5. Press . Guid-fb646e44-586b-48d0-aadb-d48c6e76864a the second half of the bottom bar is lit to indicate that the parameter value is displayed. 6. Press the up a...

Page 108

3. Do not fully press the clutch pedal if you want the tractor to move very slowly. You can use this feature when attaching implements. Note: when using the clutch to move the tractor very slowly, the coupling point of the clutch may change and the clutch engages sooner. Warning: if the engine stops...

Page 109

3. Press to enter the index list. Guid-0ad867a6-2868-411a-b022-1581a78273b4 the first half of the bottom bar is lit to indicate that the index number is displayed. 4. Press the up arrow or the down arrow to select the parameter to be changed. The parameter number for clutch pedal engagement position...

Page 110

3.8.7 braking you can use the brake pedals differently in various working situations. 1 2 guid-34380ccb-ed6a-4430-aa9e-e55a3f6893ac 1. Latch for brake pedals 2. Brake pedals the tractor has two brake pedals which apply separately to the right and to the left side rear wheels. All four wheels are bra...

Page 111

Warning: turning the ignition switch to (off) position cannot be used as an emergency brake. The emergency brake operates only when the power is switched on. Warning: using the emergency brake releases traction. 1 guid-20e98088-37ae-4ca8-bc1a-2c89f0ea4720 1. Emergency brake button 1. Press the emerg...

Page 112

Warning: turning the ignition switch to (off) position cannot be used as an emergency brake. The emergency brake operates only when the power is switched on. Warning: using the emergency brake releases traction. 1 guid-46215538-d099-4ff4-83e7-87b43a797fe4 1. Emergency brake lever 1. Pull the emergen...

Page 113

2. If on a slope, press down the brake pedals to keep the tractor stationary. Important: engage the hillhold when starting on a slope. Otherwise the tractor jerks downhill before traction engages even if the driving direction is uphill. 3. Select the speed range and gear. Select a speed range which:...

Page 114

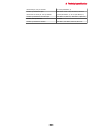

Speed range driving speed (40 km/h models) driving speed (50 km/h models) la 0.4-1.4 km/h 0.5-1.7 km/h lb 0.8-2.8 km/h 1.0-3.5 km/h a 1.9-6.9 km/h 2.4-8.6 km/h b 4.1-14.6 km/h 5.1-18.3 km/h c 6.0-21.4 km/h 7.5-26.8 km/h d 12.7-40 km/h 1) 16-50 km/h 2) 1) maximum speed with the engine speed of 1930 r...

Page 115

• shift the speed range up by pressing the speed range selection + button. You can change the speed range upwards by more than one step at a time, directly from a to d for example. A pop-up window indicating the speed range change appears on the display until the requested speed range has engaged. •...

Page 116

3.8.11.3 selecting the creeper speed range you can engage the creeper speed range with the speed range push buttons. 1 2 au to guid-d4e7a733-c112-4634-885f-617ed752142d 1. Speed range selection + button 2. Speed range selection - button important: engaging the creeper range is only allowed when the ...

Page 117

Of the selected powershift gear flashes on the a-pillar display until the requested powershift gear has engaged. Note: when turning the power on when it has been switched off for over 10 seconds, the powershift is always in the lowest stage. 1 2 au to guid-17e53104-2009-4201-8036-cdee0edf1a36 1. Pow...

Page 118

1 guid-0b056ba9-83f9-4539-b8a6-bd0df449a6f1 1. Gear and driving direction under preprogramming 1 au to 2 3 guid-47f50a7c-8649-4430-8a38-f56af60c8825 1. Powershift + and - button 2. Powershuttle lever 3. Preprogramming push button the engine must be running when you preprogram the powershift. Both di...

Page 119

• to preprogram the powershift gear: • start the engine. • press down the clutch and brake pedals to ensure safety. You can do the preprogramming also while driving. However, preprogramming the gears is not possible if either of the creeper gears is engaged. • select the driving direction f or r wit...

Page 120

Automatic shifting between the speed ranges c and d is possible if you have activated the c-d shifting automatics functionality in the a–pillar display transmission settings. Automatic shifting between the speed ranges a and b or b and c is not possible. If the c-d shifting automatics are selected a...

Page 121

• in the auto1 mode, set the desired driving speed with the drive pedal or hand throttle. The automatics adjust the engine speed and the correct powershift gear according to the driving situation and engine load. • in the auto2 mode, set the limits for shifting up and down via the a-pillar display. ...

Page 122

3. Press and use the arrow buttons to scroll to the desired engine speed limit value for shifting up. 1 guid-09a4f7b3-d255-452c-9c20-7529ab3b0922 1. Menu for setting the engine speed limit for shifting up note: the engine speed limit can be changed in the 1000-2400 rpm range. However, the upward cha...

Page 123

2. Press to enter the settings menu. Guid-2408e592-046c-4ca8-ac4b-6e1939c132a7 the text “ind” appears. 3. Press to enter the index list. 4. Scroll to the parameter to be changed with the up arrow or the down arrow. Guid-f1021bf3-538f-4eaa-8636-fe9382afe2b5 the parameter number for the limit of the a...

Page 124

• the ecopower mode reduces fuel consumption considerably. • in the ecopower mode, the maximum power and torque are achieved at approximately 200 rpm lower level than in the normal mode. • the maximum torque is higher in the ecopower mode. • you can activate or deactivate the ecopower mode in any si...

Page 125

5. Reduce the engine speed to idling. Important: before stopping the engine, allow the engine temperature to stabilise for at least two minutes. In some situations (for example, after working with a heavy load) when you engage the parking brake, the engine may perform cooling of the after- treatment...

Page 126

1. Open the fuel tank cap. 1 guid-495443fb-a0e5-4c63-827a-bd3cc2a4c459 1. Fuel tank cap 1 guid-ac446700-ea38-4d53-b0cb-47c6f5cf7f73 1. Forest equipment (optional) fuel tank cap 2. Fill the tank. 3. Close the fuel tank cap. 3. Operation - 124 -.

Page 127

Important: never put adblue/def in the fuel tank, as the engine and fuel system may become damaged. Important: never put fuel in the adblue/def tank. Even small amounts of fuel in the adblue/def tank may damage the gaskets of the selective catalytic reduction (scr) system. Important: do not start th...

Page 128

1. Open the adblue/def tank cap. 1 guid-86f38617-1130-417b-a911-1bf710b9a359 1. Adblue/def tank cap 1 guid-75dc3fc6-dfa0-4f60-bc06-aec472d7db46 1. Forest equipment (optional) adblue/def tank cap 2. Fill the tank. 3. Close the adblue/def tank cap. 3. Operation - 126 -.

Page 129

• as the adblue fluid is very corrosive, if the tractor is splashed with fluid, wipe off and rinse with water. • if an electrical connector is splashed with adblue fluid, it must be replaced. • crystals of adblue/def additive may appear on the vehicle in the event of spillage. Rinse immediately with...

Page 130

2 1 au to guid-19591e7c-8fa0-4392-b2de-cadb96c010fc 1. Hand throttle 2. Engine rpm memory button engine rpm memory button you can use this button to program values to rpm cruise control memory and to activate or deactivate the rpm cruise control. 3.8.15.2 programming the engine speed cruise control ...

Page 131

2. Press the engine rpm memory button shortly. The setting is activated and stored in the memory. The indicator light is continuously lit. 3.8.15.3 activating and deactivating the engine speed cruise control note: control the position of the hand throttle before deactivating the cruise control. 2 1 ...

Page 132

3.8.16 automatic traction control the automatic traction control allows you to stop the tractor using only the brake pedal so that you do not have to operate the clutch pedal or the power shuttle lever. Automatic traction control is useful in traffic and for example on jobs where you have to stop th...

Page 133

5 20 30 40 50 0 5 0 20 25 30 1 2 3 guid-6175e56d-3011-4ccf-b414-88d49050a654 1. Gauge 2. Air suspension bellows 3. Shock absorbers the operator can observe the air pressure in the whole air pressure system on the gauge. The suspension system has two air suspension bellows and two shock absorbers. 3....

Page 134

3.8.18 differential lock 3.8.18.1 differential lock the differential lock is used to ensure an even grip for the wheels by locking the rear wheels to rotate at the same speed. The differential lock can be engaged while driving. The differential lock has three positions: on, auto and off. On the diff...

Page 135

1 eco guid-46a07aa8-b569-42a6-8caa-0f51ebbf1cb7 1. Differential lock switch • to engage the differential lock, press down the symbol side of the differential lock switch (on). • to use the automatic function of the differential lock, turn the differential lock switch to the middle position (auto). T...

Page 136

• when starting to drive or using the power shuttle. • when pressing and releasing the clutch pedal while the driving speed is lower than 10 km/h. • when pressing and releasing the hishift push button while the driving speed is lower than 10 km/h. • the automatics disengage the 4wd after a defined d...

Page 137

3.8.20 driving start automatics 3.8.20.1 driving start automatics driving start automatics can be used to prevent the rear wheels from slipping while starting to drive or when changing the driving direction with the power shuttle. The driving start automatics engage the four-wheel drive automaticall...

Page 138

3. Press to enter the index list. Guid-be697bd3-8b95-4488-8292-a7f09dbab1da the first half of the bottom bar is lit to indicate that the index number is displayed. 4. Press the up arrow or the down arrow to change the index number. The index number for activating and deactivating the driving start a...

Page 139

3.8.20.3 setting the driving start automatics the driving start automatics is set through the a-pillar display settings. The index determines the time for how long (seconds) the four-wheel drive remains engaged when starting to drive. 1. Press to activate the a-pillar display. 2. Press to enter the ...

Page 140

5. Press . Guid-fb646e44-586b-48d0-aadb-d48c6e76864a the second half of the bottom bar is lit to indicate that the parameter value is displayed. 6. Press the up arrow or the down arrow to change the parameter value. The value ranges from 0–20. When the value is set to 0 seconds the driving start aut...

Page 141

3.8.21.2 using quicksteer 1. Quicksteer control knob 2. Quicksteer activation button 1. To turn the steering valve on, press the quicksteer activation button. The quicksteer activation button light is lit green, and the quicksteer symbol is displayed on the proline instrument panel. 2. Turn the quic...

Page 142

3.8.22.2 using hillhold important: engage the hillhold when starting on a slope. Otherwise the tractor jerks downhill before traction engages even if the driving direction is uphill. 1 guid-0d95fe0c-d403-4de7-8dce-06ead939e895 1. Symbols for hillhold when the hillhold is engaged, its symbols on the ...

Page 143

3.9 displays the tractor is equipped with the proline instrument panel display on the dashboard and the pillar display on the a-pillar. The displays give information on the power shuttle, driving speed, fuel consumption and so on. You can view and edit different values and setting parameters via the...

Page 144: 1.2 17:52

3.10 proline instrument panel display the proline instrument panel display shows information about different tractor functions. 5 20 30 40 50 0 5 0 20 25 30 1.2 17:52 1 2 25.7 10.7 guid-42a615b8-7fd7-4146-a11d-e712c5131640 1. Proline instrument panel display 2. Control panel for a-pillar display and...

Page 145

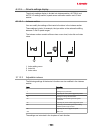

Operating hours operating hours are displayed in accuracy of one decimal place when the power is on. Clock the clock is displayed on the bottom row, either in 12-hour or 24-hour mode. You can change the time if it is not correct. 3.10.2 single-row and two-row views the proline instrument panel displ...

Page 146: 1.2 17:52

3.10.2.1 working time view the working time view shows how much time the tractor has spent on a specific task. The working time appears on the top or middle row of the display. 1.2 17:52 1:25 1 guid-f0301602-962e-4a4a-b5b6-12b9b6f9940a 1. Working time working time can, for example, show the time spe...

Page 147: 1.2 17:52

1.2 17:52 1650 1 2 0 guid-d0920a18-c78d-48a7-bb82-adb8c25a75da 1. Rpm = constant engine speed 2. Kmh = not in use the numerical value in front of the symbol stands for the value that has been saved for the constant engine speed. When the constant engine speed is engaged, the corresponding text shows...

Page 148: 1.2 17:52

3.10.2.5 rear power take-off speed view the rear power take-off (pto) speed is shown in revolutions per minute (rpm). 1.2 17:52 540 1 guid-341115a5-088f-44a7-bb56-74842f513735 1. Rear power take-off speed the pto rotation speed is shown beside the symbol with an accuracy of 10 rpm. 3.10.2.6 front po...

Page 149: 1.2 17:52

The view shows the engine speed with an accuracy of 10 rpm. 3.10.2.8 fuel consumption views the display shows different kinds of fuel consumption: instant and average fuel consumption on the area worked, instant and average fuel consumption in an hour and total fuel consumption. The instant fuel con...

Page 150: 1.2 17:52

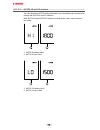

Total fuel consumption 1.2 17:52 257.7 1 guid-e15b10ab-fdbf-434d-8e9b-382dbe0f78b6 1. Total fuel consumption 3.10.2.9 rear lower links' position view the view shows the position of the rear lower links . 1.2 17:52 50 1 guid-d2673dee-e150-401f-8439-8e61709a3c22 1. Position of the rear lower links the...

Page 151: 1.2 17:52

The gearbox temperature is displayed as follows: • when the temperature is below +40°c (+104°f), the text "lo" is displayed. • when the temperature is between +40-+119°c (+104-+246°f), the actual temperature is displayed. • when the temperature is above +119°c (+246°f), the text "high" is displayed....

Page 152: 1.2 17:52

3.10.3 periodical maintenance view 1.2 17:52 600 1 guid-2a09d419-548b-43b2-b58c-263428e6edce 1. Periodical maintenance view when the tool symbol and periodical maintenance hour number are lit on the display, the appropriate service work has to be carried out by an authorised valtra workshop. If this...

Page 153: 1.2 17:52

3.10.4 resetting views you can reset the travel distance, fuel consumption, working time and square area (worked area) views. All the readings are reset at the same time. 1.2 17:52 reset 1 2 000 guid-b0609514-576d-4599-9b91-8b27b2c6f5ba 1. Reset view 2. Symbols for views that are reset 1. Navigate t...

Page 154

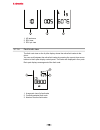

1. Activate the setting mode. Press and hold down the button until the symbol for the value to be set is blinking. 2. Display the available parameters. Press the side of the display setting switch opposite to the symbol. The available parameters are presented in the following table. Parameter parame...

Page 155: 350

• decrease a parameter value. • press the down arrow button. The parameter decreases one step at a time. • press and hold down the down arrow button. The parameter value decreases continuously. • select the next parameter to be changed. Press the button. 3.10.5.3 setting the implement width 350 1 i ...

Page 156: 18:10

3.10.5.5 changing the minute display 18:10 1 s e t c l o c k guid-b16ce581-3037-4fa8-8b01-643980f0d8ae 1. Minute display 1. Activate the minute display in the setting mode with the button. When the minute display is blinking, you can set the minutes. 2. Change the value with the arrow buttons. 3.10....

Page 157: M E T R I C

2. Change the direction indicator buzzer to either on or off with the arrow buttons. When the function is on (no cross), the buzzer is activated together with the direction indicator or the hazard warning. 3.10.5.8 changing the temperature unit you can change the unit of temperature to be shown in e...

Page 158: L I T R E

3.10.5.10 changing the volume unit you can change the unit of volume to be shown in either litre, gallon uk or gallon us mode. 1 v o l u m e u n i t l i t r e 1 v o l u m e u n i t gallon uk 2 1 v o l u m e u n i t gallon us 3 guid-92703147-262d-46cd-94b1-6df2ba440a8f 1. Litre 2. Gallon uk 3. Gallon...

Page 159: 101

3.10.5.12 adjusting the display contrast 1 c o n t r a s t 101 1 guid-d1617e87-9ae7-4350-854b-fbf0119dadc1 1. Display contrast 1. Activate the display contrast in the setting mode with the button. 2. Adjust the display contrast with the arrow buttons. The minimum contrast value is 80 and the maximum...

Page 160

1 2 3 4 5 guid-60340399-e5d3-4dfb-a1a1-67708bc33224 1. Arrow up 2. A-pillar display selection 3. Back 4. Arrow down 5. Set/selection • you can change the control panel operation from the proline instrument panel to a-pillar with the a-pillar display selection button. By default, proline is active in...

Page 161

Forward/reverse driving direction arrow the arrow shows which driving direction, forward or reverse, is engaged. The arrow flashes if the power shuttle has been operated at a driving speed over 10 km/h. The arrow flashes also when the automatic traction control is activated. Transmission neutral sym...

Page 162

Auto1 / auto2 shifting automatics symbol the auto1 or auto2 symbol appears based on the shifting automatics mode in use. When the shifting automatics is not selected, the symbol is not visible and the manual shifting is in use. Speed range symbol the selected speed range letter (a, b, c, d) is shown...

Page 163

Service code information the service code symbol is displayed if one or more service codes are active. The symbol disappears when the error has been fixed and power turned off. Power take-off (pto) information • in the basic mode view, the symbol for the rear pto is shown only if the rear pto is rot...

Page 164

3.11.2.4 changing general information section views you can scroll the function views by pressing the up and down arrows in the control panel. 1 2 3 guid-e4d55525-0af6-46eb-b1ff-7cde5701ad0d 1. A-pillar display selection 2. Arrow up 3. Arrow down 1. To operate the a-pillar display with the control p...

Page 165

3.11.3 driver's settings display the driver's settings display is divided into indexes section, auto2 hi and auto2 lo settings section, speed sensor calibration section and i/o test section. 3.11.3.1 indexes section you can modify the settings of the tractor's functions in the indexes section. These...

Page 166

3.11.3.3 auto2 hi and lo sections you can adjust the auto2 shifting automatics rpm (revolutions per minute) limits through the auto2 hi and lo sections. Both auto2 hi and auto2 lo sections consist of two views: menu level and rpm value. 1 2 guid-1eee45cc-61b9-4630-98f5-fb9e5a100749 1. Auto2 hi setti...

Page 167

3.11.3.4 speed sensor calibration section the speed sensor calibration section allows user to calibrate the speed sensor (optional equipment) when changing the tyre radius. The calibration is required for the automatic driving modes to work properly. The speed sensor calibration section consists of ...

Page 168

1 2 3 guid-b0e43208-3d08-4ed7-826e-aedb1c2f7bab 1. I/o test menu 2. Ecu view 3. Ecu pin view 3.11.4 fault code view the fault code view on the a-pillar display shows the active fault codes to the driver. You can scroll between the active fault codes by pressing the up and down arrow buttons in the a...

Page 169

3.12 rear linkage controls in the cabin 2 3 4 13 5 6 7 8 9 1 10 11 12 guid-22fcf050-99ad-41f9-84d9-f0d5ef8863b5 1. Lifting/lowering switch 2. Lowering indicator light 3. Lifting indicator light 4. Diagnostic light 5. Lowering speed selector 6. Max lifting height selector 7. Draft control selector 8....

Page 170

1 2 guid-6eef62ba-2a85-47c4-bd81-d1374f72bad5 1. Lifting push button 2. Lowering push button 3.12.1 diagnostic light when the tractor power is turned on, the diagnostic light is lit for a moment, goes out, and is lit again. The lit diagnostic light indicates that the linkage has not been activated. ...

Page 171

3.12.2 lifting/lowering indicator lights the indicator lights indicate when the lower links are moving. Lit indicator light indicates that the rear linkage is being used. 1 2 guid-7c7f1615-c812-45f7-87e7-5a650e15cffe 1. Lifting indicator light 2. Lowering indicator light • the lifting indicator (red...

Page 172

2. To increase the speed to normal, change the position of the lift/stop/lower switch again. 3.12.4 using the lift/stop/lower switch the lift/stop/lower switch has three positions. Au to auto control 1 2 guid-345dbc6b-8242-4b4e-9860-d3193568d8d1 1. Lift/stop/lower switch 2. Position control knob • p...

Page 173

Au to auto control 1 2 guid-345dbc6b-8242-4b4e-9860-d3193568d8d1 1. Lift/stop/lower switch 2. Position control knob • to lift the lower links, turn the knob anti-clockwise. • to lower the lower links, turn the knob clockwise. 3. Operation - 171 -.

Page 174

3.12.6 overriding the position set by position control knob use the override button for position control knob when you temporarily need the lower links to pass the lower limit set by the control knob. This feature is useful for example when ploughing. It allows a quicker entry of the plough to the c...

Page 175

Supplementary feature can be used to help release and lock the pick-up hitch when the upper limit is set to maximum. 3.12.7 using the linkage floating position use the floating position when working with implements which have to follow the ground surface. Such implements are, for example, sowing mac...

Page 176

3.12.8 using the lifting/lowering switch when attaching implements, using the lifting/lowering switch gives you a full control on the implement's movement. If necessary, you can stop the movement immediately by releasing the switch. The lifting/lowering switch functions even when the rear linkage is...

Page 177

1 2 guid-6eef62ba-2a85-47c4-bd81-d1374f72bad5 1. Lifting push button 2. Lowering push button • to lift the linkage, press the lifting push button. The longer the lift button is pressed the faster the linkage lifts. • to lower the linkage, press the lowering push button. The longer the lower button i...

Page 178

• to decrease the lowering speed, turn the knob anti-clockwise. 3.12.11 limiting the lifting height the height limit is a useful feature, for example, when there is a risk that the implement could hit the cabin or when using the power take-off (pto) driven implements. Important: the lifting height l...

Page 179

Position 5 is normally used for ploughing. If larger draft control is required (that is, the plough is too deep and needs a slight lift), position 6 can be used instead. When the draft control is operating, the rear linkage tries to maintain the position set by the position control knob. If the pull...

Page 180

3.12.13.1 using the drive balance control auto control au to 2 3 4 1 guid-3651db43-8120-4067-92a6-f1adaec6ddf0 1. Drive balance control knob 2. Drive balance position 3. Drive balance control light 4. Lift/stop/lower switch 1. To activate the drive balance control, turn the drive balance control sel...

Page 181

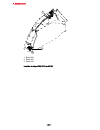

3.13 three-point linkage 7 1 2 5 4 3 6 guid-788cbef8-1508-4f67-a0ec-ec02a9c973c9 1. Top link 2. Lift link 3. Hydraulic levelling link (optional) or lift link (optional) 4. Levelling screw 5. Side limiter 6. Automatic side limiter (optional) 7. Lower links 3. Operation - 179 -.

Page 182

The tractors are supplied with category 3 ball hitch lower links. Warning: ensure that the ball hitch lower link hooks latch correctly. The top link has two different attaching holes on the tractor. Thus, it is possible to get different lifting geometry for different implements. When the top link is...

Page 183

2 1 3 4 guid-c86fabea-5349-4493-82c3-0f479b24205d 1. Lifting/lowering switch 2. Lifting/lowering indicator lights 3. Draft control selector 4. Lifting/lowering push buttons 1. Turn the draft control selector to position p. Danger: before attaching or releasing an implement, turn the draft control se...

Page 184

2. Press the lifting/lowering switch or the lifting/lowering push buttons to lift or lower the lower links. The lower links lift or lower for as long as you press the switch/button. Danger: when attaching or releasing implements, always stand outside the implement and beside the tractor. Never stand...

Page 185

1 2 guid-1ddd2046-4b88-4e75-9d71-3c5f16c4b067 1. Lever 2. Clamp 1. Pull the lever to release the implement. Guid-f490871b-0805-402d-9316-b7f4fa105dad 2. You can leave the lock open by pulling the lever backwards (for example when demounting an implement). Guid-557a2ca6-3687-4711-bc76-9af72652fdc2 3....

Page 186

3. Release the lock by pulling the lever forward. Guid-b36612f7-c256-4f58-b5cc-deee19f33df7 the ball joints lock automatically when attaching the implement. When locked, the clamp is in view and the lever is in the lower position. 3.13.3 adjusting lift links 3.13.3.1 adjusting lift links important: ...

Page 187

3.13.3.2 adjusting hydraulic lift link the hydraulic lift link is connected to rear auxiliary hydraulic valve 1 or 2. Important: when adjusting the hydraulic lift link, make sure that the implement does not hit the tractor or ground to avoid damages. 1 2 guid-14291ff4-d888-4971-82d4-2070079be10f 1. ...

Page 188

1. Lock pin 2. Plate 3. Carrier pin and plate position providing fixed position of lower links 4. Carrier pin and plate position allowing floating position of lower links 1. Remove the lock pin and pull out the carrier pin. 2. Attach the lift links to the lower links with the carrier pin and plate. ...

Page 189

3.13.6 automatic side limiters the automatic side limiters are used to limit the distance between the lower links. They can be set to a fixed position, similar to the standard side limiters, or they can be set to be released to floating position automatically. The automatic side limiters are optiona...

Page 190

3.13.6.2 setting automatic side limiters to floating position you can set the automatic side limiters so that when lowering the linkage, the side limiter is released to a floating position. 1 2 guid-4cde4c5b-b4a3-413a-99c2-af79d4a77346 1. Holding chain 2. Limiting pin 1. Adjust the chain to the leng...

Page 191

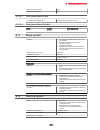

3.14 auxiliary hydraulics 2 3 4 1 5 6 7 guid-b06b6d9a-0b69-4447-87fa-2d26eb578c76 1. Front linkage shut-off valve (optional) 2. Rear valves 3 and 4 (optional) 3. Standard rear valves 1 and 2 4. Return coupling 5. Valve mode selector (optional) 6. Flow control adjustment (optional) 7. Flow control ad...

Page 192

Valves valve type valve functions flow control adjustment three valves valve 1, basic out - hold - in - floating position locks on floating and (+)-port n/a valve 2, basic out - hold - in - floating position lock on floating n/a valve 3, adjustable position lock - spring- return - kick-out in cabin ...

Page 193

3.14.1 controlling the auxiliary hydraulics rear valves you can control the auxiliary hydraulics rear valves with the control levers. 5 6 7 8 1 2 3 4 guid-4d21058d-468a-4484-9d51-aa99adf947f2 1. Control lever for the auxiliary hydraulics rear valve 1 2. Control lever for the auxiliary hydraulics rea...

Page 194

• to use the floating position: the floating position can be used in every mode of the adjustable valves. The floating position is past the extreme position of the lever: • to activate the floating position, push the control lever for the auxiliary hydraulics rear valve past the extreme position wit...

Page 195

1 2 guid-332e3bf9-a9a9-4114-9e6d-26d1da9c7701 1. Flow control adjustment knob in the cab (optional) 2. Flow control adjustment knob on the valve (optional) • to increase the oil flow in the valve, rotate the flow control adjustment knob counterclockwise. Adjust the flow control only when the control...

Page 196

1. Start the engine and set it to low idle speed. 2. Set the valve to the kick-out mode. 3. Check the adjustment of the kick-out pressure by operating the implement. If the valve lever returns too easily, increase the kick-out pressure. If the valve lever does not return as intended, decrease the ki...

Page 197

1 2 3 4 guid-13034b5b-5c34-473c-8b5d-0a7252452173 1. Shut-off valve 2. Shut-off valve lever 3. Lever in front linkage position 4. Lever in rear valve position • to use the front linkage: • disconnect quick couplings from the rear valve to which the front linkage shut-off valve is connected. • pull t...

Page 198

4. Activate the floating positions on the needed valves. Warning: before connecting or disconnecting the quick couplings, adjust the valves into the floating position (the tractor has to be running and the parking brake engaged). Note: make sure there is no load on valves as the load will come down ...

Page 199

3.14.3.3 connecting an external hydraulic motor to the auxiliary hydraulics you can attach a hydraulic motor to the tractor auxiliary hydraulics. The motor can be rotated in one or both directions. • to rotate the hydraulic motor in only one direction, attach the return coupling to the tractor retur...

Page 200

2 3 4 5 1 guid-25569676-e94e-4010-9f87-6f1c194c64d0 1. Control lever for auxiliary hydraulics rear valve 2. Shut-off valve 3. Shut-off valve lever 4. Lever in front linkage position 5. Lever in rear valve position • disconnect quick couplings from the rear valve to which the front linkage shut-off v...

Page 201

• if the implement follows the ground, use the floating position. • to activate the floating position, push the control lever past the extreme position with increased force. This locks the lever to the floating position • to deactivate the floating position, return the control lever manually to the ...

Page 202

3. When you drive on public roads and there is an implement on the front linkage covering the headlights, switch the upper headlights on (optional equipment). 3.16 valtra front loader 3.16.1 valtra front loader warning: check that all screws are tightened before using the front loader. Warning: alwa...

Page 203

3.16.2 using the valtra quick front loader coupling device the quick coupling device is optional equipment. 1 2 3 guid-ed63e61b-2b2f-4cee-8a79-4368c3c4d18c 1. Hose multicoupler 2. Lock button 3. Lever caution: hold on to the lever firmly as the pressure may cause the coupler to hit your hand. • to r...

Page 204

1 guid-56187f1f-76b3-457f-be72-6bd2444373c3 1. Button for softdrive • to activate or deactivate the softdrive function, press the button for softdrive. When activated, the light of the button is lit green. Note: you can keep softdrive activated during most working activities. It is recommended that ...

Page 205

3.17 power take-off 3.17.1 attaching implements to the power take-off before attaching implements to the tractor power take-off (pto), make sure the implement is designed for the used pto speed (540 rpm or 1 000 rpm). Caution: observe all safety precautions in any operation involving implements driv...

Page 206

1 guid-ac883573-4766-4a5f-b233-74dfde6b98b8 1. Pto cover important: make sure that the joint shaft angles are not exceeded. Important: do not exceed the maximum output durability of the pto shaft. • make sure that the length of the pto drive shaft is correct for the pto-driven implements to be used....

Page 207

• when engaging the pto and the attached implement allows it, wait approximately 5 seconds until the clutch of the pto shaft is totally engaged before loading it. 3.17.2 rear power take-off you can use power take-off (pto) to transmit power from the tractor to an implement. The pto shaft is a spline...

Page 208

On/off 1 guid-9c52e8cd-1973-4193-87d3-0fb5a42ecf73 1. Rear pto on/off push button sigma power in models t144 h, t154 h and t174e h, the sigma power control system is extra equipment. The sigma power control system gives extra power for pto work. When required for pto work, the engine will automatica...

Page 209

3.17.2.1 recommended rear power take-off shafts both power take-off (pto) nominal speeds can be used regardless of the type of shaft installed on the tractor. Implements for 540 rpm (at engine speed of approximately 1890 rpm) normally a 6-spline shaft (optional) with a diameter of 35 mm is recommend...

Page 210

• select the pto speed with the speed control knob. The tractor has one of the following pto speed range alternatives: • 540/1000 • 540/540e/1000 • 540/1000/1000e • 540e/1000/gspto • 540e/1000e/gspto important: when using the speed 540e, the shaft speed of 540 rpm is achieved with an engine speed of...

Page 211

• start the rear pto by pressing the switch down and pulling it backward. The indicator light on the proline instrument panel is lit. Au to 1 guid-1f3c8457-93b5-4937-b524-a362b42389c4 1. Switch for rear pto • to start the rear pto with the rear pto on/off push button (optional) on the mudguard, pres...

Page 212

3.17.2.4 stopping rear power take-off temporarily you can stop the rear power take-off (pto) temporarily in the following ways: • by using the switch for rear pto. • by using the speed control knob for rear pto. • by using the rear pto on/off push button (optional) on the rear mudguard. Warning: whe...

Page 213

The indicator light on the proline instrument panel blinks, indicating that the pto speed control knob is engaged. 3.17.2.5 deactivating rear power take-off warning: when you do not need the pto, keep the pto switch in the n position. Warning: use the pto speed control knob for the actual disengagem...

Page 214

• turn the pto speed control knob to the n position (pto deactivated). 1 guid-0d31e500-e360-4863-b5fe-db5b63cf763f 1. Speed control knob for rear pto the rear pto is deactivated, and the indicator light on the instrument panel goes off. 3.17.2.6 stopping the rear power take-off in emergency in case ...

Page 215

Stop 1 guid-faf5b182-b2aa-4254-b593-21749ec3a7d1 1. Pto emergency stop socket • to stop the pto from inside the cab, turn the speed control knob for rear pto to the n position to deactivate the pto. • to restart the pto: • activate the pto speed range by the speed control knob for rear pto. • start ...

Page 216

3.17.2.7 using the rear power take-off automatic start/stop the rear power take-off (pto) automatic start/stop is useful in headland turns, for example, where the implement needs to be raised temporarily and then lowered back. 2 au to auto control 1 guid-d168061b-db5a-4f18-8e3c-4dcbe6e7dd2d 1. Lifti...

Page 217

• deactivate the automatic start/stop in any of the following ways: • press the button for rear pto automatic start/stop. • use the switch for rear pto. • keep the linkage raised, that is, in the standby position for at least 90 seconds. The automatic start/stop is also deactivated if the driving sp...

Page 218

1 guid-0d31e500-e360-4863-b5fe-db5b63cf763f 1. Speed control knob for rear pto au to 1 guid-1f3c8457-93b5-4937-b524-a362b42389c4 1. Switch for rear pto 3.17.2.9 adjusting the rear power take-off engagement when working with heavily rotating implements, you can adjust the rear power take-off (pto) en...

Page 219

1. Press to activate the a-pillar display. 2. Press to enter the settings menu. Guid-2408e592-046c-4ca8-ac4b-6e1939c132a7 the text “ind” appears. 3. Press to enter the index list. 4. Scroll to the parameter to be changed with the up arrow or the down arrow. Guid-4a865c66-727a-4f6c-8676-1c2b7f32140a ...

Page 220

3.17.3 front power take-off front power take-off (pto) is only available with front linkage (extra equipment). 1 2 guid-efbc1015-b082-49cf-b382-6d6d1a1a60eb 1. Front pto shaft 2. Oil cooler the front pto shaft has a diameter of 35 mm with 6 splines. The front pto is equipped with a pump inside the h...

Page 221

Important: the maximum allowed input torque for the front pto gearbox is 1170 nm and the nominal is 925 nm. Important: always make sure that the cardan shaft does not touch the hydraulic connectors at any working position. 3.17.3.1 activating and deactivating front power take-off the front power tak...

Page 222

3.18 implement signal connection 3.18.1 implement signal connector the implement signal connector (extra equipment) complies with the iso 11786 standard. The connector is located on the side panel in the cab. 1 guid-17e63215-2963-443f-8c88-d7059beebb6e 1. Implement signal connector an implement conn...

Page 223

1 guid-ff2c2148-c40b-480a-a5a1-6dc33a780c79 1. Indicator light for the implement signal connector when the indicator light for the implement signal connector is green, the implement signal system is working normally. If light flashes there is an error in the system. 3.18.2 resetting the implement si...

Page 224

3.19 isobus implement control system the valtra isobus implement control system (extra equipment) complies with the iso 11783 standard. The system connects together the tractor, the implement and the isobus terminal, and enables information exchange between these units. The valtra isobus implement c...

Page 225

3.19.1 isobus terminal connector the isobus terminal connector is part of the isobus implement control system (extra equipment). The connector is used to connect the terminal to the isobus system. The connector includes both an isobus data bus and a power supply. 3.19.2 isobus implement connector th...

Page 226

• electrohydraulic steering valve • a bracket for automated steering system control unit (on the roof) • auto-guide receiver on/off button • auto-guide steering valve on/off button • auto-guide remote activation button 3.20.1 using auto-guide before auto-guide 3000 steering system can be used and th...

Page 227

• press the auto-guide receiver on/off button on the side panel to turn the auto-guide receiver on or off. When on, the symbol on the push button is green. Turning off the receiver also turns off the auto-guide steering valve if it was on. Note: the receiver can stay on even when tractor power is tu...

Page 228

3.20.2 using auto-guide with quicksteer if you want to use auto-guide with quicksteer, turn the auto-guide receiver on and activate the quicksteer. 1 2 3 guid-5240f5f8-bc57-4c04-b1ec-53b91e356645 1. Quicksteer control knob 2. Quicksteer activation button 3. Auto-guide receiver on/off button 1. Press...

Page 229

3.21 towing devices 3.21.1 nordic pick-up hitch the nordic pick-up hitch is optional with the fixed trailer hitch. Warning: when attaching a trailer or implement, do not exceed the maximum weight of the rear axle or the maximum load of the tyre type. See the technical specifications in this manual f...

Page 230

2 3 4 5 1 guid-b3ec3d2b-211d-4ba1-8ecf-b8ea7245bd4c 1. Euro pick-up hitch 2. K80 ball hitch with steering balls (optional) 3. Trailer hitch 4. K80 ball hitch (optional) 5. Drawbar (optional) when the trailer hitch or drawbar is not in use, it can be fastened to its bracket. 1 guid-352984bb-89fe-424f...

Page 231

See the technical specifications in this manual for the maximum permissible weights and loads. Warning: make sure that the maximum permissible towable mass is not exceeded. Check the tractor identification plate for permissible towable mass. Follow valid laws and regulations. 2 3 4 5 1 guid-af3bbec7...

Page 232

3.21.4 using the pickup hitch 3.21.4.1 unlatching the pick-up hitch warning: never unlatch the pick-up hitch when driving. 1 2 guid-96ecac76-310b-477f-8c0e-b75ff742b50f 1. Lifting/lowering switch 2. Trailer hitch release lever 1. Press the symbol side of the lifting/lowering switch to fully raise th...

Page 233

Warning: attach trailed single-axle vehicles to the pick-up hitch. When driving with a trailer with the tractor tilted to either side on a slope, the drawbar eye must be of the rotating type to prevent breakage. Important: use only drawbar eyes which comply with the regulations and are undamaged. Wh...

Page 234

5. Check the linkage position. Important: adjust the linkage so that it does not hit the towed device or power take-off shaft at any circumstance. 3.21.4.3 extending the hydraulic pick-up hitch when the frame of the towing device is lowered, you can extend it hydraulically backwards to make it easie...

Page 235

Warning: make sure that the maximum permissible towable mass is not exceeded. Check the tractor identification plate for permissible towable mass. Follow valid laws and regulations. Warning: attach trailed single-axle vehicles to the pick-up hitch. When driving with a trailer with the tractor tilted...

Page 236

4. Align the pick-up hitch hook or drawbar pin to the eye of the trailer/implement beam. 5. Press the symbol side of the lifting/lowering switch or the lifting push button until the hitch latches. You can hear a click and the trailer hitch release lever jumps a little. 6. Press the lifting/lowering ...

Page 237

3.21.5 changing the pick-up hitch implement 3.21.5.1 changing the euro pick-up hitch implement you can change the euro pick-up hitch implement. When the trailer hitch or drawbar is not in use, you can fasten it to the bracket on the rear side. 1 2 1 3 guid-7a2cac17-5e58-4744-91d1-2b502fce1387 1. Loc...

Page 238

3.21.5.2 changing the hydraulic pick-up hitch implement you can change the hydraulic pick-up hitch implement. When the trailer hitch or drawbar is not in use, you can fasten it to the bracket on the rear side. 2 1 guid-c5a77e24-a630-4327-923e-945c6ca1caf0 1. Locking pin 2. Locking ring 1. Lower down...

Page 239

3.21.6 agricultural drawbar the agricultural drawbar (optional) is used without the pick-up hitch. 1 guid-7c0d87a3-6eed-45aa-8870-a33ec5ddd993 1. Agricultural drawbar the agricultural drawbar is used for towing implements where only part of the implement weight is on the drawbar, for example balers....

Page 240

3.21.6.1 adjusting the agricultural drawbar you can adjust the agricultural drawbar to different distances and lateral positions. 1 2 1 3 4 guid-54c9dd62-9035-4269-bda2-be06937cda7a 1. Pin 2. Spring return pin 3. Drawbar 4. Ring pin 1. To adjust the drawbar distance: • secure the pin with hand and p...

Page 241

Warning: according to law, the operator has to ensure that all relevant precautions are taken (lockings secured etc.). 1 2 8 8 5 3 4 7 7 7 6 6 6 guid-70352eba-d71d-4b2c-9e80-8e7f322612c6 1. Short towing device frame 2. Towing device frame 3. Universal towing device frame 4. Towing device frame with ...

Page 242

1 guid-6527cd59-5e91-4718-8cdd-58c610ba92a7 1. Lever 1. Pull the lever upwards and turn it to the anticlockwise. 2. Move the jaw to the wanted height. 3. Release the lever. The locking pins lock the lever to the correct position with the help of the returning springs. You can also lift the jaw away ...

Page 243

3.21.7.2 attaching to the mechanical jaw you can attach a trailer to the mechanical jaw using the coupling lever. 1 2 3 guid-6fff7ab1-633f-4dd9-8879-1fdde5f3390b 1. Ring 2. Coupling lever 3. Towing pin 1. Pull up the ring at the top of the coupling lever to lift up the towing pin. Warning: after att...

Page 244

3.21.7.3 attaching to the mechanical jaw k80 you can attach a trailer to the mechanical jaw k80. 1 2 3 guid-90c43526-2e09-4b09-aa84-87eb3d63b950 1. Pin 2. Locking pin 3. Locking 1. Remove the locking pin. 2. Pull the pin off and open the locking. 3. Attach the trailer to the jaw. 4. Close the lockin...

Page 245

3.21.7.4 attaching to fixed piton fix/fixed Ø80mm ball hitch you can attach a trailer to the fixed piton fix or fixed k80 jaw. 1 2 3 guid-6cf63507-fc10-4463-8528-e15c949220fc 1. Pin 2. Locking pin 3. Locking 1. Remove the locking pin. 2. Pull the pin off and open the locking. 3. Attach the trailer t...

Page 246

2 3 4 5 6 1 guid-622a04f2-8543-4d04-a15f-02ef3c4f4273 1. Trailer hitch release lever (optional) 2. Cable for trailer hitch release lever (optional) 3. Towing pin locking lever 4. Towing pin opening lever 5. Adjusting part 6. Spring locking pin 1. Check that the adjusting parts fit for the trailer to...

Page 247

4. Check that the towing pin is locked. 1 2 guid-d9d061fb-de66-4805-aa5c-5afcaeb67093 1. Towing pin not locked 2. Towing pin locked warning: the towing pin is locked in the down position when the security knob is out. When attaching the trailer, the towing locking pin must be secured. 3.22 air press...

Page 248

Warning: the pressure of the air pressure system must be at its maximum, about 7-8 bar, before driving the tractor with a trailer equipped with air pressure brakes. When the ambient temperature is below +5°c, the antifreeze container must be filled with antifreeze liquid containing lubricant. The li...

Page 249

Important: when loading the towing device, at least 20% of the tractor weight has to be on the front wheels. Important: the maximum allowed wheel or towing device loading must not be exceeded. 3.23.1 trailer turn signals when using turn signals while towing a trailer, the first trailer turn signal i...