- DL manuals

- Value Hobby

- Toy

- 58in AeroMaster-46

- Instruction Manual

Value Hobby 58in AeroMaster-46 Instruction Manual

58in AeroMaster-46

Almost

‐

Ready

‐

to

‐

Fly

Nitro/Electric

Aerobat

INSTRUCTION

MANUAL

SPECIFICATIONS:

WINGSPAN:

59”(1470mm)

LENGTH:

49

‐

1/5”(1250mm)

WING

AREA:

604.5

sq

in(39

sq

dm)

FLYING

WEIGHT:

3.3

‐

4.4

lbs

(1500

‐

2000g)

SUGGESTED

POWER

SYSTEM:

E

‐

Flite

power

46

or

equivalent

FEATURES:

Light

‐

weight

laser

‐

cut

ply

and

balsa

construction

Two

‐

piece

wing

with

aluminum

wing

tube

Detachable

PVC

canopy

secured

by

two

magnets

Painted

fiberglass

cowl

and

wheel

pants

Aluminum

landing

gear

Complete

hardware

WARNING

This

radio

controlled

model

is

NOT

a

toy

and

NOT

intended

for

person

under

16

years

old.

Keep

this

kit

out

of

reach

of

younger

children,

as

it

contains

parts

that

could

be

dangerous.

A

radio

controlled

model

is

capable

of

causing

serious

bodily

injury

and

property

damage.

It

is

the

owner's

responsibility

to

assemble

the

aircraft

properly.

Test

fly

your

model

in

the

presence

of

an

experienced

RC

modeler.

Your

model

must

always

be

operated

and

flown

using

great

care

and

common

sense,

as

well

as

in

accordance

with

the

safety

code

of

the

AMA

or

MAAC.

We

suggest

you

purchase

proper

insurance

prior

to

flying

this

model.

The

FCC

requires

that

you

use

only

radio

frequencies

specified

for

R/C

model

aircraft.

Do

not

at

any

time

fly

this

model

while

under

the

influence

of

drugs

or

alcohol.

Summary of 58in AeroMaster-46

Page 1

58in aeromaster-46 almost ‐ ready ‐ to ‐ fly nitro/electric aerobat instruction manual specifications: wingspan: 59”(1470mm) length: 49 ‐ 1/5”(1250mm) wing area: 604.5 sq in(39 sq dm) flying weight: 3.3 ‐ 4.4 lbs (1500 ‐ 2000g) suggested power system: e ‐ flite power 46 or equivalent features: light...

Page 2

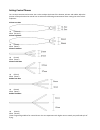

Parts of the airplane 1 2 3 4 5 3 6 1. Fuselage 2. Fin and rudder 3. Wing 4. Horizontal stabilizer and elevator 5. Cowl 6. Canopy.

Page 3

Included accessories 1 2 3 4 6 7 8 9 5 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 32 33 34 31 35 36 37 38 1. Rudder and elevator pushrod x2 [ Ф 1.8x730mm] 2. Throttle pushrod [ Ф 1.5x270mm] 3. Aileron pushrod x 2 [ Ф 1.8x170mm] 4. Elevator joiner wire [ Ф 2.5x98mm] 5. Fuel tank 6...

Page 4

Install the ailerons ca hinges 8 apply instant glue (c.A.Glue,super glue) ensure smooth non ‐ binding movement while assembleing. Assemble left and right s ides the same way. Of hin ge slot deep in cen ter drill a h ole 3/32 step 1: drill a 1/16 ‐ inch hole into the center of each hinge slot in the ...

Page 5

Step 3: join the aileron to the wing panel and remove the pins from the hinges. Center the aileron on the wing. Step 4: adjust the aileron so there is a small gap between the le of the aileron and the wing. The gap should be about 1/64 ‐ inch or just wide enough to slip a piece of paper through..

Page 6

Step 5: apply six drops of thin ca to the top and bottom of each hinge. Do not use accelerator in the hinging process. The ca must be allowed to soak into the hinge naturally. After the ca has cured, flex the surfaces several times to break in the hinges. Pull on both surfaces to make sure the hinge...

Page 7

Install the aileron servos & pushrods nylon clevis 2 nylon control horn 2 2 ez link for pushrod z ‐ bend pm2x25mm 4 round head machine screws for control horns before installation, confirm that the servos you will be using will properly fit in the servo opening. Make adjustments as necessary for you...

Page 8

Step 3: securely tie the string from inside the opening for the aileron servo to the end of the servo extension. Pull the servo wire and extension through the wing. Cut off unused arm enlarge to 2mm leading edge servo arm parallel with hinge line step 4: temporarily position the aileron servo into t...

Page 9

Step 5: place one of the nylon control horn on the aileron, positioning it as shown in the sketch and aligning it with the servo arm using a straight edge as a guide. Mark the location for the screw holes. Using a Ф 1.8mm drill bit, drill a hole through the aileron at the marks you made. Install and...

Page 10

Step 6: locate a Ф 1.8 x 170mm pushrod wire threaded on one end. Screw a nylon clevis onto the rod. It is recommended you use a clevis retainer (not included) to help keep the clevis in place. Slide a silicone clevis retainer onto the base of the clevis. Connect the clevis to the second hole on the ...

Page 11

Nylon faslink 7. Use tape or a small clamp to hold the aileron in the neutral position. With the servo arm still parallel to the hinge line, make a mark on the pushrod where it crosses the outer hole in the servo arm. Remove the pushrod and clevis from the control horn and make a 90 degree bend at y...

Page 12

Finish the wing panels 2 cm4x20mm Ф 19x400mm aluminum wing tube socket head screws for securing wings to fuselage step 1: use the wing tube to attach the wing halves to the fuselage. Metal wing bo lt step 2: test the cm4x20mm wing bolts into the blind nuts in the wing panels. If the bolts are diffic...

Page 13

Install the stabilizer step 1: locate the horizontal stabilizer slot under the covering on the tail section of the fuselage by lightly pressing with your finger. The slot is located on both sides of the fuselage. Carefully remove the covering. Make sure you do not cut into the wood. Step 2: locate t...

Page 14

Step 3: insert the stabilizer into the stabilizer slot so it is centered in the fuselage (dimension a should be equal). Place the wing onto the fuselage and secure it in place with the wing hold ‐ down bolts. View the plane from the rear and at a distance of a few feet. The stabilizer should be para...

Page 15

Step 5: with the stabilizer properly aligned, use a felt ‐ tip pen to trace a line around the tail of the airplane on the top and bottom of the horizontal stabilizer. Step 6: remove the stabilizer and draw two additional lines, top and bottom, 1/16" [1.6mm] inside the lines drawn in the previous ste...

Page 16

Install the vertical fin step 1: test fit the vertical fin in the slot in the top of the fuselage. Sand the edges of the slot if necessary to obtain a snug fit. Draw a line around the vertical fin where it meets the fuselage. Cut the covering 1/16” [1.6mm] inside the lines you drew on the vertical f...

Page 17

Joining the elevator halves step 1: without glue, position the elevator halves on the stabilizer. Measure and mark a centerline onto the elevator joiner wire. Center the joiner between the two elevator halves. Mark the position where the joiner will enter the elevator halves. Step 2: remove the elev...

Page 18

Step 3: carefully cut grooves into the leading edges of the elevator halves to allow the joiner to recess into the leading edge..

Page 19

Step 4: use a straightedge to align the elevator halves on a flat surface. Using 6 ‐ minute epoxy, glue the joiner wire into position. Make sure the joiner wire is fully seated in the elevator halves before the epoxy cures. Use weights to keep the elevator halves from moving..

Page 20

Install the elevator step 1: find the pre ‐ cut hinges from the included accessories. Test fit the hinges in the slots in the elevator halves and stabilizer. If the hinges do not slide into the slots easily, work your knife blade back and forth in the slot a few times to provide more clearance of h ...

Page 21

Step 4: temporarily insert a pushrod into the elevator pushrod exit slot. Use the position of the pushrod to align the elevator control horns onto the undersides of the elevator halves. Mark the locations of the control horn mounting holes onto the elevator halves and drill holes at the marks. Do no...

Page 22

Install the rudder and tail wheel step 1: assemble the tail wheel assembly set using the included accessories. Step 2: the installation tab of the tail wheel need to be mounted on the bottom of the fuselage. Test fit the rudder to the fuselage with the tail wheel assembly installed in the orientatio...

Page 23

Rudder exit slo t step 3: as you did with the elevator, use the pushrod to temporarily position a control horn onto the side of the rudder. Then secure the control horn using two screws..

Page 24

Installing the tail servos and pushrods step 1: install the elevator and rudder servos into the fuselage as shown using the hardware supplied with the servos. Be sure to harden the screw holes with thin ca as was done with the aileron servos. Cut three arms from two four armed servo arms. Center the...

Page 25

Step 3: with the rudder in the neutral position and the rudder servo arm perpendicular to the pushrod, mark where the pushrod crosses the outer hole of the servo arm. As you did with the aileron pushrods, make a 90 degree bend at the mark and cut off the excess pushrod 1/4" [6mm] beyond the bend. Se...

Page 26

Step 5: with the elevator in the neutral position and the elevator servo arm perpendicular to the pushrod, mark where the pushrod crosses the outer hole of the servo arm. As you did with the rudder pushrods, make a 90 degree bend at the mark and cut off the excess pushrod 1/4" [6mm] beyond the bend....

Page 27

Install the main landing gear pm4x20mm 2 socket head screws for securing landing gear cm4x40mm main wheel shaft 2 pwa2x12mm self ‐ tapping screws for wheel pants 2 c m4 x4 0 mm step 1: reinstall the wheel collars and wheels onto the axles. Thread a cm4x40 set screw into each wheel collar and tighten...

Page 28

Pm4 x2 0 mm step 3: attach the landing gear legs to the fuselage using two cm4x20mm shcs, two m4 flat washers, two m4 lock washers..

Page 29

Option 1: brushless motor, esc and battery installation 4 cm4x40mm socket head screw bolt for securing radial mount to electric motor standoff electric motor standoff mm Ф 10x68 4 m4x20mm screw bolt for securing electric motor standoff to firewall 4 4 Ф 4mm blind nuts be sure to read and understand ...

Page 30

Step 2: the electric motor is mounted on a set of stand ‐ offs to help clear the length of the cowling. In order to drill proper positions for your motor stand ‐ offs, mark the position on the firewall using your electric motor’s radial motor mount. Step 3: at the marked positions, drill holes for y...

Page 31

Step 4: install the blind nuts. Use thin ca to secure the blind nuts in place..

Page 32

Step 5: secure the motor standoffs to the blind nuts on the firewall using the included threaded rod. Step 6: using the included socket head bolts, secure the electric motor to the motor standoffs..

Page 33

Step 7: secure the esc inside the fuselage using velcro. Then connect the leads from the motor to the esc. Carefully tuck the leads from the motor and speed control into the fuselage so the leads do not get entangled with the motor or propeller. Step 8: secure the battery inside the fuselage using v...

Page 34

Option 2: nitro motor and fuel tank installation installing the fuel tank 12 mm step 1: the fuel tank can be assembled as a two line system consisting of a vent (pressure) line to the muffler and a carb line. Filling and emptying of the tank would need to be done through the carb line, or an optiona...

Page 35

To p o f t an k ven t fill an d c arb lin es step 2: fit the stopper assembly into the tank with the vent line pointing toward the top of the tank, but not touching. The fuel tubing and clunks (fuel pickup) on the carb and fill lines should almost reach the back of the tank but not touch. The clunks...

Page 36

Step 3: insert the tank into the fuselage with the correct side facing up. The fuel tubing should be routed through the hole in the center of the firewall..

Page 37

Installing the nitro motor 4 Ф 4mm blind nuts pm4x20mm 4 round head machine screws for securing nitro motor mount 4 m4 washer nitro motor mount 52mmx90mm step 1: using four pm4x20mm shcs, four m4 fiat washers, four m4 lock washers, and thread locking compound, attach the engine mount to the firewall...

Page 38

11 7 m m step 2: position the front of the engine drive washer 117mm from the front of the engine mounting box. Mark the location of the engine mount holes onto the mount rails using a dead center hole locator remove the engine from the mount and use a Ф 4 tap and drill set to create threads in the ...

Page 39

5. Install the cowling pwa3x12mm 4 self ‐ tapping screws for securing cowling step 1: before fitting the cowling, make any cutouts necessary for your power system. For example, for a glow engine, a cutout must be made for the engine head, exhaust outlets, and needle valve access. A rotary tool such ...

Page 40

Step 3: fit the cowl to the fuselage and align it with the colors on the fuselage. Temporarily install the spinner backplate onto the motor shaft and make any adjustments to the cowl position so that the backplate is centered with the front of the cowl. When satisfied, tape the cowl into position. M...

Page 41

Installing the receiver step 1: secure your receiver inside the fuselage. Then connect the servos to your receiver. Make sure the leads to not interfere with any of the pushrods. Step 2: pre ‐ cut openings are provided for mounting an on/off switch. If the hole spacing does not fit your switch, you ...

Page 42

Balancing the model after you have finished building the model into ready ‐ to ‐ fly condition you can set the c.G. Of the model. You need to have all of the systems installed before you begin, including the nitro engine or electric motor, landing gear, radio system, and battery pack. The c.G. Is lo...

Page 43

Setting control throws turn on the transmitter and receiver. Use a ruler to adjust the throw of the elevator, ailerons and rudder. Adjust the position of the pushrod at the control horn to achieve the following measurements when moving the sticks to their endpoints: aileron low rate up (13.5mm) down...