- DL manuals

- Van Norman

- Lathe

- 204

- Instruction Manual And Parts List

Van Norman 204 Instruction Manual And Parts List

Summary of 204

Page 1

204 heavy duty combination brake lathe instruction manual and parts list van norman 500 57 th st., marion, ia 52302 888-855-1789 319-377-9101 (fax) copyright 2005 all rights reserved. Equipment specifications, options and accessories subject to change without notice..

Page 3: Warranty

Warranty flywheel grinders, 777 and 204c brake lathes van norman will repair and/or replace, free of charge (fob factory) all such defective parts, only when returned to factory with shipping charges prepaid. This warranty does not cover parts and supplies (wheel dresser/diamonds/abrasives) consumed...

Page 5: Receiving Shipment

204 heavy duty combination brake lathe receiving shipment upon taking delivery of your machine, carefully inspect the assembly before removing the crating and packing materials. If evidence of damage exists, contact the shipper and van norman immediately. Although van norman is not responsible for d...

Page 6: Safety First

204 heavy duty combination brake lathe safety first this manual has been prepared for the owner and those responsible for the maintenance of this machine. It’s purpose aside from proper maintenance and operations, is to promote safety through the use of accepted practice. Read the safety and operati...

Page 7: Safety Instructions

204 heavy duty combination brake lathe safety instructions 1. Read, understand and follow the safety and operating instructions found in this manual. Know the limitations and hazards associated with operating the machine. 2. Eye safety: wear an approved safety face shield, goggles or safety glasses ...

Page 8: Specifications

204 heavy duty combination brake lathe specifications rotor capacity………………………….. 4" - 24" (102-610 mm) maximum friction surface………. 5 "(127 mm)maximum maximum thickness…………….. 2.5 "(64 mm) drum capacity…………………………. 6" – 28" (152–711 mm) maximum depth………………… 8.75" (222 mm) flywheel (flat or stepped) c...

Page 9: Installation

204 heavy duty combination brake lathe installation machine "prep" 1. Carefully uncrate the lathe and wash off the anti-rust oil or any dirt accumulated during shipment. Kerosene or any approved commercial solvent may be used. Do not use gasoline. Locate and position 1. Select a location, which prov...

Page 10: Installation (Continued)

204 heavy duty combination brake lathe installation (continued) 4. Grease spindle bearing (figure 3) once a month using a lithium based grease with moly. The grease should be an nlgi grade 1, gc-lb. Figure 3 cleaning / maintenance 1. Do not use an air hose to clean machine. Use a brush to clear chip...

Page 11

204 heavy duty combination brake lathe component/control identification and function 1. Spindle stop 2. Handwheel for spindle position 3. Oil fill (oil daily #30) 4. On/off/light switch 5. Oil fill & breather 6. Spindle arbor 7. Tool bar (for drum turning) – 204s 8. Tool holder turret 9. Handle whee...

Page 12

204 heavy duty combination brake lathe standard & optional equipment standard machines 204c disc/drum lathe with powered & manual cross-feed slides, base and standard equipment part no. Description 804-2474-01 115v, 60 hz, 1 ph 804-2474-05 230v, 60 hz, 1 ph 804-8651-44 230v, 50 hz, 1 ph standard equ...

Page 13

204 heavy duty combination brake lathe standard & optional equipment (continued) miscellaneous part no. Description 804-2059-20 chip tray 108-1061-00 vented silencer-rotor 109-1032-09 spacer, 1 x 1.5 x 1.5 804-8665-41 solid rotor silencer, magnetic band, .250" x 48" (6.35 x 1219.2 mm) 101-0230-10 au...

Page 14

204 heavy duty combination brake lathe standard & optional equipment (continued) optional accessories part no. Description 804-8626-13 hubless adapter set, large size for 1" arbor, bore range 4.00"–5.75" (101.6-146.05 mm) 804-2020-23 rotor locator 804-4161-85 cone, 3.68" x 5.93" (93.47 x 150.62mm) 8...

Page 15

204 heavy duty combination brake lathe standard & optional equipment (continued) optional accessories 804-8664-66 medium truck set, for 2" arbor, bore range 2.15"–6.10" (54.61–154.94mm) for hubless drums /discs 804-8664-53 cone, 2.15"–2.80" (54.6–71.1mm) 804-8664-54 cone, 2.70"–3.35" (68.5–85.0mm) 8...

Page 16: Operation

204 heavy duty combination brake lathe operation speeds 1. Spindle speeds are 60, 100, and 170 rpm. To change rpm loosen thumb screw (figure 4 a & b). To remove belt guard (machine must be off) loosen wing nut (figure 4c), lift motor to free belt and put belt in proper groove. Replace motor and tigh...

Page 17: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) chatter control 1. Brake drums are dish or bell shaped and have a tendency to chatter. This can result in a wavy or chatter finish accompanied by excessive noise. The vibration dampener belt must be used at all times to prevent chatter. Se...

Page 18: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) reconditioning drums 1. The knob (figure 8b) should be loosened when turning drums to insure spindle will move out during operation. This screw must be tightened when cutting rotors. 2. This knob (figure 9) should be tightened when doing d...

Page 19: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) 5. To disengage feed loosen wing nut (figure 12a) and slide stop (figure 12b) to desired position. 6. Reset stop (figure 12b) every time machine is used on a different width drum. If properly set, the machine will disengage automatically w...

Page 20: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) 10.Wrap and secure the drum silencer band tightly around the drum (figure 14). 11.Turn the cross feed handwheel and the spindle feed handwheel to their maximum clockwise position. Then back off the cross feed handwheel 2 turns and the spin...

Page 21: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) turning disc brakes 1. Tighten thumb screw (figure 8 b page 13) 2. Loosen knob (figure 9 page 14) 3. Each brake disc should be carefully inspected for scoring, rust, ridges (at the inner and outer circumference of the rotor) and hard spots...

Page 22: Operation (Continued)

204 heavy duty combination brake lathe operation (continued) 6. Feed in the slide assembly with crank [figure 18 a). (figure 18 b) locking nut is turned in to engage slide power. (must be loose to turn slide in or out manually. Figure 18 7. Feed in the moveable claw with graduated dial [figure 18 a)...

Page 23: Maintenance (Continued)

204 heavy duty combination brake lathe maintenance (continued) disassembly, repair, replacement and reassembly 1. Unplug machine. 2. Remove tooling from machine. 3. Remove arbor by loosening draw bar. 4. Drain oil. 5. You are now ready to start repair. Spindle bearing note: it is rare for the spindl...

Page 24: Basic Machine

204 heavy duty combination brake lathe basic machine item part no. Description qty 1 804-2043-00 body 1 2 804-1184-28 breather 1 804-3020-06 bearing (prior to 1984)( not shown) 4 804-1415-69 front bearing oil seal 1 5 804-3040-65 work light window 1 6 804-1050-21 screw (10-32 x 3/8) 4 7 000-1154-60 ...

Page 25: Basic Machine

204 heavy duty combination brake lathe basic machine van norman 21. 888-855-1789.

Page 26: Vertical Shaft Assembly

204 heavy duty combination brake lathe vertical shaft assembly item part no. Description qty. 1 804-2043-00 body 1 2 804-1094-24 groove pin 1 3 804-2040-19 upper collar 1 4 804-1062-54 oiler 1 5 000-4400-10 handwheel handle 1 7 804-2040-75 vertical shaft handwheel 1 8 804-2040-18 handwheel spring 1 ...

Page 27: Vertical Shaft Assembly

204 heavy duty combination brake lathe vertical shaft assembly van norman 23. 888-855-1789.

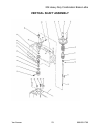

Page 28: Spindle Clamp Assembly

204 heavy duty combination brake lathe spindle clamp assembly item part no. Description qty. 1 804-2040-26 push rod 1 2 804-8035-81 retaining ring 1 3 804-1243-55 compression spring 1 4 000-1155-33 washer, 3/8 flat 1 5 804-2040-63 sleeve 1 6 000-1180-28 lockwasher, (5/16) 3 7 000-0167-64 shcs (5/16-...

Page 29: Spindle Clamp Assembly

204 heavy duty combination brake lathe spindle clamp assembly van norman 25. 888-855-1789.

Page 30: Right Rear Of Machine

204 heavy duty combination brake lathe right rear of machine item part no. Description qty. 1 bulk cable, 36”' 1 2 800-8014-71 strain relief 2 4 000-1261-01 110v motor cable 1 5 000-1160-17 washer, (5/16) 4 6 000-1180-28 lockwasher (5/16) 4 7 000-0102-86 hhcs (5/16-18 x 3/4) 4 8 804-1405-24 motor 1 ...

Page 31: Right Rear Of Machine

204 heavy duty combination brake lathe right rear of machine van norman 27. 888-855-1789.

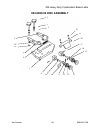

Page 32: 804-8690-56 Disc Assembly

204 heavy duty combination brake lathe 804-8690-56 disc assembly item part no. Description qty. 1 804-8693-77 hand lock down 2 2 804-1407-54 washer, .312 flat 2 3 804-1258-12 dowel pin (.75 x 2) 2 4 804-1405-35 spring 1 5 804-8678-54 r.H. Tool holder 1 6 804-8678-55 l.H. Tool holder 1 7 804-8690-23 ...

Page 33: 804-8690-56 Disc Assembly

204 heavy duty combination brake lathe 804-8690-56 disc assembly 5 18 19 6 4 7 8 14 16 9 13 12 11 10 17 20 22 21 3 2 1 15 van norman 29. 888-855-1789.

Page 34

204 heavy duty combination brake lathe power feed attachment for facing disc brakes item part no. Description qty. 1 804-2041-42 gib 1 2 000-0491-23 sss (3/8-16 x 1 3/4) 2 3 804-1405-31 knob 1 4 804-1116-33 brass plug 1 6 000-0170-35 shcs (3/8-16 x 1 1/2) 2 7 804-2041-18 power facing feed slide 1 8 ...

Page 35

204 heavy duty combination brake lathe power feed attachment for facing disc brakes van norman 31. 888-855-1789.

Page 36: Electrical Equipment

204 heavy duty combination brake lathe electrical equipment item part no. Description qty. 1 804-2043-00 body 1 2 804-1413-57 electrical cover 2 3 800-8014-69 strain relief 5 4 804-1415-26 wire clip 1 5 804-1050-21 screw (10-32 x 3/8) 1 6 804-1413-56 switch 2 7 804-8657-78 electrical box 2 8 804-105...

Page 37: Electrical Equipment

204 heavy duty combination brake lathe electrical equipment van norman 33. 888-855-1789.

Page 38

204 heavy duty combination brake lathe van norman 34. 888-855-1789.

Page 39

204 heavy duty combination brake lathe van norman 35. 888-855-1789.

Page 40

204 heavy duty combination brake lathe van norman 36. 888-855-1789.

Page 41

204 heavy duty combination brake lathe van norman 37. 888-855-1789.

Page 43: Van Norman

Van norman a division of kwik-way products inc. 500 57 th st., marion, ia 52302 usa 888-855-1789 or 319/377-9421 319/377-9101 (fax) www.Van-norman.Com service@kwik-way.Com.