- DL manuals

- Vanair

- Welding System

- AIR N ARC I 300 SERIES

- Operation Manual

Vanair AIR N ARC I 300 SERIES Operation Manual

WELDER • GENERATOR • AIR COMPRESSOR

BATTERY BOOSTER • HYDRAULIC PUMP

OPERATION MANUAL & PARTS LIST

©2013 Vanair Manufacturing, Inc.

All rights reserved

P/N: 090045-OP_r1

Effective Date:

11-2013

Read this manual before

installing, operating or

servicing this equipment.

Failure to comply with the

operation and maintenance

instructions in this manual

WILL VOID THE EQUIPMENT

WARRANTY.

NOTE

Making unauthorized

modifications to the system

components WILL VOID THE

WARRANTY!

Always inform Vanair

Manufacturing, Inc., before

beginning any changes to the

Air N Arc system.

NOTE

Use only Vanair Vanguard™

Premium Synthetic Oil and

Genuine Vanair Parts. Inspect

and replace damaged

components before operation.

Substituting non-Vanguard™

Oil or non-genuine Vanair filter

components WILL VOID THE

COMPRESSOR WARRANTY!

Vanair Manufacturing, Inc.

10896 West 300 North

Michigan City, IN 46360

Phone: (219) 879-5100

(800) 526-8817

Service Fax: (219) 879-5335

Parts Fax: (219) 879-5340

Sales Fax: (219) 879-5800

www.vanair.com

KEEP THE MANUAL

WITH THE VEHICLE

NOTE

This publication contains the

latest information available at

the time of preparation. Every

effort has been made to ensure

accuracy. However, Vanair

Manufacturing, Inc. takes no

responsibility for errors or

consequential damages

caused by reliance on the

information contained herein.

Vanair Manufacturing, Inc.

reserves the right to make

design change modifications

or improvements without prior

notification.

Summary of AIR N ARC I 300 SERIES

Page 1

Welder • generator • air compressor battery booster • hydraulic pump operation manual & parts list ©2013 vanair manufacturing, inc. All rights reserved p/n: 090045-op_r1 effective date: 11-2013 read this manual before installing, operating or servicing this equipment. Failure to comply with the oper...

Page 2

Warranty subject to the terms and conditions below, vanair ® manufacturing inc. Warrants to the original end user that new air n arc ® equipment sold after the effective date of this limited warranty is free of defects in material and workmanship at the time it was shipped from vanair. This statemen...

Page 3: Table Of Contents

Air n arc ® i - 300 series all-in-one power system ® table of contents 090045-op_r1 page - i table of contents warranty ............................................... Behind cover table of contents......................................................I warranty claims procedure .......................

Page 4

Table of contents air n arc ® i - 300 series all-in-one power system ® page - ii 090045-op_r1 section 1: safety (continued) 1.5.8 engine heat can cause fire......................................................................................................................6 1.5.9 exhaust sparks can...

Page 5

Air n arc ® i - 300 series all-in-one power system ® table of contents 090045-op_r1 page - iii section 1: safety (continued) 1.8.2 overheating can damage motors ........................................................................................................ 10 1.8.3 flying sparks can cause i...

Page 6

Table of contents air n arc ® i - 300 series all-in-one power system ® page - iv 090045-op_r1 section 4: operation ................................................. 25 4.1 general information ........................................................................................................... ...

Page 7

Air n arc ® i - 300 series all-in-one power system ® table of contents 090045-op_r1 page - v section 5: maintenance (continued) 5.4.3.3 re-tensioning the generator / hydraulic pump serpentine drive belt ....................................................................................................

Page 8

Table of contents air n arc ® i - 300 series all-in-one power system ® page - vi 090045-op_r1 section 7: illustrated parts list (continued) 7.14 decal and plate locations (1 of 4).................................................................................. 106 7.14 decal and plate locations (2 ...

Page 9: Laims

Air n arc ® i - 300 series all-in-one power system ® warranty procedure 090045-op_r1 page - vii c laims process for warranted v anair parts this process must be used by owners of vanair ® equipment in situations where a warranted item needs repair or replacement under the terms of the purchase warra...

Page 10

Warranty procedure air n arc ® i - 300 series all-in-one power system ® page - viii 090045-op_r1 key description key description a machine serial plate / serial # location c engine serial number tag b compressor serial plate / serial # location: note alternative locations of plate mounting d welder ...

Page 11

Air n arc ® i - 300 series all-in-one power system ® warranty procedure 090045-op_r1 page - ix disposition of goods , notifications and additional notes , will be required. Customers have 30 days after the rma number is issued to return the item. If the part is not returned within this period, the r...

Page 12: Blank Page

Page - x 090045-op_r1 blank page.

Page 13: 1.1 General Information

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 1 1.1 general information the products provided by vanair ® manufacturing, inc., are designed and manufactured for safe operation and maintenance. But it is ultimately the responsibility of the users and maint...

Page 14: 1.3 International Safety

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 2 090045-op_r1 1.3 international safety symbol - the symbols shown and defined in section 1: safety are used throughout this manual to call attention to and identify possible hazards. The international warning symbol shown...

Page 15

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 3 since double open-circuit voltage will be present. Wear a safety harness if working above floor level. Keep all panels and covers securely in place. Clamp work cable with good metal-to-metal contact to work ...

Page 16

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 4 090045-op_r1 wear protective clothing made from durable, flame-resistant material (leather, heavy cotton, or wool) and foot protection. 1.4.6 welding can cause fire and explosion welding on closed containers, such as tan...

Page 17: 1.5 Engine Hazards

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 5 arc welding, gouging, or spot welding operations. Shielding gas cylinders contain gas under high pressure. If damaged, a cylinder can explode. Since gas cylinders are normally part of the welding process, be...

Page 18: 1.6 Compressed Air

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 6 090045-op_r1 do not overfill tank—allow room for fuel to expand. Do not spill fuel. If fuel is spilled, clean up before starting engine. Dispose of rags in a fireproof container. 1.5.3 moving parts can cause injury keep ...

Page 19: 1.7 Hydraulic Pump

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 7 1.6.2 enclosed spaces can cause a build-up of noxious fumes and overheating do not use in enclosed spaces where deadly exhaust gasses can build up and machine can overheat, causing fire. 1.6.3 compressed air...

Page 20

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 8 090045-op_r1 1.7.3 hose and tubing inspection hydraulic hoses and tubing must be inspected on a daily basis for leaks, cuts, abrasions, damage and improper clearance along any mounting frame for hidden damage before the ...

Page 21

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 9 1.7.9 relieve hydraulic system pressure before removing any components from the system all hydraulic pressure must be relieved from the hydraulic system prior to removing any components from the system. To r...

Page 22

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 10 090045-op_r1 1.7.16 wear proper protective equipment wear the proper protective clothing when operating, servicing or maintaining the hydraulic system or the vanair pump. Wear the correct protective gear, safety glasses...

Page 23: 1.9

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 11 1.8.6 tilting of trailer can cause injury use tongue jack or blocks to support weight. Properly install unit onto trailer according to instructions supplied with trailer. 1.8.7 read instructions use only ge...

Page 24: 1.10

Section 1: safety air n arc ® i - 300 series all-in-one power system ® page - 12 090045-op_r1 the state of california to cause cancer, birth defects, and other reproductive harm. 1.10 principal safety standards safety in welding, cutting, and allied processes, ansi standard z49.1, from global engine...

Page 25: 1.12

Air n arc ® i - 300 series all-in-one power system ® section 1: safety 090045-op_r1 page - 13 about pacemakers: pacemaker wearers consult your doctor before welding or going near welding operations. If cleared by your doctor, then following the above procedures is recommended. 1.12 machine canopy ac...

Page 26

Section 2: specifications air n arc ® i - 300 series all-in-one power system ® page - 14 090045-op_r1 key description key description a instrument panel (may be remotely mounted) r compressor oil filter b air outlet service ports (x 3; one shown) s compressor air filter c welder generator t engine o...

Page 27: Section 2:

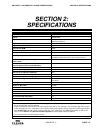

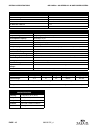

Air n arc ® i - 300 series all-in-one power system ® section 2: specifications 090045-op_r1 page - 15 section 2: specifications table 2a: engine, hydraulic system, welder, and generator specifications system information specification engine: diesel 25hp i engine oil capacity: 5.5 quarts 15w40 (refer...

Page 28

Section 2: specifications air n arc ® i - 300 series all-in-one power system ® page - 16 090045-op_r1 dc 24 volt charge volts: 30 ac generator: 61 hz (no load) ac generator 120v rh: 118 ac generator 120v lh: 118 ac generator 240v: 238 table 2b: specifications — air compressor compressor information ...

Page 29: 3.1

Air n arc ® i - 300 series all-in-one power system ® section 3: installation 090045-op_r1 page - 17 3.1 air n arc i- 300 series all- in-one power system machine package receipt/inspection upon receipt of the machine package, inspect the exterior of the shipping crate for signs of shipping/transit da...

Page 30

Section 3: installation air n arc ® i - 300 series all-in-one power system ® page - 18 090045-op_r1 when determining the factors involved with the installation of the air n arc i- 300 series machine on a vehicle, use this manual in tandem with the vehicle’s own manual to aide in determining how the ...

Page 31

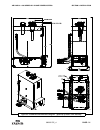

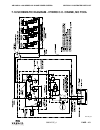

Air n arc ® i - 300 series all-in-one power system ® section 3: installation 090045-op_r1 page - 19 figure 3-1: installation and dimensions diagram - part 1 of 2 050790-001_r1_1of3.

Page 32

Section 3: installation air n arc ® i - 300 series all-in-one power system ® page - 20 090045-op_r1 figure 3-2: installation and dimensions diagram - part 2 of 2 050790-001_r0_2of3 050790-001_r0_2of3.

Page 33

Air n arc ® i - 300 series all-in-one power system ® section 3: installation 090045-op_r1 page - 21 figure 3-3: installation and dimensions diagram - (optional) hydraulic tank assembly pa6120139id_r2.

Page 34: 3.4 Connecting The Fuel

Section 3: installation air n arc ® i - 300 series all-in-one power system ® page - 22 090045-op_r1 3.4 connecting the fuel system to connect to the fuel pump, refer to figure 3-4 , and follow these steps: 1. Mount the electric fuel pump at the desired location on the service body, keeping it as clo...

Page 35: 3.6

Air n arc ® i - 300 series all-in-one power system ® section 3: installation 090045-op_r1 page - 23 hose layout and connecting functions. 3.6 installing the remote control panel for remote instrument panel mounting, install the remote control panel at the desired location on the service body and rou...

Page 36

Section 3: installation air n arc ® i - 300 series all-in-one power system ® page - 24 090045-op_r1 figure 3-5: fuel line bleed nut (receiving air in fuel line).

Page 37: 4.1 General Information

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 25 4.1 general information the air n arc i -300 all-in-one power system has a comprehensive array of controls and indicators for each function of the power system. Understanding the correct operational func...

Page 38: 4.2

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 26 090045-op_r1 4.2 machine start-up and shutdown procedure consult figure 4-2: instrument panel functions for operating procedures detailed in this section. 4.2.1 start-up from machine consult figure 4-2 , and the foll...

Page 39

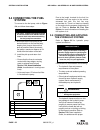

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 27 key description key description a volts/amps meter m welder lead connection b welder cc/cv toggle switch n battery cable receptacle c dc charger/welder toggle switch p ac voltage outlets d dc charger mod...

Page 40: 4.3 Engine Throttle

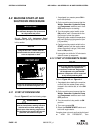

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 28 090045-op_r1 momentarily select “stop”. Then try again to start the engine. 4.2.3 machine shutdown consult figure 4-2 and figure 4-3 . To shut the engine off at any time, turn the engine control switch to the off pos...

Page 41: 4.4 Operating The

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 29 4.4 operating the welder consult figure 4-4 . The variable power dial adjusts the welder amperage (0 to 300 amps), or voltage (15 to 40 volts) for the desired weld heat. Turning the power dial clockwise ...

Page 42

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 30 090045-op_r1 electrode and the metal for 30 seconds, the engine will return to idle. What the numbers mean that are used to identify a stick welding electrode: using e6010 for an example... The “e” indicates electrod...

Page 43: 4.5 Operating The

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 31 1. With the engine shut off, insert the twist lock connection of the ground clamp into the negative (-) welder connection port on the control panel. Insert the power lead segment from the suitcase feeder...

Page 44: 4.6 Operating The

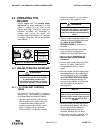

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 32 090045-op_r1 4.6 operating the compressor to operate the air compressor: 1. Start the engine as per section 4.2.1 . 2. With the engine warmed up and operating at low idle, turn the compressor switch on the control pa...

Page 45: 4.8 Using The Start

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 33 during charging, if the machine begins to cycle between high and low idle, then the battery is fully charged. 4.7.1 connection - disconnection sequence and operation 1. With the engine off, insure that t...

Page 46: 4.9 Operating The

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 34 090045-op_r1 1. If equipped, confirm that the master power switch (in vehicle cab) is on . 2. Turn key on the i -300 unit and attempt to start. 3. If the i -300 did not start then turn the key switch back to off. 4. ...

Page 47

Air n arc ® i - 300 series all-in-one power system ® section 4: operation 090045-op_r1 page - 35 gelling diesel fuel turns into a gel-like consistency at temperatures around 0°f (-18°c): the diesel forms wax crystals when the temperatures drop below 15°f (-9°c). Then, as it gets colder, these wax cr...

Page 48

Section 4: operation air n arc ® i - 300 series all-in-one power system ® page - 36 090045-op_r1 4.10.3 high dust content operation when the machine is to be used in continuously dusty environments, special care must be taken with the engine’s air cleaner and radiator, the compressor air filter and ...

Page 49: 5.1 General Information

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 37 5.1 general information a strict maintenance program is the key to long life for the air n arc i -300 series all-in- one power system package. Following is a program that, when adhered to, should keep ...

Page 50

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 38 090045-op_r1 maintenance regimen must be followed in order to protect the warranty of the machine package. Vanair ® manufacturing, inc. Especially requires that a consistent service regimen be established for engin...

Page 51

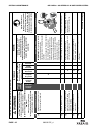

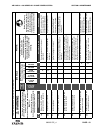

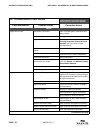

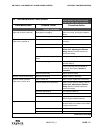

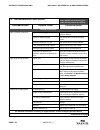

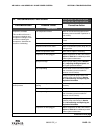

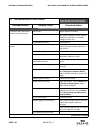

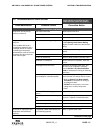

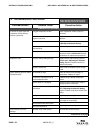

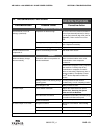

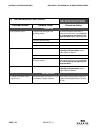

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 39 t a b l e 5 a : m a in t e n a n c e s c h e d u l e w a r n in g b e fo re p e rf o rm in g m a in te n a n c e : s h u t d o w n m a c h in e , re li e v e a ll s y s te m p re s s u re a n d l o c k...

Page 52

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 40 090045-op_r1 7 c h e c k a ir t a n k f o r w a te r a c c u m u la ti o n • d ra in a n y w a te r fr o m t h e a ir t a n k . N o te th a t th e 1 /8 ” n p t f it ti n g a t th e e n d o f th e d ra in v a lv e (...

Page 53

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 41 1 0 in s p e c t c o o le r fi n s ( b o th e n g in e a n d c o m p re s s o r o il c o o le rs ) fo r c o n ta m in a ti o n ) • c le a n o r c le a r a s n e c e s s a ry . U s e o n ly lo w p re s ...

Page 54

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 42 090045-op_r1 1 4 c h a n g e a ir c o m p re s s o r o il, o il fi lt e r a n d c o a le s c e r e le m e n t • im p o r t a n t : t h is p ro c e d u re s h o u ld o n ly b e p e rf o rm e d w h e n t h e c o m p ...

Page 55

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 43 1 9 b lo w o u t th e d c w e ld in g g e n e ra to r a n d a c g e n e ra to r • u s e c o m p re s s e d a ir t o c le a r o u t g e n e ra to rs n o t e : c a rr y o u t e v e ry 1 0 0 h o u rs i f ...

Page 56: 5.3 Replacement Parts

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 44 090045-op_r1 5.3 replacement parts replacement parts should be purchased through your local vanair ® representative or where the i -300 series power system was purchased. If, for any reason, parts are not available...

Page 57

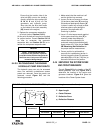

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 45 5.4.1 adjusting the engine speed consult the vanair ® service department for issues relating to adjustment of engine speed. 5.4.2 adjusting the pressure setting the cut-in pressure is defined as the pr...

Page 58

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 46 090045-op_r1 service life of the compressor system. However, you may find that over time they become loose and need to be tightened. The proper tension can be determined by using a tension tester to measure the def...

Page 59

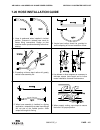

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 47 key description key description a tensioner plate mounting and adjustment bolts e loosen bolts [a] to allow tensioner plate to pivot manually to achieve new belt-tensioned position. B idler f pivot pla...

Page 60

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 48 090045-op_r1 3. Unfasten the clutch retaining cable by removing the retaining cable bolt [ d ], lock washer [ e ], washer [ f ], and harness cable clamp [ g ] securing the cable to the floor. The harness cable does...

Page 61

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 49 set bolt [ f ] and anchor bolt [ d ] to fasten the tensioner plate into the proper torqued position. Remove the torque wrench. 5.4.3.4 replacing the generator/ hydraulic pump serpentine drive belt to r...

Page 62

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 50 090045-op_r1 key description key description a upper idler sheave bolt g 2 drive belt: smooth side = outside b upper idler sheave h welder drive pulley c tensioner plate (for upper idler) j ac generator pulley d te...

Page 63

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 51 ensure that the traction side of the drive belt [ g 1 ] runs on the inside to directly contact the drive pulleys [ h , b , m , n , k and j ] that run the generators and hydraulic pump. Also note that t...

Page 64

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 52 090045-op_r1 danger fuses will need to be replaced if they are blown when tripped. When changing any fuse, or dealing directly with any function of the electrical system maintenance, always be aware of the safety w...

Page 65

Air n arc ® i - 300 series all-in-one power system ® section 5: maintenance 090045-op_r1 page - 53 figure 5-10 engine and generator breakers d c a b e note there are also two (2) 20a circuit breakers located on the instrument panel. Refer to section 7.7, item #29. Key description a engine circuit br...

Page 66: 5.5 Storage And

Section 5: maintenance air n arc ® i - 300 series all-in-one power system ® page - 54 090045-op_r1 5.5 storage and intermittent use 5.5.1 intermittent use if the unit is not used very regularly always treat the fuel with a fuel stabilizer. Check all belts and hoses for signs of deterioration such as...

Page 67: 6.1 General Information

Air n arc ® i -300 series all-in-one power system ® section 6: troubleshooting 090045-op_r1 page - 55 warning before starting, performing maintenance, or replacing parts, relieve the entire system pressure by opening the air tank drain/vent valve, which will vent all pressure to the atmosphere. Refe...

Page 68

Section 6: troubleshooting air n arc ® i -300 series all-in-one power system ® page - 56 090045-op_r1 6.2 troubleshooting guide use section 7, illustrated parts list, to visually identify and confirm any part number that may need to be replaced. Fault/malfunction possible cause corrective action eng...

Page 69

Air n arc ® i -300 series all-in-one power system ® section 6: troubleshooting 090045-op_r1 page - 57 engine (continued) engine will not start (continued) glow plugs not engaging check fuse, wiring, and engine operation manual. Fuel solenoid is faulty replace fuel solenoid. Improper control operatio...

Page 70

Section 6: troubleshooting air n arc ® i -300 series all-in-one power system ® page - 58 090045-op_r1 engine (continued) engine overheats (continued) engine oil filter plugged replace engine oil filter. Refer to engine operation manual. Engine oil radiator plugged clear debris/dirt from cooler core/...

Page 71

Air n arc ® i -300 series all-in-one power system ® section 6: troubleshooting 090045-op_r1 page - 59 compressor compressor overheats this condition will cause a compressor shutdown and compressor fault light to turn on. Before restarting the compressor, determine the cause for overheating. Low comp...

Page 72

Section 6: troubleshooting air n arc ® i -300 series all-in-one power system ® page - 60 090045-op_r1 compressor (continued) compressor shuts down with air demand present (continued) clutch faulty inspect; replace if necessary. Plugged or restricted cooler core flush cooler. Consult the vanair ® ser...

Page 73

Air n arc ® i -300 series all-in-one power system ® section 6: troubleshooting 090045-op_r1 page - 61 compressor (continued) compressor will not build up pressure (continued) inlet valve frozen shut repair/replace inlet valve. Clutch faulty inspect; replace if necessary. Broken or loose belt re-tens...

Page 74

Section 6: troubleshooting air n arc ® i -300 series all-in-one power system ® page - 62 090045-op_r1 compressor (continued) no service air output (see also compressor will not build up pressure ) (continued) clogged compressor air filter check compressor air filter; replace if necessary solenoid va...

Page 75

Air n arc ® i -300 series all-in-one power system ® section 6: troubleshooting 090045-op_r1 page - 63 compressor (continued) excess amount of oil in air discharge (continued) compressor oil level too high the correct oil level is between the bottom of the oil port threads (low level) to the top lip ...

Page 76

Section 6: troubleshooting air n arc ® i -300 series all-in-one power system ® page - 64 090045-op_r1 generator no ac generator output serpentine belt damaged or not tensioned properly re-situate and adjust belt tension, or replace belt if necessary. Consult section 5.4.3, re-tensioning and replacin...

Page 77: Section 7:

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 65 figure 7-1: machine package serial number plate / serial number location note for engine, compressor, and generator serial tag locations, refer to figure w-1 in the warranty procedure section...

Page 78

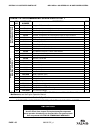

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 66 090045-op_r1 table 7a: recommended spare parts list i key no. Order part number description qty r o u t in e /s c h e d u l e d m a in t e n a n c e i t e m s 1 264626-1gal vanguard™ premium oil ii 1 gal ...

Page 79

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 67 important if additional spare parts are being stored for future use, ensure that they are stored in proper containers that allow for protection against contamination, and kept in a clean area...

Page 80: 7.2 Air N Arc

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 68 090045-op_r1 7.2 air n arc i -300 systems assemblies pa6130069-001id_r0

Page 81: 7.2 Air N Arc

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 69 7.2 air n arc i -300 systems assemblies item description part number qty reference section i 1 air storage assembly pa6000079-001id 1 7.3 2 id, compressor & parts pa6010123id 1 7.4 3 id, cool...

Page 82: 7.3 Air Storage Assembly

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 70 090045-op_r1 7.3 air storage assembly pa6000079-001id_r0

Page 83: 7.3 Air Storage Assembly

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 71 7.3 air storage assembly item description part number qty 1 elbow, 90 deg. Push on 1/4t x 1/4p 261310 1 2 connector, 1/8p x 1/4t push on 261316 1 3 valve, relief 200 psi 1/4 npt male 264232 1...

Page 84

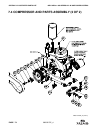

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 72 090045-op_r1 7.4 compressor and parts assembly (1 of 2) pa6010123id_r2 (1 of 2).

Page 85

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 73 7.4 compressor and parts assembly (1 of 2) item description part number qty item description part number qty 1 tee, male street 1/4 x 1/4 x 1/4 260402-102 1 24 bolt, carriage 1/2-13unc x 2- 1...

Page 86

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 74 090045-op_r1 pa6010123id_r2 (2 of 2) 7.4 compressor and parts assembly (2 of 2).

Page 87

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 75 7.4 compressor and parts assembly (2 of 2) item description part number qty item description part number qty 1 tee, male street 1/4 x 1/4 x 1/4 260402-102 1 24 bolt, carriage 1/2-13unc x 2- 1...

Page 88: 7.5 Cooling System

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 76 090045-op_r1 7.5 cooling system pa6020024id_r10

Page 89: 7.5 Cooling System

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 77 7.5 cooling system item description part number qty item description part number qty 1 elbow,90 deg 3/8p x 1/2j long 044832-007 1 17 washer, lock 5/16 838505-078 9 2 elbow,90 deg #8 mjicx#8 m...

Page 90

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 78 090045-op_r1 7.6 frame and canopy assembly (1 of 2) pa6030062-001id_r0 (1 of 2).

Page 91

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 79 7.6 frame and canopy assembly (1 of 2) item description part number qty item description part number qty 1 washer, nylon flat 1/4 262704 3 26 canopy, hood a1269763 1 2 grommet, rubber 5/8 x 7...

Page 92

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 80 090045-op_r1 7.6 frame and canopy assembly (2 of 2) pa6030062id-001_r0 (2 of 2).

Page 93

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 81 7.6 frame and canopy assembly (2 of 2) item description part number qty item description part number qty 1 washer, nylon flat 1/4 262704 3 26 canopy, hood a1269763 1 2 grommet, rubber 5/8 x 7...

Page 94: 7.7 Instrument Panel

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 82 090045-op_r1 7.7 instrument panel pa6040047id_r2.

Page 95: 7.7 Instrument Panel

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 83 7.7 instrument panel item description part number qty item description part number qty 1 elbow, 1/4t x 1/8p push-on 261309 1 31 gauge, air, dry, 0-200 psi co89649 1 2 elbow, 90 deg. Push on 1...

Page 96: 7.8 Generators And Parts

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 84 090045-op_r1 7.8 generators and parts pa6050012id_r4.

Page 97: 7.8 Generators And Parts

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 85 7.8 generators and parts item description part number qty 1 generator, ac, 6.8kw 269530 1 2 key, square 3/16 x 3/16 x 1.5 821103-150 1 3 nut, hex locking 1/2-13 825508-262 1 4 capscrew,hex gr...

Page 98

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 86 090045-op_r1 7.9 hydraulic pump assembly (1 of 3) pa6100036id-001_r1 (1of3).

Page 99

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 87 7.9 hydraulic pump assembly (1 of 3) item description part number qty item description part number qty 1 connector, #6 msae x #6 mjic 260387-105 3 27 washer, flat 3/8 838206-071 9 2 connector...

Page 100

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 88 090045-op_r1 7.9 hydraulic pump assembly - open center (2 of 3) pa6100036id-001_r1 (2of3).

Page 101

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 89 7.9 hydraulic pump assembly - open center (2 of 3) item description part number qty 1 connector, #6 msae x #6 mjic 260387-105 3 3 elbow, 90 deg. 3/8 mjic x 3/8 msae 260403-103 2 9 clamp, hose...

Page 102

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 90 090045-op_r1 7.9 hydraulic pump assembly - closed center (3 of 3) pa6100036id-001_r1 (3of3).

Page 103

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 91 7.9 hydraulic pump assembly - closed center (3 of 3) item description part number qty 3 elbow, 90 deg. 3/8 mjic x 3/8 msae 260403-103 2 10 cap, female #6 jic 9/16-18 unf-2b 264322-002 1 11 ca...

Page 104

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 92 090045-op_r1 7.10 engine and drive parts (1 of 2) pa6100056id_r1 (1 of 3).

Page 105

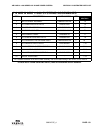

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 93 7.10 engine and drive parts (1 of 2) item description part number qty item description part number qty 1 clamp, hose 3/16 - 5/16 hose 260864 2 27 capscrew, hex gr5 1/4-20 x 1 829104-100 1 2 w...

Page 106

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 94 090045-op_r1 7.10 engine and drive parts (1 of 2) (continued) pa6100056id_r1 (1 of 3).

Page 107

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 95 7.10 engine and drive parts (1 of 2) (continued) item description part number qty item description part number qty 53 hose, fuel line 5/16 (ft) 842315-031 1 79 sheave, engine, “a” groove dr27...

Page 108

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 96 090045-op_r1 7.10 engine and drive parts (2 of 2) pa6100056id_r1 (2 and 3 of 3).

Page 109

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 97 7.10 engine and drive parts (2 of 2) item description part number qty item description part number qty 1 clamp, hose 3/16 - 5/16 hose 260864 2 27 capscrew, hex gr5 1/4-20 x 1 829104-100 1 2 w...

Page 110

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 98 090045-op_r1 7.10 engine and drive parts (2 of 2) (continued) pa6100056id_r1 (2 and 3 of 3).

Page 111

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 99 7.10 engine and drive parts (1 of 2) (continued) item description part number qty item description part number qty 53 hose, fuel line 5/16 (ft) 842315-031 1 79 sheave, engine, “a” groove dr27...

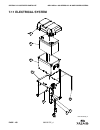

Page 112: 7.11 Electrical System

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 100 090045-op_r1 7.11 electrical system pa6120136id_r0

Page 113: 7.11 Electrical System

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 101 7.11 electrical system item description part number qty 1 capscrew, hex gr5 1/4-20 x 3/4 829104-075 4 2 washer, lock 1/4 838504-062 4 3 bracket, battery a1270389 1 4 box, battery el269924 1 ...

Page 114: 7.12 Manifold Assembly

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 102 090045-op_r1 7.12 manifold assembly pa6120134-03id_r1.

Page 115: 7.12 Manifold Assembly

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 103 7.12 manifold assembly item description part number qty 1 connector, #6 msae x #6 mjic 260387-105 3 2 connector, #8 msae x #8 mjic 260387-107 2 3 connector, #10 msae x #10 mjic 260387-109 1 ...

Page 116

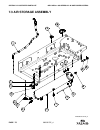

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 104 090045-op_r1 7.13 hydraulic tank assembly pa6120139id_r2.

Page 117

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 105 7.13 hydraulic tank assembly item description part number qty 1 connector, #12 msae x #12 mjic 260387-112 1 2 elbow, 90 deg #8 mjic x #8 msae 260403-104 1 3 elbow, 90 deg #12 mjic x #12 msae...

Page 118

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 106 090045-op_r1 inside view of hood panel 1 3 4 5 6 7 8 2 9 10 7.14 decal and plate locations (1 of 4) item description part number qty item description part number qty 1 i decal, explosive fuel 264377 1 6 ...

Page 119

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 107 1 2 3 4 inside front panel (shown in released position) 5 6 7 8 9 7.14 decal and plate locations (2 of 4) item description part number qty item description part number qty 1 decal, low sulfu...

Page 120

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 108 090045-op_r1 ® 1a 2 2 1b front view back view 6 7 8 a ir tan k drai n drain daily sup p ly return 4 5 3 7.14 decal and plate locations (3 of 4) item description part number qty item description part numb...

Page 121

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 109 side vie w: with instrument panel mounted side vie w: without instrument panel mounted 1 2 3 7.14 decal and plate locations (4 of 4) item description part number qty 1 decal, vanair logo dl2...

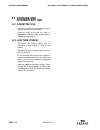

Page 122: -300 Series

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 110 090045-op_r1 7.15 wiring diagram - air n arc i -300 series id272402_r7.

Page 123

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 111 7.16 wiring diagram - switches and lights id270925_r1.

Page 124

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 112 090045-op_r1 7.17 schematic diagram - hydro crane, o.C., no tool id271786_r5.

Page 125

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 113 7.18 schematic diagram - hydro c.C. Crane, no tool 271787_r6.

Page 126

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 114 090045-op_r1 id272919_r1 7.19 schematic diagram - compressor flow.

Page 127

Air n arc ® i -300 series all-in-one power system ® section 7: illustrated parts list 090045-op_r1 page - 115 1. Hose is weakened when installed in twisted position. Pressure in twisted hose tends to loosen fitting connections. Design so that machine motion produces bending rather than twisting. 2. ...

Page 128: Blank Page

Section 7: illustrated parts list air n arc ® i -300 series all-in-one power system ® page - 116 090045-op_r1 blank page.

Page 129: Blank Page

Blank page.

Page 130

Printed in the u.S.A. Specifications subject to change without prior notice 050790-001 (g2) vanair manufacturing, inc. 10896 west 300 north michigan city, in 46360 phone: (219) 879-5100 (800) 526-8817 service fax: (219) 879-5335 parts fax: (219) 879-5340 sales fax: (219) 879-5800 www.Vanair.Com.