- DL manuals

- VanEE

- Fan

- 12LC

- Installation, Operation And Service Instructions

VanEE 12LC Installation, Operation And Service Instructions

Summary of 12LC

Page 1

Light commercial heat recovery ventilators and energy recovery ventilators installation, operation and service instructions vb0002 vb0003 vb0001 207428 rev. 12 6lc, v6lc 7000 12lc, v12lc.

Page 2: Table of Contents

2 table of contents 1. Safety considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 3

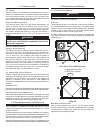

3 2. Installation 2.1 inspection inspect the exterior of the unit for shipping damage by ensuring that there is no damage to the door, door latches, door hinges, damper, duct collars, cabinet, etc. Inspect the interior of the unit for damage by ensuring that the fan motors and housings, heat or ener...

Page 4

4 2. Installation (cont’d) 2.6 exterior hoods it is important that the fresh air intake hood be positioned well away from any source of contamination. The exterior supply and exhaust hoods must be separated enough to prevent cross-contamination and at an elevation that will prevent blockage by snow,...

Page 5

5 3. Controls (cont’d) 3.3 defrost the unit functions are controlled by integrated controls in the unit which may include exhaust only defrost or recirculation defrost (via the recirculation module - 6lc, v6lc, 12lc and v12lc units only). In cold temperatures, defrost cycles will remove frost from t...

Page 6

6 5. Maintenance and service (cont’d) 5.2 annual maintenance annual maintenance should include: a ir f ilters vacuum and wash standard foam filters. Replace medium efficiency filter if present. D rain p ans and i nterior of u nit wash the foil faced insulation surfaces and wipe the drain pans with a...

Page 7

7 6. Service parts 6.1 6lc, v6lc-12lc, v12lc exhaust defrost b c d e f g h i j k m l n vl0068 ref. Part no. Description b 13036 hinge kit (male-female) c 1808139 core defrost actuator 6lc, v6lc-12lc, v12lc 63341 core defrost actuator 12lc, v12lc, powder coated d 63327 core damper 6lc, v6lc 63328 cor...

Page 8

8 6. Service parts (cont’d) 6.2 6lc, v6lc-12lc, v12lc recirculation defrost b c d d e f g i j h k l m vl0069 ref. Part no. Description b 13036 hinge kit (male-female) c 1808147 core poly csa 6lc, v6lc-12lc, v12lc (unitary) 1808146 core poly ul 6lc, v6lc-12lc, v12lc u.S. Only (unitary) 1604191 core a...

Page 9

9 6. Service parts (cont’d) 6.3 7000 b d c e f g h j i k vl0070 l ref. Part no. Description b 16035 door latch-keeper kit c 225855 damper motor belimo lmb24-3-t, 7000, 6lc, v6lc-12lc, v12lc (recirculation defrost option) d 1604178 fresh air damper e 1604168 blower ass’y 7000 1604177 blower wheel (no...

Page 10: Appendix A

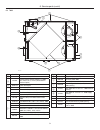

10 appendix a mounting diagrams 6lc, v6lc, 12lc and v12lc units space must be left to allow connection of drain lines with adequate slope for drainage wooden curb (supplied by others) bolt to floor rubber vibration isolator (supplied by others) u channel (supplied by others) 3/8" (10mm) threaded rod...

Page 11: Appendix B

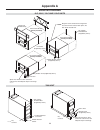

11 appendix b unit dimensions b-1: 6lc and v6lc (without recirculation module) 8.000" [203] 4.000" [102] 8.000" [203] 3.535" [90] 4.000" [102] 28.005" [71 1] 14.000" [356] 5.859" [149] 13.375" [340] 23.500" [597] 2.750" [70] 14.000" [356] 6.500" [165] 8.000" [203] 8.000" [203] 14.103" [358] 7.705" [...

Page 12: Appendix B

12 appendix b (cont’d) unit dimensions b-2: 6lc and v6lc with recirculation module (factory installed) 28.12" [714] 14.00" [356] 4.00" [102] 1.75" [44] 8.00" [203] 2.75" [70] 19.207" [488] 5.125" [130] access door str ap mounting location dr ain fitting no te: f or units with the re v ersed door opt...

Page 13: Appendix B

13 appendix b (cont’d) unit dimensions b-3: 12lc and v12lc (without recirculation module) 41.206" [1047] 40.326" [1024] 20.000" [508] 5.715" [145] 20.620" [524] 14.250" [362] 34.000" [864] 5.125" [130] 19.207" [488] 4.028" [102] 1 1.325" [288] 12.000" [305] 15.000" [381] 20.000" [508] 4.000" [102] 2...

Page 14: Appendix B

14 appendix b (cont’d) unit dimensions b-4: 12lc and v12lc with recirculation module (factory installed) 8.00" [203] 1.75" [44] 10.00" [254] 20.00" [508] 2.75" [70] line p o w e r dr y contacts 49.550" [1259] str ap mounting location f resh air f rom outside exhaust air f rom building 5.125" [130] h...

Page 15: Appendix B

15 appendix b (cont’d) unit dimensions b-5: 7000 10.000" [254] dimensions in [ ] are in millimeters center of g ra vity direction of airflo w 7000 lb . K g 32.74 14.85 68.46 31.05 35.20 15.97 73.60 33.38 210.00 1.875" [48] exha ust air opening suppl y air opening 20.750" [527] 8.000" [203] 10.750" [...

Page 16: Appendix C

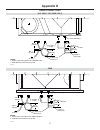

16 appendix c balancing dampers position 6lc, v6lc, 12lc and v12lc balancing damper vj0135a canvas vibration isolator reverse door option exhaust air from building fresh air from outdoors min. 8" (203 mm) (optional) canvas vibration isolator gravity backdraft damper (for recirculation defrost option...

Page 17: Appendix D

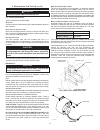

17 appendix d drain connections 6lc, v6lc, 12lc and v12lc min. 3” [76 mm] min. 1” [25 mm] 3/4” npt coupler water trap min. 4” [102 mm] min. 4” [102 mm] plastic hose to drain notes: 1. All hose, pipe and couplers to be supplied by others. 2. Slope drain lines minimum 1/4” per foot. Min. 1” [25 mm] mi...

Page 18: Appendix E

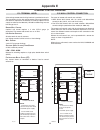

18 appendix e terminal control diagrams a low voltage remote control wiring interface is provided on the unit. The connections for the low voltage remote wiring are located on two terminals adjacent to the exhaust fan outlet (or adjacent to the supply fan outlet on the 7000 unit). All field installe...

Page 19: Appendix E

19 appendix e (cont’d) terminal control diagrams occupancy control is achieved by connection to the terminal interface shown below. These terminals require a dry contact which could be provided by a number of types of controls such as a timer, light sensor, occupancy sensor, building management syst...

Page 20: Appendix G

20 6lc, v6lc and 70 0 0 units outdoor air -40°f (-40°c) outdoor air -22°f (-30°c) outdoor air -4°f (-20°c) outdoor air 14°f (-10°c) outdoor air 32°f (0°c) desir ed air t emper atur e desir ed air t emper atur e desir ed air t emper atur e desir ed air t emper atur e desir ed air t emper atur e suppl...

Page 21: Appendix H

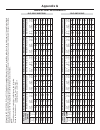

21 appendix h wiring diagrams g note a: t he medium speed wires may optionnally replace the low speed (red) wires running from relay low speed . Note b: n ot available for hm core . 1000 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1013 1020 1021 1022 1023 1024 1025 1026 1027 1028 102...

Page 22: Appendix H

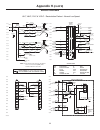

22 appendix h (cont’d) wiring diagrams from 2008 interlock from 2007 remote fan bl bl y r gn bk from 2003 12 vdc from 2003 transmit from 2005 receive from 2007 logic gnd 1 2 n/o n/c com j4 j2 1 2 3 4 5 6 7 8 9 b g r y ol oc i bk/r w/bl o w/y r w/r w bk from 1012 120 vac control board ucb1021 f f fro...

Page 23: Appendix H

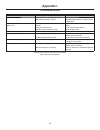

23 jumper settings for control board ju1 ju1 ju1 ju1 ju1 ju1 ju1 a b c d e f g off off off on on on on tags cr1029 cr2022 cr1024 cr1026 cr2028 fu2026 ucb1021 xf2025 qty. 2 2 1 1 1 1 description r elay spdt 120 vac 1 hp 30 a @ 120 vac r elay dpst 120 vac 1 hp 30 a @ 120 vac r elay dpdt 24 vac 1/2 hp ...

Page 24: Appendix H

24 appendix h (cont’d) wiring diagrams 7000 - recirculation defrost 1000 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1020 1021 1022 1023 1024 1025 1026 1027 1028 1029 1030 1031 1032 splitter block tb1001 2 2 3 3 r 1 1 bk/y pj1001 gn mot1008 exhaust blower high com low gnd w/y use cop...

Page 25: Appendix H

25 appendix h (cont’d) wiring diagrams 7000 - recirculation defrost ( cont’d ) jumper settings for control board ju1 ju1 ju1 ju1 ju1 ju1 ju1 a b c d e f g on off off on on on on tags cr1029 cr1030 fu2023 ucb1021 xf2024 r2004 sn1030 tb1001 qty. 2 1 1 1 1 1 1 description r elay dpdt 120 vac 1/2 hp 15 ...

Page 26: Appendix I

26 appendix i troubleshooting symptoms possible causes solutions inside air is too dry over ventilation - speed setting too high dehumidistat setting is too low adjust speed setting set dehumidistat control in a higher position (if applicable) persistent condensation on windows, walls, ceilings, etc...