- DL manuals

- VAPORSTREAM

- Humidifier

- VLC

- Installation Instructions And Maintenance Operations Manual

VAPORSTREAM VLC Installation Instructions And Maintenance Operations Manual

Summary of VLC

Page 1

Read and save these instructions vaporstream models vlc and vldi electric steam humidifiers installation instructions and maintenance operations manual ® cul listed ul listed.

Page 2

2 to the purchaser and the installer thank you for purchasing vaporstream ® model vlc equipment. We have designed and built this equipment to give you total satisfaction and many years of trouble-free service. Proper installation and operating practices will assure you of achieving that objective. W...

Page 3

3 vaporstream ® models vlc and vldi vaporstream vlc electric humidifier state-of-the-art technology in a simple, low-maintenance humidi- fier. This humidifier is designed to be used with either softened or unsoftened water (preferably softened). The probe-type level control system requires water con...

Page 4

4 *heater stage identifies the number of contactors. * *refer to table 4-2 for control cabinet dimensions. Model number heaters current draw (a) control cabinet sizes** single phase three phase qty stages* 230v kw capacities (kg/h) 400v kw capacities (kg/h) vlc/vldi 2-1 1 1 8.0 1.84 2.4 m 3-1 1 1 12...

Page 5

5 mechanical specifications om-626 b a c front view side view back view figure 5-1: dimensions table 5-1: mechanical specifications model number a b c weight empty (kg) weight full (kg) mm mm mm vlc/vldi 2-1 515 430 190 16 36 3-1 515 430 190 16 36 4-1 515 430 190 16 36 5-1 515 430 190 16 36 vlc/vldi...

Page 6

6 vaporstream ® model vlc area-type humidifier area-type humidifier application information the operating characteristics of area-type steam humidifiers should be considered when selecting humidifier capacities and choosing mounting locations. Steam discharge from the humidifier quickly cools and tu...

Page 7

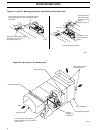

7 figure 7-1: mounting support methods floor stand method trapeze hanger method wall brackets method mounting procedures for proper operation of the electrode probe water level control and the skimmer system, the humidifier must be mounted level in both directions. Access (460 mm minimum) for period...

Page 8

8 figures 8-1 and 8-2: mounting units away from duct(s) using vapor hose mounting methods om-639 humidifier should be mounted level vapor hose (pitch back 165 mm/m to humidifier with supports to prevent sagging). Maximum length 3 m. Humidifier should be mounted level. Om-638 airflow air handling uni...

Page 9

9 capacity tube without with a b dia. Drain drain 25 mm 4.5 kg/h n/a 80 mm 25 mm 40 mm 13 kg/h 26 kg/h 80 mm 38 mm 50 mm 26 kg/h 38 kg/h 125 mm 50 mm mounting methods dispersion tube installation with condensate drain (over 13 kg/h per dispersion tube) vapor hose when a vapor hose and stainless stee...

Page 10

10 humidifier kg/h height up to 48 kw 2-62 300 mm 49 kw to 64 kw 63-83 375 mm 65 kw to 100 kw 84-103 450 mm mounting methods om-697 table 10-1: water seal minimum height* * height required to overcome humidifier internal pressure. Figure 10-1: multiple tube with condensate wasted to floor drain disp...

Page 11

11 rapid-sorb tm assembly and installation instructions for horizontal duct 1. Unpack shipment and verify receipt of all rapid-sorb components with packing list. Report any shortages to the dri-steem factory immediately. 2. Provide necessary access in and around duct work. 3. Locate stainless steel ...

Page 12

12 rapid-sorb tm assembly and installation vertical duct installation install the rapid-sorb tm with dispersion tubes and header pitched to condensate drain as shown in figures 12-1,12-2, and 12-3. See "instructions for horizontal duct" for additional information, as applicable. Figure 12-1: plan vi...

Page 13

13 caution: only qualified electrical personnel should perform installation procedures. Installation requirements when selecting a space to install the vlc humidifier, avoid areas close to sources of electromagnetic emissions such as kva transformers. Control wiring and power wiring must be run in d...

Page 14

14 for maximum e.M.C. Effectiveness, all humidity, temperature and air flow controls should be wired using multi- conductor shielded plenum-rated cable with a drain wire for the shield. The drain wire should be connected to the shield ground terminal with its length kept to less than 50 mm. Installa...

Page 15

15 figure 15-1: piping method recommended when obstruction prevents dispersion tube from being continuously pitched back to humidifier drain piping a drain line should be extended from the skimmer connection to a sanitary waste or suitable drain. If non- metallic pipe or hose is used, it must be cap...

Page 16

16 piping diagrams: steam, water and drain heaters figure 16-1: standard unit (non-di/ro water) 3/4" sst drain valve h figure 16-2: di/ro water unit h clean-out tray clean-out plate three probe level control and low-water cut-off drain connection open drain * air gap drain and water seal piping 20 m...

Page 17

17 humidifier kg/h height up to 48 kw 2-62 300 mm 49 kw to 64 kw 63-83 375 mm 65 kw to 100 kw 84-103 450 mm figure 17-1: alternate water seal and drain valve piping (by installer) used when water seal must be elevated above flow line of drain connection (humidifier near floor) table 17-1: water seal...

Page 18

18 start-up procedure introduction after the system has been properly installed and connected to both electrical and water supplies, it may then be started. Start-up and checkout procedures mounting check mounting to see that unit is level and securely supported before filling with water. Piping ver...

Page 19

19 cool down note caution: insulated and uninsulated tanks will have hot surfaces. Allow unit to cool before performing any maintenance. Manually open the drain valve and the fill valve will be energized. Let the fill water run until the tank is cooled, then shut off the field-installed supply water...

Page 20

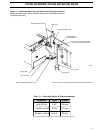

20 replacement parts figure 20-1: vaporstream ® model vlc humidifier * specify humidifier model and serial numbers when ordering. Notes: 1. For dispersion tube(s) specify type (l-tube, straight tube), humidifier model and serial numbers. 2. Parts not itemized are typical hardware stock items. Om-650...

Page 21

21 figure 21-1: vaporstream ® model vldi humidifier om-651 * specify humidifier model and serial numbers when ordering. Notes: 1. For dispersion tube(s) specify type (l-tube, straight tube, rapid-sorb™, etc), humidifier model and serial numbers. 2. Parts not itemized are typical hardware stock items...

Page 22

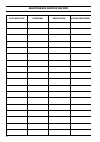

22 maintenance service record date inspected personnel observation actions performed.

Page 23

23 maintenance service record date inspected personnel observation actions performed.

Page 24

24 two-year limited warranty dri-steem humidifier company (“dri-steem”) warrants to the original user that its products will be free from defects in materials and workmanship for a period of two (2) years after installation or twenty- seven (27) months from the date dri-steem ships such product, whi...