- DL manuals

- Varec

- Accessories

- 2500

- Installation And Operation Manual

Varec 2500 Installation And Operation Manual - Gauge Systems

2500 Automatic Tank Gauge

2

Installation and Operations Manual

Getting Acquainted with the 2500 Automatic Tank

Gauge Systems

The 2500 series of Automatic Tank Gauges (ATG)

are float and tape operated instruments designed

to provide continuous liquid-level measurement

in bulk storage applications.

The gauge can be installed on the tank roof or at

the tank side (at grade), which would facilitate

ground level reading by the operator and is

available with a wide variety of accessories for

virtually every tank gauging application.

The level measurement is displayed using a dial

and counter built into the gauge head. If

electronic transmission of level data or

temperature measurement integration is

required in the control room, the gauge can be

fitted with an optional tank gauging transmitter.

Figure 1:

Typical 2500 ATG Installation

Inventory Management System

e.g. FuelsManager

Tank Gauge Interface

e.g. 8130RTU

2500 Automatic Tank Gauge

and Transmitter

Summary of 2500

Page 1

Iom001gvae1117 automation solutions for oil & gas, defense and aviation applications installation and operations manual dispatch and fuels accounting 2500 automatic tank gauge mechanically operated, float and tape gauges for continuous liquid-level measurement in bulk storage tanks.

Page 3: Copyright

Varec, inc. Iii copyright © 2016 all rights reserved. Printed in the united states of america. Except as permitted under the united states copyright act of 1976, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means - electronic, mecha...

Page 4: Disclaimer of Warranties

Disclaimer of warranties the contract between the seller and the buyer states the entire obligation of the seller. The contents of this instruction manual shall not become part of or modify any prior or existing agreement, commitment, or relationship between the seller and buyer. There are no expres...

Page 5: Safety Precautions

Safety precaution definitions caution! Damage to equipment may result if this precaution is disregarded. Warning! Direct injury to personnel or damage to equipment which can cause injury to personnel may result if this precaution is not followed. Safety precautions read this manual carefully and mak...

Page 6

Vi installation and operations manual.

Page 7: Contents

Varec, inc. 7 contents 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 getting acquainted with the...

Page 8

2500 automatic tank gauge 8 installation and operation manual connecting the cable to a float in a floatwell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 connecting the cable to a floating pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 9

Contents varec, inc. 9 general inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72 8 spare parts and maintenance kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 gauge head spare parts . . . . . . . . . . . ....

Page 10

2500 automatic tank gauge 10 installation and operation manual.

Page 11: Introduction

Varec, inc. 1 chapter 1 introduction using this manual this manual is designed to assist the user in the installation, operation, maintenance, and troubleshooting of low-pressure 2500 automatic tank gauges. Former 2600 series gauges with a hand crank are included. These gauges are for use at atmosph...

Page 12: Gauge Systems

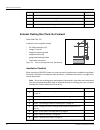

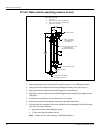

2500 automatic tank gauge 2 installation and operations manual getting acquainted with the 2500 automatic tank gauge systems the 2500 series of automatic tank gauges (atg) are float and tape operated instruments designed to provide continuous liquid-level measurement in bulk storage applications. Th...

Page 13

Introduction varec, inc. 3 tank gauge operation the 2500 atg uses a large, stainless steel float attached to a stainless steel perforated tape to detect the liquid level. The float follows the liquid level as it rises and falls due to the tension provided by a powerful negator spring or cartridge mo...

Page 14: Product Options

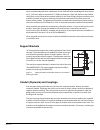

2500 automatic tank gauge 4 installation and operations manual table 1: calibration and volume measurement system integration a range of analog and digital tank gauge transmitters is available that mounts directly to mechanical tank gauges. Figure 3: 2500 atg with a 2910 float & tape trans- mitter l...

Page 15

Introduction varec, inc. 5 check knob an operation checker, provided as a standard feature on both the 2500 and 2520 atg, permits your technician to check the instrument for correct operation. Negator cassette the negator cassette improves the performance of your mechanical tank gauge by self-aligni...

Page 16

2500 automatic tank gauge 6 installation and operations manual.

Page 17: General Preparation

Varec, inc. 7 chapter 2 general preparation safety precautions before installing your 2500 atg, read and review the see the “safety precautions” section of the preface to this document. Continuing with the installation according to the instructions in this manual presumes you have reviewed these saf...

Page 18: Preparing For Installation

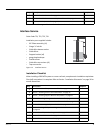

2500 automatic tank gauge 8 installation and operations manual guidelines, recommendations, and options when preparing for installation various installation options and accessories are available to suit the user installation requirements. This section provides an overview and basic recommendations f...

Page 19

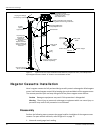

Varec, inc. 9 varec recommends guide wire installations for the 2500 atg with standard guide wire centers of 17" (432 mm) when a standard 14.5" (368 mm) diameter (type 316 stainless steel hollow shell) float is used. Guide wires provide stability for the float during turbulent conditions and provide...

Page 20

2500 automatic tank gauge 10 installation and operations manual conduit elbows conduit elbows reduce friction and wear on the tape and provide various installation options, depending on the tank type. Varec can provide various angles, materials, and low/high pressure options. Conduit oil seals (opti...

Page 21

Varec, inc. 11 floats for new installations, locate the float in the tank where it will be exposed to a minimum of agitation. If the product stream is close to the float, install a deflector. If agitators will cause excess float disturbances, contact varec before proceeding with installation. The 25...

Page 22

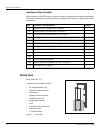

2500 automatic tank gauge 12 installation and operations manual installation steps checklist when installing a 2500 atg system on a cone roof tank, complete each installation step below. Check off a step when it is complete. Refer to “installation schematics” on page 21 for overall dimensions. Table...

Page 23

Varec, inc. 13 installation checklist when installing a 2500 atg system on a bolted tank, complete each installation step below. Check off a step when it is complete. Refer to “installation schematics” on page 21 for overall dimensions. Table 3: bolted tank — installation checklist cone roof tank wi...

Page 24

2500 automatic tank gauge 14 installation and operations manual table 4: cone roof tank with internal (floating roof) pan and floatwell — installation checklist cone roof tank and internal (floating roof) pan: no floatwell order code t07, t17 installation parts supplied include: • 90° elbow assembly...

Page 25

Varec, inc. 15 table 5: cone roof tank and internal (floating roof) pan: no floatwell — installation checklist tank top mounting order code t04, t14, t24, t32 installation parts supplied include: • gauge 'u' bolt kit • guide wire bottom anchor • guide wires • gauge head and tape • float • guide wire...

Page 26

2500 automatic tank gauge 16 installation and operations manual table 6: tank top mounting — installation checklist stilling well service cone roof tank 6" diameter float order code t55, t56 installation parts supplied include: • 90° elbow assembly (x2) • gauge 'u' bolt kit • support bracket (x6) • ...

Page 27

Varec, inc. 17 table 7: stilling well service cone roof tank 6" diameter float — installation checklist external floating roof tank and floatwell order code t03, t13 installation parts supplied include: • 90° elbow assembly (x2) • gauge 'u' bolt kit • support bracket assembly • support bracket (x6) ...

Page 28

2500 automatic tank gauge 18 installation and operations manual table 8: external floating roof tank and floatwell — installation checklist external floating roof tank: no floatwell order code t06, t16 installation parts supplied include: • 90° elbow assembly (x2) • gauge 'u' bolt kit • support brac...

Page 29

Varec, inc. 19 table 9: external floating roof tank: no floatwell — installation checklist interface service order code t51, t52, t53, t54 installation parts supplied include: • 90° elbow assembly (x2) • gauge 'u' bolt kit • guide wire bottom anchor • guide wires • support bracket (x6) • gauge head ...

Page 30

2500 automatic tank gauge 20 installation and operations manual table 10: interface service — installation checklist 11 section “initial lubrication” on page 42 12 section “install a transmitter and replace all covers” on page 42 13 section “initial operation” on page 43 step description complete.

Page 31: Installation

Varec, inc. 21 chapter 3 installation this chapter gives instructions for the various types of installations based on the order code options for the 2500 atg. Note before installing your 2500 atg, read and review all see the “safety precautions” section of the preface to this document. Continuing wi...

Page 32

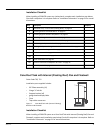

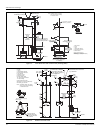

2500 automatic tank gauge 22 installation and operations manual figure 2: cone roof tank with internal pan (floating roof) figure 3: bolted cone roof tank 14.50 [368 ] 1-1/2 inch pipe and fittings furnished by customer tank roof cable guide and well furnished by customer 4 2 3 remove float guide eye...

Page 33

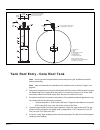

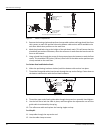

Varec, inc. 23 figure 4: horizontal bullet tank with roof reading gauge tank roof entry - cone roof tank note ensure you have completed all previous steps from your installation checklist before proceeding. Note varec recommends the installation of a manhole cover as shown in figure 1 on page 46 1. ...

Page 34

2500 automatic tank gauge 24 installation and operations manual 5. Check the pitch of the roof. Hold the coupling plumb, while welding it into the hole in the roof. Note failure to place the coupling and pipe in a true vertical position may affect the accuracy of the gauge. 6. After the coupling and...

Page 35: Pan Installation

Varec, inc. 25 tank roof entry - stilling well note to facilitate inspection and service of the gauge system, locate the well where gauge piping will pass over the top of the tank shell close to a stairway platform. 1. In a user-supplied flange that is suitable to connect to the stilling well on you...

Page 36

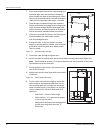

2500 automatic tank gauge 26 installation and operations manual figure 5: detail a - top anchors 3. Remove the housing nipple and cap from the top cable anchors and hang plumb lines from their centers to mark the position where the bottom cable anchor will be welded to the tank floor. Mark these pos...

Page 37

Varec, inc. 27 13. Thread the cable through the anchor, pull the cable tight, and tighten the bottom anchor to secure. 14. Trim excess cable, if needed. Installing support brackets & pipework note ensure you have completed all previous steps from your installation checklist before proceeding. Note t...

Page 38

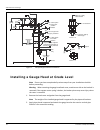

2500 automatic tank gauge 28 installation and operations manual figure 7: example support bracket installation installing a gauge head at grade level note ensure you have completed all previous steps from your installation checklist before proceeding. Warning when removing the gauge head back cover,...

Page 39

Varec, inc. 29 figure 8: conduit connection and tank side support bracket details installing a roof reading gauge head note ensure you have completed all previous steps from your installation checklist before proceeding. Warning when removing the gauge head back cover, stand to one side as the last ...

Page 40

2500 automatic tank gauge 30 installation and operations manual float installation on an out-of-service tank note be sure to read chapter before proceeding with this installation. Ensure you have completed all previous steps from your installation checklist before proceeding. Cone roof tank • from i...

Page 41

Varec, inc. 31 figure 10: tape clamp assembly with grounding cable 4. Form a 'u' at the end of the perforated tape. Form it to match the 'u' piece previously formed. Do not kink. 5. Install the gauge tape and 'u' piece to the tape connector with the tape clamps and screws provided, making certain th...

Page 42

2500 automatic tank gauge 32 installation and operations manual 1. At the outboard elbow, feed the cable through the horizontal pipe, over the tank entry elbow and down through the pipe to the floating roof. Check that it is centered on the well. Continue feeding the cable until the tape/tape cable ...

Page 43: Stilling Well

Varec, inc. 33 connecting the cable to a floating pan note ensure you have completed all previous steps from your installation checklist before proceeding. Note due to the resulting gross measurement inaccuracies, varec does not recommend that the perforated tape/tape cable be attached directly to a...

Page 44: Level

2500 automatic tank gauge 34 installation and operations manual 11. Lower the float down the stilling well so that is rests at the bottom of the tank/well (lowest measuring point). 12. Make certain that the tape is not kinked or twisted. 13. Replace the flange onto the stilling well and bolt down. F...

Page 45

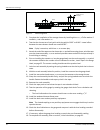

Varec, inc. 35 install tape in the gauge head figure 14: tape routing 1 2 3 4 5 6 7 8 9 2 1 4 9 tape entry for top-mounted gauge caution! Do not release crank handle (7) when negator spring motor is being loaded and thumbscrew lock is removed. Item description 1 sprocket sheave 2 tape storage sheave...

Page 46

2500 automatic tank gauge 36 installation and operations manual warning do not overwind negator motor. Winding motor greater than the indicated number of turns may cause the motor to dislodge and uncoil from its pulley, causing damage to equipment and injury to personnel. Warning use both hands for ...

Page 47

Varec, inc. 37 with a negator cassette if you have a 2500 atg with negator cassette, follow the procedure in this section to install the gauge tape and load the negator cassette on the gauge head. 1. Install the furnished crank assembly and lock it into the case keyhole slot using the spring- loaded...

Page 48

2500 automatic tank gauge 38 installation and operations manual 5. Lock the crank assembly into the case keyhole slot before releasing your grip on the han- dle. 6. At the gauge head, put the first hole in the tape on a pin of the sprocket close to the tape guide. 7. Rotate the sprocket clockwise to...

Page 49

Varec, inc. 39 caution do not continue to turn the hand crank after the float reaches the top of the tank, the bottom of the tank or the product level. Caution do not use the hand crank for any installation that directly attaches the tape/ tape cable to a floating roof. Damage to the gauge may resul...

Page 50: Reset The Counter

2500 automatic tank gauge 40 installation and operations manual 3. To adjust, loosen the screws on the cable clamp while holding on to the cable. Pull the cable through the clips while keeping the tape tension tight. When splice is in proper posi- tion, tighten the screws and release cable. The spri...

Page 51: Calibrate The Counter

Varec, inc. 41 4. Check that the float is at zero level with the tape taut. 5. If calibration is required, proceed to the next section. 6. Tighten the dial plate screws (40) , being careful to not overtighten them. Calibrate the counter note these instructions apply to systems that use a hollow-shel...

Page 52: Initial Lubrication

2500 automatic tank gauge 42 installation and operations manual figure 16: dial plate adjustments initial lubrication note ensure you have completed all previous steps from your installation checklist before proceeding. Caution gauges measuring caustic liquids require that the gauge head be oil-fill...

Page 53: Initial Operation

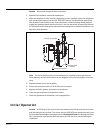

Varec, inc. 43 caution do not over-torque the back cover bolts. 1. Remove the installation crank and thumbscrew. 2. When a transmitter or other auxiliary equipment is to be installed, ensure the equipment hole size and bolt pattern matches the 2500 atg. Remove and discard the cap and red fiber washe...

Page 54

2500 automatic tank gauge 44 installation and operations manual 1. Station an observer at the gauge head. 2. Begin filling the tank to raise the float several feet (about three feet or one meter) from the bottom. Caution do not release the checker knob and allow the springs to return the mecha- nism...

Page 55

Varec, inc. 45 chapter 4 in-service installation procedures note before installing your 2500 atg, read and review all safety precautions on page ii of the preface to this document. Continuing with installation according to the instructions in this manual presumes you have reviewed these safety preca...

Page 56

2500 automatic tank gauge 46 installation and operations manual figure 1: typical in-service-tank installation with manhole, inspection hatch, and independent pipe support structure. Detail “a” shows in-service bottom anchor. Negator cassette installation varec's negator cassette is a fully enclosed...

Page 57

Varec, inc. 47 2. Vent all pressure from gauge head. 3. If the gauge is oil-filled, drain the oil. Warning if the negator motor is broken, the broken pieces can cause injury. Whenever the back cover of the gauge head is removed, stand away as the last bolt is removed. Wear gloves and safety glasses....

Page 58

2500 automatic tank gauge 48 installation and operations manual figure 2: sheave alignment 3. Complete the installation of the storage sheave by installing shims (45) , a teflon washer if needed (4) , and a flat washer (44) . 4. Test that the sheave turns freely with axial play within 0.005" to 0.01...

Page 59: Oil Seal Installation

Varec, inc. 49 • that section gives instructions to reset and calibrate the counter, install transmitters and other auxiliary equipment, and replace the back cover. Note torque back cover bolts to 6 ft-lb. Do not over torque! 19. Refill gauge head with oil if required. 20. Close the tank inspection ...

Page 60

2500 automatic tank gauge 50 installation and operations manual 27-inch water column operating pressure oil seal figure 3: installation of oil seal, 27-inch water column operating pressure oil seal 1. Apply appropriate pipe compound and install short pipe ( 3) into 180 degree elbow (1). 2. Apply pip...

Page 61

Varec, inc. 51 8.5-inch water column operating pressure oil seal figure 4: oil seal, 8.5-inch water column operating pressure oil seal 1. Apply appropriate pipe thread compound and install long pipe (1) into 135 degree elbow with bottom drain (4) . 2. Apply pipe thread compound and install short pip...

Page 62

2500 automatic tank gauge 52 installation and operations manual inspection hatch and manhole cover varec recommends the installation of a manhole or inspection hatch, if there is not already one located within arm’s reach of the tape pipe location. Inspection hatch 1. Remove the cover to a safe weld...

Page 63: Guide Wire Bottom Anchors

Varec, inc. 53 figure 5: manhole cover and inspection hatch guide wire bottom anchors varec supplies an anchor bar for in-service installations (part number ba4481) that must be ordered separately. It is for normal service only. The guide cables fasten to the anchor bar with cable clamps (see figure...

Page 64

2500 automatic tank gauge 54 installation and operations manual 5. Tighten the adjustment nut until the guide cable is tensioned by the spring. Trim excess cable. 6. Use pipe thread compound and install top anchor nipples and cap. Warning whenever the back cover of the gauge head is removed, stand t...

Page 65

Varec, inc. 55 14. Make sure there is sufficient slack tape inside the tank to allow float travel to the tank bot- tom (check reference mark previously made). Trim the tape about 6 feet (1.8 m) from the bottom of the gauge head. 15. Proceed per instructions in section , install tape in the gauge hea...

Page 66

2500 automatic tank gauge 56 installation and operations manual.

Page 67: Operation

Varec, inc. 57 chapter 5 operation caution do not release the checker knob and allow the springs to return the mecha- nism. Over time the springs will break and jam the gauge. Caution do not turn the operation checker knob on systems that have no float and that are directly connected to a floating r...

Page 68

2500 automatic tank gauge 58 installation and operations manual.

Page 69: Assembly

Varec, inc. 59 chapter 6 gauge head disassembly and re- assembly use of the maintenance kits requires that the user understand the disassembly and reassembly of the gauge head to replace parts. Gauge head disassembly figure 8 is key to understanding the disassembly/reassembly procedure. The small nu...

Page 70

2500 automatic tank gauge 60 installation and operations manual figure 8: 2500 atg (type c) gauge head spare parts perform these steps to disassemble the gauge head. Note disassemble the gauge head only as far as needed to replace worn or defective parts. Warning vapors and possible flammables! Make...

Page 71

Varec, inc. 61 warning electrostatic charge! Worker activity and worker clothing may accumulate electrostatic charges on the body of a worker. Care should be used in flammable environments to avoid this hazard. The mechanical connections between the guide cables, float, tape, and gauge head provide ...

Page 72

2500 automatic tank gauge 62 installation and operations manual figure 9: tape routing 14. Loosen the motor spring screw (fig. 3-1, item 8) and detach motor spring. 15. Remove retaining ring (23) , washer (44), and shim washers (45) from motor shaft. 1 2 3 4 5 6 7 8 9 2 1 4 9 tape entry for top-moun...

Page 73

Varec, inc. 63 16. Remove motor storage sheave assembly (48) as a unit. 17. Remove retaining ring (23) , washer (44), and shim washers (45) from tape storage sheave shaft. 18. Remove tape storage sheave assembly as a unit. Caution do not remove the sheave shafts! The sheave shafts are pressed into p...

Page 74: Gauge Head Assembly

2500 automatic tank gauge 64 installation and operations manual gauge head assembly unless otherwise labeled, numbers in parentheses, (12) for example, refer to the item callout numbers on figure 8 or figure 9. Perform the following steps to reassemble the gauge head. When white silicon grease is ca...

Page 75

Varec, inc. 65 18. Tighten the three screws (43) mounting the counter assembly. 19. Slip the dial (7) under the red pointer of the counter assembly and onto the hub. Rotate the dial until the tab from the dial gear (5) registers with the slot in the dial. 20. Install dial retainer (9) on dial (7) an...

Page 76: Counter Wheel Assembly

2500 automatic tank gauge 66 installation and operations manual counter wheel assembly if you remove the screws (43) and retainer from the counter wheel assembly (21) and the pinion gear (24) is disengaged, you must remove the dial and pinion gear in order to reset the counter drums and dial (7) to ...

Page 77

Varec, inc. 67 7. Ensure the correct vertical alignment between the dial gear and the pinion gear. • if the dial gear is below the top of the pinion gear, add shim washers (45) under the counter shaft assembly (11) as required. If the dial gear is higher than the pinion gear, remove shim washers fro...

Page 78

2500 automatic tank gauge 68 installation and operations manual if there is play between the bearing depth gauge, the counter boss, and the dial plate hub, tap the dial plate hub with a hammer with the bearing depth gauge in place. When the dial plate hub is flush against the bearing depth gauge, th...

Page 79: Maintenance Routines

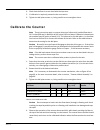

Varec, inc. 69 chapter 7 maintenance routines varec recommends a regular schedule of maintenance for the 2500 automatic tank gauge (atg), outlined in the table below. Actual frequency of inspections and maintenance may vary depending on the specific environmental conditions and operation at your sit...

Page 80: Operation Check

2500 automatic tank gauge 70 installation and operations manual operation check check the operation of the gauge by rotating the gauge check knob on the front of the gauge. The dial should show the movement of the float when the check knob is rotated. Caution do not release the gauge check knob and ...

Page 81: Lubrication

Varec, inc. 71 lubrication caution do not use any type of grease, wd-40, or lithium-based lubricant. Warning before lubrication, ensure the chemical compatibility of the lubricant with the product in the tank. Lubricate the moving parts of the gauge head at regular intervals with a silicone or teflo...

Page 82: Corrosion Check

2500 automatic tank gauge 72 installation and operations manual corrosion check check for signs of corrosion. Interior corrosion of the pipe carrying the tape may become deposited in the mechanism and affect the accuracy. Basic maintenance basic maintenance should be conducted as required depending ...

Page 83: Gauge Head Spare Parts

Varec, inc. 73 chapter 8 spare parts and maintenance kits varec can supply individual spare parts for the 2500 atg, maintenance kits, and installation accessories. The following kits are specifically designed to assist with a regular schedule of maintenance and to improve the quality and performance...

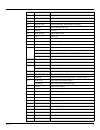

Page 84

2500 automatic tank gauge 74 installation and operations manual 8 ba7761 tape storage sheave assembly (includes item57) ba9796 crank tape storage sheave 06-10364 tape storage sheave assembly - cassette 9 b8234-001 dial retainer 10 b7693-005 shaft (2) - gauge head type b ba7763 shaft support assembly...

Page 85

Varec, inc. 75 37 b4847-005 washer 38 p031-05-1721 back cover bolts 39 p031-05-1871 counter cover bolts 40 p031-01-1719 binding head mach. Screw (brass for counter) 41 p31-247 hex jam nut (for back cap) 42 p31-612 set screw 43 p031-08-1720 counter base screws 44 p31-1 washer (2) 45 p31-13 shim washe...

Page 86

2500 automatic tank gauge 76 installation and operations manual table 3: 2500 atg gauge head spare parts list cartridge crank handles as provisioned as follows: 1 handle 06-10490 fits all gauges in which the tape storage sheave has ball bearings, which includes all cassette gauges, type b with stand...

Page 87

Varec, inc. 77 figure 11: 2500 atg gauge head (type b) with negator motor spare parts diagram 19 35 20 31 21 11 43 24 5 9 7 53 13 54 39 40 6 34 22 33 29 38 17 1 41 3 2 36 8 23 55 58 57 45 55 48 56 10 45 23 45 55 18 28 45 37 12 31 16 25 27 10 62 14 46 33 26 15 45 55 * 48 includes parts 55(x2) & 56. *...

Page 88

2500 automatic tank gauge 78 installation and operations manual figure 12: 2500 atg gauge head (type b) with negator cassette spare parts diagram 49 19 35 20 31 21 11 43 24 5 9 7 53 13 54 39 40 6 34 22 33 29 * 42 38 17 1 47 41 3 2 36 10 45 51 50 18 28 45 37 12 31 16 25 27 10 62 61 46 33 26 15 45 52.

Page 89

Varec, inc. 79 figure 13: 2500 atg gauge head (type c) with negator motor and negator cassette spare parts dia- gram 45 10 31 18 4 37 45 8 27 16 25 15 14 10 44 23 23 48 17 47 36 3 2 38 41 1 26 33 12 45 57 28 56 55 61 62 7 5 43 35 21 31 22 29 33 6 24 13 19 39 40 11 9 34 42 47 50 8 53 54 52.

Page 90

2500 automatic tank gauge 80 installation and operations manual figure 14: 2500 atg gauge head with hand crank 78 47 36 45 88 17 27 84 44 1 76 8 25 85 16 31 37 4 10 12 18 2 10 26 45 48 3 23 41 23 38 45 57 28 56 55 80 33 89 5 91 79 92 82 77 87 95 6 19 83 86 90 81 34 45 93 21 9 31 40 43 39 11 35 29 24...

Page 91

Varec, inc. 81 2500 cast iron gaugehead spare parts figure 15: 2500 cast iron gaugehead 45 47 52 8 35 25 16 27 99 37 4 18 26 33 15 14 10 45 44 23 10 48 23 45 1 41 17 38 2 3 36 2 28 61 62 57 56 55 6 75 34 33 24 96 21 43 97 22 98 29 13 42 11 5 7 9 40 74 19 39 53 54 item part description 01 b4396-046 b...

Page 92

2500 automatic tank gauge 82 installation and operations manual 02 b5059-046 back cover cap gasket (for a transmitter) b5059-146 back cover cap gasket - no center hole (if no transmitter) 03ci b5060-001-7 back cover cap, painted (cast iron gaugehead) 04 b7415-093 teflon washer (not shown - used on o...

Page 93

Varec, inc. 83 36 p031-32-1661 washer, fiber 37 b4847-005 washer, (inside at counter) 38 p031-05-1721 back cover bolts 39 p031-05-1871 hex head cap screw (counter cover) 40 p031-01-1719 binding head mach. Screw (brass for counter) 41 p31-247 hex jam nut (for back cap) 42 p31-612 set screw, (for chec...

Page 94: Basic Maintenance Kit

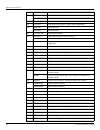

2500 automatic tank gauge 84 installation and operations manual basic maintenance kit the basic maintenance kit provides all the parts required for basic maintenance on the 2500 atg. Depending on your selection, you will receive the metric or imperial parts required. Table 4: basic maintenance kits ...

Page 95: Extended Maintenance Kit

Varec, inc. 85 figure 16: 2500 atg (type c gauge head shown) basic maintenance kit parts diagram extended maintenance kit the extended maintenance kit provides all the parts required for extended maintenance on the 2500 atg gauge head. Depending on your selection, you will receive the metric or impe...

Page 96

2500 automatic tank gauge 86 installation and operations manual item part no. Description quantity in kits 1 b4396-046 back cover gasket 2500a (prior to 1983) 1 02-04490-071 back cover gasket 2500b (1983 - 2012) 1 02-013127-046 back cover gasket 2500c (2013 and later) 1 4 b7415-093 teflon washer 1 5...

Page 97

Varec, inc. 87 table 5: extended maintenance kit parts list additional items when performing extended maintenance, varec also recommends replacing the tape or the tape-and-cable combination as shown in the following table. Table 6: additional items recommended for extended maintenance list 55 02-095...

Page 98: Overhaul/refurbishing Kit

2500 automatic tank gauge 88 installation and operations manual figure 17: 2500 atg (type c gauge head shown) extended maintenance kit parts diagram overhaul/refurbishing kit the refurbish/overhaul kit provides all the parts required for overhaul maintenance on the 2500 atg. Depending on your select...

Page 99

Varec, inc. 89 t part no. Description 13-08770 overhaul/refurbishing maintenance kit - imperial 13-08771 overhaul/refurbishing kit - metric item part no. Description quantity in kits 1 b4396-046 back cover gasket 2500a (prior to 1983) 1 02-04490-071 back cover gasket 2500b (1983 - 2012) 1 02-013127-...

Page 100

2500 automatic tank gauge 90 installation and operations manual figure 18: overhaul/refurbish maintenance kit part numbers list 44 p31-1 washer 6 45 p31-13 shim washer 18 48 ba7762 negator motor assembly (includes items 55x2 & 56) 1 52 06-10490 crank handle (not shown) 1 55 02-09598 shoulder bushing...

Page 101

Varec, inc. 91 . Figure 19: 2500 atg (type c gauge head shown) overhaul maintenance kit parts diagram 25 15 44 1 26 38 14 57 4 12 31 37 23 48 45 55 33 29 24 5 7 9 6 42 22 31 21 40 43 aa tape clamp assembly example cone roof installation bb gg hh ee or ff dd bb gg top guidewire anchor aa & cc bb shea...

Page 102

2500 automatic tank gauge 92 installation and operations manual additional items when performing a complete overhaul or refurbish, varec recommends replacement of the tape (or tape and cable combination), anchors, and guide wires as shown in the following table. Table 7: additional items recommended...

Page 103

Varec, inc. 93 table 8: shoulder busing kit and individual parts list figure 20: 2500 atg (type c gauge head shown) shoulder bushing retrofit kit parts diagram negator cassette and negator cassette kit the negator cassette kit (item 68) provides the parts required to convert a 2500 atg fitted with a...

Page 104

2500 automatic tank gauge 94 installation and operations manual table 9: negator cassette kit and individual parts list figure 21: 2500 atg (type b gauge head shown) negator cassette conversion kit parts diagram (item 68) 4 b7415-093 teflon washer (not shown - as used on older models) 2 23 p10-2 ret...

Page 105: Float Grounding Kit

Varec, inc. 95 float grounding kit the float grounding kit positively grounds the float to the tape or cable. Connect the grounding cable (a) to the tape clamp (point b) and float (point c) as shown in figure 2-6. Table 10: float grounding kit list figure 22: float grounding kit diagram other access...

Page 106: Parts

2500 automatic tank gauge 96 installation and operations manual condensate reservoir the condensate reservoir is designed to collect condensate that would otherwise accumulate in the gauge head. Its use is recommended where an excessive amount of condensate could develop or in oil filled gauge appli...

Page 107

Varec, inc. 97 table 11: part numbers for complete 2500 atg gauge heads spare parts list bm13661-111ext alum-english w/check knob, extended range bm13661-111out alum-english w/check knob - outage bm13661-211 cast iron-english w/check knob bm14514-110 alum-metric w/check knob bm14514-110ext alum-metr...

Page 108

2500 automatic tank gauge 98 installation and operations manual.

Page 109: Troubleshooting

Varec, inc. 99 chapter 9 troubleshooting friction is a common problem that affects gauge accuracy. Some liquids produce corrosion in the mechanism. Periodic inspection and maintenance provided by a varec service contract can prevent problems from occurring. Periodic cleaning, lubrication, and replac...

Page 110

2500 automatic tank gauge 100 installation and operations manual table 12: broken negator spring - possible cause / action calibration repeatability unstable caution broken negator spring may cause injury. Stand clear of gauge head when remov- ing back cover. 4 dials stopped? Yes - • check for froze...

Page 111

Varec, inc. 101 table 13: broken negator spring - possible cause/ action 5 guide cables loose, kinked or broken? Yes - • tighten, repair or replace. No - • go to 6. 6 worn teflon bushings or bearings? Yes - • refurbish gauge, replace teflon bushings or bearings. • special tools may be required. Poss...

Page 112

2500 automatic tank gauge 102 installation and operations manual.

Page 113: Device Designation/nameplate

Varec, inc. 103 chapter 10 specifications and reference data device designation/nameplate figure 27: nameplate for the 2500 atg ce marks, declaration of conformity the instrument is designed to meet state-of-the-art safety requirements, has been tested, and left the factory in a condition in which i...

Page 114: 2500 Atg Product Dimensions

2500 automatic tank gauge 104 installation and operations manual 2500 atg product dimensions figure 28: 2500 atg product dimensions 3.2" (82 mm) 2.0" (51 mm) 3.5" (89 mm) 4.0" (101 mm) 5/16"-18x1 3.0" (76 mm) 1.28" (32 mm) 5/16"-18x1.125 5.4" (137 mm) 8.5" (216 mm) 3/8" npt 2.2" (56 mm) 0.6" (15 mm)...

Page 115: Floats

Varec, inc. 105 figure 29: 2500 cast iron gauge head product dimensions floats table 15: floats conduit elbows part # material net weight size bm9074-000 316 s.S. 8.8 lb (4 kg) 17” (432 mm) flat bm12339-000 alloy 20 10.7 lb (4.9 kg) 17” (432 mm) flat bm12338-000 monel 10.5 lb (4.8 kg) 17” (432 mm) f...

Page 116: Standard Installation Kits

2500 automatic tank gauge 106 installation and operations manual table 16: conduit elbows standard installation kits table 17: standard installation kits oil seals table 18: oil seals 06-08564 90° elbow atmospheric aluminum delrin 06-07726 90° elbow atmospheric aluminum 316 ss bm4675 90° elbow atmos...

Page 117: Approvals

Varec, inc. 107 approvals table 19: approvals other specifications table 20: other specifications item description approval type atex en 13463-1 “non-electrical equipment for use in potentially explosive atmospheres - basic method and requirements” approval certificate number fm06atex0009 product op...

Page 118

2500 automatic tank gauge 108 installation and operations manual.

Page 119: Order Codes

Varec, inc. 109 chapter 11 order codes note • for outage reading, please specify "out". For example n250001-t55 out. For outage versions with metric units, please contact the factory. • for asphalt applications, please specify "ap". For example n250001-t55 ap. • for an ip66 certified gauge, please s...

Page 120: Negator Motor

2500 automatic tank gauge 110 installation and operations manual aluminum gauge head – metric configuration – negator motor aluminum gauge head – english configuration – float crank aluminum gauge head – metric configuration – float crank 10 tank type t11 standard service cone roof tank t12 standard...

Page 121: Negator Cassette

Varec, inc. 111 iron gauge head – english configuration iron gauge head – metric configuration aluminum gauge head – english configuration – negator cassette 10 tank type t21 standard service cone roof tank ss316 t22 extreme service cone roof tank; monel t23 extreme service cone roof tank; carp. 20 ...

Page 122: Negator Cassette

2500 automatic tank gauge 112 installation and operations manual aluminum gauge head – metric configuration – negator cassette 10 tank type t11 standard service cone roof tank t12 standard service cone roof tank with pan and floatwell t13 standard service floating roof tank and floatwell t14 standar...

Page 124

Varec, inc. • 5834 peachtree corners east, peachtree corners (atlanta), ga 30092 usa tel: +1 (770) 447-9202 • fax: +1 (770) 662-8939 www.Varec.Com © 2014 varec, inc. All rights reserved. This document is for information purposes only. Varec, inc. Makes no warranties, express or implied, in this summ...