- DL manuals

- Varec

- Recording Equipment

- TankGate Interface 8315 Series

- Installation & Operation Manual

Varec TankGate Interface 8315 Series Installation & Operation Manual

Summary of TankGate Interface 8315 Series

Page 1

Varec, inc. 5834 peachtree corners east, norcross (atlanta), ga 30092 usa tel: +1 (770) 447-9202 fax: +1 (770) 662-8939 www.Varec.Com iom035gvae0405 8315 series tankgate interface data communication gateway for l&j tankway (mcg 1000, mcg 1500, mcg 2000) devices installation & operations manual.

Page 3: Copyright

I 8300 copyright all rights reserved. Printed in the united states of america. Except as permitted under the united states copyright act of 1976, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means- electronic, mechanical, photocopyi...

Page 4: Disclaimer of Warranties

Tankgate interface ii installation and operations manual disclaimer of warranties the contract between the seller and the buyer states the entire obligation of the seller. The contents of this document shall not become part of or modify any prior or existing agreement, commitment or relationship bet...

Page 5: Safety Precautions

Iii 8300 safety precaution definitions caution! Damage to equipment may result if this precaution is disregarded. Warning! Direct injury to personnel or damage to equipment which can cause injury to personnel may result if this precaution is not followed. Safety precautions read and understand this ...

Page 6: Preface

Tankgate interface iv installation and operations manual preface this manual is intended for users of the tankgate. The operating instruction manual contains eight chapters and an appendices. Chapter 1 - overview this chapter provides a general overview of the tankgate such as features and product s...

Page 7

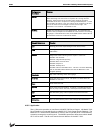

V 8300 contents contents 1 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.1 versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.2 features. . . . . . . . . . . . . ....

Page 8

Contents tankgate interface vi installation and operations manual 4.1.7 database manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4.1.8 system tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 4.2 tankgate software ...

Page 9

Vii 8300 contents 4.16.1 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 4.17 l&j mcg1000 tank gauge (lj1000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 4.17.1 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 10

Contents tankgate interface viii installation and operations manual 7 troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 7.1 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 7.2 troub...

Page 11

1 8300 overview 1 overview the tankgate (83x series) unit acts as a tank gauge interface for data acquisition and host gateway for tank farm, pipeline or refinery applications. Options are available for interfacing to nearly any brand of tank gauge equipment or technologies, making it possible to in...

Page 12

Overview tankgate interface 2 installation and operations manual 1.4 specifications 1.4.1 system design • 16-bit processor with optional intelligent communication modules • intelligent field device communications • 128k bytes non-volatile database memory • serial rs-232 or rs-485 • visual indication...

Page 13

3 8300 overview 1.4.9 humidity • 5...95% (non-condensing) 1.4.10 storage temperature • -40...+212 °f (-40...100 °c) 1.4.11 mechanical construction • dimensions (hxdxw) - 2.5" (64 mm) x 8.6" (220 mm) x 5.2" (133 mm) • material - aluminum powder coated *gauge/transmitter dependent.

Page 14

Overview tankgate interface 4 installation and operations manual.

Page 15

5 8300 hardware 2 hardware the tankgate consists of an enclosure, motherboard, single tank gauge interface module and connectors. Figure 2-1: tankgate hardware components.

Page 16

Hardware tankgate interface 6 installation and operations manual 2.1 hardware block diagram a tankgate hardware functional block diagram is shown below. This diagram shows the relationship between major subsystems and components in the tankgate. Figure 2-2: tankgate functional block diagram the hear...

Page 17

7 8300 hardware • communications figure 2-3: the tankgate motherboard 2.2.1 power supply • unit ac power terminal block (j2) • surge protection terminal block (j4) • field power terminal block (j3) • auxiliary dc power output terminal block (j8) • ac power fuses (500 ma - 250v 5x20 mm) (f1, f2) • fi...

Page 18

Hardware tankgate interface 8 installation and operations manual 2.2.1.1 unit ac input power terminal block (j2) the unit ac power terminal block is used to provide ac power to the tankgate. The power requirements for the tankgate are 100-240 vac, 50/60 hz. The ac input power terminal block is shown...

Page 19

9 8300 hardware +15 and -15 volts. These are rated 210 ma, 50 ma, and 5 ma, respectively. The dc power terminal block is shown below: figure 2-6: dc input voltage terminal block 2.2.1.5 ac power fuses (f1,f2) the ac power fuses provide protection for the ac input power. The two fuses, f1 and f2, are...

Page 20

Hardware tankgate interface 10 installation and operations manual there is 230 ma of field power available. At +48vdc, there is 230 ma of field power available. Figure 2-8: selection jumper w3 2.2.2 switches and indicators 2.2.2.1 reset push-button (sw3) the reset switch is used to re-initialize the...

Page 21

11 8300 hardware 2.2.3 communications the communications installation requires connection of the appropriate communication cable to one of two connectors. The available options include rs-232 and rs-485 communications. • com0 (rs-232) (j7) • com1 (rs-232 or rs-485) (j5) • com1 transmit control (rs-2...

Page 22

Hardware tankgate interface 12 installation and operations manual 2.2.3.2 com1 (rs-232/rs-485) (j5) note! On some versions of the tankgate, com1 is not available rs-232 is one of the two types of high-speed serial communications channels available to interface to host systems using several different...

Page 23

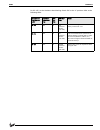

13 8300 hardware for rs-485, set the hardware handshaking switch sw1 to the ‘a’ position. Refer to the following table: communica- tion physical layer hardware handshak- ing sw1 set- ting sw2 set- ting notes rs-232 no a up (towards the rs- 232 side) use with a pc. Signals at terminal block j5 will b...

Page 24

Hardware tankgate interface 14 installation and operations manual 2.3 tankgate communications cable the layout for the rs-232 cable between the pc and the tankgate is shown in the following illustrations figure 2-14:com 1 cable without rts/cts tank gate j7 pc com 0 (rs-232) txd rxd gnd 2 3 5 db9 fem...

Page 25

15 8300 8315 l&j tankway interface module 3 8315 l&j tankway interface module 3.1 features • supports up to 50 tanks • communicates using l&j tankway protocol • interfaces to l&j tankway compatible tank gauge transmitters • ansi/ieee surge protection the model 8215 interface with tank gauge transmit...

Page 26

8315 l&j tankway interface module tankgate interface 16 installation and operations manual figure 3-2: model 8315 tankgate 3.2 description the components of the 8315 are illustrated in the following figure. This section explains how to connect field wiring and to configure jumper settings. • unit id...

Page 27

17 8300 8315 l&j tankway interface module figure 3-3: model 8315 l&j tankway interface 3.2.1 id dip switch (sw1) the id dip switch is a binary switch that sets the unit id number (1-4). This value is set to the port number on which the model 8315 is installed (e.G. P1=1). The switch is set according...

Page 28

8315 l&j tankway interface module tankgate interface 18 installation and operations manual • com: communication between the tankgate and the host computer • txd: transmitting data to tank gauge • rxd: receiving data from tank gauge • +5v: indicates interface module power • +vext: indicates external ...

Page 29

19 8300 8315 l&j tankway interface module 3.2.5 field wiring terminal block (j3) a schematic illustrating the terminal connections of the model 8315 is shown below: figure 3-7: model 8315 input circuit connect the field wiring • connect the wiring following the diagram below. Figure 3-8: l & j engin...

Page 30

8315 l&j tankway interface module tankgate interface 20 installation and operations manual.

Page 31

21 8300 8315 l&j tankway software description 4 8315 l&j tankway software description the tankgate software platform is based on a real-time, multi-tasking operating system. The software consists of i/o scanning functions for data acquisition, a database/database manager and communication functions ...

Page 32

8315 l&j tankway software description tankgate interface 22 installation and operations manual 4.1.4 communications there are two communications tasks - one for each of the communication channels. Com ports 0 and1 are used to interface to external devices or host systems. Refer to the hardware chapt...

Page 33

23 8300 8315 l&j tankway software description 4.2 tankgate software blocks the user can configure pre-defined subprograms known as software blocks. These software blocks program the tankgate to perform various tasks, such as scaling an analog input value, or scanning level, temperature and status in...

Page 34

8315 l&j tankway software description tankgate interface 24 installation and operations manual 4.3 database organization points are the individual instances of software blocks. Examples include whessoe varec 1900 (wv1900) and scaler points. In both cases the user configures the config parameters and...

Page 35

25 8300 8315 l&j tankway software description note! Viewrtu inserts default values for the config parameters when the point is first defined. It is usually only necessary to fill in a few configuration parameters, such as channel numbers, to configure references and to configure links to other point...

Page 36

8315 l&j tankway software description tankgate interface 26 installation and operations manual pntchecksum parameter the pntchecksum is a crc-16 checksum of the configuration parameters of a point. Most points have the pntchecksum parameter; a few like the clk (clock) point, diag (diagnostics) point...

Page 37

27 8300 8315 l&j tankway software description 4.4 gathering point data for host to tankgate communications, there are two primary methods for gathering point data. These methods are listed below: 4.4.1 standard request-response format the host issues scan requests, and the tankgate responds with the...

Page 38

8315 l&j tankway software description tankgate interface 28 installation and operations manual note! Not all host protocols support the change of state method. The rtu slave protocol used with fuelsmanager supports either method. Note! The modbus protocol is scan-based. Therefore, the report and max...

Page 39

29 8300 8315 l&j tankway software description 4.5 modbus communications the tankgate is capable of communicating with modbus compatible devices. It is possible to communicate with both modbus masters and slave devices. The tankgate is flexible, allowing communications with devices that strictly comp...

Page 40

8315 l&j tankway software description tankgate interface 30 installation and operations manual tankgate responds to the following function codes: there are two methods for data addressing within the tankgate •the tankgate has a fixed modbus map of selected parameters •gateway block (gwblk) software ...

Page 41

31 8300 8315 l&j tankway software description 4.5.3 gwblk method the gwblk is the preferred means to address data in the tankgate. The gwblk has a great deal of flexibility. Data can be scaled, or grouped using the gwblk. The gateway block (gwblk) allows the user to specify data address and point re...

Page 42

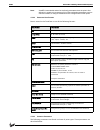

8315 l&j tankway software description tankgate interface 32 installation and operations manual in this example, the modbus register map is configured according to the following table:.

Page 43

33 8300 8315 l&j tankway software description data address parameter comments 100-101 wv1900.00.Level level is in ieee floating point format. 102-103 wv1900.01.Level 104-105 . . . 138-139 wv1900.02.Level . . . Wv 1900.19.Level 200-201 wv1900.00.Temp temperature is in ieee floating point format. 202-...

Page 44

8315 l&j tankway software description tankgate interface 34 installation and operations manual 4.6 clock (clk) the clock point provides access to the system clock. Standard time format is in the form of mm/dd/yy hh:mm:ss. 4.6.1 parameters the database parameters used by the clk point are listed and ...

Page 45

35 8300 8315 l&j tankway software description 4.7 communications (com) the communications point reports the status and controls the operation of the communications interfaces. Com points are automatically created by the system at initialization. 4.7.1 parameters the database parameters used by the c...

Page 46

8315 l&j tankway software description tankgate interface 36 installation and operations manual 4.7.2 application the com point controls the operation of host and slave communications. The baud rate, communications parameters and protocol may be changed by assigning values to the appropriate paramete...

Page 47

37 8300 8315 l&j tankway software description 4.8 floating point register (fpreg) the floating register point provides four bytes of storage in ieee floating point format. It is often used for inter-point communications where no other means is provided. 4.8.1 parameters the database parameters used ...

Page 48

8315 l&j tankway software description tankgate interface 38 installation and operations manual 4.9 emulator (emu) the emulator point allows the tankgate to emulate a whessoe-varec model 6820 tank scanning unit (tsu). This point provides access for level, temperature data, and gauge status informatio...

Page 49

39 8300 8315 l&j tankway software description 4.9.2 application the emulator point (emu) provides a communication interface between older tank gauging system and point blocks within the tankgate. Currently, the tankgate can emulate a whessoe varec model 6810 tank scanning unit (tsu). The emu point a...

Page 50

8315 l&j tankway software description tankgate interface 40 installation and operations manual 4.10 emu gateway (emugw) the emu gateway point is used to manage scanning functions for the emu point. Statistics are maintained for the communications between the series 8130 and the tank gauging software...

Page 51

41 8300 8315 l&j tankway software description 4.10.2 application the emugw point is automatically created when the tankview (tsu slave) protocol is initiated. In order to use the tsu slave protocol, set the protocol parameter of the com point to tsu slave. At that time, an emugw and an emu point wil...

Page 52

8315 l&j tankway software description tankgate interface 42 installation and operations manual 4.11 gauging systems inc. Model 2000 interface (gs2000) the gs2000 point provides an interface to gsi 2000 tank gauge transmitters. This point provides both level and temperature data. Point and gauge stat...

Page 53

43 8300 8315 l&j tankway software description tempoffset specifies the amount of offset to add to the temp. The default is 0. Report causes automatic notification to the host (in response to a change of state request) when the value changes state. Parameter value can be high, low or no. Report=no di...

Page 54

8315 l&j tankway software description tankgate interface 44 installation and operations manual 4.11.2 application the gs2000 point provides an interface to gsi model 2000 tank gauge transmitters. Tank gauges are connected directly to a tankgate. At startup, a wvscan point is automatically created to...

Page 55

45 8300 8315 l&j tankway software description 4.12 gateway block (gwblk) the gateway block point is used for compatibility with modbus master devices. Rather, the user configures a gwblk to function as a look-up table. The gwblk point lets the user specify which point references will respond to data...

Page 56

8315 l&j tankway software description tankgate interface 46 installation and operations manual 4.12.2 application the gwblk point is a look-up table used by the modbus slave protocol handler. Up to sixteen address-point reference pairs may be used per gwblk point. Multiple gwblk points may be used i...

Page 57

47 8300 8315 l&j tankway software description 4.13 integer register (ireg) the integer register point provides two bytes of storage. It is often used for inter-point communications where no other means is provided. 4.13.1 parameters the database parameters used by the ireg point are listed and descr...

Page 58

8315 l&j tankway software description tankgate interface 48 installation and operations manual 4.14 modbus gateway (modgw) the modbus gateway provides dynamic and statistical information for the communications between the model 8310 and the modbus masters. 4.14.1 parameters the database parameters u...

Page 59

49 8300 8315 l&j tankway software description 4.14.2 application the modgw point provides status information for the communications with any modbus masters used with the tankgate. On the tankgate motherboard, the modgw point is created automatically whenever the modbus slave protocol is defined for ...

Page 60

8315 l&j tankway software description tankgate interface 50 installation and operations manual 4.15 scaler point (scaler) the generic scaling point allows the user to perform math functions in the tankgate. The scaler point monitors one or more database reference values and performs an equation in t...

Page 61

51 8300 8315 l&j tankway software description 4.15.2 application the scaler point allows the user to perform simple math functions such as conversion of units. The scaler point takes the value from user specified database references, multiplies each by a constant and adds the three product terms. A ...

Page 62

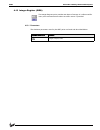

8315 l&j tankway software description tankgate interface 52 installation and operations manual 4.16 system information (sys) the system information point lists the hardware and software specifications of the system. Other information includes the hardware version and any connected devices. 4.16.1 pa...

Page 63

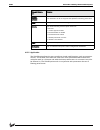

53 8300 8315 l&j tankway software description 4.17 l&j mcg1000 tank gauge (lj1000) the lj1000 point provides an interface to l & j mcg1000 tank gauge transmitters. This point provides both level and temperature data. Point and gauge status information is also available in this point block. This poin...

Page 64

8315 l&j tankway software description tankgate interface 54 installation and operations manual maxtime specifies the maximum time (in secs) between automatic change of state data being sent to the host in response to a change of state request. Report must be set to either low or high for the value p...

Page 65

55 8300 8315 l&j tankway software description 4.17.2 application the lj1000 point provides an interface to l&j mcg1000 direct digital gauges. L&j model 1000 tank gauge transmitters are connected directly to a model 8315 tank gauge interface module. The model 8315 is automatically detected at startup...

Page 66

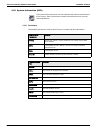

8315 l&j tankway software description tankgate interface 56 installation and operations manual 4.18 l&j mcg1500 tank gauge (lj1500) the lj1500 point provides an interface to l & j mcg1500 tank gauge transmitters. This point provides both level and temperature data. Point and gauge status information...

Page 67

57 8300 8315 l&j tankway software description 4.18.2 application the lj1500 point provides an interface to l&j mcg1500 servo gauges. L&j model 1500 servo gauges are connected directly to a model 8315 tank gauge interface module. The model 8315 is automatically detected at startup, and an ljscan poin...

Page 68

8315 l&j tankway software description tankgate interface 58 installation and operations manual scanning begins when the module is assigned. The devtype must match the configuration of the transmitter. Conversion from english to metric can be performed be setting the levelconvert and the tempconvert ...

Page 69

59 8300 8315 l&j tankway software description 4.19 l&j mcg2000 tank gauge (lj2000) the lj2000 point provides an interface to l & j mcg2000 tank gauge transmitters. This point provides both level and temperature data. Point and gauge status information is also available in this point block. This poin...

Page 70

8315 l&j tankway software description tankgate interface 60 installation and operations manual 4.19.2 application the lj2000 point provides an interface to l&j mcg2000 gauges. L&j model 2000 gauges are connected directly to a model 8315 tank gauge interface module. The model 8315 is automatically de...

Page 71

61 8300 8315 l&j tankway software description scanning begins when the module is assigned. The devtype must match the configuration of the transmitter. Conversion from english to metric can be performed be setting the levelconvert and the tempconvert parameters in the ljscan point associated with th...

Page 72

8315 l&j tankway software description tankgate interface 62 installation and operations manual 4.20 l&j scanner (ljscan) the l&j scanner point is used in conjunction with l&j tank (lj1000, lj1500 and lj2000) gauge points. This point provides dynamic and statistical data for the model 8315 tank gauge...

Page 73

63 8300 8315 l&j tankway software description 4.20.2 application the ljscan point monitors the status of the model 8315 tank gauge interface. The ljscan point is created automatically by the model 8315. The point number will correspond to the module such that ljscan.1 is created for module 1 (the 83...

Page 74

8315 l&j tankway software description tankgate interface 64 installation and operations manual.

Page 75

65 8300 installation 5 installation before attempting installation, review the safety precautions below. Installation and maintenance personnel should become familiar with any hazards present as well as any agency requirements before working with any equipment. 5.1 general safety guidelines the user...

Page 76

Installation tankgate interface 66 installation and operations manual 5.3 installation standard systems are shipped with the motherboard and tank gauge interface module installed. The tankgate installation procedure includes the installation of these individual components. Tankgate installation incl...

Page 77

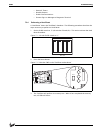

67 8300 installation 5.3.1 mounting the tankgate before mounting the tankgate, make certain that any enclosure used can house the tankgate. Refer to the dimensional drawing below (all dimensions are in inches). Figure 5-1: mounting the tankgate inside the enclosure. 197 204 125.

Page 78

Installation tankgate interface 68 installation and operations manual 5.3.2 mounting the enclosure the recommended standard housing for the tankgate is a nema type 4 enclosure. This enclosure is suitable for both indoor and outdoor applications. 5.3.3 select the unit address switch sw1 sets the tank...

Page 79

69 8300 installation rs-485 communications • to install the rs-485 communications option, connect a single twisted wire pair to j5 (com1). Note! When using com1, switch sw2 must be set for rs-485 mode. Power-up before the field cables are attached, perform an initial system verification. Initial sys...

Page 80

Installation tankgate interface 70 installation and operations manual.

Page 81

71 8300 using viewrtu 6 using viewrtu 6.1 overview this chapter describes the software used to configure the tankgate. This chapter describes each of the menus found in the menu bar. Additionally, the chapter describes the system requirements and the installation procedure. Use this chapter in accor...

Page 82

Using viewrtu tankgate interface 72 installation and operations manual • double-click on the icon to execute the viewrtu application. If more than one tankgate definition file (dvr) exists, the following dialog box is displayed. Figure 6-1: viewrtu version selection dialog each version file contains...

Page 83

73 8300 using viewrtu 6.4.1 viewrtu window this main window allows the user to perform the commands necessary to configure the tankgate. The viewrtu window contains the standard windows components such as the application control menu, minimize/maximize icon buttons, title bar and menu bar. The syste...

Page 84

Using viewrtu tankgate interface 74 installation and operations manual 6.5.1.2 open the user is able to select an existing configuration file by clicking on the open push-button from the tool bar, or by selecting open from the file menu. When selected, a dialog box appears displaying a list of confi...

Page 85

75 8300 using viewrtu select point to add dialog box this dialog box displays a list of available point types, the point number, quantity and the corresponding point icon. The point icon is then added to the point icon selection area if it does not already exist. The point type lists the currently s...

Page 86

Using viewrtu tankgate interface 76 installation and operations manual once a point is selected, the edit point dialog box appears: figure 6-7: edit point dialog edit point dialog this dialog box contains all dynamic and configurable field information. The user is able to edit point data. Exiting th...

Page 87

77 8300 using viewrtu 6.5.3 the config menu figure 6-9: the configuration menu 6.5.3.1 download database to rtu the download database to rtu option is used to download configuration data to the tankgate. The following dialog box appears: figure 6-10:dialog used to download tankgate data click the do...

Page 88

Using viewrtu tankgate interface 78 installation and operations manual 6.5.3.3 spreadsheet the spreadsheet option is used to configure, download, and upload point data points in spreadsheet mode. Figure 6-13:spreadsheet mode edit window 6.5.3.4 password the user can use the password option to gain a...

Page 89

79 8300 using viewrtu • click on ok. Figure 6-15:change password dialog note! Make sure that you write down the password and store it in a secure place. 6.5.3.7 changing the password changing the password • select config and click on modify change password. The change password dialog appears, as ill...

Page 90

Using viewrtu tankgate interface 80 installation and operations manual appears. This example dialog box contains the default settings for communications setup. Figure 6-17:port communications setup dialog port communications setup dialog this dialog box allows the user to enter the specifications of...

Page 91

81 8300 using viewrtu 6.5.4.3 connect the connect option is used when the user needs to search for a specific tankgate. The following dialog box appears when the option is selected. Figure 6-19:tankgate search dialog tankgate search dialog this dialog box lists the address, description and current s...

Page 92

Using viewrtu tankgate interface 82 installation and operations manual 6.5.5.1 convert configuration files the convert configuration files option is used once the download firmware option has been executed. This option converts configuration files from one version to another. When selected, the foll...

Page 93

83 8300 using viewrtu points are imported from the file ‘ai.Csv’. The user must select the subdirectory to import the data from. The csv file data can also be imported using the spreadsheet mode. 6.5.5.4 view i/o list the view i/o list option allows the user to create a list of the i/o points connec...

Page 94

Using viewrtu tankgate interface 84 installation and operations manual configuring the point involves entering configuration parameters. In some cases, connections to other points are required in order to perform a task. Creating connections involves setting references to allow data to be transferre...

Page 95

85 8300 using viewrtu several methods can be used to display this window depending on the user’s current location in the program: • if in the main window, select edit from the point menu. Select the desired point type and corresponding point number. • if in the main window, double-right click on the...

Page 96

Using viewrtu tankgate interface 86 installation and operations manual clicking the minimize shrinks the window so that only one or more selected list box parameters are displayed. The user may have multiple minimize windows opened simultaneously. This capability is useful for testing and debugging....

Page 97

87 8300 using viewrtu upload the upload push-button allows the user to upload the entire point data from the tankgate. 6.6.3 to modify a value figure 6-25:edit point dialog (adding a value) to modify a value • double-click the desired parameter to enter a new value. The following example modify poin...

Page 98

Using viewrtu tankgate interface 88 installation and operations manual to modify a reference • in the edit point window double-click the desired reference parameter to enter a new value. The following dialog box appears. • in the point connections window drag and drop the point icon onto the pntref....

Page 99

89 8300 using viewrtu adding multiple points • double-click on the desired point type in the spreadsheet summary. The following example spreadsheet mode window appears. Figure 6-28:spreadsheet mode window note! Refer to the following entering point data section for a description of the spread- sheet...

Page 100

Using viewrtu tankgate interface 90 installation and operations manual the point menu this menu contains the same menu options found in the main window’s menu bar. Refer to the point menu section for a description of the menu options. Figure 6-30:spreadsheet mode: the point menu this option is usefu...

Page 101

91 8300 using viewrtu • select the paste option from the edit menu. Figure 6-32:spreadsheet mode: copying and pasting point parameter data rows. Note! If the number of rows and columns in both selections do not match, the extra copied cells are truncated. Incompatible cells containing different data...

Page 102

Using viewrtu tankgate interface 92 installation and operations manual • click on each desired cell or column. • select set value from the edit menu. The following dialog box appears: figure 6-34:spreadsheet mode: editing point parameter values using auto increment each value in the column is increm...

Page 103

93 8300 using viewrtu view the view option allows the user to display selected parameter types. Selecting this option displays the following view point parameters dialog box. Figure 6-36:spreadsheet mode: viewing selected parameter types dialog the user is able to select any combination of parameter...

Page 104

Using viewrtu tankgate interface 94 installation and operations manual the selected rows or columns are indicated by a ‘+’ in the row or column buttons heading. The following dialog box illustrates this feature. Figure 6-37:spreadsheet mode: hiding columns the user can unhide a row or column by clic...

Page 105

95 8300 using viewrtu displaying the point connections window. • double-click on one of the icons to display the point connections window. The following example point connections window appears. Figure 6-39:point connections window point connections window this graphic display visually illustrates t...

Page 106

Using viewrtu tankgate interface 96 installation and operations manual note! Double-left clicking on the input source or the output destination icon allows the user to step through each corresponding point connections window, if applicable. Note! Double-right clicking on the input source or the outp...

Page 107

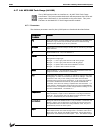

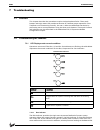

97 8300 troubleshooting 7 troubleshooting 7.1 overview this chapter describes the procedures used to isolate hardware faults. Three push- buttons and eight status led provide verification of tankgate proper operation. If the tankgate is not functioning normally, the user is able to troubleshoot the ...

Page 108

Troubleshooting tankgate interface 98 installation and operations manual by observing the run indicator duty cycle. Under normal conditions, this indicator flashes once every second. 7.2.1.2 communications indicator the communications indicator provides communication line status. When it is toggling...

Page 109

99 8300 troubleshooting • reset all timers • disable outputs • enable communications • present sign-on message to diagnostic terminal 7.2.4 performing a hard reset a ‘hard reset’ clears the tankgate’s database. The following procedure describes the steps necessary to perform a hard reset: 1. Set the...

Page 110

Troubleshooting tankgate interface 100 installation and operations manual 4. Set the id dip switch to the desired address (1-14). At this point, there is no further action required by the user. Figure 7-3: set the id dip switch to the desired addresses 5. The leds will light (and remain steady) to i...

Page 111

101 8300 troubleshooting 7.3 maintenance field maintenance of the tankgate is simplified by several built-in features. The modular design of the computer control system, in conjunction with quick-disconnect connectors, allows for on-site replacement of questionable components. The following standard...

Page 112

Troubleshooting tankgate interface 102 installation and operations manual.

Page 113

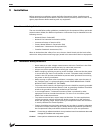

I 8300 appendix 1 appendix 1.1 ordering structure remote terminal unit tankgate 1.2 ordering structure nema 4 enclosure 10 communications 03-2 dual rs-485 communications interface - modbus™ protocol 03-3 dual rs-485 communications interface - mts dda protocol 03-5 dual rs-485 communications interfac...

Page 114

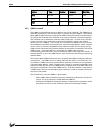

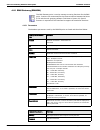

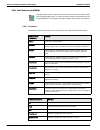

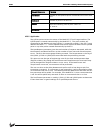

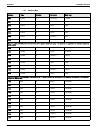

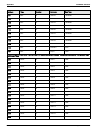

Appendix tankgate interface ii installation and operations manual 1.2.1 modbus map address type number parameter data type 5000 lj2000 0 command coded 5001 lj2000 0 level real 5003 lj2000 0 temp real 5005 lj2000 0 value real 5007 lj2000 0 status hex 5008 lj2000 0 pntstatus ihex 5009 lj2000 0 elapse ...

Page 115

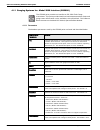

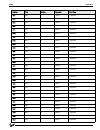

Iii 8300 appendix 1011 ireg 0 value12 uinteger 1012 ireg 0 value13 uinteger 1013 ireg 0 value14 uinteger 1014 ireg 0 value15 uinteger 1015 ireg 0 value16 uinteger 1016 ireg 0 value17 uinteger 1017 ireg 0 value18 uinteger 1018 ireg 0 value19 uinteger 1019 ireg 0 value20 uinteger 1020 ireg 0 value21 u...

Page 116

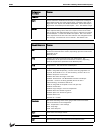

Appendix tankgate interface iv installation and operations manual 1041 ireg 0 value42 uinteger 1042 ireg 0 value43 uinteger 1043 ireg 0 value44 uinteger 1044 ireg 0 value45 uinteger 1045 ireg 0 value46 uinteger 1046 ireg 0 value47 uinteger 1047 ireg 0 value48 uinteger 1048 ireg 0 value49 uinteger 10...

Page 117

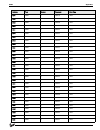

V 8300 appendix 3034 fpreg 0 value18 real 3036 fpreg 0 value19 real 3038 fpreg 0 value20 real 3040 fpreg 0 value21 real 3042 fpreg 0 value22 real 3044 fpreg 0 value23 real 3046 fpreg 0 value24 real 3048 fpreg 0 value25 real 3050 fpreg 0 value26 real 3052 fpreg 0 value27 real 3054 fpreg 0 value28 rea...

Page 118

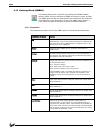

Appendix tankgate interface vi installation and operations manual 3094 fpreg 0 value48 real 3096 fpreg 0 value49 real 3098 fpreg 0 value50 real 3100 fpreg 0 pntstatus ihex 3101 fpreg 0 elapse time there are a total of 10 fpreg points. There are a total of 102 registers available per fpreg point the ...

Page 119: Notes

I 8300 notes.

Page 120

Your offical representative varec, inc. 5834 peachtree corners east, norcross (atlanta), ga 30092 usa tel: +1 (770) 447-9202 fax: +1 (770) 662-8939 © 2004 varec, inc. All rights reserved. This document is for information purposes only. Varec, inc. Makes no warranties, express or implied, in this sum...