- DL manuals

- Vari

- Lawn Mower

- BDR-595 E EuroAdela

- Instructions For Use Manual

Vari BDR-595 E EuroAdela Instructions For Use Manual

Summary of BDR-595 E EuroAdela

Page 1

Drum mower bdr-595 e euroadela instructions for use.

Page 2: Contents

Bdr-595 e euroadela 2 contents 1 basic information ............................................................................................................... 3 2 ec-conformity statement.................................................................................................. 4 3 introdu...

Page 3: 1 Basic Information

Bdr-595 e euroadela 3 1 basic information , ask your dealer to provide unpackaging of the machine and briefing. Fill in the following table with data on your machine. The data are important for ordering spare parts. It is advisable to have a copy of this page with all data on the machine purchase fo...

Page 4: 2 Ec-Conformity Statement

Bdr-595 e euroadela 4 2 ec-conformity statement ec-conformity statement according to act no. 22/1997 gaz. (as amended) , manufacturer: vari,a.S., opolanská 350, 289 07 libice nad cidlinou, czech republic identification no.: 00660574 issues the following statement at its own responsibility , machine ...

Page 5: 3 Introduction

Bdr-595 e euroadela 5 3 introduction dear customer and user, thank you for the trust you have shown by purchasing our product. You have become owner of machine from a wide range of machines and attachments made by ,a.S. As a system of gardening, farming, small agricultural and communal technology. D...

Page 6: 4 Operation Safety

Bdr-595 e euroadela 6 4 operation safety 4.1 safety regulations , this international symbol indicates important messages concerning safety. When you see the symbol, be aware of a possible injury to yourself or to other persons and read attached instructions carefully. , the machine operator must be ...

Page 7

Bdr-595 e euroadela 7 , don’t start the engine in enclosed spaces! Pay an increased attention when handling the machine since the exhaust silencer remains hot after the engine has been switched off; make sure there are no leakages and spills on engine parts when refuelling. If they happen to occur, ...

Page 8

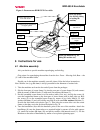

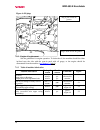

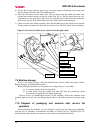

Bdr-595 e euroadela 8 l wa 2. 1. 3. 4. 5. 6. 7. 8. 11. 12. 9. 10..

Page 9

Bdr-595 e euroadela 9 5 machine: its use, technical specification and description 5.1 use of the machine drum mower model bdr-595 euroadela has been designed and manufactured to the latest knowledge in the field of small gardening and farming machinery, its design meeting the most recent european sa...

Page 10: 6 Instructions For Use

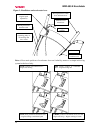

Bdr-595 e euroadela 10 6 instructions for use 6.1 machine assembly ask your dealer to provide machine unpackaging and briefing. Grip points for unpackaging the machine from the box: front – mowing disk; rear – the „u“ tube of the machine frame. Should you do the machine assembly yourself, please fol...

Page 11

Bdr-595 e euroadela 11 5. Put the apron with frame into the cut-out in the upper casing (13). Then put the casing with the apron frame on the machine and bolt it with two nuts m8 (14) with large flat washers Ø9mm (10). Provide the nuts with plastic caps (19). The apron frame will be screwed to the m...

Page 12

Bdr-595 e euroadela 12 6.2 putting into operation , the machine can be delivered without working fillings of the engine (as depending on varied national regulations)! , first read the instruction for engine use thoroughly! You can prevent a possible damage to the engine. 1. Check oil in the engine a...

Page 13

Bdr-595 e euroadela 13 2. Move the accelerator lever into the front position (choke). Start the engine by pulling on the manual starter (instructions for starting see the guidelines for engine use). 3. Let the new or cold engine running for about 30 seconds on the choke (accelerator lever in the cho...

Page 14

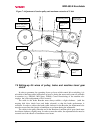

Bdr-595 e euroadela 14 note: all four main positions of accelerator lever are locked by means of a simple hollow-lug system in the lever body. Mowing disk drive clutch lever and brake lever machine travel clutch lever accelerator lever (engine speed adjustment) bowden cable of machine travel mowing ...

Page 15

Bdr-595 e euroadela 15 6.5 machine stop , prior to performing any activities in the near vicinity of the machine, switch off the engine and wait until the mowing disk stops! Always switch the engine off before leaving the machine. , never let the engine running at maximum speed or idling with the mo...

Page 16

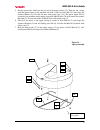

Bdr-595 e euroadela 16 ground and does not rebound. Disk rebounding results in uneven stand mowing 6.6.2 mowing grass stands set the engine to maximum speed, let the mowing disk rotate at maximum speed (starting the mowing disk see chapter 6.3 ) and get the machine into motion ( see chapter 6.4 ) fa...

Page 17

Bdr-595 e euroadela 17 7 maintenance, care and storage to ensure a long-term satisfaction with our product, it must be given proper care and maintenance. Regular maintenance of the machine will prevent its early wear ensuring at the same time a correct functioning of all its parts. Follow all instru...

Page 18

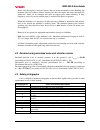

Bdr-595 e euroadela 18 7.1.2 engine oil replacement see the guidelines for engine operation. To drain the oil, the machine should be either inclined onto the side with the pour-in neck with oil gauge, or the engine should be dismounted from the machine ( see chapter 7.4 a,b,d). 7.1.3 table of machin...

Page 19

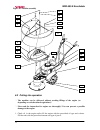

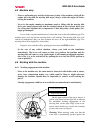

Bdr-595 e euroadela 19 7.2 tightening of bolted connections check the bolted connections for proper tightening. Check tightening of bolts fastening the knives in the upper disk and bolts fastening the lower disk onto the flange prior to any machine use. 7.3 replacement and sharpening of working kniv...

Page 20

Bdr-595 e euroadela 20 2. Hold the upper disk so that it does not turn and dismount the knife bolted connection by using the barrel spanner no. 16 and flat wrench no. 17. 3. Take the knife and parts of knife seating out of the mowing disk. Level the blade and sharpen the knife cutting edges. Inclina...

Page 21

Bdr-595 e euroadela 21 a) drain petrol from the engine tank. Dismount the accelerator lever (2x spanner no. 8) from the handlebars. Bowden cable should never be dismounted from the control on the engine! B) unscrew three safety nuts (spanner no. 13) on the engine flange and pull the engine out from ...

Page 22

Bdr-595 e euroadela 22 7.5 setting-up litz wires of pulley, brake and machine travel gear clutch in order to guarantee low operating forces on levers which control drive switching, it is advisable to lubricate cables in bowdens at least 2x during the season with some oil available in atomiser (e.G. ...

Page 23

Bdr-595 e euroadela 23 safety nuts in all adjustment bolts should be tightened by using two flat side spanners no. 10 or no. 9. If there is no more step to be used in the adjustment bolt, it is possible to displace the hook on the cable into another hole in the metal sheet lever on the handlebars (o...

Page 24

Bdr-595 e euroadela 24 7.6 driving problems: diagnostics problem reason remedial action tightening pulley does not stress the belt sufficiently set-up tightening pulley by means of adjustment bolt no. 2 (see fig. 8) cable fallen out from the tightening pulley lever put the cable back v-belt fallen b...

Page 25

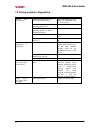

Bdr-595 e euroadela 25 7.7 table of service operations operation during season after season gearbox oil check 1x/month yes * engine oil check before each use ** engine air filter check before each use check check of knives for fastening and intactness before each use *** check upper and lower disk i...

Page 26

Bdr-595 e euroadela 26 d) fill the hub inside with new grease (e.G. For water pumps) lubricating at the same time also the flange with balls and free wheel surfaces. E) slide the free wheel on the wheel axis. The pin driven into the wheel axis must lean against the inclined surface on the free wheel...

Page 27: Contact To Manufacturer

Bdr-595 e euroadela 27 the following procedure is recommended for machine disposal after the end of its service life: 1. Dismount all parts from the machine that can still be used. 2. Dismount plastic machine parts and parts of non-ferrous metals. The stripped machine remainder and the dismounted pa...

Page 28: 8 List Of Components

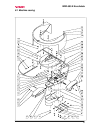

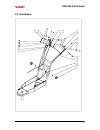

Bdr-595 e euroadela 28 8 list of components.

Page 29

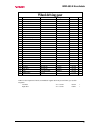

Bdr-595 e euroadela 29 8.1 machine casing.

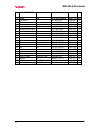

Page 30: Machine Casing

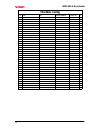

Bdr-595 e euroadela 30 pos. Name size drawing-standard order. No. Pcs 1 frame assembly 22 9 1536 050 196 001 1 2 apron frame-front 22 9 1856 008 196 018 1 3 apron frame-rear 22 9 1856 009 196 019 1 4 5 upper housing 22 9 8545 029 196 020 1 6 mud-guard flap holder 32 0 1530 129 196 012 1 7 8 mud-guar...

Page 31

Bdr-595 e euroadela 31 8.2 handlebars.

Page 32

Bdr-595 e euroadela 32 handlebars pos. Name size drawing-standard order. No. Pcs 1 handlebars 22 9 8078 059 196 002 1 2 control lever 32 0 8058 009 196 013 2 3 4 clutch bowden cable 622 9 8074 044 196 515 1 5 pulley bowden cable 622 9 8074 045 196 516 1 6 brake bowden cable 622 9 8074 046 196 517 1 ...

Page 33

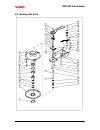

Bdr-595 e euroadela 33 8.3 mowing disk drive.

Page 34

Bdr-595 e euroadela 34 mowing disk drive pos. Name size drawing-standard order. No. Pcs 1 brake shoe 22 9 1664 024 189 014 2 2 driven belt pulley 22 9 3325 012 189 004 1 3 upper disk 22 9 5025 007 189 056 1 4 brake cam 22 9 8032 048 196 003 1 5 pulley arm 32 0 3330 034 196 010 1 6 drive 32 0 3821 01...

Page 35

Bdr-595 e euroadela 35.

Page 36

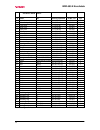

Bdr-595 e euroadela 36 8.4 wheel driving gear.

Page 37: Wheel Driving Gear

Bdr-595 e euroadela 37 pos. Name size drawing-standard order. No. Pcs 1 gearbox bdr-595 22 9 3282 052 196 014 1 2 driven belt pulley 22 9 3325 030 196 026 1 3 driven clutch element 32 0 3625 029 196 025 1 4 engine plate 22 9 8032 050 196 008 1 5 feather 3/16" 32 0 3330 021 189 036 1 6 screw w 3/8" 3...

Page 38

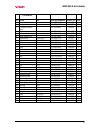

Bdr-595 e euroadela 38 8.5 gearbox.

Page 39

Bdr-595 e euroadela 39 gearbox pos. Name size drawing-standard order. No. Pcs 1 fork weldment 22 1 3330 013a 189 078 1 2 complete lever 22 9 3330 017 196 022 1 3 complete carrier plate 22 9 3616 006 189 029 1 4 worm 2:54 32 0 3214 028 196 023 1 5 worm wheel 32 0 3221 016 196 027 1 6 shaft-wheel axis...