- DL manuals

- Vari

- Lawn and Garden Equipment

- Hurricane F-600

- Instructions For Use Manual

Vari Hurricane F-600 Instructions For Use Manual

Summary of Hurricane F-600

Page 1

Mulcher hurricane f-600 instructions for use 2006.

Page 2

F-600 2 contents 1 basic information. ..............................................................................................................3 2 foreword.............................................................................................................................4 2.1 warning ....

Page 3

F-600 3 1 basic information. ask your dealer to provide the machine unpackaging, assembly and setup and the briefing! Fill in the following data concerning your machine. The data are important for ordering spare parts. It is advised to have a spare copy of this page with all data on the machine pu...

Page 4

F-600 4 2 foreword. Dear customer and user, thank you for trusting our products. You have become owner of machine from a wide range of machines and attachments made by ,a.S. As a system of gardening, farming, small agricultural and communal technology. The mulcher hurricane f-600 is designed to meet...

Page 5

F-600 5 3 operation safety. 3.1 safety regulations. this international symbol indicates important messages concerning safety. When you see the symbol, be aware of a possible injury threatening to you or to other persons and read the attached instructions carefully. the machine operator must be o...

Page 6

F-600 6 when the machine is in operation, all other persons (children in particular) and animals have to be outside the machine’s working space. The machine operator can continue working only after they have been shown out to a safe distance (see pictograph 6). Note: the outer safety zone a around...

Page 7

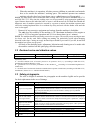

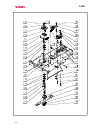

F-600 7 1 2 3 4 5 6 7 8 9 10 11.

Page 8

F-600 8 4 use, technical specifications and technical description of the machine. 4.1 machine use. This mulcher is designed for mowing swards of all kinds of stalky grasses, preferably old and dry, on both maintained and not-maintained sites. The mulcher can be used for cutting woody species from se...

Page 9

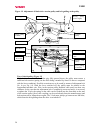

F-600 9 figure 1: mulcher hurricane f-600 5 instructions for use. 5.1 machine assembly. Ask your dealer to provide unpackaging of the machine and briefing in machine operation. With respect to difficult withdrawal of the machine from the box, it is advised to cut the box through in corners and then ...

Page 10

F-600 10 figure 2: machine assembly unscrew the front cover from the machine chassis (on both sides) run the front cover through the cutouts in the chassis deflector (the front cover must crane at the deflector when lifting) and screw it back to the machine chassis. Tighten the nuts so that the cove...

Page 11

F-600 11 5.3 putting into operation. the machine may be delivered without engine fillings (in dependence on different national regulations)! first thoroughly read the instruction for engine use. You can prevent a possible damage to the engine. 1. Check oil volume in the engine and/or fill the en...

Page 12

F-600 12 the pin differential in wheels). Start walking simultaneously with the machine start, adapting your walk pace to the direction and speed of the machine. be prepared when the machine starts moving with a little jerk. • travel back: move the gear-shifting lever to the „r“ position. Then pre...

Page 13

F-600 13 time! Machine drive components (v-belt, belt pulley, clutch pulley, etc.) might suffer damage! If you wish to switch the engine off, do it by shifting the lever to the „stop" position. in the case of any critical situation, release your hold on the handlebars without any delay. Do not hol...

Page 14

F-600 14 cutting height adjustment by means of guide wheels: a) push on both handrails so that the arresting pin in the arresting plate is released b) press the black plastic lever of cutting height adjustment on the bottom side of the right handlebar grip with fingers of your right hand (see fig. 4...

Page 15

F-600 15 5.7.3 sward cutting set the engine on the maximum speed, let the cutting blade rotate at the maximum speed and then get the machine into motion, facing the to-be-cut sward. At cutting, you should proceed only in such a way that the to-be-cut sward is – if possible – on the left side of the ...

Page 16

F-600 16 figure 7: arrestment of leading wheels on the slope 5.7.6 machine transport by road for the machine transport by road shift in neutral gear (“n”) and press the travel clutch lever on the left handrail. The automatic brake will be unblocked and the machine can be pushed manually. 6 mainten...

Page 17

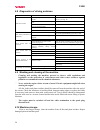

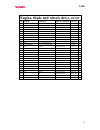

F-600 17 table of machine lubrication * besides lubrication intervals in this table, lubricate the marked points after each water washing, especially when using power water figure 9: other lubrication points 6.2 tightening of bolted connections. Regularly check the tightening of all important bolted...

Page 18

F-600 18 6.3 working blade replacement and sharpening. the machine must be standing on a firm support plate and must be secured so that the blade is easily accessible and an unexpected spontaneous machine motion cannot occur. be very careful when dismounting the blade. Its cutting edges are shar...

Page 19

F-600 19 designation of recommended and by manufacturer approved v-belts on the machine : 1. V-belt of gearbox drive: optibelt tx13 x 660ld 6t6k 2. V-belt of blade drive: optibelt tx17 x 1290ld 6t6k ld = mean length of the belt it is possible to use equivalent v-belts made by other manufacturers. Ho...

Page 20

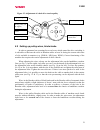

F-600 20 figure 12: adjustment of blade drive tension pulley and belt guiding at the pulley travel clutch pulley (figure 13) with the lever on the left handlebar grip fully pressed down, the pulley must ensure a sufficient belt tension (spring on the cable being extended by about 10 mm as compared w...

Page 21

F-600 21 figure 13: adjustment of wheel drive tension pulley 6.5 setting up pulley wires, blade brake. In order to guarantee low operating forces on levers which control the drive switching, it is advisable to lubricate the wires in bowden cables at least 2x during the season with some of oils avail...

Page 22

F-600 22 figure 14: bowden cables and adjustment bolts bowden cable no. 1 2 3 4 5 6 description automatic brake blade drive pulley arrestment of leading wheels wheel drive clutch gear shifting blade brake 6.6 adjustment of the automatic brake. The automatic brake is activated by releasing the travel...

Page 23

F-600 23 b) tighten the nut of the automatic brake behind the left wheel (see fig. 14) so that the machine can keep on the slope and will not continue in downhill movement. C) gradually loosen the nut of the automatic brake until the moment when the machine starts moving. Then tighten the nut by abo...

Page 24

F-600 24 6.8 diagnostics of driving problems. 6.9 washing and cleaning of the machine. cleaning and washing the machine, proceed to observe valid regulations and legislation on the protection of watercourses and other water resources against pollution or contamination with chemical substances. n...

Page 25

F-600 25 for any long-time storage of the machine it is advisable: a) to conserve the blade b) to drain petrol out of the engine fuel tank and from the carburettor (more instructions see instructions for engine operation and maintenance) access of unauthorized persons to the machine is to be prevent...

Page 26

F-600 26.

Page 27

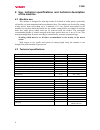

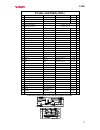

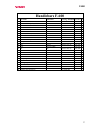

F-600 27 frame and blade drive pos. Part name dimensions drawing - standard ord. No. Pcs 100 chassis of mulcher f-600 22 9 1536 027 184 096 1 101 brake shoe 22 9 1664 024 189 014 2 102 driven pulley of blade f-700 32 0 3325 072 184 103 1 103 travel clutch pulley separate part list 1 104 blade drive ...

Page 28

F-600 28.

Page 29

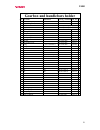

F-600 29 gearbox and handlebars holder pos. Part name dimensions drawing - standard ord. No. Pcs 200 driven travel pulley f-700 22 9 3325 039 184 041 1 201 gear shifting lever weldment 22 9 3832 008 184 045 1 202 prefabricated handlebars holder separate part list 1 203 complete handlebars f-600 sepa...

Page 30

F-600 30

Page 31

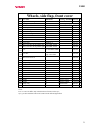

F-600 31 wheels, side flap, front cover pos. Part name dimensions drawing - standard ord. No. Pcs 300 lug of differential gear 22 9 1625 031 184 102 2 301 leading wheels f-600 separate part list 1 302 front cover f-600 weldment 22 9 8549 033 184 098 1 303 side flap f-600 weldment 22 9 8549 034 184 0...

Page 32

F-600 32.

Page 33

F-600 33 engine, blade and wheels drive, cover pos. Part name dimensions drawing - standard ord. No. Pcs 400 driving pulley f-600 22 9 3325 044 184 100 1 401 engine plate f-700 weldment 22 9 8032 054 184 049 1 402 mulcher blade cover complete 22 9 8545 039 184 020 1 403 woodruff key 3/16" 32 0 3330 ...

Page 34

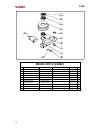

F-600 34 leading wheels pos. Part name dimensions drawing - standard ord. No. Pcs 1 frame of leading wheels weldment 22 9 1646 034 184 095 1 2 wheel hinge, left 22 9 1646 036 184 104 1 3 wheel hinge, right 22 9 1646 037 184 105 1 4 sliding washer 32 0 9220 229 182 039 4 5 elastic cotter pin ama 2914...

Page 35

F-600 35 handlebars holder pos. Part name dimensions drawing - standard ord. No. Pcs 1 pivot 32 0 9311 103 192 007 1 2 pin 3x18 Čsn 02 2156 127 504 1 3 spring 1.25x11.25x28x8.5 32 0 9746 004 124 500 1 4 nut m10 Čsn 02 1492.25 195 527 1 5 washer 10.5 Čsn 02 1702.15 189 567 1 6 handlebars holder f-700...

Page 36

F-600 36.

Page 37

F-600 37 handlebars f-600 pos. Part name dimensions drawing - standard ord. No. Pcs 1 red knob 1ac02040 184 519 1 2 bowden cable of pulley f-700 22 9 8074 050 184 502 1 3 bowden cable of brake f-700 22 9 8074 051 184 501 1 4 bowden cable of clutch f-700 22 9 8074 053 184 503 1 5 bowden cable of whee...

Page 38

F-600 38 blade drive pulley pos. Part name dimensions drawing - standard ord. No. Pcs 1 pulley arm 22 9 3330 021 184 069 1 2 pulley for belt x17 632 0 3325 069 184 579 1 3 bearing 6300 2rs 189 585 2 4 retaining ring 35 Čsn 02 2931 126 503 2 5 retaining ring 10 Čsn 02 2930 602 1 519 1 6 friction bear...

Page 39

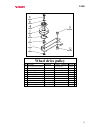

F-600 39 wheel drive pulley pos. Part name dimensions drawing - standard ord. No. Pcs 1 arm of wheel drive pulley 22 9 3330 025 184 091 1 2 wheel drive pulley 632 0 3325 068 184 512 1 3 pulley bearing shell 632 0 9320 071 196 528 1 4 friction bearing 6300 2rs 189 585 1 5 retaining ring 35 Čsn 02 293...

Page 40

F-600 40 10 letter of guarantee. To be completed by manufacturer name of product mulcher model hurricane f-600 serial number …………………………………………………………………………. Engine serial number …………………………………………………………………………. Warranty (months) …………………………………24………………..……………………... Output control …………………………………………………..……………...

Page 41

F-600 41 warranty inspection 1 date: ………………………………………person in charge:………………………………………………… service shop stamp and signature warranty inspection 1 machine model………………………… serial no.:…………………………… warranty inspection 2 date:………………………………………person in charge:………………………………………………… service shop stamp and signatu...