- DL manuals

- Vari

- Lawn and Garden Equipment

- Hurricane F-700

- Instructions For Use Manual

Vari Hurricane F-700 Instructions For Use Manual

Summary of Hurricane F-700

Page 1

Mulcher hurricane f-700 instructions for use 2007.

Page 2

F-700 2.

Page 3

F-700 3 text and illustrations c 2004 vari,a.S. Publication no. Vl-094-2004 year on the front page is the year of manual printing.

Page 4

F-700 4 contents 1 basic information ............................................................................................................... 5 2 foreword ............................................................................................................................ 6 2.1 basic w...

Page 5

F-700 5 1 basic information ask your dealer to provide the machine unpackaging, assembly and briefing fill in the following data concerning your machine. The data are important for ordering spare parts. It is advised to have a spare copy of this page with all data on the machine purchase for the c...

Page 6

F-700 6 2 foreword dear customer and user, t hank you for trusting our products. You have become owner of a machine from a wide range of machines and attachments made by ,a.S. As a system of gardening, farming, small agricultural and communal technology. The hurricane f-700 mulcher is designed to me...

Page 7

F-700 7 3 operation safety 3.1 safety regulations this international safety symbol indicates important messages concerning safety. When you see the symbol, be aware of a possible injury threatening to you or to other persons and read the following instructions carefully. the machine operator mus...

Page 8

F-700 8 when the machine is in operation, all other persons (children in particular) and animals have to be outside the machine’s working space. The machine operator can continue working only after they have been shown out to a safe distance (see pictograph 6). Note: the outer safety zone a around...

Page 9

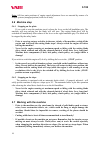

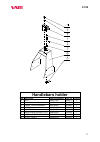

F-700 9 1 135 2 3 4 5 6 7 8 9.

Page 10

F-700 10 4 use, technical specifications and technical description of the machine 4.1 machine use this professional mulcher is designed for mowing grass stands of all kinds of stalky grasses, preferably old and dry, on both maintained and unkept sites. The mulcher can be used for cutting self-seedin...

Page 11

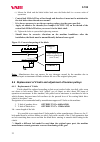

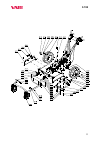

F-700 11 figure 1: mulcher hurricane f-700 5 instructions for use 5.1 machine assembly ask your dealer to provide unpackaging of the machine and briefing in machine operation. With respect to difficult withdrawal of the machine from the box, it is advised to cut the box through in corners and then t...

Page 12

F-700 12 5. Fasten the gear shifting lever (7) by means of 3 bolts m6x50 (8), 3 flat washers (9) and 3 self-locking nuts m6 (10) from the left to the lever holder on the bottom part of handlebars. The bolt with the washer should be mounted from the right. 6. Hook the springs (11) into eyes in front ...

Page 13

F-700 13 bumper assembly unscrew 4 bolts m8x20 holding the handlebars holder on the machine chassis. Put the bumper on the handlebars holder and screw the bolts m8x20 back. The bowden cable of brake must lead between the machine chassis and the bumper. 5.2 adjustment of handlebars handlebars can be ...

Page 14

F-700 14 in order to lessen the machine size e.G. For transport in a car, the handlebars should be either tilted forward over the engine or lowered into horizontal position and then turned clockwise by 180°. Bowden cables must be watched not to get tensioned somewhere on the machine construction. Fi...

Page 15

F-700 15 starting of the cutting blade is accompanied with a partial v-belt slippage and with the accompanying phenomena such as whistling, rattling, etc. The phenomenon usually disappears after the belt has run in. 4. After the cutting blade starts turning, press the lever completely to the handrai...

Page 16

F-700 16 note: all four main positions of engine speed adjustment lever are arrested by means of a simple system (stamp/projection) in the lever body. 5.6 machine stop 5.6.1 stopping on the plain if you wish to stop the machine travel, release the lever on the left handlebar grip. The machine will s...

Page 17

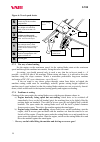

F-700 17 5.7.1 adjustment of cutting height adjustment of cutting height is affected by several important factors: • stand height and density • plant species prevailing in the stand • machine travel speed • cutting width • surface unevenness there is a general rule that the higher value of above men...

Page 18

F-700 18 figure 6: travel speed choice 5 maximum speed. Meant exclusively for the machine transportation . 4 maximum working speed. Low-height or low-density stand . Good for flat and even terrains. 3 2 medium working speed. Medium-height and high-density stands. Good for mild slopes. 1 minimum work...

Page 19

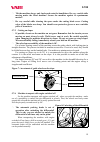

F-700 19 tilt the machine always only backwards onto the handlebars. Be very careful while moving under the lifted machine! Secure the machine against its spontaneous motion! be very careful while cleaning the space under the cutting blade cover. Cutting edges of the blades are sharp. You should...

Page 20

F-700 20 5.7.7 cutting of high grass stands this machine can also be used for cutting high grass stands without crushing. Herbage can be then used both for drying and as green fodder. Note: with respect to the cutting method, the proportion of crushed plants is higher than in other methods more frie...

Page 21

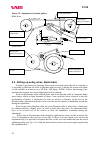

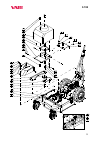

F-700 21 figure 9: other lubrication points 6.2 tightening of bolted connections regularly check the tightening of all important bolted connections. Always check the tightening of bolts fastening the blade to the blade holder and the blade holder to the shaft prior to any machine use. Maximum tighte...

Page 22

F-700 22 c) mount the blade and the blade holder back onto the blade shaft in a reverse order of operations. central bolt m10x1x25 has a fine thread and therefore it must not be mistaken for the side bolts whose threads are normal! it is always necessary to use the new spring washers (see the sp...

Page 23

F-700 23 the procedure of replacing v-belts is as follows: a) drain petrol from the engine tank. Remove the plastic ball from the accelerator lever. Dismount the accelerator lever from the handlebars crossbar. Bowden cable should never be dismounted from the control on the engine! Then dismount (or ...

Page 24

F-700 24 figure 12: adjustment of tension pulleys blade drive wheel drive 6.5 setting up pulley wires, blade brake in order to guarantee low operating forces on levers which control the drive switching, it is advisable to lubricate the wires in bowden cables at least 2x during the season with some o...

Page 25

F-700 25 figure 13: bowden cables and adjustment bolts bowden no. 1 2 3 4 5 6 description automatic brake blade drive pulley arrestment of guide wheels wheel drive clutch gear shifting blade brake 6.6 adjustment of the automatic brake the automatic brake is activated by releasing the wheel drive clu...

Page 26

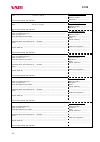

F-700 26 6.7 the table of service operations operation during season after season engine oil check prior to any use * engine air filter check prior to any use * blade check for clamping and intactness prior to any use, ** check of the condition of v-belts as required inspection, *** check of the fun...

Page 27

F-700 27 the engine must be switched off and the cable termination to the spark plug disconnected! 6.10 machine storage prior to any longer storage, clean the machine from all dirt, debris and plant residues. Repair damaged paint on machine parts. For any long-time storage of the machine it is adv...

Page 28

F-700 28 8 contact to manufacturer vari, a.S. Telephone: (+420) 325 607 111 opolanská 350 fax: (+420) 325 607 264 libice nad cidlinou (+420) 325 637 550 czech republic e-mail: vari@vari.Cz 289 07 internet: http://www.Vari.Cz/ 9 the list of parts if not mentioned otherwise, the tables of spare parts ...

Page 29

F-700 29.

Page 30

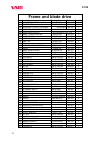

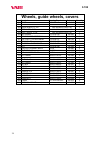

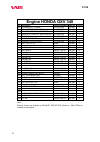

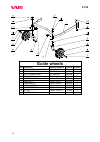

F-700 30 frame and blade drive pos. Description drawing-standard order.No. Quantity 100 mulcher chassis 22 9 1536 059 184 115 1 101 brake shoe 22 9 1664 024 189 014 2 102 driven belt pulley of blade 3203325072 184 038 1 103 wheel drive clutch pulley see separate part list 1 104 blade drive pulley se...

Page 31

F-700 31.

Page 32

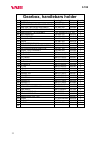

F-700 32 gearbox, handlebars holder pos. Description drawing-standard order.No. Quantity 200 lever dc10 1lc0717001 184 534 1 201 driven belt pulley of wheel drive 22 9 3325 039 184 041 1 202 gear shifting lever weldment 22 9 3832 008 184 045 1 203 handlebars holder - preassembly see separate part li...

Page 33

F-700 33.

Page 34

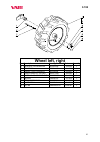

F-700 34 wheels, guide wheels, covers pos. Description drawing-standard order.No. Quantity 300 hinge 905500531 p 184 612 1 301 302 guide wheels f-700 see separate part list 1 303 left wheel f-700 see separate part list 1 304 right wheel f-700 see separate part list 1 305 mud guard 32 0 8530 038 184 ...

Page 35

F-700 35.

Page 36

F-700 36 engine honda gxv 340 pos. Description drawing-standard order.No. Quantity 400 intermediate flange 22 9 2752 020 184 050 1 401 driving belt pulley f-700 22 9 3325 035 184 048 1 402 engine plate f-700 weldment 22 9 8032 054 184 049 1 403 complete cover of mulcher belt 22 9 8545 039 184 020 1 ...

Page 37

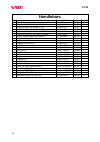

F-700 37 handlebars holder pos. Description drawing-standard order.No. Quantity 1 pivot 3209311103 192 007 1 2 pin 3x18 csn022156 127 504 1 3 spring 1.25x11x25x28x8.5 3209746004 124 500 1 4 nut m10 csn021492.25 195 527 1 5 washer 10,5 csn021702.15 189 567 1 6 handlebars holder f-700 2298045064 184 0...

Page 38

F-700 38 guide wheels pos. Description drawing-standard order.No. Quantity 1 guide wheels frame f-700 22 9 1646 039 184 121 1 2 left wheel hinge 22 9 1646 036 184 104 1 3 right wheel hinge 22 9 1646 037 184 105 1 4 slide washer 32 0 9220 229 182 039 4 5 flexible split pin ama art. 2914 182 533 2 6 w...

Page 39

F-700 39.

Page 40

F-700 40 handlebars pos. Description drawing-standard order.No. Quantity 1 red knob 1ac02040 184 519 1 2 bowden cable of roller f-700 22 9 8074 050 184 502 1 3 bowden cable of brake f-700 22 9 8074 051 184 501 1 4 bowden cable of clutch f-700 22 9 8074 053 184 503 1 5 bowden cable of wheel arrestmen...

Page 41

F-700 41 wheel left, right pos. Description drawing-standard order.No. Quantity 1 driver of differential 2291625029 184 059 1 2 driver pin 3209311165 184 057 1 3 spring 1.25x11.25x28x8.5 3209746004 124 500 1 4 wheel 16x6,5-8 f-700 left 62291770037 184 526 1 5 wheel 16x6,5-8 f-700 right 62291770038 1...

Page 42

F-700 42 blade drive pulley pos. Description drawing-standard order.No. Quantity 1 pulley arm 22 9 3330 021 184 069 1 2 pulley for belt x17 632 0 3325 069 184 579 1 3 bearing 6300 2rs 189 585 2 4 retaining ring 35 Čsn 02 2931 126 503 2 5 retaining ring 10 Čsn 02 2930 6021519 1 6 friction bearing a 1...

Page 43

F-700 43 10 letter of guarantee to be completed by manufacturer name of product mulcher model hurricane f-700 serial number …………………………………………………………………………. Engine serial number …………………………………………………………………………. Warranty (months) …………………………………24………………..……………………... Output control …………………………………………………..………………...

Page 44

F-700 44 warranty inspection 1 date: ………………………………………person in charge:………………………………………………… service shop stamp and signature warranty inspection 1 machine model………………………… serial no.:…………………………… warranty inspection 2 date:………………………………………person in charge:………………………………………………… service shop stamp and signatu...