Varian 1200 GC/MS Pre-installation Instructions - 1200/1200L Gc/ms and Lc/ms

Varian,Inc.

2700 Mitchell Drive

Walnut Creek, CA 94598 U.S.A.

03-914961-00:6

1

of 24

1200/1200L MS Pre-installation Instructions

1200/1200L GC/MS and LC/MS

Pre-installation Instructions

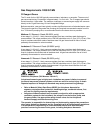

Congratulations on your purchase of the Varian 1200 Quadrupole Mass Spectrometer. The

information provided in this pre-installation guide will help you prepare your installation site for

your Varian 1200 GC/MS, 1200L GC/MS, 1200L LC/MS, or 1200L GC/LC/MS system. Use the

general requirements and the appropriate section of these pre-installation instructions as a

guide while preparing the installation site. When your site meets all the requirements detailed

in these instructions, contact the Customer Service office in your region to schedule installation.

The Varian 1200L LC/MS and 1200/1200L GC/MS have been designed to operate reliably

under carefully controlled environmental conditions. It is the responsibility of the customer to

provide a suitable location, power source, and operating environment. Operating or maintaining

a system in operational conditions outside of the power and operating environment limits

described in this manual could cause failures of many types. The repair of such failures is

specifically excluded from the Warranty and Service contract conditions.

CAUTION

All phases of the installation site preparation must conform to

local safety, electrical, and building codes. These codes take

precedence over any recommendations in these instructions,

and compliance to them is the responsibility of the customer.

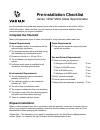

General Requirements..................................................2

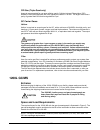

Operating Environment ...........................................2

Temperature/Humidity.............................................2

Particulate Matter ....................................................2

Vibration ..................................................................2

Exhaust System ......................................................2

1200 GC/MS.................................................................3

Entrance..................................................................3

Space and Load Requirements...............................3

Power Requirements 1200 GC/MS.........................4

Gas Requirements 1200 GC/MS ............................5

1200L GC/MS...............................................................6

Entrance..................................................................6

Space and Load Requirements...............................6

Power Requirements 1200L GC/MS.......................7

Gas Requirements 1200L GC/MS ..........................8

1200L LC/MS..............................................................10

Entrance................................................................10

Space and Load Requirements ............................ 10

Power Requirements 1200L LC/MS...................... 11

Gas Requirements 1200L LC/MS ......................... 12

Solvent Requirements 1200L LC/MS.................... 13

1200L GC/LC/MS ....................................................... 13

Entrance................................................................ 13

Space and Load Requirements ............................ 13

Power Requirements 1200L GC/LC/MS ............... 14

Gas Requirements 1200L GC/LC/MS................... 15

Solvent Requirements 1200L LC/MS.................... 18

Instrument Arrival ....................................................... 19

Inspection.............................................................. 19

Unpacking and Installation.................................... 20

Spare Parts ........................................................... 20

Preventive Maintenance ....................................... 20

Appendix 1. Module Specifications............................ 21

Appendix 2. Power Consumption .............................. 22

Appendix 3. NEMA Plugs and Power Outlets............ 24