- DL manuals

- Varian

- Touch terminals

- 947

- Operation And Service Manual

Varian 947 Operation And Service Manual - List Of Tables

xi

Models 947, 948 and 960 Leak Detectors Operations and Service Manual

List of Tables

Table Description

Page

NOT READY Condition Codes ........................................................................................ 3-12

Zustandscodes für nicht betriebsbereites System ........................................................... 3-31

Summary of 947

Page 1

Vacuum technologies operation and service manual models 947, 948 and 960 leak detectors part no. 699909947 revision h may 2003 advanced test equipment rentals www.Atecorp.Com 800-404-atec (2832) ® established 1981 notice: this document contains references to varian. Please note that varian, inc. Is ...

Page 2

Copyright 2003 varian vacuum technologies models 947, 948 and 960 leak detectors contra-flow, macrotorr, triscroll and convectorr are trademarks or registered trademarks of varian vacuum technologies. Apiezon is a registered trademark of m&i materials ltd. Alconox is a registered trademark of alcono...

Page 3: Table Of Contents

Iii models 947, 948 and 960 leak detectors operations and service manual table of contents declaration of conformity ............................................................................................................ Xiii warranty ...............................................................

Page 4

Models 947, 948 and 960 leak detectors operations and service manual iv section 1. Introduction to models 947, 948 and 960 leak detectors ....................................... 1-1 1.1 platform electronics ................................................................................................

Page 5

Models 947, 948 and 960 leak detectors operations and service manual v section 2. Leak detector integration ........................................................................................... 2-1 2.1 physical considerations .......................................................................

Page 6

Models 947, 948 and 960 leak detectors operations and service manual vi section 4. Maintenance ................................................................................................................ 4-1 4.1 daily maintenance .....................................................................

Page 7

Models 947, 948 and 960 leak detectors operations and service manual vii section 5. Troubleshooting .......................................................................................................... 5-1 5.1 error condition codes ..................................................................

Page 8

Models 947, 948 and 960 leak detectors operations and service manual viii b.5.2 dry system ..............................................................................................................B-26 b.5.2.1 removing the dry system forepump.........................................................

Page 9: List Of Figures

Ix models 947, 948 and 960 leak detectors operations and service manual list of figures figure description page 1-1 947 leak detector............................................................................................................... 1-2 1-2 948/960 leak detector.............................

Page 10

Models 947, 948 and 960 leak detectors operations and service manual x 4-9 947/948/960 spectrometer tube installation .................................................................... 4-24 4-10 tc1 gauge in the mvba ....................................................................................

Page 11: List Of Tables

Xi models 947, 948 and 960 leak detectors operations and service manual list of tables table description page 2-1 valve operation ................................................................................................................. 2-4 2-2 j120 input connections ............................

Page 12

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 13: Declaration Of Conformity

Varian vacuum technologies 121 hartwell avenue lexington, ma, 02421-3133 usa declare under our sole responsibility that the product, erklären, in alleniniger verantwortung, daß dieses produkt, déclarons sous notre seule responsabilité que le produit, declaramos, bajo nuestra sola responsabilidad, qu...

Page 14: Warranty

Models 947, 948 and 960 leak detectors operations and service manual xiv warranty products manufactured by seller are warranted against defects in materials and workmanship for twelve (12) months from date of shipment thereof to customer, and seller’s liability under valid warranty claims is limited...

Page 15: Garantie

Models 947, 948 and 960 leak detectors operations and service manual xv garantie die vom anbieter hergestellten produkte sind im hinblick auf schadhafte werkstoffe und verarbeitung für eine zeitdauer von zwölf (12) monaten ab versanddatum derselben an den kunden garantiert, und die verpflichtungen d...

Page 16

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 17: Factory Calibration Data

Models 947, 948 and 960 leak detectors operations and service manual xvii factory calibration data model number: date: serial number: initials: your varian 947/948/960 leak detector has been thoroughly tested prior to shipment. It is shipped tuned to helium on filament no. 1. Normally, once set, the...

Page 18

Models 947, 948 and 960 leak detectors operations and service manual xviii hazard and safety information this manual uses the following standard safety protocols: warning the warning messages are for attracting the attention of the operator to a particular procedure or practice which, if not followe...

Page 19

Models 947, 948 and 960 leak detectors operations and service manual xix solvents caution the mechanical components of leak detectors are typically cleaned with alcohol, methanol, or other solvents. When heated, sprayed, or exposed to high-temperature equipment, these solvents become flammable and e...

Page 20

Models 947, 948 and 960 leak detectors operations and service manual xx equipment, general warning the leak detector is not designed for use with hazardous gases. Verify that the system to be tested has been purged of all hazardous gases prior to using the leak detector.When testing a system that co...

Page 21

Models 947, 948 and 960 leak detectors operations and service manual xxi power and static warning disconnect power from the leak detector before performing any maintenance procedure that requires physically disconnecting any part of the system. Caution many components of the leak detector are static...

Page 22

Models 947, 948 and 960 leak detectors operations and service manual xxii caution this equipment generates, uses, and can radiate rf energy, and if not installed and used in accordance with the instructional manual, may cause harmful interference to radio communications. When this equipment is opera...

Page 23

Models 947, 948 and 960 leak detectors operations and service manual xxiii o-ring care when removing, checking, or replacing o-rings, keep in mind the following: note varian vacuum technologies recommends replacing all o-rings during routine maintenance or during any maintenance procedure requiring ...

Page 24

Models 947, 948 and 960 leak detectors operations and service manual xxiv spectrometer tube caution the spectrometer tube operates at a very high vacuum produced by the high vacuum pump. Service of the spectrometer tube requires that this vacuum be vented to the atmosphere. Caution do not use grease...

Page 25: Varian Services

Models 947, 948 and 960 leak detectors operations and service manual xxv varian services the following are just a few of the many services that varian offers its customers. Please see our catalog, or contact us to learn of the services that are available. Contact varian vacuum technologies customer ...

Page 26

Models 947, 948 and 960 leak detectors operations and service manual xxvi informationen über gefahren und sicherheit in diesem handbuch werden die folgenden standardgemäßen sicherheitsprotokolle verwendet: warnung warnhinweise dienen dazu, die aufmerksamkeit des bedieners auf bestimmte verfahren ode...

Page 27

Models 947, 948 and 960 leak detectors operations and service manual xxvii lösungsmittel vorsicht die mechanischen komponenten des lecksuchers werden in der regel mit alkohol, methanol oder anderen lösungsmitteln gereinigt. Werden diese komponenten erwärmt, besprüht oder hochtemperaturgeräten ausges...

Page 28

Models 947, 948 and 960 leak detectors operations and service manual xxviii maschinen, allgemein warnung der lecksucher eignet sich nicht für eine verwendung mit gefährlichen gasen. Vergewissern sie sich, dass alle gefährlichen gase vom system abgelassen wurden, bevor sie den lecksucher benutzen. Be...

Page 29

Models 947, 948 and 960 leak detectors operations and service manual xxix strom und statik warnung trennen sie den lecksucher von der netzstromversorgung, bevor sie jegliche wartungsverfahren durchführen, die eine physikalische trennung eines beliebeigen systemteils erfordert. Vorsicht viele kompone...

Page 30

Models 947, 948 and 960 leak detectors operations and service manual xxx vorsicht diese maschine generiert, benutzt und gibt u.U. Hochfrequenzenergie ab und kann, wenn sie nicht in Übereinstimmung mit den im handbuch enthaltenen anleitungen installiert und benutzt wird, schädliche störungen des funk...

Page 31

Models 947, 948 and 960 leak detectors operations and service manual xxxi vakuumgeräte und sauberkeit bei der wartung von lecksuchern oder vakuumgeräten jeglicher art ist sauberkeit von größter bedeutung. Einige vorgehensweisen spielen bei der wartung von lecksuchern eine größere rolle als bei allge...

Page 32

Models 947, 948 and 960 leak detectors operations and service manual xxxii pflege von o-ringen beim entfernen, prüfen oder auswechseln von o-ringen ist folgendes zu beachten: hinweis varian vacuum technologies empfiehlt, im rahmen routinemäßiger wartungsarbeiten oder verfahrensweisen, die das entfer...

Page 33

Models 947, 948 and 960 leak detectors operations and service manual xxxiii spektrometerrohr vorsicht das spektrometerrohr wird mit einem sehr hohen vakuum betrieben, das von der hochvakuumpumpe generiert wird. Bei der wartung des spektrometerrohrs ist eine ableitung dieses vakuums ins freie erforde...

Page 34: Dienstleistungen Von Varian

Models 947, 948 and 960 leak detectors operations and service manual xxxiv dienstleistungen von varian im folgenden werden nur einige der umfassenden dienstleistungen aufgeführt, die varian seinen kunden zu bieten hat. Um näheres über die verfügbaren dienstleistungen zu erfahren, nehmen sie bitte au...

Page 35: And 960 Leak Detectors

1-1 models 947, 948 and 960 leak detectors operations and service manual section 1. Introduction to models 947, 948 and 960 leak detectors varian vacuum technologies’ model 947, model 948 and model 960 are platform auto-test ® helium mass spectrometer leak detectors. In this manual, these leak detec...

Page 36

Models 947, 948 and 960 leak detectors operations and service manual 1-2 the model 947 is shown in figure 1-1. Descriptions of the turret and operational buttons identified in figure 1-1 follow the figure. Models 948/960 are shown in figure 1-2. Figure 1-1 947 leak detector ➀ turret enclosure for se...

Page 37

Models 947, 948 and 960 leak detectors operations and service manual 1-3 models 948/960 are shown in figure 1-2. The door on the working surface of the 948/960 provides access to the nitrogen cold trap. Descriptions of the turret, operational buttons, and nitrogen trap identified in figure 1-2 follo...

Page 38: 1.1 Platform Electronics

Models 947, 948 and 960 leak detectors operations and service manual 1-4 1.1 platform electronics the 947/948/960 use varian vacuum technologies’ platform leak detector electronics architecture to: ❑ operate the spectrometer assembly ❑ control the mechanical and high vacuum pumps ❑ control the valve...

Page 39

Models 947, 948 and 960 leak detectors operations and service manual 1-5 3. Inspect the leak detector and related items immediately for any indication of shipping damage. 4. Carefully cut the strapping holding the leak detector on the skid. 5. Remove any loose boxes or packages and put them aside. K...

Page 40

Models 947, 948 and 960 leak detectors operations and service manual 1-6 1.2.3 removing loose packing from interior of 947/948/960 once the 947/948/960 is off the skid, the loose packing inside the enclosure must be removed. 1. Open the front panel of the 947/948/960, which is the main access to ser...

Page 41

Models 947, 948 and 960 leak detectors operations and service manual 1-7 1 volume control controls the volume of the audible leak rate signal. 2 display button displays the selected reject level of the leak detector using the 50-segment leak rate bar graph and the appropriate range exponent. 3 rough...

Page 42

Models 947, 948 and 960 leak detectors operations and service manual 1-8 13 smaller/larger exponent selection buttons when manual range changing is selected: smaller decreases the leak rate exponent. Larger increases the leak rate exponent. Holding the smaller or larger button down for more than 3 s...

Page 43

Models 947, 948 and 960 leak detectors operations and service manual 1-9 1.4 inner door instruction label thelabel on the inside of the lockable turret door (figure 1-4) provides: ❑ an abbreviated list of leak detector operating instructions to be used when the operator is familiar with normal opera...

Page 44

Models 947, 948 and 960 leak detectors operations and service manual 1-10 1.5 rear panel power connection and circuit breakers figure 1-5 shows the rear power panel of the 947/948/960. Descriptions of the rear panel elements follow the figure. Figure 1-5 rear power panel rear panel power and circuit...

Page 45: 1.6 Service Pendant

Models 947, 948 and 960 leak detectors operations and service manual 1-11 1.6 service pendant the service pendant is used to set and display parameters for the 947/948/960 leak detector. It is a handheld terminal with a 40-key keypad and a 20 character x 4 line backlit lcd display (see figure 1-6). ...

Page 46

Models 947, 948 and 960 leak detectors operations and service manual 1-12 1.7 installation preparation to prepare the 947/948/960 for operation: ❑ have power and liquid nitrogen (948/960 only) available ❑ check oil level of wet pumps ❑ adhere to special installation requirements for a clean room (if...

Page 47

Models 947, 948 and 960 leak detectors operations and service manual 1-13 1.7.2 liquid nitrogen (models 948/960 only) the amount of liquid nitrogen needed to keep the cold trap operational is approximately three liters per day (slightly more on initial startup). Note add liquid nitrogen to the trap ...

Page 48: 1.8 Storage

Models 947, 948 and 960 leak detectors operations and service manual 1-14 1.8 storage if the leak detector is not used immediately, it can be stored as received without special precautions. A dry, relatively dust-free area is preferred. The required environmental conditions for storage are: ❑ 0% to ...

Page 49: Und 960

Models 947, 948 and 960 leak detectors operations and service manual 1-15 einführung in die lecksucher, modell 947, 948 und 960 die modell 947, modell 948 und modell 960 von varian vacuum technologies sind plattform auto-test ® helium-spektrometer-lecksucher. In diesem handbuch werden die lecksucher...

Page 50

Models 947, 948 and 960 leak detectors operations and service manual 1-16 modell 947 ist in abbildung 1-8 zu sehen. Beschreibungen des aufsatzes und der betriebstasten, die in abbildung 1-8 gekennzeichnet sind, entsprechen der abbildung. Modelle 948/960 sind in abbildung 1-9 zu sehen. Abbildung 1-8 ...

Page 51

Models 947, 948 and 960 leak detectors operations and service manual 1-17 modelle 948/960 sind in abbildung 1-9 zu sehen. Die tür auf der arbeitsfläche der 948/960 ermöglicht den zugang zur stickstoff-kühlfalle. Beschreibungen des aufsatzes, der betriebstasten und stickstoff-kühlfalle, die in abbild...

Page 52: 1.10 Plattformelektronik

Models 947, 948 and 960 leak detectors operations and service manual 1-18 1.10 plattformelektronik die 947/948/960 benutzen die plattform-lecksuchelektronik von varian vacuum technologies, um: ❑ die spektrometereinheit zu betätigen ❑ die mechanischen und hochvakuum-pumpen zu steuern ❑ die ventile zu...

Page 53

Models 947, 948 and 960 leak detectors operations and service manual 1-19 1.11.6 anleitungen zum auspacken gehen sie beim auspacken und lösen der 947/948/960 von der palette wie folgt vor: 1. Untersuchen sie den container auf anzeichen von während des transports entstandenen schäden. A. Entsorgen si...

Page 54

Models 947, 948 and 960 leak detectors operations and service manual 1-20 vorgehensweise 1 1. Rollen sie den lecksucher mit hilfe einer zweiten person vorsichtig zur vorderseite der palette. 2. Heben sie das vordere ende der einheit an und senken sie sie behutsam auf den boden. 3. Heben sie die rück...

Page 55

Models 947, 948 and 960 leak detectors operations and service manual 1-21 1.12 anzeigen und steuerelemente der fronttafel die steuerelemente und anzeigen der fronttafel werden in abbildung 1-10 anhand von zahlen gekennzeichnet abbildung 1-10. Abbildung 1-10 anzeigen und steuerelemente der fronttafel...

Page 56

Models 947, 948 and 960 leak detectors operations and service manual 1-22 6 prüfschalter "umstellen auf fein" stellt den lecksucher im großleckmodus in der position nein fest. In der position auto erfolgt eine umstellung auf den feinprüfmodus. 7 anzeige sollwerttaste zeigt den sollwert des Übertragu...

Page 57

Models 947, 948 and 960 leak detectors operations and service manual 1-23 13 wahltasten für kleinere / größere exponenten bei einer auswahl der manuellen bereichsänderung: verringert kleiner den exponenten der leckrate. Erhöht grÖsser den exponenten der leckrate. Wird die taste kleiner oder grÖsser ...

Page 58

Models 947, 948 and 960 leak detectors operations and service manual 1-24 1.13 anweisungsschild an der innentür dasschild an der innenseite der verschließbaren aufsatztür (abbildung 1-11) enthält folgende angaben: ❑ eine verkürzte liste der betriebsanleitungen des lecksuchers, die dann zu benutzen i...

Page 59

Models 947, 948 and 960 leak detectors operations and service manual 1-25 1.14 rückseitige schalttafelstromanschluss und trennschalter abbildung 1-12 zeigt die rückseitige schalttafel der 947/948/960. Die beschreibungen der elemente auf der rückseitigen schalttafel entsprechen der abbildung. Abbildu...

Page 60: 1.15 Hängebedienungstafel

Models 947, 948 and 960 leak detectors operations and service manual 1-26 1.15 hängebedienungstafel die hängebedienungstafel dient zum einstellen und anzeigen von parametern für die lecksucher 947/948/960. Es handelt sich dabei um eine handgehaltene einheit mit einem 40 tasten umfassenden tastenfeld...

Page 61

Models 947, 948 and 960 leak detectors operations and service manual 1-27 1.16 vorbereitung zur installation bereiten sie die 947/948/960 wie folgt auf den betrieb vor: ❑ vergewissern sie sich, dass ein stromanschluss und flüssigstickstoff (nur 948/960) verfügbar sind. ❑ prüfen sie den Ölstand der n...

Page 62

Models 947, 948 and 960 leak detectors operations and service manual 1-28 1.16.2 flüssigstickstoff (nur modell 948/960) die menge des flüssigstickstoffs, die zur wahrung der betriebsfähigkeit der kühlfalle erforderlich ist, beträgt ca. Drei liter täglich (bei der ersten inbetriebnahme etwas mehr). H...

Page 63: 1.17 Aufbewahrung

Models 947, 948 and 960 leak detectors operations and service manual 1-29 1.16.5 installationsdienste installation, betriebsprüfungen und betriebsanleitungen für ihre 947/948/960 sind von einem qualifiziertenvarian techniker von vacuum technologies erhältlich. Wenn sie ihren lecksucher ausgepackt ha...

Page 64

Models 947, 948 and 960 leak detectors operations and service manual 1-30 1.18 optionale anschlüsse an der rückseitigen schalttafel abbildung 1-14 zeigt die optionale rückseitige schalttafel der 947/948/960. Die beschreibungen der anschlüsse auf der rückseitigen schalttafel entsprechen der abbildung...

Page 65: 2.1 Physical Considerations

2-1 models 947, 948 and 960 leak detectors operations and service manual section 2. Leak detector integration although models 947/948/960 are considered stand-alone units, all the models can be incorporated into a production line connected to a host computer or plc. This section details the setup an...

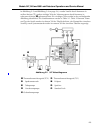

Page 66

Models 947, 948 and 960 leak detectors operations and service manual 2-2 in figure 2-1 and figure 2-3 on page 2-5, valves are designated by numbers in white circles ( ➀ ), other key parts of the vacuum system are designated by numbers in black circles ( ➊ ). The key parts are identified below the fi...

Page 67

Models 947, 948 and 960 leak detectors operations and service manual 2-3 in abbildung 2-2 und abbildung 2-4 on page 2-6, werden ventile durch nummern in weißen kreisen ( ➀ ), andere wichtige teile des vakuumsystems durch nummern in schwarzen kreisen ( ➊ ) gekennzeichnet. Die wichtigen teile werden i...

Page 68

Models 947, 948 and 960 leak detectors operations and service manual 2-4 table 2-1 serves two purposes. In the upper portion, the valve name and type are defined. In the lower portion, table 2-1 indicates the valve state (open or closed) in relation to the system status for testing the 947/948/960. ...

Page 69

Models 947, 948 and 960 leak detectors operations and service manual 2-5 in figure 2-3, numbers in white circles designate the location of valves. Other key parts of the vacuum system, represented by numbers in black circles, are identified after figure 2-3. Figure 2-3 948 flow diagram ❶ thermocoupl...

Page 70

Models 947, 948 and 960 leak detectors operations and service manual 2-6 in abbildung 2-4 kennzeichnen die nummern in weißen kreisen die position der ventile. Andere wichtige teile des vakuumsystems, angezeigt durch nummern in schwarzen kreisen, werden nach abbildung 2-4 identifiziert. Abbildung 2-4...

Page 71

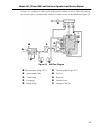

Models 947, 948 and 960 leak detectors operations and service manual 2-7 in figure 2-5, numbers in white circles designate the location of valves. Other key parts of the vacuum system, represented by numbers in black circles, are identified after figure 2-5. Figure 2-5 960 flow diagram reservoir the...

Page 72

Models 947, 948 and 960 leak detectors operations and service manual 2-8 in figure 2-6, numbers in white circles designate the location of valves. Other key parts of the vacuum system, represented by numbers in black circles, are identified after figure 2-6. Figure 2-6 960 flow diagram reservoir the...

Page 73

Models 947, 948 and 960 leak detectors operations and service manual 2-9 2.3 electronic considerations for the optional rear panel interface this section includes information necessary to interface the 947/948/960 with a plc or a host computer using either serial or parallel communications through t...

Page 74

Models 947, 948 and 960 leak detectors operations and service manual 2-10 2.3.2 bcd j121 outputs table 2-3 provides the j121 output connections. 21 calibrating active high active when auto cal. 23 ready active high active when system is operating (inverse of “not ready”). 25 ground return for j120 o...

Page 75

Models 947, 948 and 960 leak detectors operations and service manual 2-11 2.3.3 host serial port j123 pinouts the host serial port is used to interface the 947/948/960 to a plc or host computer via an rs-232 connection. Table 2-4 provides details about the connection. J123 connections are referenced...

Page 76

Models 947, 948 and 960 leak detectors operations and service manual 2-12 2.4 optional interface connections available ports for interface connection: ❑ service rs-232 serial port for a service pendant or host computer to monitor and change parameters in the 947/948/960 platform (j1 male 9-pin d con...

Page 77

Models 947, 948 and 960 leak detectors operations and service manual 2-13 2.4.2 setup parameters relating to the operation and performance of the 947/948/960 platform are stored in eprom. These parameters can be viewed and changed via the service pendant or rear serial ports. A standard host compute...

Page 78

Models 947, 948 and 960 leak detectors operations and service manual 2-14 if the i/o on j120 is used, then: ❑ +5 vdc to +24 vdc must be applied to j120, pins 27 and 28. ❑ the +5 vdc to +24 vdc return must be connected to j120, pins 1 and 25. If the i/o on j121 is used, then: ❑ +5 vdc to +24 vdc must...

Page 79

Models 947, 948 and 960 leak detectors operations and service manual 2-15 2.5 operation using the optional rear panel interface once setup is complete and the 947/948/960 is warmed up, operation can be turned over to the discrete i/o by asserting the parallel enable input (j120 pin 6). Operations ca...

Page 80

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 81: Section 3. Operation

3-1 models 947, 948 and 960 leak detectors operations and service manual section 3. Operation to obtain accurate readings using the 947/948/960 leak detectors, follow the operational procedures listed in this section. The 947/948/960 measure the leak rate in atm cc/sec. The procedures explain how to...

Page 82

Models 947, 948 and 960 leak detectors operations and service manual 3-2 during operation, the led functions are illuminated to indicate the operation being performed. The definitions of the operations are as follows: vent illuminates when the vent valve is open. The led is off when the valve is clo...

Page 83

Models 947, 948 and 960 leak detectors operations and service manual 3-3 3.2 initial system parameter setup the 947/948/960 performs functions and tests based upon parameter values. Some parameters are entered and set when the system is assembled and tested. Some parameters are calculated and change...

Page 84

Models 947, 948 and 960 leak detectors operations and service manual 3-4 this feature is useful when a product specification is more than one decade less stringent than the sensitivity of the leak detection system as it is configured. If the configured system is capable of detecting 10 − 9 atm cc/se...

Page 85

Models 947, 948 and 960 leak detectors operations and service manual 3-5 reject set points the reject set points are used to alert the operator that a measured leak rate has exceeded the set value. There are four set points available. Each set point must be enabled before they are operational. Conve...

Page 86

Models 947, 948 and 960 leak detectors operations and service manual 3-6 auto-sequencer provides clear accept/reject signals and allows programming for roughing, testing, and cycling times. Auto sequencer provides the ability to set up the 947/948/960 so that it automatically runs through a complete...

Page 87

Models 947, 948 and 960 leak detectors operations and service manual 3-7 rough time the rough time variable determines the amount of time that the leak detector is allowed to evacuate the test object to the tolerable test transfer pressure. In auto sequencer mode, the 947/948/960 transfers into test...

Page 88

Models 947, 948 and 960 leak detectors operations and service manual 3-8 transfer points set the test transfer pressures for each testing mode. The transfer pressure settings can be adjusted to lower values for specific applications. The 947/948/960 has pre-programmed upper transfer pressure limits ...

Page 89: 3.3 Start-Up

Models 947, 948 and 960 leak detectors operations and service manual 3-9 3.3 start-up to operate the 947/948/960, you need: ❑ test fixtures appropriate to the unit under test ❑ helium tank with spray gun or hook up for auto test (helium for the 948/960) figure 3-2 shows the important 947/948/960 ope...

Page 90

Models 947, 948 and 960 leak detectors operations and service manual 3-10 ➀ power switch/circuit breaker main power switch and circuit breaker. ➁ rough pump switch powers the rough pump. ➂ detector switch powers the backing pump and high vacuum pump. ➃ start button starts the 947/948/960 testing rou...

Page 91

Models 947, 948 and 960 leak detectors operations and service manual 3-11 refill the cold trap as required to prevent it from thawing in the vacuum system. The trap needs to be filled approximately every 14 hours. Monitor the level and fill more often if necessary. Caution if the cold trap in the 94...

Page 92

Models 947, 948 and 960 leak detectors operations and service manual 3-12 table 3-1 lists the not ready condition codes and the action to take to correct the error condition. 3.4.1 calibration and sensitivity checks to perform calibration and sensitivity checks: 1. Warm up the 947/948/960 for 30 min...

Page 93

Models 947, 948 and 960 leak detectors operations and service manual 3-13 5. Press the start button. ❑ the vent led goes off. ❑ the start led illuminates. ❑ the test led illuminates when test pressure drops. ❑ the start led goes off (1 second) after test led illuminates. ❑ the leak rate range displa...

Page 94: 3.5 Operating Procedures

Models 947, 948 and 960 leak detectors operations and service manual 3-14 3.5 operating procedures the testing parameters vary from one manufacturing environment to another. Appendix g, “leak detection theory” describes the conditions under which the 947/948/960 leak detectors can be utilized. There...

Page 95

Models 947, 948 and 960 leak detectors operations and service manual 3-15 3. Press the start button. ❑ the vent led goes off and one second later, the start led illuminates. ❑ the test led illuminates. ❑ the start led goes out. ❑ the leak rate range exponent goes to the most appropriate range. 4. In...

Page 96: 3.6 Standby

Models 947, 948 and 960 leak detectors operations and service manual 3-16 5. Press the start button. ❑ the vent led goes off. ❑ the start and test leds illuminate a second later. ❑ the start led turns off and the led rate range (exponent) displays at the selected range. 6. Introduce helium to the it...

Page 97: 3.7 Shutdown

Models 947, 948 and 960 leak detectors operations and service manual 3-17 3.7 shutdown complete shutdown for a move or temporary storage is accomplished by the following shutdown procedure: 1. Place the test port plug securely in the test port. 2. Turn the rough pump switch off. 3. Turn detector swi...

Page 98: 3.9 Optional Discrete I/o

Models 947, 948 and 960 leak detectors operations and service manual 3-18 figure 3-5 service pendant keypad several parameters relating to the operation and performance of the 947/948/960 platform are stored in eprom. These parameters are viewed and changed via the service or rear serial ports. Some...

Page 99: Betrieb

Models 947, 948 and 960 leak detectors operations and service manual 3-19 betrieb um mit den lecksuchern 947/948/960 genaue werte zu erzielen, befolgen sie die in diesem abschnitt aufgeführten betriebsverfahren. Die 947/948/960 messen die leckrate in atm cc/sek. Die verfahren erkären: ❑ starten und ...

Page 100

Models 947, 948 and 960 leak detectors operations and service manual 3-20 3.10 led-anzeigen und steuerelemente auf der fronttafel abbildung 3-6 zeigt die led-anzeigen und steuerelemente auf der fronttafel (rechte seite) des 947/948/960 aufsatzes. Eine definition der tasten ist unter abschnitt 1.12, ...

Page 101

Models 947, 948 and 960 leak detectors operations and service manual 3-21 zero (null) leuchtet auf, wenn die taste zero betätigt oder wenn im rahmen der kalibrierungssequenz die automatische nullstellung durchgeführt wird. Die led erlischt eine sekunde nach beendigung der automatischen nullstellung ...

Page 102

Models 947, 948 and 960 leak detectors operations and service manual 3-22 3.11 erste einstellung der systemparameter die 947/948/960 führen funktionen und prüfungen durch, die auf parameterwerten beruhen. Einige parameter werden beim aufstellen und prüfen des systems eingegeben und eingestellt. Eini...

Page 103

Models 947, 948 and 960 leak detectors operations and service manual 3-23 range stop mit der funktion range stop werden die 947/948/960 so konfiguriert, dass ihr bereich automatisch nur bis zur vorab ausgewählten dekade, die im variablenfeld für "bereich stopp" eingegeben wurde, eingestellt wird. We...

Page 104

Models 947, 948 and 960 leak detectors operations and service manual 3-24 zero (null) die funktion zero liest das hintergrund-leckratensignal, speichert den wert und stellt dann den nullbezugspunkt zurück. Anschließende tatsächliche prüfmessungen schließen sowohl helium vom echten leck als auch heli...

Page 105

Models 947, 948 and 960 leak detectors operations and service manual 3-25 auto-sequencer (automatische ablaufsteuerung) diese funktion generiert annahme-/rückweisungssignale und ermöglicht die programmierung von grob-, prüf- und zykluszeiten. Die automatische ablaufsteuerung ermöglicht die einstellu...

Page 106

Models 947, 948 and 960 leak detectors operations and service manual 3-26 rough time (grobzeit) die variable rough time bestimmt die zeitdauer, die dem lecksucher für die evakuierung des prüfobjekts zum annehmbaren prüfübertragungsdruck zugemessen wird. Im automatischen ablaufsteuerungsmodus beginne...

Page 107

Models 947, 948 and 960 leak detectors operations and service manual 3-27 gross test only (nur grobprüfung) holding in gross for large leaks (grobtestposition für große lecks wird gehalten) die lecksucher 947/948/960 benutzen das contra-flow-system, das über ein grobleckmanifold verfügt und eine prü...

Page 108: 3.12 Inbetriebnahme

Models 947, 948 and 960 leak detectors operations and service manual 3-28 3.12 inbetriebnahme für den betrieb der 947/948/960 benötigen sie: ❑ prüfanschlüsse für die zu prüfende einheit ❑ heliumtank mit spritzpistole oder anschluss für automatische prüfung (helium für 948/960) abbildung 3-7 zeigt di...

Page 109

Models 947, 948 and 960 leak detectors operations and service manual 3-29 ➀ netzschalter / trennschalter netzstrom- und trennschalter ➁ schalter für grobvakuumpumpe zum ein-/ausschalten der grobvakuumpumpe ➂ lecksucher-schalter zum ein-/ausschalten der vorvakuum- und hochvakuumpumpe ➃ start-taste st...

Page 110

Models 947, 948 and 960 leak detectors operations and service manual 3-30 3.12.1 anleitungen zur inbetriebnahme gehen sie bei der inbetriebnahme wie folgt vor: 1. Identifizieren sie den netzstrom-/trennschalter ➀ an der rückseite des unteren schranks und stellen sie ihn auf ein. 2. Stellen sie den s...

Page 111

Models 947, 948 and 960 leak detectors operations and service manual 3-31 3.13 kalibrierungs- und empfindlichkeitsprüfungen verifizieren sie zu beginn jedes arbeitstages oder jeder schicht oder je nach bedingungen die integrität der 947/948/960, indem sie eine kalibrierungs- und empfindlichkeitsprüf...

Page 112

Models 947, 948 and 960 leak detectors operations and service manual 3-32 3.13.1 kalibrierungs- und empfindlichkeitsprüfungen gehen sie bei der durchführung von kalibrierungs- und empfindlichkeitsprüfungen wie folgt vor: 1. Lassen sie die 947/948/960 30 minuten lang warmlaufen. 2. Setzen sie den prü...

Page 113

Models 947, 948 and 960 leak detectors operations and service manual 3-33 5. Drücken sie die taste start. ❑ die led vent erlischt. ❑ die led start leuchtet auf. ❑ die led test leuchtet auf, wenn der prüfdruck abfällt. ❑ die led start erlischt (1 sekunde) nach aufleuchten der led test. ❑ die leckrate...

Page 114: 3.14 Betriebsverfahren

Models 947, 948 and 960 leak detectors operations and service manual 3-34 3.14 betriebsverfahren die prüfparameter sind von fertigungsumgebung zu fertigungsumgebung verschieden. Anhang g, “leak detection theory” beschreibt die bedingungen, unter denen die lecksucher 947/948/960 eingesetzt werden kön...

Page 115

Models 947, 948 and 960 leak detectors operations and service manual 3-35 abbildung 3-9 position des schalters auto/man mode 3. Drücken sie die taste start. ❑ die led vent erlischt und eine sekunde später leuchtet die led start auf. ❑ die led test leuchtet auf. ❑ die led start erlischt. ❑ der leckra...

Page 116

Models 947, 948 and 960 leak detectors operations and service manual 3-36 3.14.2 manuelle bereichseinstellung die manuelle bereichseinstellung wird dann benutzt, wenn der fehlerbereich des teils, das geprüft wird, bekannt ist. Gehen sie bei der manuellen bereichseinstellung wie folgt vor: 1. Drücken...

Page 117: 3.15 Bereitschaft

Models 947, 948 and 960 leak detectors operations and service manual 3-37 3.15 bereitschaft wenn nicht mit einem kontinuierlichen gebrauch der 947/948/960 zu rechnen ist, kann der modus standby, in dem die einheit teilweise abgeschaltet wird, benutzt werden, um energie zu sparen. 947/948/960 werden ...

Page 118

Models 947, 948 and 960 leak detectors operations and service manual 3-38 3.17 parametereinstellung mit der hängebedienungstafel die hängebedienungstafel wird im aufsatz aufbewahrt und ist zwecks parameteränderungen, Überwachung und diagnostik an den modellen 947/948/960 an j1 im aufsatz angeschloss...

Page 119

Models 947, 948 and 960 leak detectors operations and service manual 3-39 verschiedene parameters, die sich auf den betrieb und die leistung der re947/948/960 plattform beziehen, sind auf dem eprom gespeichert. Diese parameter werden über die wartungs- oder rückseitigen seriellen ports eingesehen od...

Page 120

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 121: Section 4. Maintenance

4-1 models 947, 948 and 960 leak detectors operations and service manual section 4. Maintenance like other sensitive test equipment, a mass spectrometer leak detector requires periodic maintenance to ensure continued reliable operation. After prolonged use, the leak detector accumulates contaminants...

Page 122

Models 947, 948 and 960 leak detectors operations and service manual 4-2 cleanliness is vital when servicing the leak detector or any vacuum equipment. The following are especially important in the servicing of leak detectors: caution do not use silicone oil or silicone grease. Use powder-free butyl...

Page 123

Models 947, 948 and 960 leak detectors operations and service manual 4-3 due to the effective cleaning nature of vacusolv solvent and its residue-free properties, varian vacuum technologies’ component and spectrometer tube cleaning kit (varian p/n 670029096), used in accordance with the kit instruct...

Page 124

Models 947, 948 and 960 leak detectors operations and service manual 4-4 on-demand maintenance functions are listed in table 4-2. Table 4-2 as-required maintenance most common symptom refer to trap almost empty, nearly 14 hours without a refill. “liquid nitrogen cold trap (models 948/960 only)” on p...

Page 125: 4.1 Daily Maintenance

Models 947, 948 and 960 leak detectors operations and service manual 4-5 4.1 daily maintenance 4.1.1 calibration check to perform a calibration check: 1. Press the std leak button. 2. Compare the value displayed on the 947/948/960 to the value of the known calibrated leak listed on the label on the ...

Page 126

Models 947, 948 and 960 leak detectors operations and service manual 4-6 4.1.1.2 general suggestions for leak checking the following suggestions apply whether leak checking components, systems, or the leak detector itself: 1. When spraying suspected leak locations: ❑ always apply helium sparingly. ❑...

Page 127: 4.2 Yearly Maintenance

Models 947, 948 and 960 leak detectors operations and service manual 4-7 4.2 yearly maintenance 4.2.1 replacing the calibrated leak 4.2.2 re-calibrate the internal calibrated leak helium calibrated leaks typically degrade at 3 percent per year. The calibrated leak supplied with your 947/948/960 must...

Page 128

Models 947, 948 and 960 leak detectors operations and service manual 4-8 to remove the internal calibrated leak: 1. Disconnect the mains power supply and make sure all pumps are off. Warning disconnect power from the 947/948/960 before performing any maintenance procedure that requires physically di...

Page 129

Models 947, 948 and 960 leak detectors operations and service manual 4-9 4.2.2.2 replacing the internal calibrated leak to replace the calibrated leak: 1. Wipe the o-ring with a lint-free cloth to ensure that no foreign matter is present. Caution varian recommends replacing all used o-rings. Do not ...

Page 130

Models 947, 948 and 960 leak detectors operations and service manual 4-10 4.2.3 liquid nitrogen cold trap (models 948/960 only) the trap should be refilled with liquid nitrogen (ln 2 ) as needed. A typical time frame for refilling is every 14 hours, depending on usage. During normal usage of the 948...

Page 131

Models 947, 948 and 960 leak detectors operations and service manual 4-11 4.2.4 flüssigstickstoff-kühlfalle (nur modele 948/960) die falle muss je nach bedarf mit flüssigstickstoff (ln 2 ) aufgefüllt werden. Je nach gebrauch ist ein nachfüllen alle 14 stunden erforderlich. Während des gebrauchs des ...

Page 132

Models 947, 948 and 960 leak detectors operations and service manual 4-12 4.2.5 spectrometer tube overhaul spectrometer tube overhaul consists of removing, cleaning, and re-installing the 947/948/960 spectrometer tube assembly. Warning liquid nitrogen causes burns upon contact. Use appropriate prote...

Page 133

Models 947, 948 and 960 leak detectors operations and service manual 4-13 4.2.5.1 removal of the spectrometer tube and preamplifier refer to figure 4-2 for the removal of the 947/948/960 spectrometer tube. Warning liquid nitrogen causes burns upon contact. Use appropriate protective devices, includi...

Page 134

Models 947, 948 and 960 leak detectors operations and service manual 4-14 6. Disconnect all four electrical connections to the spectrometer tube ➀ . Note to remove the locking connector shown in figure 4-2, both metal tabs at the left of the connector must be pushed to unlock the connector, then pul...

Page 135

Models 947, 948 and 960 leak detectors operations and service manual 4-15 4.2.5.2 disassembly of the spectrometer tube and preamplifier to disassemble the spectrometer tube: 1. Remove the four screws on the spectrometer tube (figure 4-3), noting the placement of the grounding strap ➀ . The grounding...

Page 136

Models 947, 948 and 960 leak detectors operations and service manual 4-16 figure 4-3 spectrometer tube disassembly warning store the ion source in a cool, dry area in a tightly sealed container. Wash hands thoroughly after handling the ion source and especially before smoking or eating. Caution do n...

Page 137

Models 947, 948 and 960 leak detectors operations and service manual 4-17 use new o-rings wiped clean with a lint-free cloth. Do not apply vacuum grease to o-rings that come in contact with the spectrometer tube. 4.2.5.3 spectrometer tube cleaning to clean the spectrometer tube: 1. Use the scotch-br...

Page 138

Models 947, 948 and 960 leak detectors operations and service manual 4-18 figure 4-4 spectrometer tube reassembly 6. Put the heater cartridge ➀ back in its cavity (figure 4-5). Figure 4-5 spectrometer tube reassembly (ground slit plate) 7. With the new o-rings on each of the two deflection pole piec...

Page 139

Models 947, 948 and 960 leak detectors operations and service manual 4-19 8. When installing the ground slit plate ➃ , be sure that the snap prongs are facing up, then align the slit at 90° with the side wall of the spectrometer tube, and concentrically align the circular hole in the plate with the ...

Page 140

Models 947, 948 and 960 leak detectors operations and service manual 4-20 figure 4-6 spectrometer tube reassembly (magnet assembly) ➀ ➁ ➂ ➃ ➅ ➄ ➆ ➇ ➈ a ➂ a.

Page 141

Models 947, 948 and 960 leak detectors operations and service manual 4-21 4.2.5.5 reinstallation of the spectrometer tube warning liquid nitrogen causes burns upon contact. Use appropriate protective devices, including heavy loose gloves and eye or face shields. Note models 948/960 only: before serv...

Page 142

Models 947, 948 and 960 leak detectors operations and service manual 4-22 4. Models 948/960 only: fill the liquid nitrogen cold trap using the procedure described in “liquid nitrogen cold trap (models 948/960 only)” on page 4-10, steps 5 and 6. 5. Reconnect power and start the leak detector and refe...

Page 143

Models 947, 948 and 960 leak detectors operations and service manual 4-23 4.2.7 spectrometer tube exchange the spectrometer tube replaceable parts consist chiefly of the ion source, the preamplifier, the magnetic poles, and the spectrometer tube as a complete assembly. Note because of the complexity...

Page 144

Models 947, 948 and 960 leak detectors operations and service manual 4-24 caution do not use grease or other substances on o-rings that come in contact with the spectrometer tube. Wipe all o-rings clean with a lint-free cloth before installation to ensure that no foreign matter is present to impair ...

Page 145

Models 947, 948 and 960 leak detectors operations and service manual 4-25 7. Models 948/960 only: once the system has pumped down, clean and fill the liquid nitrogen cold trap using the procedure described in “liquid nitrogen cold trap (models 948/960 only)” on page 4-10. Follow all warnings and cau...

Page 146

Models 947, 948 and 960 leak detectors operations and service manual 4-26 4.2.8 tc1 and tc2 gauge replacement and calibration 4.2.8.1 replacement of the tc1 gauge in the main valve block assembly figure 4-10 shows the valve block removed from the system. Note it is not necessary to remove the valve ...

Page 147

Models 947, 948 and 960 leak detectors operations and service manual 4-27 6. Examine the o-ring for wear. If necessary, use a new o-ring, otherwise clean the o-ring. Note before re-using o-rings or installing new o-rings, wipe them down with a lint-free cloth before installation to ensure that no fo...

Page 148

Models 947, 948 and 960 leak detectors operations and service manual 4-28 4.2.8.2 replacement of the tc2 gauge in the service block assembly warning liquid nitrogen causes burns upon contact. Use appropriate protective devices, including heavy loose gloves and eye or face shields. Note models 948/96...

Page 149

Models 947, 948 and 960 leak detectors operations and service manual 4-29 7. Clean the centering ring and adapter with acetone. Making sure all traces of pipe sealant are removed from the threads of the adapter. 8. Examine the o-ring for wear. If necessary, use a new o-ring, otherwise clean the o-ri...

Page 150

Models 947, 948 and 960 leak detectors operations and service manual 4-30 4.2.8.3 thermocouple gauge calibration procedures use the service pendant to perform a calibration on either the system pressure thermocouple (tc2) or the test port thermocouple gauge (tc1). Refer to appendix a, “service penda...

Page 151

Models 947, 948 and 960 leak detectors operations and service manual 4-31 4.2.8.4.2 atmospheric calibration calibration of the system pressure thermocouple (tc2) gauge to atmosphere is only required if the system tc2 gauge is replaced or if the calibration appears to be off. Note do not replace the ...

Page 152

Models 947, 948 and 960 leak detectors operations and service manual 4-32 4.2.8.5 test port pressure gauge (tc1) calibration this procedure allows for calibration of the test port pressure thermocouple gauge (tc1). Both the vacuum and atmospheric calibrations procedures must be performed in the orde...

Page 153

Models 947, 948 and 960 leak detectors operations and service manual 4-33 9. Type xyzzy, then 100 init-tptczero. ❑ the system should respond ok. ❑ the test port pressure on the test port pressure bar graph should read 1.0e-01 torr. A failed response on the pc is an indication that the calibration wa...

Page 154

Models 947, 948 and 960 leak detectors operations and service manual 4-34 4.2.9 rough pump and forepump oil level check (oil-sealed mechanical pumps) both the rough pump and forepump are equipped with an oil level sight glass that can be viewed when the front lower panel cover is removed (figure 4-1...

Page 155

Models 947, 948 and 960 leak detectors operations and service manual 4-35 4.2.9.1 condition of oil (oil-sealed mechanical pumps) excess water in the oil of the rough pump or the forepump is indicated by a milky or frothy appearance. Refer to your pump manual for instructions. 4.2.10 cleaning the tes...

Page 156

Models 947, 948 and 960 leak detectors operations and service manual 4-36 2. Remove the test port compression ring and o-ring from the top of the test port (figure 4-14). Figure 4-14 remove the test port compression ring and o-ring 4.2.10.2 examining and cleaning the test port to perform this proced...

Page 157: 4.3 Spare Parts

Models 947, 948 and 960 leak detectors operations and service manual 4-37 4.2.10.3 replacing the test port to replace the test port: 1. Place the o-ring into the groove of the compression ring. 2. Place the compression ring and o-ring onto the top of the test port (figure 4-15). Figure 4-15 placing ...

Page 158

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank. Table 4-4 lists the exchange assembly parts. 4.3.10.5 replacement parts table 4-5 lists the spare parts available for the 947/948/960. Table 4-4 exchange assembly parts section description part n...

Page 159

Models 947, 948 and 960 leak detectors operations and service manual 4-39 tablelle 4-6 enthält eine liste der auswechselbaren bauteile. 4.3.10.6 ersatz teile tablelle 4-7 enthält eine liste von verfügbaren ersatzteilen für die 947/948/960. Tablelle 4-6 auswechselbare bauteile abschnitt beschreibung ...

Page 160

Models 947, 948 and 960 leak detectors operations and service manual 4-40

Page 161: Section 5. Troubleshooting

5-1 models 947, 948 and 960 leak detectors operations and service manual section 5. Troubleshooting this section explains how to solve common problems with your leak detector, by listing symptoms, possible causes, and actions that will correct the problem. The system automatically lists error condit...

Page 162: 5.1 Error Condition Codes

Models 947, 948 and 960 leak detectors operations and service manual 5-2 5.1 error condition codes use table 5-1 to identify the problem by condition code or figure 5-2 to identify the symptom. Note a c6 condition code means that maintenance of this leak detector may soon be necessary. Notify varian...

Page 163

Models 947, 948 and 960 leak detectors operations and service manual 5-3 5.2 troubleshooting symptoms and solutions table 5-2 lists the particular symptoms encountered when troubleshooting the leak detector. For every symptom, there is a list of possible causes and actions you can take to remedy the...

Page 164

Models 947, 948 and 960 leak detectors operations and service manual 5-4 call varian vacuum technologies customer service for any other problems. Note varian vacuum technologies will not accept any part for return without both a properly completed return materials authorization (rma) and a health an...

Page 165: 5.3 Fehlerzustandscodes

Models 947, 948 and 960 leak detectors operations and service manual 5-5 5.3 fehlerzustandscodes identifizieren sie das problem nach zustandscode unter bezugnahme auf table 5-3 oder das symptom unter bezugnahme auf tablelle 5-4. Hinweis ein c6 zustandscode bedeutet, dass in kürze eine wartung des le...

Page 166

Models 947, 948 and 960 leak detectors operations and service manual 5-6 5.4 symptome und lösungen bei der fehlersuche table 5-4 enthält eine liste spezifischer symptome, die bei der fehlersuche am lecksucher auftreten können. Für jedes symptom wird eine liste möglicher ursachen und maßnahmen zur be...

Page 167

Models 947, 948 and 960 leak detectors operations and service manual 5-7 elektrische komponenten kein strom, keine lampen an der schalttafel on/off schalter an der rückseitigen schalttafel steht nicht auf on. Vergewissern sie sich, dass der schalter auf on steht. Netzkabel ist nicht angeschlossen. V...

Page 168

Models 947, 948 and 960 leak detectors operations and service manual 5-8 beim auftreten anderer probleme wenden sie sich bitte an den kundendienst von varian vacuum technologies. Hinweis varian vacuum technologies verweigert die annahme eines zurückgesendeten teils ohne das vorschriftsmäßig ausgefül...

Page 169: A.1 Keypad Functions

A-1 models 947, 948 and 960 leak detectors operations and service manual appendix a. Service pendant keypad functions a.1 keypad functions figure a-1 shows the service pendant keypad. “glossary of function keys” on page a-3 explains the keys that perform special functions when entering information. ...

Page 170

Models 947, 948 and 960 leak detectors operations and service manual a-2 a.1.1 using the service pendant each function is printed in black in the center of the key (for example, rej#). Some functions require the input of a number before the function key is pressed. Other functions, such as queries, ...

Page 171

Models 947, 948 and 960 leak detectors operations and service manual a-3 a.2 glossary of function keys a.3 glossary of input and data keys the keys listed below start at the top of the keypad and continue from left to right. Shift performs the red function on the key pressed after the shift key. Lk ...

Page 172

Models 947, 948 and 960 leak detectors operations and service manual a-4 [shift] set gr xfr show sets the value of the gross leak transfer point. Enter x.Xe-x (the desired value), followed by shift, then the function key. Example: 5.0e-2 [shift] set gr xfer (sets gross leak transfer to 50 mtorr). Se...

Page 173

Models 947, 948 and 960 leak detectors operations and service manual a-5 [shift] prsrs show vlv st displays the test port and system pressures. Set offset show displays the value of the electronic offset in the preamplifier. [shift] set offset show sets a temporary value of the electronic offset in ...

Page 174

Models 947, 948 and 960 leak detectors operations and service manual a-6 note system tc being at atmosphere is not a normal state for the leak detector. The turbo pump must be turned off, and the spectrometer tube must be vented by operating the valves or by opening the vent screw on the turbo pump....

Page 175

Models 947, 948 and 960 leak detectors operations and service manual a-7 [shift] on a seq off turns on the auto sequencer function. 2 fil sel 1 selects filament #1 in the ion source. [shift] 2 fil sel 1 selects filament #2 in the ion source. Out v show fil # displays the active filament number. [shi...

Page 176

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 177: B.1 Removing The Covers

B-1 models 947, 948 and 960 leak detectors operations and service manual appendix b. Parts replacement this appendix contains the following parts replacement procedures: ❑ “removing the covers” on page b-1 ❑ “replacing the ion source” on page b-6 ❑ “turbo pump” on page b-9 ❑ “replacing the rough pum...

Page 178

Models 947, 948 and 960 leak detectors operations and service manual b-2 b.1.1 opening the turret the turret opens by unlocking and lifting its cover. To remove the top cover, you must remove the shelf that the service pendant sits on. B.1.1.1 removing the service pendant shelf to remove the service...

Page 179

Models 947, 948 and 960 leak detectors operations and service manual b-3 b.1.2 removing the top panel the top panel is one piece that includes the turret and its door, a covering of the sides of the control and display panel, and the stainless steel top of the 947/948/960. To remove the 947/948/960 ...

Page 180

Models 947, 948 and 960 leak detectors operations and service manual b-4 6. Remove the three, 5-16 screws from under the front of the top cover (figure b-4). Figure b-4 the top panel from the front of the 947/948/960 7. Lift the top panel from the chassis. B.1.3 replacing all panels and covers b.1.3...

Page 181

Models 947, 948 and 960 leak detectors operations and service manual b-5 b.1.3.2 replacing the top panel warning ❑ be sure power is disconnected from the leak detector before attempting to replace the top cover. The start button could be pressed while maneuvering the cover into place and the leak de...

Page 182

Models 947, 948 and 960 leak detectors operations and service manual b-6 b.2 replacing the ion source if the ion source needs replacement (figure b-5), replace it during spectrometer tube cleaning. Adjustment is required after replacement is complete. Refer to “calibration and sensitivity checks” on...

Page 183

Models 947, 948 and 960 leak detectors operations and service manual b-7 2. Remove the four phillips head screws that hold the flange cap ➀ onto the body of the spectrometer tube ➁ (figure b-5). 3. Firmly but gently separate the flange cap from the ion source ➂ . 4. Remove the ion source. Examine it...

Page 184

Models 947, 948 and 960 leak detectors operations and service manual b-8 11. When installing the ground slit plate, be sure that the snap prongs are facing up. Align the slit at 90° with the side wall of the spectrometer tube and concentrically align the circular hole in the plate with the smaller g...

Page 185

Models 947, 948 and 960 leak detectors operations and service manual b-9 b.3 replacing the turbo pump models 947/948/960 have one turbo pump and two mechanical pumps: a forepump and a rough pump. B.3.1 turbo pump the turbo pump (figure b-6) is located in the middle front of the main cabinet. You mus...

Page 186

Models 947, 948 and 960 leak detectors operations and service manual b-10 b.3.1.1 removing the turbo pump to replace the turbo pump: 1. Disconnect the mains power supply and make sure that all pumps are off. Warning disconnect power from the 947/948/960 before performing any maintenance procedure th...

Page 187

Models 947, 948 and 960 leak detectors operations and service manual b-11 4. Follow the power wire from the fan to two pink connectors labeled 1 + and 2 − . If the connections are not fully labeled, label them now (figure b-8). Figure b-8 the turbo power connection 5. Loosen the radiator clamp screw...

Page 188

Models 947, 948 and 960 leak detectors operations and service manual b-12 6. Loosen the wing nut and remove the nw25 clamp that connects the foreline to the turbo (figure b-7 on page b-10). 7. Remove the centering ring and o-ring and place them on a clean surface. Caution at this point the pump is h...

Page 189

Models 947, 948 and 960 leak detectors operations and service manual b-13 3. Before re-using o-rings or installing new o-rings, wipe them down with a lint-free cloth to ensure that no foreign matter is present to impair the seal. Caution remove o-rings carefully with your fingers. Do not use metal t...

Page 190

Models 947, 948 and 960 leak detectors operations and service manual b-14 7. Place the foreline against the turbo flange centering ring and o-ring. Note gently pivot the turbo pump until it is in the position to make the connection without placing stress on the manifold. The claw clamps should be lo...

Page 191

Models 947, 948 and 960 leak detectors operations and service manual b-15 b.4 replacing the rough pump b.4.1 wet systems this discussion includes procedures for replacing rough pumps in wet systems (“removing the wet system rough pump” on page b-16) and rough pumps in dry systems (“removing the dry ...

Page 192

Models 947, 948 and 960 leak detectors operations and service manual b-16 b.4.1.1 removing the wet system rough pump to perform this procedure: 1. Disconnect the mains power supply and make sure that all pumps are off. Warning disconnect power from the 947/948/960 before performing any maintenance p...

Page 193

Models 947, 948 and 960 leak detectors operations and service manual b-17 8. Remove the centering ring and o-ring and place all connections where the oil will not contaminate other parts. 9. Remove the nw16 clamp from the exhaust connection. 10. Remove the exhaust fitting. 11. If desired, remove the...

Page 194

Models 947, 948 and 960 leak detectors operations and service manual b-18 b.4.1.1.3 re-installing the wet system rough pump warning to avoid injury, use proper lifting techniques when moving pumps. Your system may have pumps that require two people to move them safely. To perform this procedure: 1. ...

Page 195

Models 947, 948 and 960 leak detectors operations and service manual b-19 7. Place the nw25 clamp onto the connection and tighten fully. 8. Place the centering ring and o-ring against the pump outlet on the right side. 9. Place the exhaust manifold against the centering ring and o-ring. 10. Place th...

Page 196

Models 947, 948 and 960 leak detectors operations and service manual b-20 b.4.2 dry systems b.4.2.1 removing the dry system rough pump to perform this procedure: 1. Disconnect the mains power supply and make sure that all pumps are off. Warning disconnect power from the 947/948/960 before performing...

Page 197

Models 947, 948 and 960 leak detectors operations and service manual b-21 b.4.2.2 replacing the dry system rough pump before you replace the mechanical pump, examine and clean all o-rings centering rings, clamps and the manifold. B.4.2.2.1 examining and cleaning centering rings, o-rings and manifold...

Page 198

Models 947, 948 and 960 leak detectors operations and service manual b-22 12. Replace the front panel. 13. Replace the side panel. 14. Reconnect the mains power supply. 15. Turn the leak detector on and wait for the system to be ready. Allow the pumps to warm up if the detector has been off for some...

Page 199

Models 947, 948 and 960 leak detectors operations and service manual b-23 b.5.1.1 removing the wet system forepump to perform this procedure: 1. Disconnect the mains power supply and make sure that all pumps are off. Warning disconnect power from the 947/948/960 before performing any maintenance pro...

Page 200

Models 947, 948 and 960 leak detectors operations and service manual b-24 b.5.1.2 replacing the wet system forepump before you replace the forepump, examine and clean all o-rings, centering rings, clamps, and manifold. Caution there may be oil on these parts. Take care not to place them where other ...

Page 201

Models 947, 948 and 960 leak detectors operations and service manual b-25 9. Place the centering ring and o-ring against the pump outlet on the right side. 10. Place the exhaust fitting against the centering ring. 11. Place the nw16 clamp onto the connection and tighten fully. 12. Working from under...

Page 202

Models 947, 948 and 960 leak detectors operations and service manual b-26 b.5.2 dry system b.5.2.1 removing the dry system forepump to perform this procedure: 1. Disconnect the mains power supply and make sure that all pumps are off. Warning disconnect power from the 947/948/960 before performing an...

Page 203

Models 947, 948 and 960 leak detectors operations and service manual b-27 b.5.2.1.2 removing the nitrogen purge connection from pump note an electrician or electrical technician is required for proper removal and installation. If only maintenance is being performed, the pump can be removed with the ...

Page 204

Models 947, 948 and 960 leak detectors operations and service manual b-28 b.5.2.2.2 re-installing the dry system forepump warning to avoid injury, use proper lifting techniques when moving pumps. Your system may have pumps that require two people to move them safely. To perform this procedure: 1. En...

Page 205

Models 947, 948 and 960 leak detectors operations and service manual b-29 b.5.2.2.5 replacing the exhaust fitting to perform this procedure: 1. Place the centering ring and o-ring against the right side pump outlet. 2. Place the exhaust manifold against the centering ring. 3. Place the nw16 clamp on...

Page 206

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 207: C.1 Protocol (Rs-232)

C-1 models 947, 948 and 960 leak detectors operations and service manual appendix c. Communications protocol this appendix defines the technical specifications for the rs-232 protocol to be used with the 947/948/960 leak detection system optional rear panel interface. C.1 protocol (rs-232) the rs-23...

Page 208

Models 947, 948 and 960 leak detectors operations and service manual c-2 table c-1 through table c-4 outline the available control and query commands. ❑ table c-1 lists inquiries used to determine internal operating parameters. All inquiries, except ver, begin with ? And end with . ❑ table c-2 on pa...

Page 209

Models 947, 948 and 960 leak detectors operations and service manual c-3 ?Gl-xfer a string of seven characters that tells the maximum pressure in torr for transfer from roughing to gross leak test (e.G., 7.5e-01). ?Ionchamber reports the ion chamber voltage. The format is: ionchamber 269.1 ?Leak an ...

Page 210

Models 947, 948 and 960 leak detectors operations and service manual c-4 ?Setup eight lines that report a summary of setup parameters. Each line begins with a . The format is as follows: first line reports the turbo pump speed as high, low, or off. Second line reports the least sensitive leak rate r...

Page 211

Models 947, 948 and 960 leak detectors operations and service manual c-5 table c-2 lists the commands used to set non-volatile operating parameters. The current value of the operating parameter is changed to a new value. If parallel enable is asserted, the response is cant . Table c-2 non-volatile o...

Page 212

Models 947, 948 and 960 leak detectors operations and service manual c-6 table c-3 lists the commands used to cause an immediate change in the spectrometer operating parameters. These commands do not change the non-volatile operating parameters. Init-rangestop sets the most sensitive range exponent ...

Page 213

Models 947, 948 and 960 leak detectors operations and service manual c-7 table c-4 lists the commands used to cause leak detection actions. Table c-4 command parameters for leak detection actions command action calibrate adjusts the ion source parameters to cause a maximum response to helium, then a...

Page 214

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 215

D-1 models 947, 948 and 960 leak detectors operations and service manual appendix d. Inputs and outputs the table d-1 through table d-5 list the signals available on the connector in the turret, and the various connectors of the optional rear panel interface. D.1 service serial interface (j1) the se...

Page 216

Models 947, 948 and 960 leak detectors operations and service manual d-2 6 parallel enable active high enables rear panel plc interface. Input 7 zero 200 msec high pulse begins auto zero routine. Input 9 auto cal 200 msec high pulse begins auto calibrate. Input 10 decrement 200 msec high pulse decre...

Page 217

Models 947, 948 and 960 leak detectors operations and service manual d-3 d.2.2 bcd discrete output parallel interface (j121) the discrete i/o db25 connector is used to control operations via a plc. Table d-3 provides the j121 db25 bcd connections. Table d-3 optional bcd discrete output parallel inte...

Page 218

Models 947, 948 and 960 leak detectors operations and service manual d-4 d.2.3 interface (j122) for optional universal remote control the optional universal remote control connects to j122, a db9 connector. The serial communication cable from the universal remote control is connected to j122 on the ...

Page 219: Appendix E.

E-1 models 947, 948 and 960 leak detectors operations and service manual appendix e. 947/94 8 spec if ic ations ta ble e- 1 cont ains t h e spec if ic ati ons f o r m ode ls 947/ 948/ 960. T a b le e-1 947/ 948/96 0 speci fi cat ions p la tf o rm 94 7 948/ 960 high v a c uum p u mp t y pe : air -c o...

Page 220

Models 947, 948 and 960 leak detectors operations and service manual e-2 a u to m a ti c v a lv e s e que nc in g m ic ro pr oc e s s o r- c o nt ro lled v a lv e op er a tio n p rov ides a u to m a ti c s y s te m c y c lin g. T he te s t a n d r o u ghi ng v a lv e s ar e v a c u um -a c ti v at e...

Page 221

E-3 models 947, 948 and 960 leak detectors operations and service manual ta ble e- 2 cont ains t h e 947/ 948/9 60 model type s and p art n u m b er s. T abl e e- 2 947 /948/ 960 m o del t ypes a nd par t num ber s v a cu u m s yst em p u mp t y p e s m a in s s upply 50/6 0 hz 1 1 5 va c 2 3 0 va c...

Page 222: Echnische

Models 947, 948 and 960 leak detectors operations and service manual e-4 t echnische d a ten für 947 /9 48 ta ble e- 3 enth ält d ie te chni schen dat en für model le 947/ 948/ 960. 96 0 w it h co ld t rap l9 602 020 0t 120 l 960 202 00t 22 0 v 7 0 sd- 2 01 l9 600 920 0t 120 l 960 092 00t 22 0 v 7 0...

Page 223

E-5 models 947, 948 and 960 leak detectors operations and service manual v o rv a k uum pu m pe, t y p: f rei e l u ft v e rdr än gu ng l/ m , 60 /5 0 h z ds -2 0 2 ds -2 0 2 ds -202 t ri s c ro ll™ ds -2 0 2 ds -202 ds -2 02 t ri s c ro ll™ ds -2 0 2 ds -202 d s -2 02 d s -2 02 ds -2 0 2 ds -2 0 2 ...

Page 224

E-6 models 947, 948 and 960 leak detectors operations and service manual ta ble e- 4 enth ält d ie m o dell ty pen und t ei lnummern f ü r 947/ 948/9 60. E m pf o h lend e b e tr ie bs b edi ng un ge n g e b ra u c h i n g ebä ud en. E in s a tz h ö he: bi s z u 2 0 0 0 m , t e m p er at ur : 1 0 ° ...

Page 225

Models 947, 948 and 960 leak detectors operations and service manual e-7 94 7 ma cr ot or r ld l9 472 030 0m1 2 0 l 947 203 00m 220 v7 0d ds- 3 02 ds- 2 0 2 94 7 ma cr ot or r ld l9 472 045 0m1 2 0 l 947 204 50m 220 v7 0d ds- 4 02 ds- 2 0 2 94 7d t u rb o dr y l d d94 735 350 t 120 d 947 3535 0t 22 ...

Page 226

Models 947, 948 and 960 leak detectors operations and service manual e-8 d96 035 350 t 120 d 960 3535 0t 22 0 v 7 0 t ri s c rol l 3 0 0 t ri sc ro ll 30 0 und v7 0d d96 035 550 t 120 d 960 3555 0t 22 0 v 7 0 t ri s c rol l 6 0 0 t ri sc ro ll 60 0 und v7 0d t a ble e-4 947/ 948/9 60 model t ypes an...

Page 227: Appendix F. Accessories

F-1 models 947, 948 and 960 leak detectors operations and service manual appendix f. Accessories the accessories listed below can be purchased separately for use with the 947/948/960. Call varian vacuum technologies for further information at 1-800-8varian. * factory installed option table f-1 947/9...

Page 228

Models 947, 948 and 960 leak detectors operations and service manual this page intentionally left blank..

Page 229

G-1 models 947, 948 and 960 leak detectors operations and service manual appendix g. Leak detection theory g.1 leak testing—why is it needed? Even with today's complex technology it is, for all practical purposes, impossible to manufacture a sealed enclosure or system that can be guaranteed leak pro...

Page 230: G.3 Terminology

Models 947, 948 and 960 leak detectors operations and service manual g-2 g.3 terminology the following terminology has application throughout this manual: flow atm cc/sec one cubic centimeter of gas per second at a pressure differential of one standard atmosphere (760 torr at 0 °c). Std cc/sec one c...

Page 231

Models 947, 948 and 960 leak detectors operations and service manual g-3 g.4 various methods of testing for leaks there are many methods of testing for leaks in enclosures, systems or containers. The more commonly used methods and their accuracy ranges are listed below: water immersion (air bubble o...

Page 232

Models 947, 948 and 960 leak detectors operations and service manual g-4 g.5 helium mass spectrometer leak detection (msld) helium is an excellent trace gas because it is the lightest of the inert gases and as a consequence readily penetrates small leaks. In addition, its presence in the atmosphere ...

Page 233: G.6 Leak Detection Methods

Models 947, 948 and 960 leak detectors operations and service manual g-5 audible or visual detection by observer a. Bubbles rising in water 10 − 4 atm cc/sec or larger b. Audible leaks 10 − 1 atm cc/sec or larger sizes of leaks in man-made joints studies indicate that almost all leaks at joints are ...

Page 234

Models 947, 948 and 960 leak detectors operations and service manual g-6 g.6.1 test piece evacuated the object to be tested is evacuated by the leak detector roughing pump, then valved into the spectrometer vacuum system (see figure g-1 and figure g-2). The surface of the test object is then probed ...

Page 235

Models 947, 948 and 960 leak detectors operations and service manual g-7 a sampling probe is connected to the leak detector. The object to be tested is filled with helium at the desired test pressure and the probe is moved over its surface. Some of the helium escaping from a leak is captured through...

Page 236

Models 947, 948 and 960 leak detectors operations and service manual g-8 g.7 mass spectrometer leak detector—simplified description the 947/948/960 consist of an analytical sensing tube called a spectrometer tube, electronics to operate the tube, and a vacuum system to maintain a very high vacuum wi...

Page 237: Index

I-1 models 947, 948 and 960 leak detectors operations and service manual index a accessories available f-1 air filter replacement 4-21 atm vs. Std g-2 atmospheric calibration 4-28 system pressure gauge 4-28 test port 4-31 audio volume control 3-5 auto cal routine indicator 3-2 auto ranging 3-13 auto...

Page 238

Models 947, 948 and 960 leak detectors operations and service manual i-2 h hazard and safety information 1-iv helium for sealing g-7 helium mass spectrometer leak detection g-4 hermetic enclosures g-1 systems g-1 hold mode indicator 3-2 host serial port interface (option) d-4 host serial port j123 p...

Page 239

Models 947, 948 and 960 leak detectors operations and service manual i-3 manual tuning 4-5 mass spectrometer leak detector g-8 mass spectrometry principles g-4 model specifications e-1 model types and part numbers e-3 monitoring leak rate with the service pendant 3-16 msld technique g-4 leak rate g-...

Page 240

Models 947, 948 and 960 leak detectors operations and service manual i-4 gauge cal 4-27 service pendant 1-10, 2-9, 3-16, a-1, d-1 function keys a-3 input and data keys a-4 keypad functions a-1 service serial interface d-1 setup 2-9 shutdown 3-15 signals bcd discrete i/o parallel interface (option) d...

Page 242

Sales and service offices argentina varian argentina ltd. Sucursal argentina av. Ricardo balbin 2316 1428 buenos aires argentina tel:(54) 1 783 5306 fax:(54) 1 786 5172 benelux varian vacuum technologies rijksstraatweg 269 h, 3956 cp leersum the netherlands tel:(31) 343 469910 fax:(31) 343 469961 br...