- DL manuals

- Varian

- Water Pump

- 949-9350

- Nstruction Manual

Varian 949-9350 Nstruction Manual

Summary of 949-9350

Page 1

Ds102 1ph ds202 1ph ds302 1ph dual stage rotary vane pumps u.K. Model 949-9350 model 949-9351 model 949-9352 manuale di istruzioni bedienungshandbuch notice de mode d’emploi instruction manual 87-900-943-01(e) january 2006.

Page 2: Ds102 – Ds202 – Ds302

Ds102 – ds202 – ds302.

Page 5

Istruzioni per l’uso .................................................................................................... 1 gebrauchsanleitung ................................................................................................. 3 mode d’emploi ..............................................

Page 6

Istruzioni per l’uso 1 87-900-943-01(e) informazioni generali questa apparecchiatura è destinata ad uso professionale. L'uti- lizzatore deve leggere attentamente il presente manuale di i- struzioni ed ogni altra informazione addizionale fornita dalla varian prima dell'utilizzo dell'apparecchiatura. ...

Page 7

Istruzioni per l’uso 2 87-900-943-01(e) attenzione! Controllare che la tensione di alimentazione corrisponda a quel- la indicata sul cartellino del motore. Collegare la pompa all’alimentazione. Attenzione! Nel caso di motore trifase, una inversione di polarità provoca l'inversione del verso di rotaz...

Page 8

Gebrauchsanleitung 3 87-900-943-01(e) allgemeine hinweise dieses gerät ist für den professionellen gebrauch bestimmt. Vor dem gebrauch soll der benutzer dieses handbuch sowie alle weiteren von varian mitgelieferten zusatzinformationen genau lesen. Bei vollständiger bzw. Teilweiser nichtbeachtung der...

Page 9

Gebrauchsanleitung 4 87-900-943-01(e) achtung! Kontrollieren, daß die versorgungsspannung mit der spannungsangabe auf dem typenschild des motors übereinstimmt. Die pumpe an das versorgungsnetz anschließen. Achtung! Bei dreiphasenstrommotoren bewirkt eine polumkehrung die umkehrung des drehsinns der ...

Page 10

Mode d'emploi 5 87-900-943-01(e) indications gÉnÉrales cet appareillage a été conçu en vue d'une utilisation profes- sionnelle. Il est conseillé à l'utilisateur de lire attentivement cette notice d'instructions ainsi que toute autre indication four- nie par varian avant d'utiliser l'appareil. Varian...

Page 11

Mode d'emploi 6 87-900-943-01(e) attention ! Contrôler que la tension d'alimentation correspond à la tension indiquée sur la plaquette du moteur. Brancher la pompe à la source d'alimentation. Attention ! En cas de moteur triphasé, une inversion de polarité provoque l'inversion du sens de rotation de...

Page 12

Instruction manual 7 87-900-943-01(e) general information this equipment is destined for use by professionals. The user should read this instruction manual and any other additional information supplied by varian before operating the equipment. Varian will not be held responsible for any events occur...

Page 13

Instruction manual 8 87-900-943-01(e) caution check that your electrical mains voltage corresponds to that indicated on the motor’s plate. Connect the pump to the power supply. Caution pay special attention to the three-phase motor, where an inver- sion of polarity causes inversion of the direction ...

Page 14

Technical information section i technical description the ds102 1ph, ds202 1ph and ds302 1ph pumps are dual-stage, rotary vane pumps oil sealed, driven by a single-phase or three-phase electric motor. These vacuum pumps are suitable for pumping non corrosive gases. The main features are: - all parts...

Page 15

Technical information gas ballast valve when the pump sucks in vapors, these condense during compression and mix with the oil, forming an emulsion (an aqueous vapor, for example) or a solution (organic solvent vapors, for example). A number of problems arise from this, such as the impossibility of o...

Page 16

Technical information view of the pump 11 87-900-943-01(e).

Page 17

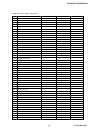

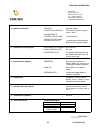

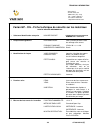

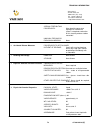

Technical information legend (cf. Figure view of the pump) n° description ds 102 ds202 ds302 1 electric motor sr03700702 sr03700702 sr03700702 1a electric motor 370-450w sr03700865 sr03700865 sr03700865 1b three phase electric motor sr03700922 sr03700922 sr03700922 2 rubber foot 3 screw 4 screw 5 sc...

Page 18

Technical information 13 87-900-943-01(e) n° description ds 102 ds202 ds302 51 valve gasket (3) - (1) (3) - (2) (3) - (2) 52 first stage stator sr03700261 sr03700316 sr03700495 53 middle plate sr03700262 sr03700262 sr03700262 56 gasballast valve shutter (3) - (1) (3) - (2) (3) - (2) 57 gasballast va...

Page 19

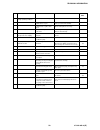

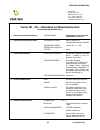

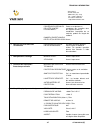

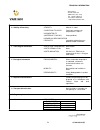

Technical information technical data the following table lists the main technical data of the ds102 1ph, ds202 1ph and ds302 1ph pumps. Technical data hz units ds102 ds202 ds302 60 l/min (cfm) 114 (4) 192 (6,8) 285 (10) free air displacement 50 l/min (m 3 /h) 95 (5,7) 160 (9,6) 237 (14,2) 60 cfm 3,5...

Page 20

Technical information dimensions model units a b c d h l m n p r w ds102 mm inch 30 1,18 30 1,18 35 1,38 3 0,12 212 8,3 430 16,9 250 9,8 100 3,9 105 4,1 165 6,5 132 5,2 ds202 mm inch 30 1,18 30 1,18 35 1,38 3 0,12 212 8,3 467 18,4 250 9,8 100 3,9 105 4,1 205 8,1 132 5,2 ds302 mm inch 30 1,18 30 1,18...

Page 21

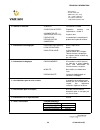

Technical information typical performance curves 16 87-900-943-01(e).

Page 22

Technical information safety precautions - always carry the pump by means of the han- dles provided. - the pump must be set in position taking the upmost care in order to avoid accidental falls. , warning! In case of a need to handle the pump after a pe- riod of operation, it must be left to cool fi...

Page 23

Technical information the motor has a main on/off bipolar switch. Section ii electrical motors the motor includes a thermal protection against overloads. If the motor is switched off by this relay, it can be started again after a few minutes. Single phase universal motors they are world wide motors,...

Page 24

Technical information single-phase universal motors voltage setting caution before connecting to the mains, check that your electrical mains voltage corresponds to the motor voltage setting. , warning! Disconnect the motor from the mains before open- ing the electrical box. The motors are factory se...

Page 25

Technical information connections to the inlet and exhaust flanges remove the protective caps from both flanges. Connect the system to be evacuated to the inlet flange, using a centering ring with or and a lock- ing collar. Note for guaranteed reliable sealing, use an or gasket in perbunan or viton....

Page 26

Technical information stopping the pump there are no special procedures for switching the pump off; it needs only to be disconnected from the electric power by means of the bipolar switch (see section models with single-phase universal motors). When the pump is stopped, the anti-suckback de- vice ma...

Page 27

Technical information caution notes a. Before putting the pump back into operation after a breakdown, inspect it and check care- fully for any other signs of damage. B. Use only tools that are in perfect working or- der and specially designed for the job; use of inappropriate or ineffective tools ma...

Page 28

Technical information varian s.P.A. - vacuum technologies via varian 54 10040 leinì (torino) - italy telephone: (39) 011.9979111 fax: (39) 011.9979344 lubricants it will be readily understood how important ade- quate lubrication is to high technology pumps like the varian vacuum pumps. Correct use o...

Page 29

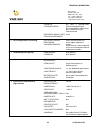

Technical information varian gp oil characteristics property unit of measure gp oil vapor pressure @ 25 °c -5 boiling point @ 0,01 torr °c 112 viscosity @ 40 °c cst (sus) 55 (258) viscosity @ 100 °c cst (sus) 8,1 (52,7) viscosity index 119 pour point °c (°f) -15 (5) flash point °c (°f) 213 (415) fir...

Page 30

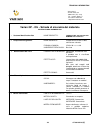

Technical information scheduled maintenance cards no. Frequency pump status (*) operation 01 monthly r oil level checking 02 twice yearly s cleaning the inlet filter (*) r=running s=stopped note when the pump is equipped with: • a filter for dust on the inlet side • a condensation separator on the i...

Page 31

Technical information scheduled maintenance card no. 01 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: monthly time: 5 min. Machine status: s r type of action: lubrification item: lubrificating oil 1 no. Description time equipment materials oil 1 check the oil level and top up if necessary. 5...

Page 32

Technical information 1. Check the oil level through the sight glass: there are two clearly visible arrows indicating maximum and minimum levels for proper pump operation. Note the amount of oil consumed depends on the type of work, particularly on the volume being evacuated and on the frequency of ...

Page 33

Technical information scheduled maintenance card no. 02 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: twice yearly time: 10 min. Machine status: s r type of action: cleaning inlet filter item: 1 no. Description time equipment materials 1 clean the suction filter. 10 min. • compressed air gun...

Page 34

Technical information 1. Remove the filter (26) from the inlet flange (28). 2. Clean the filter using an aqueous solution and dry with hot air. 3. Put the filter back in place. Caution the filter element is designed to prevent solid particles in the air from entering the inside of the pump and if it...

Page 35

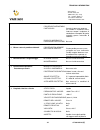

Technical information unscheduled maintenance cards no. Subject frequency 101 general warnings 102 changing the oil whenever necessary 103 disassembly of oil level indicator when damaged 104 disassembly of anti-suckback device shutter when damaged 105 disassembly of electric motor and joint when dam...

Page 36

Technical information unscheduled maintenance card no. 101 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: time: machine status: f l type of action: general warnings item: 1. Pump disassembly and reassembly require some basic operations and use of tools found in most work- shops. 31 87-900-943...

Page 37

Technical information note the pump’s component parts are modular and therefore fully interchangeable. Whenever parts have to re- placed, please specify in the order: - pump type - serial number (marked on pump identification plate). - reference number on the detailed diagram, name and part number a...

Page 38

Technical information - lock without forcing the nuts on the four tie-rods (44) connecting the parts of the pump block. Before locking, check that all parts are touching as required. - before putting the springs and shutters of the discharge valves back in, pour a little oil into the stators through...

Page 39

Technical information unscheduled maintenance card no. 102 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: as required time: 30 min. Machine status: s r type of action: changing oil lubricant item: action area materials required: equipment required: • varian gp oil (1 liter) • fixed wrench for...

Page 40

Technical information , warning! If you have to perform maintenance on the pump after a considerable time in operation, leave it to cool as temperature of the outer surface may be in excess of 60 °c. Note the oil has to be replaced: 1) when it has become particularly dirty due to the presence of con...

Page 41

Technical information note monitor through the sight glass at the front of the pump that you are not exceeding the maximum oil level per- mitted. Caution for disposal of waste oil, it is strictly necessary to respect the currently applicable legislation on this matter. 6. To achieve a good vacuum le...

Page 42

Technical information unscheduled maintenance card no. 103 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 30 min. Machine status: s r type of action: disassembly sight glass item: action area materials required: equipment required: • mechanical tools • or gaskets (for pumps...

Page 43

Technical information , warning! If you have to perform maintenance on the pump after a considerable time in operation, leave it to cool as temperature of the outer surface may be in excess of 60 °c. 1. Drain off the oil from the pump. Note for a description of how to drain off the oil, see the unsc...

Page 44

Technical information unscheduled maintenance card no. 104 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 30 min. Machine status: s r type of action: replacement anti-suckback device shutter item: action area materials required: equipment required: • shutter • mechanical to...

Page 45

Technical information 1. Disconnect the flange (28) from the inlet pipe line. 2. Remove the 6 securing screws (17) and remove the two half-plates (25) pressing the suction flange (28) into its seat. 3. Remove the flange (28) and take out the piston (30) with the shutter (29) of the anti-suckback dev...

Page 46

Technical information unscheduled maintenance card no. 105 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 30 min. Machine status: s r type of action: replacement electric motor and joint item: action area materials required: equipment required: • electric motor • mechanical...

Page 47

Technical information 1. Disconnect the motor bearing plate (8) from the support (34) by removing the four screws (4). 2. Remove the half-joint/fan (19) from the support, together with the motor (1), the plate (8). 3. Slacken the nut blocking the half-joint (19) to the motor shaft and take it out, u...

Page 48

Technical information unscheduled maintenance card no. 106 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 1 hour machine status: s r type of action: disassembly discharge valves item: action area materials required: equipment required: • valves (gaskets kit) • mechanical to...

Page 49

Technical information 1. Drain off all the oil from the pump. Note for a description of how to drain off the oil, see the unscheduled maintenance card no. 102. 2. Disconnect the discharge flange from its piping. 3. Remove the nuts (3) and remove the pump casing (75). 4. Remove the securing screw (47...

Page 50

Technical information 5. Remove the two screws (47) on the valve press-bracket (46) and remove the bracket (46), the springs (50) and the shutters (51). 6. Reassemble by proceeding in the inverse order. Note when reassembling, replace all the gaskets stripped down. Caution when reassembly is complet...

Page 51

Technical information unscheduled maintenance card no. 107 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 1 hour machine status: s r type of action: disassembly oil circulation pump item: action area materials required: equipment required: • oil circulating pump • mechanica...

Page 52

Technical information 1. Drain off all the oil from the pump. Note for a description of how to drain the oil from the pump, see the unscheduled maintenance card no. 102. 2. Disconnect the discharge flange from its piping. 3. Remove the nuts (3) and remove the casing from the pump (75). 4. Remove the...

Page 53

Technical information note a magnet may be used to remove the gear-wheels. 6. Reassemble by proceeding in the inverse order. Note when reassembling, replace all the gaskets you have stripped down. Caution when reassembly is complete, proceed to fill the pump with oil again following the instructions...

Page 54

Technical information unscheduled maintenance card no. 108 ds102 1ph, ds202 1ph, ds302 1ph pump type: frequency: when damaged time: 1 hour machine status: s r disassembly type of action: anti-suckback device item: action area materials required: equipment required: • gaskets kit • mechanical , warni...

Page 55

Technical information 1. Drain off all the oil from the pump. Note for a description of how to drain the oil, see the unscheduled maintenance card no. 102. 2. Disconnect the discharge flanges from their piping. 3. Remove the locking nuts (3) and remove the casing (75) from the pump. 4. Remove the se...

Page 56

Technical information note when reassembling, replace all the gaskets stripped down. Caution when reassembly is complete, proceed to fill the pump with oil again following the instructions of unsched- uled maintenance card no. 102. 51 87-900-943-01(e).

Page 57

Technical information card no. Unscheduled maintenance 109 pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 1 hour machine status: s r type of action: disassembly pump body item: materials required: action area equipment required: • gaskets kit • mechanical tools , warning! M...

Page 58

Technical information 1. Drain off all the oil from the pump. Note for a description of how to drain off the oil, see the unscheduled maintenance card no. 102. 2. Disconnect the discharge flange from its piping. 3. Disconnect the electric motor (1) complete with half-joint. Note for a description of...

Page 59

Technical information card no. 110 unscheduled maintenance pump type: ds102 1ph, ds202 1ph, ds302 1ph frequency: when damaged time: 2 hours machine status: s r type of action: disassembly functional block rotors item: action area materials required: equipment required: • oil shaft seal ring • anti-w...

Page 60

Technical information , warning! Machine safety: disconnect all power lines. Hang the card “machine undergoing maintenance - do not power on” from the main breaker switch. When finished, remove the safety warning. , warning! If you have to perform maintenance on the pump after a considerable time in...

Page 61

Technical information 3. Disassemble the discharge valves. Note for a description of how to disassemble the discharge valves, see the unscheduled maintenance card no. 106. 4. Detach the end plate (61) from the rest of the pump body, exerting leverage if necessary on the reference notches between the...

Page 62

Technical information troubleshooting and corrective action note if the pump breaks down or does not work well, first check thoroughly that all the standards rules listed in the sections relevant installation and operation are currently observed. If you cannot get sufficiently low pressure, the prob...

Page 63

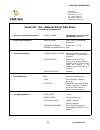

Technical information symptom probable cause suggested remedy card ref. 6 the pump is very noisy even at steady operating conditions. A) exhaust valves damaged. Inspect the valves. 106 b) high suction pressure, or gas ballast device is open. Check the system and the gas ballast valve (see items 4-a ...

Page 64

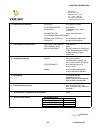

Technical information spare parts list other spare parts p/n ds102 1ph ds202 1ph ds302 1ph minor maintenance kit (*) x x x 949-9370 minor maintenance kit (*) 949-9371 major maintenance kit (**) x 949-9380 major maintenance kit (**) x x 949-9381 major maintenance kit (**) 949-9382 accessory item on e...

Page 65

Technical information 60 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com varian gp - oil - scheda di sicurezza del materiale data revisione: dicembre 2002 1. Sostanza/identificativo ditta nome prodotto: ...

Page 66

Technical information 61 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com procedure antincendio particolari: quando si opera per spegnere un incendio in ambiente chiuso, indossare sempre il respiratore; l...

Page 67

Technical information 62 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com 10. Stabilità & reattività stabilitÀ: materiale stabile condizioni da evitare: esposizione continua a tempe- rature > 200° c incom...

Page 68

Technical information 63 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com varian gp - oil – datenblatt zur materialsicherheit revisionsdatum: dezember 2002 1. Substanz/herstelleridentifikation produktnam...

Page 69

Technical information 64 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com spezielle bei feuer in geschlossenen lÖschmethoden: räumen atemgerät tragen. Bei unvollständiger verbrennung dieses materials ent...

Page 70

Technical information 65 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tel.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com 10. Stabilität und reaktivität stabilitÄt: das material ist stabil zu vermeidende be- kontinuierlich dingungen: temperaturen von ...

Page 71

Technical information 66 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tél.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com varian gp - oil - fiche technique de sécurité sur les matériaux date de rÉvision dÉcembre 2002 1. Substance/identification entrep...

Page 72

Technical information 67 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tél.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com procÉdures spÉciales porter un respirateur en de lutte contre combattant des incendies dans les incendies : des espaces fermés; l...

Page 73

Technical information 68 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy tél.: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com 10. Stabilité et réactivité stabilitÉ: le matériau est stable conditions À Éviter: exposition continue aux températures > à 200° ...

Page 74

Technical information 69 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy ph: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com varian gp - oil - material safety data sheet revision date december 2002 1. Substance/company identification product name: varian g...

Page 75

Technical information 70 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy ph: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com special firefighting procedures: wear breathing gear when fighting fires in enclosed spaces; incomplete combustion of this material...

Page 76

Technical information 71 87-900-943-01(e) varian s.P.A. Via f.Lli varian, 54 10040 leinì (to) - italy ph: +39-011-9979-111 fax:+39-011-9979-237 http://www.Varianinc.Com 10. Stability & reactivity stability: material is stable conditions to avoid: continuous exposure to temperatures > 200° c incompat...

Page 77

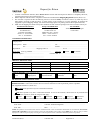

Request for return 1. A return authorization number (ra#) will not be issued until this request for return is completely filled out, signed and returned to varian customer service. 2. Return shipments shall be made in compliance with local and international shipping regulations (iata, dot, un). 3. T...

Page 78

Request for return failure report turbo pumps and turbocontrollers position parameters does not start noise vertical power: rotational speed: does not spin freely vibrations horizontal current: inlet pressure: does not reach full speed leak upside-down temp 1: foreline pressure: mechanical contact o...

Page 79

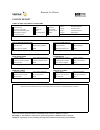

Sales and service offices argentina varian argentina ltd. Sucursal argentina av. Ricardo balbin 2316 1428 buenos aires argentina tel: (54) 1 783 5306 fax: (54) 1 786 5172 benelux varian vacuum technologies rijksstraatweg 269 h, 3956 cp leersum the netherlands tel: (31) 343 469910 fax: (31) 343 46996...