- DL manuals

- Varian

- Laboratory Equipment

- archon

- Operator's Manual

Varian archon Operator's Manual - Contents

03-914642-00:6

i

Contents

1

Introduction

1-1

1.1

Product Description

1-1

1.2

Design Features

1-2

1.3

Specifications

1-3

1.4

Component Description

1-3

1.4.1

Front Panel

1-3

1.4.2

Rear Panel

1-4

1.4.3

Interior

1-5

1.5

Vial Types

1-6

2

Site Preparation / Installation

2-1

2.1

Materials Needed

2-1

2.2

Unpacking the Archon

2-1

2.3

Parts and Materials Included in the Accessory Kit (DY-505224-90)

2-2

2.4

Lab and Bench Space Requirements

2-2

2.5

Gas Connections

2-3

2.6

Electrical Connections

2-4

2.7

Electronic I/O Signal Connections

2-4

2.7.1

Purge and Trap Sync Cable Connector

2-4

2.7.2

Personal Computer Connection

2-4

2.8

Water and Waste Lines Setup

2-4

2.8.1

Blank / Wash Bottle Setup

2-4

2.8.2

Waste Lines Setup

2-6

2.9

Sample Tray Setup

2-6

2.10

Sample Tray Coolant Setup (Optional)

2-7

2.11

Archon Soil Transfer Line Installation

2-7

2.11.1

Archon to Tekmar 3000

2-8

2.11.2

Archon to Tekmar 2000

2-14

2.11.3

Archon to OI 4560

2-18

2.12

Soil Helium Purge Gas Flow Adjustment

2-22

2.13

Loop Calibration for Internal Standard

2-23

2.14

Installation Checklist

2-23

Summary of archon

Page 1

Varian analytical instruments 2700 mitchell drive walnut creek, ca94598-1675/usa ©varian, inc. 1999 printed in u.S.A. 03-914642-00:6 purge and trap autosampler system operator’s manual.

Page 2: Contents

03-914642-00:6 i contents 1 introduction 1-1 1.1 product description 1-1 1.2 design features 1-2 1.3 specifications 1-3 1.4 component description 1-3 1.4.1 front panel 1-3 1.4.2 rear panel 1-4 1.4.3 interior 1-5 1.5 vial types 1-6 2 site preparation / installation 2-1 2.1 materials needed 2-1 2.2 un...

Page 3

Ii 3 keypad definition & layout / screen display 3-1 3.1 general 3-1 4 operation keys 4-1 4.1 auto key 4-1 4.2 manual / priority sample key 4-2 4.2.1 running a priority sample during an autorun. 4-2 4.3 flush key 4-3 4.3.1 drain sparge tube 4-4 4.3.2 flush syringe 4-4 4.3.3 rinse sparge tube 4-4 4.3...

Page 4

03-914642-00:6 iii 6.4.5 equilibrium block 6-9 6.4.6 knockoff clearance 6-9 6.4.7 standard clearance 6-10 6.4.8 manual calibration: coordinate settings menu items 6-11 6.5 system diagnostics 6-12 6.6 system settings 6-14 6.7 system options 6-16 7 maintenance 7-1 7.1 removal and replacement of the ne...

Page 5

Iv 9 error code screen messages 9-1 10 spare parts and service information 10-1 11 technical assemblies 11-1 11.1 front panel 11-1 11.2 syringe plate 11-2 11.2.1 internal standard valve assembly 11-3 11.2.2 mixing solenoids / 26 ml syringe assembly 11-4 11.2.3 probe section 11-5 11.2.4 vial sample s...

Page 6: 1 Introduction

03-914642-00:6 1-1 1 introduction 1.1 product description the archon purge and trap autosampler is designed to automate the tedious sample handling procedures associated with purge and trap analysis for volatile organic compounds (voc's) under current epa methods. The archon can be used for drinking...

Page 7

1-2 1.2 design features large 51 position removable sample tray for water or soil samples. Runs blanks from its own blank/wash water reservoir. Programmable sample dilution using blank h 2 o from reservoir, e.G., 0, 2, 5, 10, and 20, directly from the 40 ml vial. Water sample volumes programmable in...

Page 8

Introduction 03-914642-00:6 1-3 1.3 specifications tray capacity: 51 sample vials. 40 ml epa voc or soilvials sample volume: 0-25 ml flush volume: 0-25 ml indoor use altitude: up to 2000 m operating temperature: 15 c to 35 c; storage temperature 5 c to 85 c relative humidity: 10 to 90% line voltage:...

Page 9

1-4 1. Regulator: a regulator is provided for accurate adjustment of the soil purge gas pressure and for pressurizing the 40 ml vial during a water sample. 2. Pressure gauge: a pressure gauge is located above the regulator to monitor the purge gas and to pressurize gas pressure. 3. Flow controller: ...

Page 10

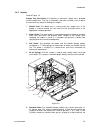

Introduction 03-914642-00:6 1-5 1.4.3 interior refer to figure 1-3. Sample tray (not shown): a 51 position, all aluminum, sample tray is provided to hold sample vials. The tray is removable, and when installed, rests on top of the aluminum tray cooler for cooling the samples. 1. Robotic arm: the rob...

Page 11

1-6 standard. Approximately 15 µl of standard solution is flushed during each cycle. 6. Equilibrium zone: the archon utilizes a 5 position temperature equilibrium station. If a sample has been cooled or heated, it can be cycled for an equilibrium time in minutes, prior to analysis. 7. Vial identific...

Page 12

03-914642-00:6 2-1 2 site preparation / installation please read this section carefully before you begin to assemble the archon. 2.1 materials needed regulator, single, two-stage with stainless steel diaphragm in line on/off valve gas supply line tubing, minimum 1/8" diameter helium gas, 99.999% pur...

Page 13

2-2 c a u t io n if the archon is to be shipped for any reason, the shipping screw and spacer must be installed or serious damage will occur! See section 7.15 before turning the instrument on: check the eight blue reverse ferrule fittings located in the sample area behind the rear panel (section 11,...

Page 14

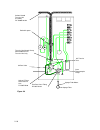

Site preparation / installation 03-914642-00:6 2-3 the archon dimensions are: 21.5w x 17h x 21d inches; 54.6w x 43.2h x 53.3d centimeters (see figure 2-1), and weighs approximately 80 lbs./36.5 kilograms. Figure 2-1 2.5 gas connections ultra high purity helium (99.999% gc/ms grade) is required for p...

Page 15

2-4 2.6 electrical connections the archon uses a grounded, three-pronged receptacle. Make certain the electrical voltage is a constant source with no severe drops or spikes in the voltage. If the power source is not certain, install a power conditioner on the electrical line. Verify the correct fuse...

Page 16

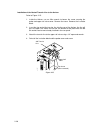

Site preparation / installation 03-914642-00:6 2-5 figure 2-2 insert the cap, with the peek pickup line, into the bottle, screw the cap onto the bottle. Note: do not overtighten the cap. Slowly turn the cap only until snug. Overtightening will spilt the cap. Verify the helium is turned on at the sou...

Page 17

2-6 figure 2-3 2.8.2 waste lines setup wa r n in g : s h o c k h a za r d dangerous voltages exposed when covers are removed. Unplug power cord. Remove the rear panel of the archon and route the bundle of four plastic lines through the slot in the chassis labeled “waste lines.” these waste lines sho...

Page 18

Site preparation / installation 03-914642-00:6 2-7 grouped together. The method parameters, “first vial - last vial”, will determine what vial numbers are run together. The archon vial gripper calibration coordinate settings must now be checked as factory settings may have changed during shipping, t...

Page 19

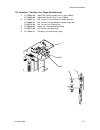

2-8 tools required are: 1/4", 2 ea. 5/16" open end wrenches, small flat blade screwdriver, 9/64" and 3/32" allen wrenches, and small needle nose pliers. The installation of the archon involves four primary steps. Note: all steps do not apply to every purge and trap. Installation to each instrument i...

Page 20

Site preparation / installation 03-914642-00:6 2-9 this does not allow the archon to be installed. Therefore, the 3-port fitting must be replaced with a 4-port cross fitting. 1. Remove the top, left side and valve oven covers from the tekmar 3000. 2. Using a screwdriver, loosen the screw which secur...

Page 21

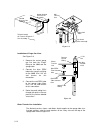

2-10 figure 2-6 archon heated transfer line assembly dy-700001-01/02 bolt with spacer transfer line sheath clamp with standoff for gc transfer line only gc transfer line six port valve archon e-form nickel transfer line dy-505745-00 four port cross fitting dy-505716-00 sparge tube sparge tube mount ...

Page 22

Site preparation / installation 03-914642-00:6 2-11 installation of the heated soil transfer line assembly to the purge and trap refer to figure 2-7 and figure 2-8. Remove the accessory kit from the shipping carton. Examine the contents and verify all items are correct. Remove the top, left side and...

Page 23

2-12 figure 2-7 figure 2-8 installation of purge gas lines see figure 2-9. 1. Remove the current purge gas line from the “purge” fitting on the 3000 and the sparge tube. 2. Connect the blue peek tube to the “purge” out fitting on the 3000. Use 1/16” nut and ferrules for this connection. 3. Connect t...

Page 24

Site preparation / installation 03-914642-00:6 2-13 1. Locate the nut and ferrule and the line from the accessory kit. 2. Uncoil the line. Locate the tan-colored peek valve body manifold inside the right rear of the archon. Slide the line into the fitting on the left. Tighten the fitting by hand. 3....

Page 25

2-14 to move cursor across page, enter a “number” (0) and press enter. 3. Meth method 14 type aquatek 50 note: if aquatek 50 is not selected the purge and trap will not send a ready signal. C=command =edit enter the number 14 and press “enter”. Select the “type” (63/31) according to gc selection. No...

Page 26

Site preparation / installation 03-914642-00:6 2-15 installation of the 4-port cross fitting and the heated soil transfer line in the tekmar 2000 valve oven refer to figure 2-10. Remove the trap cover, left side panel, right side panel, top and the valve oven cover from the tekmar 2000 as described ...

Page 27

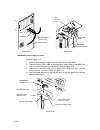

2-16 figure 2-11 figure 2-12 installation of the purge gas lines refer to figure 2-13. 1. Remove the purge gas supply line at the fitting on the lsc 2000. 2. Connect the blue peek tube to the purge gas supply fitting on the 2000. Use 1/16” nut and ferrules for this connection. Refer to figure 2-13. ...

Page 28

Site preparation / installation 03-914642-00:6 2-17 water transfer line installation the archon transfers, cleans and dilutes liquid samples to the sparge tube via a five-foot stainless steel line and attaches to the 2-way valve on the top of the sparge tube. Refer to figure 2-13. 1. Locate the nut ...

Page 29

2-18 2.11.3 archon to oi 4560 remove the installation and accessory kits from the shipping carton. Examine the contents and verify all items are correct. The archon may be positioned on either the right or left side of the oi 4560. Wa r n in g : s h o c k h a za r d be certain both the archon and th...

Page 30

Site preparation / installation 03-914642-00:6 2-19 figure 2-14 installation of soil transfer line to o.I. 4560 clamp heated transfer line assembly water transfer line from archon (red peek tube) voc transfer line purge gas outlet (blue peek tube connects here) sparge tube fitting special 4560 fitti...

Page 31

2-20 installation of the heated transfer line to the archon refer to figure 2-15. 1. Inside the archon, use an allen wrench to loosen the screw securing the probe and upper soil valve cover. Remove the cover. Remove the insulation block. 2. Insert the free end of the transfer line into the rear of t...

Page 32

Site preparation / installation 03-914642-00:6 2-21 water transfer line installation refer to figure 2-16. The archon transfers, cleans and dilutes liquid samples to the sparge tube via a five-foot stainless steel line and attaches to the 2-way valve on the top of the sparge tube. Remove the rear pa...

Page 33

2-22 oi 4560 setup specifications these parameter settings will ensure handshaking of the oi 4560 and the archon. Note: the sample mount heater cartridge option should be installed to minimize carryover. 1. From the keypad on the oi 4560, select: 2nd function - configure and select “states”, then pr...

Page 34

Site preparation / installation 03-914642-00:6 2-23 2.13 loop calibration for internal standard the absolute volume of the internal loop of the standard valve must be determined to achieve accurate sample data. The stated 1 µl volume is approximated within the stated tolerance from the valve manufac...

Page 35

2-24 lines attached to the upper soil valve must be installed with a valco stainless nut, p/n 28-694501-00 and a set of swagelok stainless ferrules, p/n 28-693996-00 and 28-693997-00. Perform a soil purge leak check by checking and balancing flows at the soil probe gas outlet bulkhead swagelok fitti...

Page 36

03-914642-00:6 3-1 3 keypad definition & layout / screen display 3.1 general figure 3-1 the keypad provides a complete numeric pad as well as a motion operation pad for the x-y-z axis arm. The keypad is coupled with a 4 line, 20 character lcd screen for displaying programming and status information....

Page 37

3-2 special keys enter used to terminate the entry of a numeric or menu item selection. It also serves as a scroll down key when selecting the method parameter setting. Used to scroll up within the method parameter setting. Also used to toggle the current motor selection and place the archon in “sys...

Page 38: Operation Keys

03-914642-00:6 4-1 4 operation keys 4.1 auto key the auto key starts the archon autosampling sequence. When the auto key is pressed the screen displays three lines: keypad display entry range autosampler start * start autorun delayed start 1-30 the method number line will be in brackets (). Enter th...

Page 39

4-2 4.2 manual / priority sample key the manual key starts a single sample or priority run. When the manual key is pressed the screen displays four entry selections: keypad display entry range *manual sample* method number xx sample type: soil > (water, blank) 1-51 1-30 soil, water blank the “sample...

Page 40

Operation keys 03-914642-00:6 4-3 2. Enter the method number for the type of sample to be run. Press enter. 3. Press enter again scheduling the priority sample. A “p” will appear in the upper left corner informing the user a priority sample has been scheduled. The priority sample will begin after th...

Page 41

4-4 4.3.1 drain sparge tube the drain sparge tube menu line will be highlighted with brackets (). Press enter to initiate draining the sparge tube. A two-line menu appears: keypad display entry range * drain sparge tube* drain sparge tube* 1-25 enter a drain volume from 1-25 ml. Press enter. The “dr...

Page 42

Operation keys 03-914642-00:6 4-5 4.3.4 backflush water probe this function allows the water probe to be flushed with hot blank water and helium. With the “2 ” or “8 “ keys scroll to the “” menu line, press enter. The flush process will begin immediately. The waste block will be lifted then the prob...

Page 43

4-6.

Page 44: 5 Method

03-914642-00:6 5-1 5 method setup 5.1 method editing the archon allows 30 methods to be edited and saved into a battery backed memory. To edit these parameters, press the method key. The * method * menu will be displayed. Enter the method number from 1-30, and press enter. Keyboard display entry ran...

Page 45

5-2 parameter range default description last vial 1-51 01 this is the last vial or blank number to be run. If blank sample type is selected, enter the last number of blank to be run. For example if you want two blank to be run enter first vial=1 and last vial =2. Sample volume 0-25 ml 05 if the samp...

Page 46

Method setup 03-914642-00:6 5-3 parameter range default description stir yes/no no this parameter turns the soil mechanical stirrer on during purge time, or the water mechanical stirrer on for a sample mixing prior to sampling. W. Stir time (min.) 0-9.9 minutes 0.0 min the stir motor will run for th...

Page 47

5-4 parameter range default description operate mode local / remote remote this mode determines if the archon will depend on switch signals from the purge and trap to advance, or be dependent on the cycle timer. In the “local” mode, the archon will start when the cycle timer parameter, set in the me...

Page 48

Method setup 03-914642-00:6 5-5 5.3 blanks after vial editing single blank runs can be programmed after specific sample vials within a particular method. These are known as "method blanks" and complement the alternative of creating a whole method where all of the runs are blanks. Method blanks are p...

Page 49

5-6 5.4 method programming guidelines 5.4.1 water method program to aid you in programming, please review the following example of a typical water sample you may want to start with these settings and if necessary, make adjustments after running several standards and or samples. In this example, meth...

Page 50

Method setup 03-914642-00:6 5-7 5.4.3 blank method program if blank is selected as the sample type in the method edit screen, the parameters entered will be the same as for a water sample, except those requiring vial movement. However, the first vial, last vial parameter entries are not actual vial ...

Page 51

5-8 5.6 operating sequence steps this section describes the archon operational sequence steps during a typical sample run. As an aid to the operator, the sequence steps are displayed on the lcd screen while the archon is running. 5.6.1 water sample sequence sequence step purpose 1. Getting vial the ...

Page 52

Method setup 03-914642-00:6 5-9 sequence step purpose 21. Syringe -> waste the syringe now transfers the water to the waste bottle. 22. Helium ->waste helium is flushed through the sample path to the waste bottle. 23. Flush complete. Syringe flushing is complete. 24. Return vial the robotic arm veri...

Page 53

5-10 sequence step purpose 43. Helium -> waste helium is again flushed through the sample path to the waste bottle. 44. End liquid sample this completes the water sample process sequence. 5.6.2 soil sample sequence sequence step purpose 1. Getting vial the robotic arm picks up the sample vial. 2. Ch...

Page 54

Method setup 03-914642-00:6 5-11 sequence step purpose 18. Helium -> waste helium is now flushed through the sample path to the waste bottle. 19. Rinse sparge tube the sparge tube is rinsed if rinses have been programmed. 20. Heating water water is heated. 21. Water -> lines hot water fills the line...

Page 55

5-12 sequence step purpose 9. Syringe -> waste the syringe transfers the water to the waste bottle. 10. Rinse sparge tube the sparge tube is rinsed if rinses have been programmed. 11. Heating water water is heated. 12. Water -> lines hot water fills the lines. 13. Water -> syringe hot water fills th...

Page 56: System Setup

03-914642-00:6 6-1 6 system setup the “system” key provides a menu to access all settings, maintenance, calibration, and options of the archon. Pressing the “system” key will display the following menu. *system setup * status maintenance calibration diagnostics settings options c a u t io n contact ...

Page 57

6-2 the “2 ” or “8 ” keys will scroll through the temperature zones. They are: zone default set point soil sample chamber off equilibrium block off upper soil probe 110°c soil transfer line 110°c upper soil valve 95°c ambient off tray temp off the set point and actual (current) temperatures are disp...

Page 58

System setup 03-914642-00:6 6-3 figure 6-1 after the lines have been primed, select the menu line . Press enter, the arm will now move to the rear of the cabinet. Note: see section 7 for standard vial installation instructions. 6.3.2 adjust counters * counter adjust * xxxxx> plunger xxxxx waste bloc...

Page 59

6-4 6.3.4 clean syringe this prompt will move the xyz mechanism to the front of the unit to allow clear access to the syringe. The display will prompt you for each step of the syringe cleaning. Refer to section 7.13 “cleaning or replacing the syringe plunger o- ring” for a description of the procedu...

Page 60

System setup 03-914642-00:6 6-5 note: if calibration test fails go to section 6.4.2. Note: before beginning refer to the default operation value table on page 6-15. 6.4.2 auto calibrate the "auto calibrate" program allows the archon to automatically establish the correct coordinate position settings...

Page 61

6-6 remove the sensor device from the vial gripper. (gently pull it down until it slides out.) press any key to park the vial gripper. C a u t io n if you fail to insert the sensor device into the vial gripper, the archon will still attempt to run the program, however, it will not be able to detect ...

Page 62

System setup 03-914642-00:6 6-7 the position adjustment commands are described below: key menu label action comments 0 grip opens/closes gripper press "0" to release any vial before making position adjustments or (none) selects axis to adjust press an arrow key to select the axis to calibrate. Note:...

Page 63

6-8 6.4.3 vial 22 position the vial 22 position is critical because all other tray vial locations are determined from this setting. Use the following protocol to recalibrate this position: 1. Push the sample tray towards the rear of the archon to make sure the tray is properly positioned. 2. Place a...

Page 64

System setup 03-914642-00:6 6-9 7. Press enter to save the position values and complete the routine. The arm will return to its home position. 6.4.5 equilibrium block this coordinate setting positions the 40 ml water sample vial into the center vial position of the equilibrium block. From this point...

Page 65

6-10 figure 6-4 use the following protocol to recalibrate this position: 1. From the calibration setup menu, scroll to the "knockoff clearance" menu item and press enter. 2. The robotic arm will move and the following message will be displayed: * knockoff clearance* press enter to get vial 22 for al...

Page 66

System setup 03-914642-00:6 6-11 necessary. The standard clearance value set at the factory is 00970. If the value clearance needs to be readjusted, continue with the next step. 6. Press a directional motion key (either "8 " or "2 ") to adjust the clearance. (if the gripper steps too far, adjust the...

Page 67

6-12 5. If the other horizontal axis needs to be adjusted, press an arrow key to select the other axis and adjust the gripper positioning with the appropriate directional motion key. 6. Press an arrow key to select the vertical axis 7. Press enter to save the position values and complete the routine...

Page 68

System setup 03-914642-00:6 6-13 standby: this signal line will verify the status of the standby signal received from the concentrator. Desorb drain: this signal line will verify the status of the signal received from the concentrator to empty the sparge tube during the concentrator's desorb step. M...

Page 69

6-14 6.6 system settings this menu allows the changing of the overall system parameters. These include temperature settings, motor speeds and acceleration rates, signal polarity, vial gripper time specifications, delay time and equilibrium data. When the *system settings* menu line is selected, pres...

Page 70

System setup 03-914642-00:6 6-15 desbdrn pol. Desorb drain polarity this is at the desorb mode on the concentrator. This sets the input signal from shorted (normally closed), to an open (normally open) position. Stop pol. Stop polarity incoming signal used for the emergency stop. This sets the input...

Page 71

6-16 6.7 system options the *system options* menu allows for enabling optional features of the archon. When *system options* is selected, the following menu is displayed. The “2 ” and “8 ” keys are used to scroll through the menu lines. The “4 ” and “6 ” keys are used to toggle the “no - yes" respon...

Page 72

System setup 03-914642-00:6 6-17 ignore no vial: when this option is “yes,” tray positions that have no vials will be ignored. The gripper “no vial” sensor will always be used to detect the presence of a vial and the potential of lost vials in transit. The default should be “no”. Hot water rinse: wh...

Page 73

6-18.

Page 74: 7 Maintenance

03-914642-00:6 7-1 7 maintenance this section describes maintenance procedures for the archon, including how to change the soil and water probes and soil transfer line. Wa r n in g : s h o c k h a za r d service to the archon should only be performed by qualified service personnel. Before any servic...

Page 75

7-2 figure 7-2 figure 7-3 1 cover (see figure 7-1). 9 knock off plate 2 bulkhead nut 10 gas line and nut 3 sample out line (short line) 11 reverse ferrule/super flangeless nut/ferrule 4 soil transfer line (and nut) 12 retaining nut 5 helium flush line 13 mount plate 6 #4-40 screws 14 valve manifold ...

Page 76

Maintenance 03-914642-00:6 7-3 2. With a 1/4" wrench, loosen the nuts on the sample out line (3) and on the helium flush line (5). Remove the lines from the probe. 3. With a 5/16" wrench, loosen and remove the bulkhead nut (2) with line, on the helium purge gas / water in line. 4. Loosen the two #4-...

Page 77

7-4 4. Attach the flangeless fitting and ferrule (11) into the hole in the center of the valve manifold (14). Be certain the line, with ferrule, is seated all the way to the bottom of the hole. Finger-tighten the nut. 7.3 cleaning the soil transfer line frit (pn dy-505599-00) (refer to figure 7-2 an...

Page 78

Maintenance 03-914642-00:6 7-5 2. Slide the valco nut and a compression ferrule set onto the new line. Insert the line, with nut and ferrule into the upper soil valve (15). Using a 1/4" open wrench tighten the nut. 3. Attach the other end to the purge and trap using whatever fittings are required. 4...

Page 79

7-6 wa r n in g : b u r n h a za r d components may be hot! Be certain the “upper soil probe temp” and “upper soil valve temp” are off and the parts are cool before continuing. 1. Remove the soil probe cover. Disconnect the short line (16) going into the heated upper soil valve (15). Attach the tubi...

Page 80

Maintenance 03-914642-00:6 7-7 5. Trace the valve wires to the rear panel and unplug the connector. Cut off the old connector, then remove the valve (15) from its mount. 6. Install the new valve in the reverse order. Run the valve wires through the back panel then attach the connector. Reinstall the...

Page 81

7-8 7.11 drip pan cleaning the drip pan, located under the sample tray, should be cleaned occasionally to prevent or remove any algae buildup. Wa r n in g : s h o c k h a za r d disconnect instrument from power source before proceeding. Wipe the pan and clean the drain hole with a pipe cleaner or a ...

Page 82

Maintenance 03-914642-00:6 7-9 5. The following menu will be displayed. Remove syringe pull down carefully press any key to continue. Gently pull the syringe barrel down off the valve manifold assembly (6). Examine the plunger and o-ring for any corrosion or damage. If the o-ring has been leaking or...

Page 83

7-10 13. The plunger rod arm will stop about ½" from the bottom of the plunger rod (5). Grasp the plunger rod with your fingers and pull it down into the hole in the arm (3). 14. Press any key. The display will now show the following menu. Replace the thumbscrew then press any key. Replace thumbscre...

Page 84

Maintenance 03-914642-00:6 7-11 3. Blow through the lines with clean nitrogen or helium. 4. Remove the two lines (7or 8) from the bottom of the valve. These two lines are water/sample supply lines to and from the valve manifolds. Unscrew the lines from the manifold assemblies and using clean nitroge...

Page 85

7-12 s ta n d a rd m o u n t b la ck t h u m b n ut 5 m l r eservo ir v ials figure 7-9 5. Return the toggle switch to the on position. Prime the lines as described in section 6.3.1. Figure 7-10 7.15 shipping instructions if the archon must be shipped, the “shipping positions” menu must be accessed ...

Page 86

03-914642-00:6 8-1 8 remote i/o cable hookup instructions the following drawings are to be used to interface the archon to the purge and trap and or gas chromatograph. The interface will allow the archon, the purge and trap, and the gc to send and receive correct signals such as the gc ready and rem...

Page 87

8-2 8.1 archon to tekmar lsc-2000 and 3000 , p/n dy-505872-00 r e d b la ck pin outs remote i/o archon color tekmar function color in out green 24 3 gc ready green #6 spade term. Desorb drain 15 2 brown 23 4 gc ready white #6 spade term. Red 1 21 gc start red #6 spade term. Start purge 5 18 white 2 ...

Page 88

Remote i/o cable hookup instructions 03-914642-00:6 8-3 8.2 archon to tekmar 3000 with hp 5890, p/n dy-505869-00 r e d bla ck pin outs remote i/o archon color tekmar function color hp 5890 in out green 24 3 gc ready green 5 desorb drain 15 2 brown 23 4 gc ready white 9 red 1 21 gc start red 1 start ...

Page 89

8-4 8.3 archon to tekmar lsc 2000/3000 with varian 3400/3600 p/n dy-505868-00 r ed p 23 p 16 b lack pin outs remote i/o archon color tekmar function color j23-j16 varian motherboard in out green 24 3 gc ready green desorb drain 15 2 brown 23 4 gc ready white 3 1 p23 red 1 21 gc start red start purge...

Page 90

Remote i/o cable hookup instructions 03-914642-00:6 8-5 8.3.1 varian gc motherboard attachments – j16 and j32 8.3.2 j-16 splitter dy-700030-00 8.3.3 j-23 splitter dy-700031-00

Page 91

8-6 when connecting to a varian series 3400 or 3600 gc with star workstation, connectors from both the archon i/o cable and the star workstation cable must access the j16 and j23 connectors on the gc motherboard. This is possible using the j16 splitter (dy-700030-00) and the j23 splitter (dy-700031-...

Page 92

Remote i/o cable hookup instructions 03-914642-00:6 8-7 8.4 archon to tekmar lsc 2000 / 3000 with hp 5895/96/85/87/88/92 gc/ms with hp-1000/rte gc/ms software, hp 5890 msd rte (rte-a, rte-6, or rev f2), p/n dy-505876-00 pin outs remote i/o archon color tekmar function color connection in out green 2...

Page 93

8-8 sample. In slave mode, the gc/ms or data system commands or signals the tekmar unit to start processing a sample. This interface has two cables, master and slave control. If you install the master cable, the unit will operate in master mode. If you install the slave control cable, your system wi...

Page 94

Remote i/o cable hookup instructions 03-914642-00:6 8-9 8.5 archon to tekmar lsc 2000 / 3000 with hp 5890 w/5970/71/72 msd and unixb or ms-dos software, and hp 5890/5989 ms engine, p/n dy-505874-00 red black pin outs remote i/o archon color tekmar function color hp 5890 in out green 24 3 gc ready gr...

Page 95

8-10 8.6 archon to tekmar lsc 2000 / 3000 to hp 6890, p/n dy-505873-00 pin outs remote i/o archon color tekmar function color hp 6890 m/s in out green 24 gc ready desorb drain 15 2 brown 23 4 gc ready white 7 7 - ready red 1 1,17,19 start purge red 1 1 - gc start purge 5 18 white 2 20 start purge gr...

Page 96

Remote i/o cable hookup instructions 03-914642-00:6 8-11 8.7 archon to oi 4460/4560 with hp 5890, p/n dy-505871-00 re d w hite b lack pin outs remote i/o archon color relay i/o oi function color hp 5890 terminal 15 green 5 gc ready red 1 desorb drain 2 brown 4 gc ready black 2 5 red 7 start purge 18...

Page 97

8-12 8.8 archon to oi 4460 / 4560 with varian 3400/3600, p/n dy-505870-00 r ed p 2 3 p 1 6 w h ite b lack pin outs remote i/o archon color relay i/o oi terminal function color j16-j23 varian motherboard 15 green 5 start purge red 3 desorb drain 2 brown 4 start purge black 4 5 red 7 start purge 18 wh...

Page 98

Remote i/o cable hookup instructions 03-914642-00:6 8-13 8.9 archon to oi 4460 / 4560 to hp 5890, rte hp 1000 gc / ms software hp 5970 msd or hp 5988 ms, p/n dy-505875-00 r ed w hite b la ck pin outs remote i/o archon color relay i/o oi function color hp 5890 terminal 15 green 5 start purge red 1 de...

Page 99

8-14 8.10 archon to tekmar 2000/3000 with varian 3800, pn 03-925673-01 pin outs remote i/o archon color tekmar color 3800 in out 15 green 24 3 brown 17 rdy out desorb/ drain 2 brown 23 4 orange 16 rdy out 5 red 1 21 black 22 gnd start purge 18 white 2 22 red 15 start in 14 blue 16 p&t ready signal 1...

Page 100: Error Code Screen Messages

03-914642-00:6 9-1 9 error code screen messages message description must calibrate (target position) first. Vial 1 position water probe equilibrium block knockoff clearance press any key to reset. This message appears if one of the calibrations has not been performed. Refer to section 6. First vial ...

Page 101

9-2 message description lost vial. Press any key to reset. This indicates the gripper has lost a vial. Check for a jammed vial or damaged sensor. Replace vial (#) in the tray. Press any key to continue. This message indicates a vial was removed from the tray or equilibrium block. Examine the vial lo...

Page 102

Error code screen messages 03-914642-00:6 9-3 message description serial error. Press any key to reset. This indicates bad or no internal communication between internal boards or cables. Check cables and reboot. At home timeout. (motor failure) press any key to reset. This is another internal commun...

Page 103

9-4.

Page 104

03-914642-00:6 10-1 10 spare parts and service information to obtain technical information, order parts, or service for your archon call: (800) 926-3000 outside the u.S.A., contact your nearest varian office listed at the front of this manual. Before calling for service or parts please note: 1. The ...

Page 105

10-2 part number description vials / caps, septa, stir bars dy-504252-00 22 mm epa low-bleed soil septa, pkg. Of 60 dy-504104-00 22 mm epa low-bleed soil septa, pkg. Of 300 dy-505023-00 22 mm epa low-bleed soil septa, pkg. Of 3000 dy-664671-00 teflon/silicon water vial septa, pkg. Of 72 dy-630068-00...

Page 106

Spare parts and service information 03-914642-00:6 10-3 part number description dy-505726-00 1 µl rotor loop dy-505407-00 valco valve and actuator assembly dy-505599-00 soil probe filter frit dy-700019-90 internal standard pickup and waste line kit lines / fittings dy-505514-00 transfer line (water ...

Page 107

10-4 part number description dy-505254-00 keypad dy-505236-00 lcd display dy-504763-00 power supply dy-505242-00 up/down sensor board dy-505243-00 left/right sensor board installation kits dy-505624-90 installation kit for tekmar 3000* dy-505746-90 installation kit for tekmar 2000 / 3000 dy-505747-9...

Page 108: 11 Technical Assemblies

03-914642-00:6 11-1 11 technical assemblies 11.1 front panel 1 27-239992-00 purge gas pressure gauge 2 03-918707-04 purge gas regulator 3 dy-504156-00 helium flow controller p u rg e g a s p r e s s u r e p u r g e g as f lo w + _ + 1 2 3.

Page 109

11-2 11.2 syringe plate 1 internal standard valve assembly 2 mixing solenoids/26 ml syringe assembly 3 sample probes 4 vial sample stations 1 2 4 3.

Page 110

Technical assemblies 03-914642-00:6 11-3 11.2.1 internal standard valve assembly 1 dy-505879-00 standard motor w/6-port valve with gray cable 1a dy-505407-00 standard valve and actuator 2 dy-505484-00 5 ml reservoir vials 3 dy-505726-00 rotor with 1 l internal loop 4 28-694637-00 3/8” teflon ferrule...

Page 111

11-4 11.2.2 mixing solenoids / 26 ml syringe assembly 1 dy-505830-00 syringe mixing manifold assembly 1a dy-505720-00 single burkert valve 2 dy-700060-91 valcon e-2 plunger and rod assembly (units > 12216) 3 dy-505495-00 o-ring 4 dy-505598-00 10 micron water probe screen 5 dy-502968-00 syringe glass...

Page 112

Technical assemblies 03-914642-00:6 11-5 11.2.3 probe section 1 dy-505491-00 water probe (archons with external valve) dy-505739-90 water probe (> s/n 995) 2 dy-505490-90 dy-505743-90 soil probe (sv units only for sn soil probe (sv units only for sn >995) for use with double ended cap vials only 3 d...

Page 113

11-6 11.2.4 vial sample stations 1 dy-505883-00 stir motor assembly 2 dy-505896-00 soil vial block heater assembly 3 dy-505463-90 lower soil purge gas needle assembly (for use with double ended cap vials only) 4 dy-700024-00 probe guide support rod 5 dy-700056-00 guide rod assembly 6 dy-5055451-00 w...

Page 114

Technical assemblies 03-914642-00:6 11-7 11.3 interface / transfer line, purge gas solenoid 1 dy-700032-00 upper soil valve assembly (units > than 120038) dy-700039-00 upper soil valve kit (units > than 120039) 2 dy-700001-01 soil transfer line and heater assembly (dual dia) dy-700001-02 soil transf...

Page 115

11-8 11.4 rear panel 1. Dy-505899-02 3- way angar solenoid valve assembly (press gas solenoid) 2. Dy-505899-01 2- way angar solenoid valve assembly (soil transfer gas solenoid) 3. Dy-505363-00 timing pulley (leadscrew) 4. Dy-505477-00 timing belt for vial elevator motor 5. Dy-505429-00 ¼ “ motor pul...

Page 116

Technical assemblies 03-914642-00:6 11-9 11.5 robotic arm 1 dy-505884-00 up/down motor assembly 2 dy-505393-00 motor pulley (gripper) 3 dy-505384-00 timing belt up/down motor 4 dy-505881-00 front/rear motor assembly 5 dy-505362-00 timing belt front/rear motor 6 dy-505363-00 timing pulley (up/down le...

Page 117

11-10 11.6 interconnect diagram . Note: f/r, l/r and u/d p.O.T. Should be set at 3/4, std. Valve full power.

Page 118: 12 Flow Diagrams

03-914642-00:6 12-1 12 flow diagrams the following flow diagrams are included in this section, sequentially by method. Page sample ready 12-3 water sample to sparge tube 12-4 water probe rinse 12-5 helium rinse 12-6 water sample drain 12-7 drain to syringe 12-8 drain from syringe 12-9 water sparge t...

Page 119

12-2.