- DL manuals

- Varian

- Laboratory Equipment

- CP-3800 GC

- Getting Started Manual

Varian CP-3800 GC Getting Started Manual

Summary of CP-3800 GC

Page 1

©varian, inc. 1999 printed in u.S.A. 03-914647-00:rev. 4 1 cp-3800 gc getting started manual getting started installation basic operation maintenance parts and supplies varian analytical instruments 2700 mitchell drive walnut creek, ca 94598-1675/usa.

Page 2: Read Before Operating

Read before operating important safeguards c a u t io n the following items are frequently not recognized or are overlooked by new users while learning to operate a gas chromatograph. They are brought to your attention to safeguard against damage to your equipment. • carrier gas must be flowing thro...

Page 3: Table of Contents

Cp-3800 gc getting started manual 1 table of contents introduction .......................................................................................................................5 guide to the 3800 user manuals.....................................................................................

Page 4

2 03-914647-00:4 basic operation ............................................................................................................... 39 setting carrier and detector gas flow rates ..................................................................... 39 condition the gc system ..............

Page 5

Cp-3800 gc getting started manual 3 parts and supplies..........................................................................................................75 to order parts and supplies … .......................................................................................75 injectors...........

Page 6: Introduction

Cp-3800 gc getting started manual 5 introduction guide to the 3800 user manuals the purpose of these user manuals is to provide instructions for the safe installation and operation of the varian 3800 gas chromatograph. Finding information in these manuals the 3800 is supplied with two user manuals: ...

Page 7

6 03-914647-00:4 brief description of the 3800 gas chromatograph the following are some of the key features of the 3800: • three injectors, columns and detectors can be installed and operated simultaneously. • the 1079 universal capillary injector provides five modes of injection - isothermal split ...

Page 8: Configuration and Options

Cp-3800 gc getting started manual 7 configuration and options the 3800 has seven heated zones, one of which is always configured as the column oven. The following options may be configured in the other six available heated zones: • 1079 universal capillary injector • 1041 on-column injector for larg...

Page 9: Installation

Cp-3800 gc getting started manual 9 installation site requirements for gc installation power requirements power source each 3800 gc requires a separate circuit with the following characteristics: 101 vac ± 10%, 50 or 60 hz ± 2%, 25 amps, 2.5 kilowatts 120 vac ± 10%, 60 hz ± 2%, 20 amps, 2.4 kilowatt...

Page 10

10 03-914647-00:4 space requirements allow sufficient bench space to permit installation of workstations, integrators, autosamplers and other peripheral gc equipment. The table below lists the physical dimensions and weight of the gc and the peripheral instruments which may be installed near it. All...

Page 11

I nstallation site requirements for gc installation cp-3800 gc getting started manual 11 peripheral connectors the 3800 gas chromatograph is equipped with various connectors on the rear panel and top of the instrument intended for use with peripheral equipment such as autosamplers and data handling ...

Page 12: Gc Installation

12 03-914647-00:4 gc installation inspection the 3800 gas chromatograph will arrive packed in one large palletized box and one or more smaller cartons. Inspect the cartons carefully for damage or signs of rough handling. Report damage to the carrier and to your local varian office. Unpacking unpack ...

Page 13

I nstallation gc installation cp-3800 gc getting started manual 13 select gases the following gases are commonly used in gas chromatography for the following functions. Note that the recommended purity for carrier make-up and detector fuel gases is 99.999%. In addition, the use of gas filters to rem...

Page 14

14 03-914647-00:4 5 push the copper tubing into the bulkhead fitting as far as it will go, then pull back very slightly and tighten 3/4-turn past finger-tight with a 7/16" wrench. 6 make sure the gas supply control valve, which controls gas pressure to the gc, is completely closed. Open this valve s...

Page 15

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 15 quick guide to the 3800 keyboard and display getting around the keyboard the 3800 user interface is designed for maximum ease of use. The keyboard is laid out in functional sections allowing quick access ...

Page 16

16 03-914647-00:4 table e dit n e w lin e d e le t e lin e c le a r ta b le if you are modifying a table such as a temperature ramp table or timed events table, the table edit keys can be used to add new lines to the table, delete the highlighted line from the table, or clear the table of all entrie...

Page 17

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 17 s e t u p the instrument setup key allows access to the instrument configuration screens for the purpose of viewing or modifying the 3800 configuration. Note that the 3800 has already been configured at t...

Page 18

18 03-914647-00:4 heated zones identify the type of device installed in each of the heated zones of the 3800, the upper temperature limit of these devices, their location and what type of coolant, if any, the device uses. Column oven always occupies one heated zone. The other available heated zones ...

Page 19

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 19 efc (electronic flow control) identifies any installed efc modules and their type. Types 1, 3, and 4 are used with inlet systems and types 11 through 16 with detectors. Detector efc setup involves selecti...

Page 20

20 03-914647-00:4 valve type abbr. Default state (-) activated state (+) front split valve fsv on (split) off (splitless) middle split valve msv on (split) off (splitless) rear split valve rsv on (split) off (splitless) gas sampling valve gsv fill inject liquid sampling valve lsv fill inject sample ...

Page 21

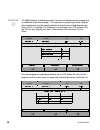

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 21 active method edit method ctrl run time end time , 0-2 5 6 , 0-2 5 6 * * # # 34 -' 01 2 34 -' 01 2 % % "# "7 0"82 "# "7 0"82 "# $#$ 0*2 "# $#$ 0*2 % % "# -' * 01 2 "# -' * 01 2 % % -' 0 -' 0 ° 2 2 -#*# 0&...

Page 22

22 03-914647-00:4 active method edit method ctrl run time end time 01 2: % 01 2: % ,)#" 01 2: % ,)#" 01 2: % ;" ;" "# -': - "# -': - -/ -&= 5 6 -/ -&= 5 6 * * * 01 2 * 01 2 01 82 01 82 " 02 " 02 " 02 " 02 " " % % >> % % % % % % #$ -' - #$ -' - #$ -' -66 #$ -' -66 s a m p le d e l iv e r y in je c t ...

Page 23

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 23 note that all heated zones, with the exception of the column oven, are off when the 3800 is first powered up. In je c to r the 1079 method uses three pages of screen displays, a page for setting the injec...

Page 24

24 03-914647-00:4 the example shown below is a splitless injection with efc pneumatics. In this case the injector is held in the split off state for a period of time at the beginning of the run (the sampling time). The injector is then switched to the split on state, typically after 0.5 - 1.5 minute...

Page 25

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 25 active method edit method ctrl run time end time 01 2: % ,)#" 01 2: % *" : - 01 2: % ,)#" 01 2: % *" : - - 34 5 6 - 34 5 6 34 -' 7$ 34 -' 7$ - - " -8- " -8- - - ;" " 01 2 ;" " 01 2 % % " # 02 " # 02 %% th...

Page 26

26 03-914647-00:4 f lo w / p r e s s u r e if the 3800 is equipped with electronic flow control, then pressing the flow/pressure key will bring up the screens associated with programming efc. Efc modules are identified by type and location to coincide with the sample delivery or injection device wit...

Page 27

I nstallation quick guide to the 3800 keyboard and display cp-3800 gc getting started manual 27 active method edit method ctrl run time end time 01 2: % 01 2: % ,)#" 01 2: % ,)#" 01 2: % ;" ;" "# -': - "# -': - -/ -& 5 6 -/ -& 5 6 * * * 01 2 * 01 2 01 82 01 82 " 02 " 02 " 02 " 02 " " % % >> % % % % ...

Page 28

28 03-914647-00:4 d e t e c to r the 3800 detector methods generally have two method parameter pages and an additional adjustments page. The adjustments page is generally used for advanced features of the specific detectors and also for setting detector gas flows, if efc is installed. The following ...

Page 29

I nstallation column installation and conditioning cp-3800 gc getting started manual 29 column installation and conditioning connect column to injector your gc arrives ready for installation of an analytical column. On first installation, a new column needs to be conditioned. Conditioning is perform...

Page 30

30 03-914647-00:4 three types of ferrules are common: graphite, vespel® or polyimide, and graphite/vespel. • do not use graphite with ecd or gc/ms systems. • ferrule id is based on the diameter of the capillary column. See the following table. Part number ferrule id (mm) fitting size (inches) column...

Page 31

I nstallation column installation and conditioning cp-3800 gc getting started manual 31 connect capillary column to injector follow steps 1-7 to install a capillary column into your injector. 1041 (530 µ ) 1061 (530 µ ) 1079 (50-530 µ ) 1 cut off sealed section at each end of new column. 2 uncoil 10...

Page 32

32 03-914647-00:4 nuts and ferrules for packed columns • metal packed columns are usually installed with a metal 2-piece ferrule. (a commonly used metal packed column is 1/8 ″ od stainless steel. It uses a 1/8 ″ id stainless steel ferrule.) • glass packed columns are 1/4 ″ od and are installed with ...

Page 33

I nstallation column installation and conditioning cp-3800 gc getting started manual 33 varian test column at points throughout this manual, specific values and conditions are given for the analysis of varian test samples on varian test columns. The following table provides information on varian tes...

Page 34

34 03-914647-00:4 1079 split vent flow and septum purge flow whether you are making an injection in the split or splitless mode, a split vent flow rate needs to be set. In this example, the split vent flow is set to 100 ml/min. The split state is set in the injector section of the 3800 method if efc...

Page 35: C A U T Io N

I nstallation column installation and conditioning cp-3800 gc getting started manual 35 set carrier gas flow rate to condition column to condition the column, flow rates need only be approximate. For packed columns and large bore (0.53 mm id) capillary columns set the flow rate to 15 - 30 ml/min. Pr...

Page 36

36 03-914647-00:4 in this example the injector and column are conditioned at 250°c for two hours. The column is programmed to 250°c at 5°c/min as a gentle temperature program is generally recommended for column conditioning. After this conditioning is complete, allow the column oven to cool and re- ...

Page 37

I nstallation column installation and conditioning cp-3800 gc getting started manual 37 3 move the column nut and ferrule to within 5 cm of the column end. Find the column insertion depth for your detector in the diagram below. Measure the correct distance from the end of the column and mark this di...

Page 38: C A U T Io N

38 03-914647-00:4 4 place the column into the base of the detector. 5 thread the capillary column nut and ferrule finger-tight. 6 gently slide the column into the detector until the mark on the column aligns with the bottom edge of the column nut. 7 continue to hold the column as you tighten the nut...

Page 39: Basic Operation

Cp-3800 gc getting started manual 39 basic operation important note: at points throughout this section, specific values and conditions are given for analysis of the varian test samples on varian test columns. Your analytical column and application may require different values and conditions. Please ...

Page 40

40 03-914647-00:4 the following instructions are for instruments configured with manual pneumatics. Gas flows for detectors with efc are set in the adjustments section of the detector method. Follow the steps below to set all gas flow rates on the 3800 gas chromatograph. Flows are typically set with...

Page 41: Condition The Gc System

B asic o peration condition the gc system cp-3800 gc getting started manual 41 condition the gc system as the injector and column were conditioned earlier, this procedure represents a quick conditioning of the entire gc system including the detector. Follow the steps below to build an analytical met...

Page 42

42 03-914647-00:4 method to analyze a varian test sample on a varian test column varian test samples for use with … sample composition part number ecd 33 ppb lindane and aldrin in iso-octane 82-005048-02 fid (packed column) 0.03% c14, c15, c16 in iso-octane 82-005048-00 fid (capillary column) 0.003%...

Page 43: Prepare The Test Sample

B asic o peration prepare the test sample cp-3800 gc getting started manual 43 for systems with 1079 injectors method settings to analyze the varian test sample on varian gcs installed with the varian test column ecd fid tcd 1 tsd pfpd micro-tcd initial column temp ( ° c) 80 80 80 80 80 40 initial c...

Page 44

44 03-914647-00:4 recommended solvents for gas chromatography column phase recommended solvent boiling point ( ° c) non-polar • pentane 36.1 • 100% methyl • n-hexane 69.0 • 5% phenyl, 95% methyl • cyclohexane 80.7 • iso-octane 99.3 • benzene 80.1 • toluene 110.6 • ethyl ether 34.6 • methyl tert-buty...

Page 45: Inject The Test Sample

Inject the test sample cp-3800 gc getting started manual 45 inject the test sample use 1 µ l of the varian test sample for all detectors. In addition, if you are using a pfpd, make a 1:20 dilution of the test sample in iso-octane. With the ready light on at the gc and the appropriate volume of test ...

Page 46: Maintenance

Cp-3800 gc getting started manual 47 maintenance overview it is important for the gc user to learn general maintenance techniques and carry these procedures out on a regular basis. Some common gc maintenance procedures are changing septa and injector inserts, checking for leaks, conditioning columns...

Page 47: General Gc Maintenance

48 03-914647-00:4 general gc maintenance the common general gc maintenance tasks are checking and changing gas supply cylinders, leak checking, and changing gas purifier filters. These should be performed at the frequency suggested above. The following procedures are critical to the successful long ...

Page 48

M aintenance general gc maintenance cp-3800 gc getting started manual 49 the use of soap-based leak detection fluids is not recommended for a high performance capillary gas chromatograph due to the danger of introducing contaminants into the system. If leak detection fluids are being used they shoul...

Page 49

50 03-914647-00:4 5 with all outlet ports plugged, pressurize the system to 20 - 30 psi. This can be accomplished by adjustment of manual pneumatic controls or electronic flow control. For information on setting carrier gas pressure see the basic operation section of this manual. 6 shut off the carr...

Page 50

M aintenance general gc maintenance cp-3800 gc getting started manual 51 the carrier gas should first pass through a hydrocarbon trap, then an indicating moisture filter, then a high capacity oxygen trap and finally through an indicating oxygen trap. As moisture reduces the effectiveness of an oxyge...

Page 51

52 03-914647-00:4 the following are the gas purifiers available from varian. Purifier part number high capacity oxygen trap 03-949770-02 indicating oxygen trap 88-501019-00 combined hydrocarbon and moisture trap 03-949862-00 indicating moisture trap 01-900007-00 injector maintenance the injector is ...

Page 52: 1079 Injector

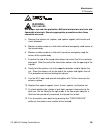

M aintenance 1079 injector cp-3800 gc getting started manual 53 use the following procedure to change a septum on any varian injector: 1 cool the column oven and injector oven to 50°c. This ensures safe handling of injector parts and protects the column from elevated temperatures while it is exposed...

Page 53

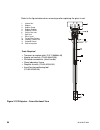

54 03-914647-00:4 refer to the figure below when removing and/or replacing the glass insert. 1 injector nut 2 septum 3 septum purge 4 septum support 5 graphite ferrule 6 carrier gas inlet 7 split vent 8 glass insert 9 fused silica column 10 capillary column nut 11 vespel® ferrule 12 point of injecti...

Page 54: Wa R N In G :

M aintenance 1079 injector cp-3800 gc getting started manual 55 remove the glass insert follow these steps to remove the glass insert from the 1079 injector. 1 use the injector nut wrench to remove the injector nut (item 1). Place the nut on a clean surface (e.G., clean tissue). Wa r n in g : b u r ...

Page 55

56 03-914647-00:4 replace the glass insert follow these steps to replace the glass insert in the 1079 injector. 1 use the insert/ferrule positioning tool supplied in the 1079 accessory kit to set the 5 mm graphite ferrule on the insert and in the septum support. See the above pictures for an explode...

Page 56: Wa R N In G :

M aintenance 1079 injector cp-3800 gc getting started manual 57 clean the glass insert glass inserts must be clean and free from sample residue and particulate matter (such as bits of septum rubber or graphite). Follow these steps to clean the glass insert in the 1079 injector. 1 remove the glass in...

Page 57

58 03-914647-00:4 deactivate the glass insert follow these steps to deactivate the glass insert in the 1079 injector. Note: this procedure can be used on all glass inserts except inserts packed with 10% ov-101 on chromosorb w-hp (p/n 03-918956-00). Up to three inserts can be deactivated at a time us...

Page 58: Wa R N In G :

M aintenance 1079 injector cp-3800 gc getting started manual 59 wa r n in g : fir e h a za r d use proper eye and skin protection. Methanol and acetone are toxic and flammable chemicals. Exercise appropriate precautions when these chemicals are used. 4. Remove the injector nut, septum, and septum su...

Page 59: 1041 Injector

60 03-914647-00:4 1041 injector hardware replacement and cleaning procedures routine cleaning and maintenance of the 1041 universal injector system includes septum replacement and column conditioning. Pressure testing and leak checking procedures are included to assure proper functioning of the syst...

Page 60

M aintenance 1041 injector cp-3800 gc getting started manual 61 figure 4 1041 injector assembly needle/ syringe cleaning for normal use, rinse the needle/syringe by slowly drawing up and quickly expelling solvent or the next sample to be used. Repeat the process several times. Note: when rinsing wit...

Page 61: C A U T Io N

62 03-914647-00:4 leak checking leak checking methods used with the 1041 universal injector are presented in order of overall sensitivity and performance. When leak checking the injector only, be sure to use the appropriate procedure. 1 remove the test column and plug the injector outlet with a 1/16...

Page 62: C A U T Io N

M aintenance 1041 injector cp-3800 gc getting started manual 63 gas leak checking a convenient and non-contaminating way to leak test fittings and connections after installation or hardware replacement procedures is to direct a small jet of gas (butane from a disposable lighter recommended for flame...

Page 63: 1061 Injector

64 03-914647-00:4 1061 injector the 1061 is mechanically similar to the 1041 except that it uses a glass insert for flash vaporization injection. Follow the same maintenance procedures for the 1061 that are outlined above for the 1041, except in the case of changing or cleaning glass inserts. Replac...

Page 64: Wa R N In G :

M aintenance 1061 injector cp-3800 gc getting started manual 65 remove the glass insert follow these steps to remove the glass insert from the 1061 injector. 1 use the injector nut wrench to remove the injector nut (item 1). Place the nut on a clean surface (e.G., clean tissue). Wa r n in g : b u r ...

Page 65: Wa R N In G :

66 03-914647-00:4 clean the glass insert glass inserts must be clean and free from sample residue and particulate matter (such as bits of septum rubber or graphite). Follow these steps to clean the glass insert of the 1061 injector. 1 remove the glass insert. It is safest to cool the injector to 50°...

Page 66

M aintenance 1061 injector cp-3800 gc getting started manual 67 deactivate the glass insert follow these steps to deactivate the glass insert in the 1061 injector. 1 in a 10 ml glass graduated cylinder, add 0.5-1 ml of dimethyldichlorosilane. Fill to 10 ml with isooctane, hexane or toluene. 2 cover ...

Page 67: Flame Ionization Detector

68 03-914647-00:4 flame ionization detector when the performance of the fid has degraded you may want to replace the flame tip ferrule, or clean the deposits from the internal parts, including the flame tip. Clean the flame tip and internal parts if the fid noise increases with frequent spikes, the ...

Page 68

M aintenance flame ionization detector cp-3800 gc getting started manual 69 figure 6 flame ionization detector assembly replace the ferrule after a period of prolonged use, the flame-tip ferrule may deteriorate and crack. As a consequence, a leak may develop around the base of the flame tip assembly...

Page 69: Thermionic Specific Detector

70 03-914647-00:4 thermionic specific detector cleaning/ maintenance when the tsd exhibits low sensitivity or high background noise, cleaning is indicated. Visual inspection may also indicate a need for cleaning. The ceramic bead, collector, or flame tip are all parts that are deposit prone, dependi...

Page 70

M aintenance thermionic specific detector cp-3800 gc getting started manual 71 figure 7 thermionic specific detector assembly 1 signal cable 2 signal probe 3 bead supply cable 4 bead probe 5. Ceramic bead 6 collector 7 ceramic insulators 8 tsd tower 9 flame tip 10 aluminum crunch washer 11 detector ...

Page 71: Electron Capture Detector

72 03-914647-00:4 electron capture detector chemical contaminants may deposit on the components of the detector assembly as the ecd is operated. In many cases, you can remove contaminants deposited on the radioactive foil or cell ceramic insulators by heating. Refer to the radiation safety manual (p...

Page 72

M aintenance thermal conductivity detector cp-3800 gc getting started manual 73 2 monitor the output signal while the detector heats to its maximum temperature. The signal will increase initially, then gradually decrease as chemical contaminants vaporize from the detector surfaces. 3 allow the detec...

Page 73: Parts and Supplies

Cp-3800 gc getting started manual 75 parts and supplies to order parts and supplies … • in the usa and canada, call 1-800-926-3000. • in europe, call your local country office. • in the rest of the world, call your local varian representative • or, contact varian on the internet at http://www.Varian...

Page 74: Detectors

76 03-914647-00:4 1041/1061 injector packed column adapter kit for 1041, 1/8” ss columns 03-925588-91 packed column adapter kit for 1061, 1/8” ss columns 03-925588-92 note that these kits contain injector and detector adapters packed column adapter kit for 1/4” glass columns 03-925586-91 packed colu...

Page 75

P arts and s upplies detectors cp-3800 gc getting started manual 77 thermal conductivity detector tcd make-up gas option 03-925605-01 pulsed flame photometric detector aluminum crunch washer 15-003347-00 combustor, quartz (2mm id) 03-925176-00 combustor, quartz (3 mm id) 03-925177-00 filter assembly...