- DL manuals

- Varian

- Laboratory Equipment

- Saturn 2000 GC/MS

- Hardware Manual

Varian Saturn 2000 GC/MS Hardware Manual

Summary of Saturn 2000 GC/MS

Page 1

Varian, inc. 2700 mitchell drive walnut creek, ca 94598-1675/usa saturn 2000 gc/ms hardware manual ©varian, inc. 2002 -2003 printed in u.S.A. 03-914978-00:rev. 1.

Page 2

All rights reserved including the right of reproduction in whole or in part in any form. This document may be electronically reproduced, distributed, or printed in its entirety provided this copyright and statement are attached. Any modification or any other reproduction, distribution, or use of thi...

Page 3: Applicable Standards

Declaration of conformity we hereby declare that the equipment listed below complies with the requirements of: the low voltage directive 73/23/eec (93/68/eec) the emc directive 89/336/eec (92/31/eec and 93/68/eec) applicable standards lvd en 61010 emc en 50082-1 en 55011 tuv file number(s): e9672056...

Page 4

Quality systems at varian, inc. The iso 9000 series standards were created in geneva in 1987 to cut through a morass of conflicting quality definitions. These standards define a model for quality assurance systems in product design, development, manufacturing, installation, service, and customer sup...

Page 5

Qualitätssysteme bei varian, inc. Die standards der iso 9000 serien wurden 1987 in genf mit dem ziel geschaffen, das durch- einander gegensätzlicher qualitätsbestimmungen zu entwirren. Diese standards legen ein modell für qualitätssicherungssysteme hinsichtlich produktdesign, entwicklung, herstellun...

Page 6

Systèmes de qualité chez varian, inc. Les normes iso série 9000 ont été créées à genève, en 1987, pour remédier à la confusion dans la définition des normes de qualité. Ces normes définissent un modèle de contrôle de qualité dans le domaine de la conception produit, du développement, de la productio...

Page 7

I sistemi di qualità della varian, inc. La serie degli standard iso 9000 è stata presentata nel 1987 a ginevra con lo scopo di mettere ordine in un groviglio di definizioni contrastanti sulla qualità. Tali standard definiscono un modello che assicura la qualità nella progettazione, nello sviluppo, n...

Page 8

Sistemas de calidad en varian, inc. Las normas iso 9000 fueron creadas en ginebra en 1987 para acabar con una multitud de definiciones de calidad contradictorias. Estas normas constituyen un modelo de sistemas de garantía de calidad en el diseño, desarrollo, fabricación, instalación, mantenimiento y...

Page 9

Varian, inc. Analytical instrument warranty hardware products all analytical instruments sold by varian, inc. Are warranted to be free from defects in material and workmanship for the periods specified and in accordance with the terms on the face of varian's quotation or as otherwise agreed upon in ...

Page 10

Varian, inc. Analytical instrument garantie hardwareprodukte es wird garantiert, daß alle von varian, inc. Verkauften analytischen instrumente für die angegebene zeitdauer und in Übereinstimmung mit den „allgemeinen liefer- bedingungen“ oder anderen schriftlichen zusagen zwischen varian und dem kund...

Page 11

Garantie des instruments d'analyse varian, inc. Matériel les instruments d'analyse vendus par varian, inc. Sont garantis exempts de défauts de matière et de fabrication, pour les périodes spécifiées et conformément aux conditions mentionnées sur le recto du devis ou aux termes de tout autre accord é...

Page 12

Garanzia sugli strumenti analitici varian, inc. Prodotti hardware tutti gli strumenti analitici commercializzati dalla varian, inc. Sono garantiti da eventuali difetti di materiali e di costruzione per i periodi ed alle condizioni indicati sull'offerta varian o comunque concordati per iscritto tra l...

Page 13

Instrumentos analíticos varian, inc. Garantía productos hardware todos los instrumentos analíticos vendidos por varian, inc. Están garantizados contra defectos de materiales y de fabricación por la duración especificada y de acuerdo con los términos establecidos en las ofertas de varian, o según lo ...

Page 14: Safety

03-914603-00:10 1 of 4 safety information operating instructions this instruction manual is provided to help you establish operating conditions which will permit safe and efficient use of your equipment. Special considerations and precautions are also described in the manual, which appear in the for...

Page 15: General Safety Precautions

2 of 4 03-914603-00:10 general safety precautions follow these safety practices to ensure safe equipment operation. T perform periodic leak checks on all supply lines and pneumatic plumbing. T do not allow gas lines to become kinked or punctured. Place lines away from foot traffic and extreme heat o...

Page 16: Gc Safety Practices

03-914603-00:10 3 of 4 gc safety practices exhaust system no special exhaust ducting is necessary for gc detectors installed in a well-ventilated room except when the detectors are used to test hazardous chemicals. If you do install ducting: t use only fireproof ducting. T install a blower at the du...

Page 17: Spare Parts Availability

4 of 4 03-914603-00:10 spare parts availability it is the policy of varian to provide operational spare parts for any instrument and major accessory for a period of five (5) years after shipment of the final production run of that instrument. Spare parts will be available after this five (5) year pe...

Page 18: Sicherheitsinformationen

03-914603-81:10 1 of 4 sicherheitsinformationen arbeitsanleitungen diese arbeitsanleitung will ihnen bei der aufstellung solcher arbeitsbedingungen helfen, die einen sicheren und wirkungsvollen gebrauch ihrer geräte ermöglichen. Besondere Überlegungen und vorsichtsmaßnahmen erscheinen in diesem hand...

Page 19: Hinweis:

2 of 4 03-914603-81:10 allgemeine sicherheitsmaßnahmen befolgen sie diese sicherheitspraktiken für eine gefahrlose gerätebenutzung. Prüfen sie regelmäßig alle versorgungs und pneumatikleitungen auf lecks. Gasleitungen dürfen nicht geknickt oder angestochen werden. Verlegen sie die leitungen außerhal...

Page 20: Gc Sicherheitspraktiken

03-914603-81:10 3 of 4 gc sicherheitspraktiken abgassystem für gc detektoren, die in einem gut durchlüfteten raum installiert sind, ist keine spezielle abgasführung erforderlich, außer wenn die detektoren zum testen gefährlicher chemikalien benutzt werden. Wenn sie eine abgasführung installieren: be...

Page 21: Serviceverfügbarkeit

4 of 4 03-914603-81:10 verfügbarkeit von ersatzteilen es ist varian’s grundsatz, ersatzteile für alle instrumente und die wichtig- sten zubehöre für einen zeitraum von fünf (5) jahren nach dem fertigung- sauslauf dieser geräteserie verfügbar zu haben. Nach diesem zeitraum von fünf (5) jahren können ...

Page 22: Note

03-914603-82:10 1 of 4 informations et mesures de sécurité instructions de fonctionnement ce manuel d’instruction est conçu pour aider l’utilisateur à créer des conditions opératoires lui permettant de faire fonctionner le matériel efficacement et en toute sécurité. Il contient entre autres certaine...

Page 23: Note:

2 of 4 03-914603-82:10 précautions générales en matière de sécurité les pratiques suivantes garantissent une utilisation sans risques du matériel: effectuer régulièrement des essais d’étanchéité de tous les conduits d’alimentation et de tous les tuyaux du système pneumatique. Ne pas travailler avec ...

Page 24: Mesures De Sécurité En Cpg

03-914603-82:10 3 of 4 mesures de sécurité en cpg système d’échappement les détecteurs cpg installés dans une pièce bien ventilée ne nécessitent pas de conduits spéciaux d’échappement excepté lorsqu’ils sont destinés à analyser des substances chimiques dangereuses. Lors de l’installation de tels con...

Page 25: Service D’Assistance À

4 of 4 03-914603-82:10 disponibilité des pièces de rechange la politique de varian consiste à fournir des pièces de rechange pour tous les appareils et accessoires majeurs durant une période de cinq (5) ans après livraison de leur production finale. Les pièces de rechange ne sont fournies au terme d...

Page 26: Informazioni Sulla Sicurezza

03-914603-83:10 1 of 4 informazioni sulla sicurezza instruzioni per l’uso questo manuale ha lo scopo di aiutare l’operatore ad utilizzare lo strumento in modo sicuro ed efficiente. Le considerazioni e le precauzioni speciali vengono presentate in questo manuale sotto forma di avvisi di nota , cautel...

Page 27: Norme Di Sicurezza

2 of 4 03-914603-83:10 norme di sicurezza per lavorare in modo sicuro sullo strumento, vi consigliamo si adottare le seguenti procedure. Verificare periodicamente che non ci siano perdite sulle linee e sui raccordi pneumatici. Evitare che le linee dei gas vengano piegate o forate. Le linee vanno pos...

Page 28: Procedure Di Sicurezza In Gc

03-914603-83:10 3 of 4 procedure di sicurezza in gc scarico dei gas per i rivelatori gc non è richiesto alcun sistema particolare di scarico dei gas, se lo strumento è installato in una stanza ben ventilata e se non viene utilizzato per l’analisi di sostanze chimiche pericolose. Se si deve installar...

Page 29: Servizi Tecnico

4 of 4 03-914603-83:10 disponibilità delle parti di ricambio e’ politica della varian il fornire le parti di ricambio per lo strumento ed i suoi accessori per un periodo di cinque (5) anni a partire dalla data di produzione dell’ultima unità della serie. Le parti di ricambio saranno disponibili anch...

Page 30: Instrucciones De

03-914603-84:10 1 of 4 instrucciones de seguridad instrucciones de operación este manual de instrucciones está diseñado para ayudarle a establecer las condiciones de operación que le permitan operar su instrumento de forma segura y eficaz. Así mismo, se describen consideraciones especiales ó precauc...

Page 31: Nota:

2 of 4 03-914603-84:10 precauciones generales de seguridad siga estas indicaciones de seguridad para una correcta operación del equipo. Realice verificaciones periódicas de fugas en todas las líneas de suministro y tuberías. No permita que las líneas de gas se doblen ó pinchen. Manténgalas alejadas ...

Page 32: Gc Prácticas De Seguridad

03-914603-84:10 3 of 4 gc prácticas de seguridad sistema de extracción no se necesita un sistema de extracción para los detectores gc instalados en un laboratorio bien ventilado, excepto cuando se analicen muestras químicas peligrosas. Si instala un sistema de extracción: utilice conductos a prueba ...

Page 33: Disponibilidad De Recambios

4 of 4 03-914603-84:10 disponibilidad de recambios es política de varian disponer de recambios para cualquier instrumento y la mayoría de los accesorios por un periodo de cinco (5) años después del último instrumento fabricado. Los recambios durante esos cinco años estarán disponibles, pero siempre ...

Page 34: Contents

03-914978-00:1 1 contents contents functional description ............................................................................................................ 7 introduction .........................................................................................................................

Page 35

2000 ms hardware maintenance 2 contents use polypropylene caps to preserve liquids in reservoirs............................................................................. 43 setting flows of vapor from liquid ci reagents ...............................................................................

Page 36

03-914978-00:1 3 contents remove the analyzer assembly............................................................................................................................ 102 replace the electron multiplier ........................................................................................

Page 37

2000 ms hardware maintenance 4 contents check the ion content of the trap .................................................................................................................. 134 check the axial modulation setting............................................................................

Page 38

03-914978-00:1 5 contents parts and supplies ................................................................................................................................................. 161 kits, assemblies, boards, and cables .......................................................................

Page 39

2000 ms hardware maintenance 6 contents.

Page 40: Functional Description

03-914978-00:1 7 functional description functional description introduction the saturn 2000 gc/ms has four principal components: • gas chromatograph (gc) • mass spectrometer (ms) • data system (ds) • autosampler (optional) the following figure is a functional block diagram of the saturn gc/ms. A s...

Page 41

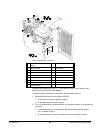

2000 ms hardware maintenance 8 functional description a foreline pump b transfer line c gc oven d capillary column e turbomolecular pump f ion trap assembly principal components of saturn gc/ms (top view).

Page 42: Technical Specifications

03-914978-00:1 9 functional description technical specifications note: specifications are identical for turbomolecular pump and diffusion pump gc/ms systems unless specified. Saturn 2000 gc/ms system performance specifications ionization mode: electron ionization standard, chemical ionization option...

Page 43: The Mass Spectrometer

2000 ms hardware maintenance 10 functional description the mass spectrometer the saturn gc/ms employs an ultra trace ion trap mass spectrometer. The mass spectrometer consists of the mechanical and electronic assemblies. The following sections describe these assemblies. The instrument is separated i...

Page 44: Cooling Fans

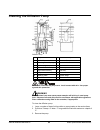

03-914978-00:1 11 functional description a main power switch (rear panel) j cal gas vial b service switch k vent valve c transfer line heater l rf coil d trap heater m rf coil adjustment screw e manifold heater n transfer line f led o turbomolecular pump g pneumatics manifold p cooling fans h ci cal...

Page 45: Diffusion Pump System

2000 ms hardware maintenance 12 functional description the electronics section fan draws air from the back, and blows it across the sap/wave and power boards in the electronics compartment. Hot air from the gc oven does not affect the ms as long as the system is at least six inches from a wall. The ...

Page 46: Caution

03-914978-00:1 13 functional description zone 3 is the diffusion pump compartment. The lower fan on the rear panel pulls air in through carefully positioned vents in the left side panel. Airflow is ducted around the diffusion pump’s cooling fins, and expelled through the rear of the instrument. Caut...

Page 47: Turbomolecular Vacuum Pump

2000 ms hardware maintenance 14 functional description the vacuum manifold sits atop the rf coil housing. The turbomolecular pump makes an airtight seal with the manifold, to which it is mounted horizontally with a viton o-ring. The ion trap assembly suspends from the analyzer flange, and extends ...

Page 48

03-914978-00:1 15 functional description if the speed of the pump is 92% or more of the maximum operating speed, the signal from the controller prompts the power control board to send a turbomolecular speed ok signal to the sap/wave board. The sap/wave board uses the signal for enable or disable the...

Page 49: Peltier Baffle

2000 ms hardware maintenance 16 functional description diffusion pump vacuum manifold the vacuum manifold is a stainless steel tube that maintains the ion trap assembly in a vacuum. Carrier gas is fed into the ion trap via the transfer line, and calibration gas and chemical ionization gases are fed ...

Page 50: Diffusion Pump

03-914978-00:1 17 functional description diffusion pump the ion trap assembly requires a vacuum of approximately 1 x 10 -5 torr (1.3 x 10 -3 pa) for the generation and detection of ions. The varian ax65 air-cooled diffusion pump with a pumping speed of 30 l/s for air and 65 l/s for helium provides t...

Page 51: Thermocouple Gauge

2000 ms hardware maintenance 18 functional description the diffusion pump may be restarted at any time during the shutdown procedure providing no fault condition exists. The controller will restore power to the diffusion pump if it receives a restart command during the first fifteen minutes of the s...

Page 52: The Transfer Line

03-914978-00:1 19 functional description the transfer line a stainless-steel-tube transfer line directly couples the gc to the mass spectrometer. The transfer line keeps the gc column warm as the column enters the mass spectrometer. The transfer line is 12 cm (5 in.) long, and has a diameter of 4.1 ...

Page 53: Ion Trap Assembly

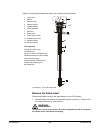

2000 ms hardware maintenance 20 functional description a heating cable h o-ring b boot i transfer line tip c nut j heating cable slot d ferrule k nose clip e transfer line/alignment tool l bayonet mount f nose m analyzer assembly tongue g nose hole n analyzer assembly lock-down tabs transfer line ex...

Page 54: Trap Oven

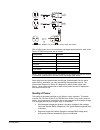

03-914978-00:1 21 functional description a screw, 6/32, 4 places h wave washer b clamping plate i gate conductor c exit end cap j trap oven, “t” is located this side. D quartz or silica coated spacer, 2 places k filament assembly e rf ring electrode l filament clip f filament end cap m screw g elect...

Page 55: Electron Gate

2000 ms hardware maintenance 22 functional description filament assembly shown with ion trap each filament is a rhenium wire. When sufficiently heated by electric current, the filament produces electrons by thermionic emission. The filament emission current refers to the flow of emitted electrons fr...

Page 56: Ion Trap Electrodes

03-914978-00:1 23 functional description ion trap electrodes the ion trap assembly contains three stainless steel electrodes: • filament endcap electrode • exit endcap electrode • rf ring electrode the filament endcap, exit endcap, and rf-ring electrodes have hyperbolic inner surfaces. Together, the...

Page 57: Ion Gauge

2000 ms hardware maintenance 24 functional description a exit end cap f multiplier contacts b electron multiplier track g multiplier high voltage pin c multiplier signal pin h transfer line alignment d em grid i transfer line entrance hole e electron multiplier mount position of the electron multipl...

Page 58: Foreline Pump

03-914978-00:1 25 functional description in general, the ion gauge exhibits good repeatability. However, the ion gauge response depends on gas composition. A certain pressure of air and water will give a different reading than that of helium. The ion gauge is meant to be a rough indicator of vacuum ...

Page 59

2000 ms hardware maintenance 26 functional description the electronics functions have been distributed throughout the spectrometer to minimize cable lengths between critical components. The sap/wave and power boards reside in an electronics enclosure that is separated from the analyzer section by a ...

Page 60: Pump Controller

03-914978-00:1 27 functional description the saturn 2000 gc/ms diffusion pump electronic assemblies the power input subsystem and turbomolecular pump controller the power input subsystem contains the following circuits and switches: • main power switch • service switch • line voltage switches main p...

Page 61: Warning:

2000 ms hardware maintenance 28 functional description electronics service switch allows the vacuum to the maintained in the event that the electronics need to be serviced. The line voltage switches are located on the power board and the turbomolecular controller. These switches are set at the facto...

Page 62: The Rf Generator Assembly

03-914978-00:1 29 functional description • the electron energy control circuits, which controls the dc bias on both the ion trap and ion gauge filaments. • the diagnostic multiplexer circuit, which routes the voltage output of various components, and circuits on the power control board to the sap/wa...

Page 63

2000 ms hardware maintenance 30 functional description the ion trap assembly the manifold electronics assembly two boards reside in the enclosure directly atop the analyzer flange. The following circuitry, which is critical to the functioning of the ion trap or that must be in close proximity to the...

Page 64

03-914978-00:1 31 functional description • the scan acquisition processor/waveform generator board • the scan acquisition processor/waveform generator (sap/wave) board is a real-time control and acquisition microcomputer that makes use of an 80c186 microprocessor. The sap/wave board communicates wit...

Page 65: The Data System

2000 ms hardware maintenance 32 functional description • a variable operational frequency range that depends on whether you are using the high frequency transformer (12 to 500 khz) or low frequency transformer (200 hz to 1.25 khz) • application of the waveform output to the endcap electrodes of the ...

Page 66: Chemical Ionization Options

03-914978-00:1 33 chemical ionization options chemical ionization options introduction chemical ionization (ci) provides mass spectral data that complement electron ionization (ei) data for the analysis of complex compounds. In the standard ci mode of operation, a ci reagent gas is introduced into t...

Page 67: Ci Reagent Gas Requirements

2000 ms hardware maintenance 34 chemical ionization options ci reagent gas requirements these paragraphs give the requirements for the reagent gases used for ci operation with saturn gc/ms. The following reagent gases are recommended: methane, isobutane, and ammonia. Other reagent gases can also be ...

Page 68

03-914978-00:1 35 chemical ionization options ci reagent gases may be hazardous. Use proper protection when installing the reagent gas. 1. Enter the system control and select the manual control tab dialog. 2. Make sure that the electron multiplier, filament, and rf voltage are all off. The multiplie...

Page 69

2000 ms hardware maintenance 36 chemical ionization options 7. On the back of the saturn gc/ms instrument, loosen the two screws that hold the plug in the ci shutoff manifold 2 to 3 turns. Remove the plug by pulling straight out and twisting. A power switch b shutoff manifold c plug d 6/32" screws (...

Page 70

03-914978-00:1 37 chemical ionization options checking the reagent gas plumbing for leaks to check for air leaks in the reagent gas line connections and the presence of water vapor in the gas line, follow the procedure using a leak detection gas to troubleshoot for air leaks in the troubleshooting s...

Page 71

2000 ms hardware maintenance 38 chemical ionization options you are now ready to operate the system in the ci mode. If you are a new user, we recommend that you perform the introductory example of ci operation in tuning the saturn for chemical ionization inthe tutorial manual. Default parameters for...

Page 72

03-914978-00:1 39 chemical ionization options ion intensities for standard ci reagents the ci adjust function gives recommendations of an acceptable level of ci reagent ions for each of the five standard ci reagents. The general principles used in implementing these tests are: methane adjust the rea...

Page 73: The Liquid Ci Inlet Option

2000 ms hardware maintenance 40 chemical ionization options • note the diffusion pump foreline pressure reading under the vacuum system field. The reading should be less than 100 mtorr. Higher readings may indicate problems (i.E., leaks) and the user should refer to the troubleshooting sectionfor ad...

Page 74

03-914978-00:1 41 chemical ionization options d. Loosely attach the liquid ci inlet assembly to the back of the instrument via the l-bracket with the screw that was removed. E. Rotate the liquid ci inlet assembly out of the way to remove the remaining screw. F. Rotate the liquid ci inlet assembly ba...

Page 75

2000 ms hardware maintenance 42 chemical ionization options e. Gently install the peek tube end into the pneumatics manifold, being careful not to let the retaining plate scratch the tube. F. Do not retighten the 4 screws on the pneumatics manifold yet. G. Insert the other end of the peek tube into ...

Page 76: Reservoirs

03-914978-00:1 43 chemical ionization options filling/refilling the liquid ci reservoir bulb 1. Be sure the ci valves are closed. Disengage the 4 screws that retain the liquid ci reservoir cover. They may remain in the block. 2. Remove the reservoir cover. 3. Gently pull the bulb down to remove it f...

Page 77

2000 ms hardware maintenance 44 chemical ionization options setting flows of vapor from liquid ci reagents 1. Connect a liquid reagent reservoir containing the chosen liquid to the liquid reagent inlet block. 2. Open the ci needle valve 6-7 turns counterclockwise. 3. Open the ci solenoids by clickin...

Page 78

03-914978-00:1 45 chemical ionization options 1. Loosen the 2 screws that attach the liquid ci inlet l-bracket to the back of the instrument. Also, loosen the 2 screws that attach the l-bracket to the liquid ci inlet block. 2. Remove the liquid ci restrictor end that inserts into the back of the ins...

Page 79: Pre-Installation Checklist

2000 ms hardware maintenance 46 chemical ionization options schematic diagram of the mci module multiple ci module (shown with and without cover) pre-installation checklist 1. Preparing the mass spec a. The saturn ms should be shut down, vented, and unplugged. 2. Tools required a. #2 philips screw d...

Page 80

03-914978-00:1 47 chemical ionization options 3. Vent the mass spec. 4. Unplug the power cord from the back of the mass spec. 5. Unpack the multiple ci kit and place the parts on a table. 6. Open the front door on the mass spec until it presses against the right side panel. 7. Find the register plat...

Page 81

2000 ms hardware maintenance 48 chemical ionization options 13. Use two #6 x 0.50 inch long screws to attach the multiple ci manifold to the register plate and side panel. 14. Stand the side panel next to the right side of the mass spec. 15. Guide the two tubes past the power board and through the o...

Page 82

03-914978-00:1 49 chemical ionization options 20. There are now three openings in the pneumatics block. 21. Connect the metal tube from the multiple ci assembly to the opening on the left. 22. Connect the previously removed u-shaped tube, to the two right openings in the pneumatics block. 23. Tighte...

Page 83: 3800 Gc

2000 ms hardware maintenance 50 chemical ionization options 3800 gc if you are installing the mci module on a 3400 or 3600 gc, skip to the installation instructions following this section. 1. The multiple ci solenoid cable plugs into the external events on the 3800 gc. 2. Remove the gc left side, to...

Page 84

03-914978-00:1 51 chemical ionization options 5. Unplug the power cord. 6. Remove the top covers. 7. Remove the high voltage cover. 8. Connect the rectifier pwa to pins 3 - 8 on the external events board in the gc. 9. Tighten all six of the connector screws to ensure good electrical contact. If ther...

Page 85

2000 ms hardware maintenance 52 chemical ionization options adding liquid ci reagents to the mci module the addition of liquid reagents to the mci module is accomplished in much the same manner as addition of liquid reagent to the single liquid ci option (lci). The lci liquid filling process is show...

Page 86

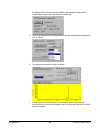

03-914978-00:1 53 chemical ionization options adjusting flows of ci reagents there are two ways to turn channels of the mci module on and off. The simplest way, which you may want to use when you are adjusting ci flows, is from the keyboard of the gc. The second way is to program a gc/ms method in t...

Page 87

2000 ms hardware maintenance 54 chemical ionization options select the section gc relays under 3400 or 3600 gc control. You will see the following screen: if you wish to adjust flows of all three ci reagents in the mci module, you will want to save three methods with relays turned on for each specif...

Page 88

03-914978-00:1 55 chemical ionization options now use the menu command file…save as to save the method with a name such as channela. Check the box for either relay 2 (channel b) or relay 3 (channel c) and save these methods as channelb and channelc. You may now open channels a, b, or c by using the ...

Page 89

2000 ms hardware maintenance 56 chemical ionization options highlight external event a and release the mouse button. You will see the following display: now, if channels b and c are connected to valves 2 and 3, enter the appropriate state by highlighting the first row under valve 2 and valve 3. Othe...

Page 90

03-914978-00:1 57 chemical ionization options setting ci/ms parameters in the ms method editor to adjust ci reagent flows for a given ci gas and to use the appropriate parameters in a ci/ms acquisition, you will need to modify the gc/ms method for each reagent channel so that ci/ms parameters for ea...

Page 91

2000 ms hardware maintenance 58 chemical ionization options the values of each parameter for acetonitrile ci are identified in the table default parameters for liquid ci reagentsand already entered into the fields on the right side of the table. (if we were setting up for any of the standard gaseous...

Page 92

03-914978-00:1 59 chemical ionization options the manual control comes up with the method tab displayed. Note that the method name, mode, and scan range are displayed. 5. Click on the adjustments tab dialog and then choose acetonitrile as the gas and click on adjust. 6. The adjustment process will b...

Page 93: Reagents

2000 ms hardware maintenance 60 chemical ionization options 8. While observing the spectrum using adjust ci gas, turn the ci needle valve for the selected channel on the mci module clockwise to increase (or counterclockwise to decrease) the amount of reagent until the reagent ions abundances meet th...

Page 94

03-914978-00:1 61 chemical ionization options now choose the method directory item column oven and set an appropriate column oven program. The following program requires a 30-minute run: choose the method directory item sample delivery and create a sample delivery method with all external events off...

Page 95

2000 ms hardware maintenance 62 chemical ionization options save the gc/ms method. Methods for single ci reagents open the standard gc/ms method you have created and saved (e.G., ei_gc.Mth) in the saturn gc/ms workstation. Before proceeding use the method editor menu command file… save as to save th...

Page 96: Acquisitions

03-914978-00:1 63 chemical ionization options if you are planning to use a different ci reagent in each channel of the mci module, save a unique gc/ms method specific to each channel of the mci, each with external events programming of the correct event. Under saturn 2000 mass spec control choose th...

Page 97

2000 ms hardware maintenance 64 chemical ionization options to prepare the sample list for alternating ei/ci acquisitions, click on the edit automation files button on the star toolbar or choose the option start…programs…saturn gcms workstation…automation file editor. The automation file editor dial...

Page 98

03-914978-00:1 65 chemical ionization options since ei and ci analyses are to be performed on three samples in succession, enter the appropriate names for the data files in each row of the samplelist. Use the scroll bar at the bottom of the dialog to display fields farther to the right in the sample...

Page 99

2000 ms hardware maintenance 66 chemical ionization options acquisition in the command field and click ok. In this example the method is ei_gc.Mth. Since the same ei_gc method will be used later in the list highlight the autolink button in the list and click on fill down. The ei_gc method is now sel...

Page 100: 3800 Gc Method Section

03-914978-00:1 67 chemical ionization options use the autolink field to activate the appropriate method for the ei or particular ci reagent required. Multiple ci reagents in the same run in some demanding applications, it may be desirable to change ci reagents within a single chromatographic acquisi...

Page 101

2000 ms hardware maintenance 68 chemical ionization options then, while segment 2 is highlighted, click the add twice to create two additional segments. Segment 2 is left as an acetonitrile ci segment ending at 10 minutes. Segment 3 parameters are changed in the ionization mode tab dialog to those f...

Page 102: McI Module Maintenance

03-914978-00:1 69 chemical ionization options in a complex method such as this, it is always advisable to review the ms method to assure that the segment times and acquisition parameters have been entered correctly. Switching times between reagents if one is interested in switching ci reagents on co...

Page 103: Bulbs

2000 ms hardware maintenance 70 chemical ionization options handling and storage of ci liquids in reservoir bulbs use the procedure filling/refilling the liquid ci reservoir bulb to fill the reservoir bulbs (03-920270- 00) with liquid. If you wish to replace a liquid reagent with a different liquid,...

Page 104

03-914978-00:1 71 chemical ionization options adapter fitting and the long restrictor (03-930597-01). The long restrictor was connected between the pneumatics manifold and the gas shut off valve before the mci module was installed. Protect the ends of the restrictors to prevent contamination and plu...

Page 105

2000 ms hardware maintenance 72 chemical ionization options 15. Do not turn on the filament or multiplier for about 2-3 minutes after opening the ci valves. A convenient way to verify that air and water have been removed sufficiently is to check the ion gauge pressure with the ci valves open. Verify...

Page 106: Leak Checking

03-914978-00:1 73 chemical ionization options for more than 20 seconds. After a few seconds, return the valve setting to ½ open or their previous setting (approximately 7 turns). 14. Do not turn on the filament or multiplier for about 2-3 minutes after opening the ci valves. A convenient way to veri...

Page 107

2000 ms hardware maintenance 74 chemical ionization options hints for successful operation of the mci module 1. Acquisition with each ci reagent using the mci module requires a unique gc/ms method. The gc section method must contain external events programming (done in the sample delivery section) t...

Page 108: System Start-Up and Shutdown

03-914978-00:1 75 system start-up and shutdown system start-up and shutdown diffusion pump shutdown note: during the shutdown procedure, the gc and ms temperature zones are reduced ( trap temperature is less than 80 °c. From the system control click on shutdown tab. The display of the shutdown progr...

Page 109: Caution

2000 ms hardware maintenance 76 system start-up and shutdown this represents a group of error messages indicating that the diffusion pump has been shut down. To precisely identify the problem, the user should go to the diagnostics tab, check “system test and run to completion.”. Fault messages may a...

Page 110: Diffusion Pump Startup

03-914978-00:1 77 system start-up and shutdown diffusion pump startup note: the diffusion pump system startup sequence takes at least 30 minutes. First, the peltier baffle cooler is turned on while the pump heater is left off. This step lasts 15 minutes and allows the cooler to drop in temperature b...

Page 111

2000 ms hardware maintenance 78 system start-up and shutdown.

Page 112: Periodic Maintenance

03-914978-00:1 79 mass spectrometer maintenance mass spectrometer maintenance periodic maintenance to ensure the saturn gc/ms peak-performance, you will have to perform periodic maintenance on the vacuum and cooling systems. The following table identifies relevant maintenance intervals. Procedure in...

Page 113: Purging Foreline Pump Oil

2000 ms hardware maintenance 80 mass spectrometer maintenance a foreline b clamping ring c seal d inlet e gas ballast valve f drain plug g oil level sight glass h filler plug i exhaust foreline pump purging foreline pump oil condensable vapors accumulate in the foreline pump oil during routine opera...

Page 114: Changing Foreline Pump Oil

03-914978-00:1 81 mass spectrometer maintenance changing foreline pump oil to ensure peak performance and maximum pump lifetime, change the pump oil whenever the oil becomes thick, dark in color and has a burnt smell; or at least every six months. The oil change must be performed while the oil is wa...

Page 115: Flushing

2000 ms hardware maintenance 82 mass spectrometer maintenance 15. Fill the pump with fresh oil (88-299517-00) through the filler port until the oil level reaches the maximum level in the sight glass. A funnel may be helpful. Flushing the pump should be flushed if the pump oil is particularly dirty. ...

Page 116

03-914978-00:1 83 mass spectrometer maintenance saturn 2000 gc/ms, front view a main power switch (rear panel) j cal gas vial b service switch k vent valve c transfer line heater l rf coil d trap heater m rf coil adjustment screw e manifold heater n transfer line f led o turbomolecular pump g pneuma...

Page 117

2000 ms hardware maintenance 84 mass spectrometer maintenance 3. Turn off the electronics compartment fan via the service isolation switch. • if the noise continues, it is coming from the turbomolecular pump-cooling fan. • if the noise stops, it is coming from the electronics compartment fan. 4. Con...

Page 118

03-914978-00:1 85 mass spectrometer maintenance • take care not to completely unscrew the two inner clamping screws. (if you should unscrew them, restart the screws after you have removed the turbomolecular pump from the instrument.) 12. Remove the outside bottom clamping screw. 13. Remove the botto...

Page 119: Caution

2000 ms hardware maintenance 86 mass spectrometer maintenance check cooling fans diffusion pump system caution to prevent electronics overheating and diffusion pump failure, do not block air intakes or remove covers. Cooling fans perform two important functions in the saturn gc/ms. They prolong the ...

Page 120

03-914978-00:1 87 mass spectrometer maintenance • if not, the fan is broken and should be replaced. Contact your varian customer support representative to arrange for a replacement. 9. Zone 3: diffusion pump compartment. The zone 3 fan is located in the lower left corner of the rear panel. Failure o...

Page 121: Warning:

2000 ms hardware maintenance 88 mass spectrometer maintenance diffusion pump compartment a thermocouple gauge e exhaust clamp b elbow f diffusion pump controller (behind cover) c pneumatics exhaust tube g inlet clamp d diffusion pump h fan turning off the diffusion pumped mass spectrometer warning: ...

Page 122

03-914978-00:1 89 mass spectrometer maintenance replacing the diffusion pump thermocouple gauge the thermocouple gauge will need replacing if its filament has burned out or its thermocouple has become detached. This will be indicated in the diagnostics report. To replace the thermocouple gauge: 1. T...

Page 123

2000 ms hardware maintenance 90 mass spectrometer maintenance 24. Reinstall the clamp by pushing it onto the joined exhaust flanges. 25. Rotate the clamp 180° and install the screw from the left side. 26. Thread the wing nut onto the screw. 27. Rotate the clamp as far to the left as possible, while ...

Page 124: Caution

03-914978-00:1 91 mass spectrometer maintenance 9. Ensure the new seal and sealing surfaces are clean and free of particles and fibers. 10. Fit the new seal to the peltier baffle and lower the baffle into position on the manifold. Do not allow the seal to twist. 11. Reconnect the peltier baffle lead...

Page 125: Removing The Diffusion Pump

2000 ms hardware maintenance 92 mass spectrometer maintenance removing the diffusion pump 1. Turn off the ms. 2. Carefully separate the ms from the gc by approximately 250 mm (10"). Be careful not to break the gc column. 3. Remove the top cover. 4. Remove the transfer line. 5. Rotate the ms to give ...

Page 126: Caution

03-914978-00:1 93 mass spectrometer maintenance 14. Grip the pump with your right hand, tilt towards you until the inlet flange clears the manifold flange. Caution be careful not to scratch or damage sealing surfaces. 15. Pull the pump out to the full extent of its cable. 16. Disconnect the cable fr...

Page 127: Warning

2000 ms hardware maintenance 94 mass spectrometer maintenance cleaning the diffusion pump diffusion pump a circlip j heater assembly b inlet baffle k harness clamp c centering plate & spring l insulation disk d jet assembly m insulation e exhaust baffle & circlip n over temperature switch f sight gl...

Page 128: Caution

03-914978-00:1 95 mass spectrometer maintenance 4. Using a pair of circlip pliers, remove the circlip that holds the exhaust baffle in the exhaust port. Place the circlip on the towels. Caution be careful not to scratch or damage sealing surfaces. 5. Withdraw the baffle and place it on the towels. 6...

Page 129: Caution

2000 ms hardware maintenance 96 mass spectrometer maintenance caution be careful not to scratch or damage sealing surfaces. 21. Pour the diffusion pump fluid (03-930639-01) through one of the holes in the diffusion pump’s inlet baffle. Part number 03-930639-01 contains 40 cm 3 . This is a full charg...

Page 130: Attention

03-914978-00:1 97 mass spectrometer maintenance e. If the heater does not pull out freely, a second application of penetrating oil may be necessary. 9. Apply the anti-seize compound to the new heater and install it in the base. 10. Refit the insulating pad, retaining plate, harness clamp, ground wir...

Page 131: Caution

2000 ms hardware maintenance 98 mass spectrometer maintenance 10. Inspect the exhaust seal. Replace if it is worn or damaged (27-402536-00). 11. Wipe the exhaust seal clean with a lint free cloth, and refit to the exhaust port. 12. Lower the elbow onto the diffusion pump exhaust port. Caution take c...

Page 132

03-914978-00:1 99 mass spectrometer maintenance a inlet clamp d exhaust clamp b manifold e elbow c exhaust f diffusion pump relative positions of the manifold, diffusion pump, elbow and clamps as viewed from above. Note: the manifold and elbow are shown as outlines for clarity. Turning on the mass s...

Page 133

2000 ms hardware maintenance 100 mass spectrometer maintenance how to service the ion trap note: the saturn 2000 maintenance tutorial on cd-rom provides viewing maintenance procedures on computer screen. Refer to ms maintenance section. You will need to service the ion trap if it needs to be cleaned...

Page 134: Warning:

03-914978-00:1 101 mass spectrometer maintenance turn off the mass spectrometer warning: burn hazard allow heated zones to cool before disassembly. Turn off the mass spectrometer by invoking the shutdown procedure. Refer to chapter on system start-up and shutdown. 1. Shut off the turbomolecular pump...

Page 135

2000 ms hardware maintenance 102 mass spectrometer maintenance a heating cable h o-ring b boot i transfer line tip c nut j heating cable slot d ferrule k nose clip e tool l bayonet mount f nose m analyzer assembly tongue g nose hole n analyzer assembly lock-down tabs transfer line assembly remove th...

Page 136

03-914978-00:1 103 mass spectrometer maintenance note: some saturn systems have a transfer line removal flap warning that will block the locking tabs. If such a flap is present, tip it out of the way during the procedure and return it to its original position once the analyzer is replaced. 6. Tilt t...

Page 137

2000 ms hardware maintenance 104 mass spectrometer maintenance replace the electron multiplier when positioned to collect ions, the electron multiplier sits as close as possible to the ion trap. The electron multiplier grid should never be in contact with the trap. To remove the electron multiplier,...

Page 138: Replace The Filament(S)

03-914978-00:1 105 mass spectrometer maintenance replace the filament(s) to replace the filament(s), proceed as follows: 1. Orient the trap so the filament assembly is facing you. 2. Disconnect the filament connectors from the flange-feedthrough pins by gently pulling each pin connector up until the...

Page 139: Remove The Ion Trap Oven

2000 ms hardware maintenance 106 mass spectrometer maintenance remove the ion trap oven using gloves to remove the ion trap oven, proceed as follows: 1. Remove the electron multiplier and place it on its side. 2. Disconnect the filament wires from the flange feed-through pins (labeled 1, 2, c) by ge...

Page 140: Clean The Trap Components

03-914978-00:1 107 mass spectrometer maintenance a screw, 6/32, 4 places h wave washer b clamping plate i gate conductor c exit end cap j trap oven, “t” is located this side. D quartz or silica coated spacer, 2 places k filament assembly e rf ring electrode l filament clip f filament end cap m screw...

Page 141

2000 ms hardware maintenance 108 mass spectrometer maintenance 2. After you clean a part, hold it under running water and use a clean applicator to remove the last visible traces of aluminum oxide. 3. Immediately place the clean part in a beaker containing a solution of detergent and warm water. Not...

Page 142: Reassemble The Trap

03-914978-00:1 109 mass spectrometer maintenance clean silchrom ion trap electrodes the silica top surface of the silchrom ion trap electrode is a very thin (only about 1 µm), but durable layer which is strongly bonded. However, abrasives such as alumina powder must not be used to clean the trap par...

Page 143: Re-Install The Trap Oven

2000 ms hardware maintenance 110 mass spectrometer maintenance note: the orientation of the trap components is important. Make sure that all parts are free of particles, lint, etc. 1. Replace the gate conductor, tab-down into position. 2. Replace the wavy washer on the gate conductor. The washer ori...

Page 144: Install The Transfer Line

03-914978-00:1 111 mass spectrometer maintenance 5. Replace and tighten the nut until it is snug. 6. Attach filament wires 1, 2, and c to the flange feed-through pins. Reposition the electron multiplier to install the electron multiplier, proceed as follows: 1. Slide the electron multiplier forward ...

Page 145: Close The Vent

2000 ms hardware maintenance 112 mass spectrometer maintenance 3. Orient the assembly so that the heating cable fits inside the shell slot. 4. Rotate the nose so that the nose holes line up with the small slots in the shell. These holes will be found at the 4:00 and 10:00 positions. 5. Install the n...

Page 146: Check Ion Trap Operation

03-914978-00:1 113 mass spectrometer maintenance check ion trap operation to check the ion trap operation, proceed as follows: 1. Once bake out is finished, re-establish the analysis temperature in the trap for at least 2 hours to achieve thermal equilibrium. • the manifold temperature should be bel...

Page 147

2000 ms hardware maintenance 114 mass spectrometer maintenance.

Page 148: Gc Maintenance

03-914978-00:1 115 gc maintenance gc maintenance overview note: the saturn 2000 maintenance tutorial on cd-rom provides viewing maintenance procedures on computer screen. Refer to gc maintenance section. It is important for the gc user to learn general maintenance techniques and carry these procedur...

Page 149: General Gc Maintenance

2000 ms hardware maintenance 116 gc maintenance general gc maintenance the common general gc maintenance tasks are checking and changing gas supply cylinders, leak checking, and changing gas purifier filters. These should be performed at the frequency suggested above. The following procedures are cr...

Page 150: Gas Purifier Replacement

03-914978-00:1 117 gc maintenance note: when conducting leak check procedures it is important to completely seal all carrier gas exits, including septum purge and split vent outlets. If more than one injector is present, then the outlets of all the injectors must be sealed. The following procedure r...

Page 151

2000 ms hardware maintenance 118 gc maintenance their lowest possible level. For the ms detector an oxygen filter should be employed as well varian supplies several types of carrier gas purifiers. These include a combined moisture / hydrocarbon trap, indicating moisture trap, indicating or non-indic...

Page 152: Injector Maintenance

03-914978-00:1 119 gc maintenance if filters are mounted on a separate stand: filters have been supplied in either a single combined moisture/hydrocarbon/oxygen filter arrangement or as two filters (a moisture/hydrocarbon filter and oxygen filter). Two valves automatically take care of stopping and ...

Page 153: 1079 Injector

2000 ms hardware maintenance 120 gc maintenance pressure-controlled injector, the column head pressure will remain constant even if a leak is present. Use the following procedure to change a septum on any varian injector: 1. Cool the column oven and injector oven to 50 °c. This ensures safe handling...

Page 154: Remove The Glass Insert

03-914978-00:1 121 gc maintenance refer to the figure below when removing and/or replacing the glass insert. 1 injector nut 2 septum 3 septum purge 4 septum support 5 graphite ferrule 6 carrier gas inlet 7 split vent 8 glass insert 9 fused silica column 10 capillary column nut 11 vespel® ferrule 12 ...

Page 155: Replace The Glass Insert

2000 ms hardware maintenance 122 gc maintenance note: if the gc is equipped with an 8200 autosampler, to access the injector nut, push the carrousel release button (back left) and swing the carrousel out. 2. With tweezers or septum pick, lift the edge of the septum (item 2). Remove the septum. Note:...

Page 156: Clean The Glass Insert

03-914978-00:1 123 gc maintenance 2. Position the tool as shown above on a flat, clean surface. Use clean laboratory tissue on the surface. Tighten the septum support finger-tight. Holding the tool with a 5/8 ″ wrench, give the septum support an extra 1/3 to 1/2 turn past finger-tight. Now unscrew t...

Page 157: Deactivate The Glass Insert

2000 ms hardware maintenance 124 gc maintenance note: rinsing the glass inserts with strong acids or bases or heating to a high temperature will remove the deactivation coating on the glass inserts. Rinsing the glass inserts with solvents or mixed solvents will not remove the deactivation coating. D...

Page 158: Warning:

03-914978-00:1 125 gc maintenance warning: fire hazard use proper eye and skin protection. Methanol and acetone are toxic and flammable chemicals. Exercise appropriate precautions when these chemicals are used. 4. Remove the injector nut, septum, and septum support, with ferrule and insert attached....

Page 159

2000 ms hardware maintenance 126 gc maintenance note: avoid contamination of the transfer line, injector, and capillary column by using clean tools and wearing clean lint-free nylon gloves. As you remove parts, place them on a clean, lint-free, unpainted surface. 4. Use the alignment tool and a 5/...

Page 160

03-914978-00:1 127 gc maintenance how to install a new capillary column in the system to install a new capillary column in the mass spectrometer, proceed as follows: 1. Unwind about 60 cm (24 in.) of the mass spectrometer end of the column from the support cage. 2. Insert this end of the column thro...

Page 161

2000 ms hardware maintenance 128 gc maintenance 19. Gently push the transfer line toward the manifold, and rotate the collar in the clockwise direction until the bayonet lock engages. 20. Reconnect the transfer line heating cable to the mass spectrometer. 21. Gently push the mass spectrometer toward...

Page 162: Troubleshooting

03-914978-00:1 129 troubleshooting troubleshooting how to isolate a gc or mass spectrometer problem in general, whenever you attempt to isolate a saturn gc/ms problem, you will check the system in the following order: • data system • gas chromatograph (gc) • mass spectrometer checking the data syste...

Page 163

2000 ms hardware maintenance 130 troubleshooting there are two procedures for isolating problems associated with the mass spectrometer. Running the auto tune routine from system control will provide you with information about system performance. Running the diagnostics program will initiate a hardwa...

Page 164: Check For An Open Filament

03-914978-00:1 131 troubleshooting check for an open filament diagnostics will determine is one or both filaments are open. If only one filament is open, enter system control. Click on set points. Under filament selection, select the other filament. If both filaments are open, shut down the instrume...

Page 165: Check The Electronics

2000 ms hardware maintenance 132 troubleshooting check the assembly of the trap check whether you have incorrectly installed the oven components, proceeding as follows: 1. Display the axial modulation readback by selecting diagnostics and checking axial modulation under the waveform system box. 2. I...

Page 166: Check The Rf Adjustment

03-914978-00:1 133 troubleshooting note: if, after performing these tests, you are still unable to isolate the cause of the problem, contact your varian customer support representative. What to do if you experience a loss of high mass peaks the loss of high mass peaks maybe due to: • rf ramp needs a...

Page 167: Check The Rf Storage Level

2000 ms hardware maintenance 134 troubleshooting 3. Adjust the rf ramp by turning the rf tuning screw on the front panel. Adjust to minimize the highest reading. Check the rf storage level check whether the rf storage level is incompatible with the scan range, proceeding as follows: 1. Open the meth...

Page 168

03-914978-00:1 135 troubleshooting check the axial modulation setting check whether the axial modulation is set too high or too low, proceeding as follows: 1. Click on set points from manual control. Make sure the axial modulation is set between 2.5 and 5 volts. If you adjust the axial modulation, c...

Page 169: Check The Cal Gas Pressure

2000 ms hardware maintenance 136 troubleshooting what to do if the trap function calibration fails after the calibration ions have been correctly identified if the trap function calibration fails after the calibration ions have been correctly identified, you should investigate the following possible...

Page 170: Caution

03-914978-00:1 137 troubleshooting caution often, major air leaks are accompanied by a hissing sound. These leaks may be due to extremely loose fittings, improperly seated o-rings, or open valves. If you suspect a major leak, do not turn on the electron multiplier, rf voltage, or filament. Using the...

Page 171

2000 ms hardware maintenance 138 troubleshooting air/water spectrum from a system with a very high water vapor background.

Page 172

03-914978-00:1 139 troubleshooting air/water spectrum from a system with excess water vapor and a relatively small air leak • if the ratio of the height of the peak of mass 18 (h 2 o + ) to mass 19 (h 3 o + ) is about 10:1, there is little water vapor in your system. • if the ratio of peak height of...

Page 173

2000 ms hardware maintenance 140 troubleshooting 100% value tic 18:28 ratio 19:18 ratio 28 width ~ 1:1 10 to 15% 7. Spectra observed if there is an air leak in your system. An air/water spectrum obtained from a system with a small air leak and little water vapor as indicated by: • the peak height at...

Page 174

03-914978-00:1 141 troubleshooting an air/water spectrum obtained from a system with a large air leak and little water vapor as indicated by: • the peak at mass 32 is the base (highest) peak. • the peaks at masses 18, 19, and 28 are broadened. As a leak increases, all peaks broaden and eventually be...

Page 175

2000 ms hardware maintenance 142 troubleshooting be sure to wait until all gc zones are cool before beginning. If the leak is coming from the transfer line connection, you will have to shutdown the gc/ms system and vent the system before fixing it. Note: set the mass range from 35 to 50 if you will ...

Page 176: Check Gc Connections:

03-914978-00:1 143 troubleshooting the brass nut on the transfer line is not tight enough, recheck the system. Do not over tighten the fittings. Otherwise, you may generate an even larger leak. If you cannot eliminate the leak, vent the system, and check the o-ring on the manifold and transfer line ...

Page 177: Set Up The Column

2000 ms hardware maintenance 144 troubleshooting how to troubleshoot the gc note: please refer to the gc operator’s manual for information about gc troubleshooting and diagnostics procedures not described in this section. This section describes chromatographic troubleshooting, with particular emphas...

Page 178: Conditions

03-914978-00:1 145 troubleshooting set up the transfer-line and trap-temperature conditions 1. Set the transfer line temperature to 260 °c. 2. Set the trap temperature to 150 °c. 3. Set the manifold temperature to 35 °c. Set up the mass spectrometer acquisition method to set up the mass spectrometer...

Page 179: Problems

2000 ms hardware maintenance 146 troubleshooting typical chromatogram of coltest text mixture the following figure demonstrates the resolving power of saturn for coeluting compounds. Resolution of saturn for coeluting compounds you can also effectively separate the individual components in the mixtu...

Page 180: Active Components

03-914978-00:1 147 troubleshooting correction of solvent tailing or broadening problems symptom solution poor column installation resulting in dead volume in the injector reinstall the column in the injector. Check the column seal with the insert in the spi/1079 (on-column). Make sure you have a goo...

Page 181: Tailing)

2000 ms hardware maintenance 148 troubleshooting correction of leading sample peaks (reverse tailing) symptom solution column overhead due to injection of excessive amounts of a component dilute the sample, or perform a split injection. Degradation of the stationary phase change the column. Carrier ...

Page 182: Chromatogram

03-914978-00:1 149 troubleshooting correction of peak splitting (particularly for low boilers) symptom solution sample flashing in injector (1077, 1078 or 1079), simulating two injections lower the injection temperature, or use a spi/1079 programmed injection. Column temperature programming starts b...

Page 183

2000 ms hardware maintenance 150 troubleshooting.

Page 184: System

03-914978-00:1 151 troubleshooting of diffusion pump system troubleshooting of diffusion pump system overview this section describes symptoms that the user may observe during startup and routine operation. Problems during startup the user should check for faults during startup by monitoring the fore...

Page 185

2000 ms hardware maintenance 152 troubleshooting of diffusion pump system c. Check for air leaks. Refer to how to check for leaks. D. Check the fluid level in the diffusion pump. E. Check the level and condition of foreline pump oil. F. Check the foreline hose between the diffusion pump and foreline...

Page 186

03-914978-00:1 153 troubleshooting of diffusion pump system d. Check the fluid level and condition of the foreline pump, if it’s time for maintenance, change the oil. E. If a foreline trap is used, replace the pellets. F. Check all the vacuum seals: diffusion pump, elbow, foreline pump, etc. The dif...

Page 187

2000 ms hardware maintenance 154 troubleshooting of diffusion pump system common contaminant ions (m/z) compound possible source 18, 28, 32, 44 h 2 o, n 2 , o 2 , co 2 air leak 69, 131, 219, 264, 414, 464, 502, 614 pftba leaking calibration valve 31, 32 methanol cleaning solvent 43, 58 acetone clean...

Page 188: Miscellaneous Procedures and

03-914978-00:1 155 miscellaneous procedures and instructions miscellaneous procedures and instructions other documents other documents that you may wish to consult regarding saturn operation include the following: • software reference, 03-914979-00 • saturn gc/ms workstation tutorials, 03-914988-00 ...

Page 189

2000 ms hardware maintenance 156 miscellaneous procedures and instructions equipment, we recommend a separate dedicated power source for their operation. Note: do not use the free outlet for equipment that draws more than 2 amps. Interconnect diagram for the saturn gc/ms note: avoid using power supp...

Page 190: Quality Of Power

03-914978-00:1 157 miscellaneous procedures and instructions nema 5-20p, nema 5-15p, and cee 7/7 power plugs and outlets with a 120v power source, the maximum amperage requirements for each of the saturn gc/ms components are as follows: component amperes mass spectrometer 12 gas chromatograph 20 var...

Page 191: Operating Environment

2000 ms hardware maintenance 158 miscellaneous procedures and instructions • transients (or impulses) are brief voltage excursions of up to several thousand volts with durations of less than 50 µsec. Constant high line voltage or surges in voltage can produce overheating and component failures. Cons...

Page 192: Exhaust System

03-914978-00:1 159 miscellaneous procedures and instructions exhaust system it is your responsibility to provide an adequate exhaust system. Much of what is introduced into the mass spectrometer will eventually be exhausted from the mechanical pump, along with the small amounts of oil vapor that the...

Page 193: Other Gases

2000 ms hardware maintenance 160 miscellaneous procedures and instructions if you are not sure which one of these cryogenic options you ordered, check your purchase order. Other gases if you ordered an 8200 autosampler or automated valves, an independent supply of air or n 2 at 40-60 psig may be req...

Page 194: Parts And Supplies

03-914978-00:1 161 miscellaneous procedures and instructions 3. Open the vent valve lever on the front of the mass spectrometer for ten minutes. 4. Keep an eye on the capillary column inside the gc as you gently slide the mass spectrometer away from the gc. Be sure not to bend or kink the capillary ...

Page 195: Trap Components

2000 ms hardware maintenance 162 miscellaneous procedures and instructions trap components note: the silica coated spacers have a shiny, mirror like finish on the inside surface. Part number description 03-930552-01 gate conductor 03-930551-01 gate 14-920009-00 wavy washer 03-930315-01 assembly, mul...

Page 196: Diffusion Pump Spares

03-914978-00:1 163 miscellaneous procedures and instructions diffusion pump spares part number description 03-930053-01 chassis fan, electronics side 03-930645-01 chassis fan, pump side 03-920510-00 plastic nut 03-930109-02 o-ring, elbow 27-402294-00 o-ring, diffusion pump inlet 27-402536-00 o-ring,...

Page 197: Gc Spares

2000 ms hardware maintenance 164 miscellaneous procedures and instructions gc spares part number description 03-917742-00 serial i/o pwa 03-925367-31 pwa, cpu, ibdh, 3400 soc 03-925367-33 pwa, cpu, ibdh, 3600 soc 03-918332-01 insert, spi, high performance, glass 03-949551-00 nut, capillary injector ...

Page 198: Additional Saturn Spares

03-914978-00:1 165 miscellaneous procedures and instructions additional saturn spares part number description 03-914763-00 saturn gc/ms workstation hardware maintenance manual 03-914764-00 saturn gc/ms workstation software reference manual 03-914765-00 saturn gc/ms workstation tutorials manual 03-93...

Page 199: McI Module Accessory Kit

2000 ms hardware maintenance 166 miscellaneous procedures and instructions part number description 12-222006-08 screw, 6-32 x 1/2, ss 12-222006-05 screw, 6-32 x 5/16 28-158923-00 tubing, vacuum 28-849918-00 fitting, tee, barb 03-930870-02 cap, polypro, 1/8 inch 03-930109-10 o-ring, 2-104 03-930109-1...

Page 200: Calling Varian Service

03-914978-00:1 167 miscellaneous procedures and instructions calling varian service if you have a problem with your saturn gc/ms that you are unable to resolve using the procedures described, you may want to call a varian customer support representative. When you call, please be prepared to provide ...