- DL manuals

- Varian

- Controller

- sentorr

- Instruction Manual

Varian sentorr Instruction Manual

Summary of sentorr

Page 1

Sentorr ™ gauge controller instruction manual varian vacuum technologies 121 hartwell avenue lexington, massachusetts 02421 (781)861-7200 manual no. 6999-08-165 revision g february 1999.

Page 2: Telephone Numbers

Telephone numbers u.S. Only 1-800-8-varian (1-800-882-7426) from alaska and hawaii, dial (781) 861-7200 order entry (sales)............Press 1........ Fax (781)860-5405 technical support............Press 2........ Fax (781)860-5437 field service............Press 3........ Fax (781)860-9210 training ...

Page 3

Warranty products manufactured by seller are warranted against defects in materials and workmanship for twelve (12) months from date of shipment thereof to customer, and seller’s liability under valid war- ranty claims is limited, at the option of seller, to repair, replacement, or refund of an equi...

Page 4

I hazards operators and service personnel must be aware of all hazards associated with this equipment. They must know how to recognize hazardous and potentially hazardous conditions, and know how to avoid them. The consequences of unskilled, improper, or careless operation of the equipment can be se...

Page 5

Ii an independent agency has determined that all vacuum chambers regardless of manufacture, can possibly become charged to lethal voltage levels, under certain conditions, if they are not grounded with a quality, common ground with the controller of their ionization tube. After each maintenance/serv...

Page 6

Iii warning _____________ this equipment contains high voltages (up to 3000 volts), high enough to produce electric shock and cause death or serious injury. Equipment utilizing these controls should be designed to prevent per- sonal contact with high voltages. Always break the primary circuit when d...

Page 7

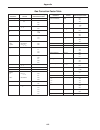

Table of contents page safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I i introduction and description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1-1 general . . . . . . . . . . . . . . . . . . . ...

Page 8

Section 1 introduction and description 1-1 general varian’s sentorr gauge controller is a complete, half-rack vacuum gauge controller that offers contin- uous, reliable pressure measurement from rough to high vacuum. The controller comes completely configured from the factory to operate one of six g...

Page 9

Introduction and description varian cannot guarantee compliance with fcc regulations for radiated emissions unless all external wiring is shielded. (see page iii) hfig gauge (ba2, ba2c, ba, uhv, uhv2c models) minimum pressure 1.3 x 10 -7 pa/1 x 10 -9 torr (ba) capability 5.3 x 10 -9 pa/4 x 10 -11 to...

Page 10

Introduction and description heater current 165 ma ± 10% (tc models) calibration 1.3 x 10 -1 pa /1 x 10 -3 torr (vacuum) (two points) 1.0 x 10 5 pa/7.6 x 10 2 torr (atmosphere) auto-on threshold 1.3 x 10 -1 pa to 6.6 pa (1 x 10 -3 torr to 5 x 10 -2 torr) (available on tc1 only) analog output 1 v/dec...

Page 11

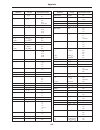

To determine the ordering number, select the desired configuration as follows: basic configurations one ion gauge ba – bayard-alpert (563, 564, 571, 572, 580) . . . . . L 9 1 2 0 3 0 1 x x 0 x cc – standard cold cathode (524, 525) . . . . . . . . . L 9 1 2 1 3 0 1 x x 0 x uhv – ultra-high-vacuum nud...

Page 12

Introduction and description 1-4 part numbers and descriptions 1-5 serial communication the sentorr offers computer interface options allowing complete operation of the unit remotely via ser- ial link. The rs232 option consists of a plug-in printed circuit board (varian part no. L9141301) avail- abl...

Page 13

Introduction and description 1-6.

Page 14

Section ii preparation for use 2-1 unpacking each sentorr unit is inspected and carefully packed prior to shipment. If the unit arrives damaged, save the packing material and immediately notify the carrier. Because the packing materials are designed specifically for this instrument, they should alwa...

Page 15

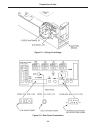

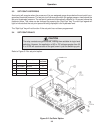

2-2 preparation for use figure 2-2. Rear panel connections figure 2-1. Setting line voltage.

Page 16

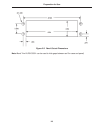

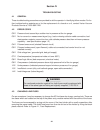

2-3 preparation for use figure 2-3. Panel cutout dimensions note: bezel trim kit r0130301 can be used to hide gaps between sentorr case and panel).

Page 17

2-4 preparation for use.

Page 18

Section iii operation 3-1 keypad functions refer to figure 3-1 for the locations of the keys and display features described in following paragraphs. Following each key name are the sentorr models and the option (if any) to which the function applies. Note that some of the keys may not work unless a ...

Page 19

Operation 9. Baud rate key (all models) this key is used to display and set the serial communications baud rate, parity, and the controller address (for use in a multi-drop communication link. After pressing “baud rate”, the baud rate will flash in the ig display mantissa. Use the arrow keys to sele...

Page 20

Operation 3-2 parameter programming the set point and ion gauge parameters listed in a column on the front panel display (see figure 3-1) can be viewed or programmed by putting the sentorr into the program mode. To the left of each para- meter is a single yellow led. If the yellow led is flashing, t...

Page 21

Operation tc2 setpt (all models with tc or convectorrs with set point option) the tc2 set point can be set to energize when tc2 reads less than the tc2 setpt threshold setting. It will de-energize when the tc2 pressure goes above the tc2 setpt hysteresis setting (refer to para. 3-3, set point hyster...

Page 22

Operation 3-5 3-3 set point hysteresis a set point will energize when the pressure of its pre-assigned gauge drops below the set point's pro- grammed threshold pressure. The set point will de-energize when the gauge pressure rises above the set point hysteresis pressure. The set point hysteresis aut...

Page 23

Operation 3-6 figure 3-3. Assembling the cable 3-5 recorder output recorder output for each gauge is provided at the back of the unit. A two-conductor micro jax con- nector is plugged into each output. Varian strongly recommends the use of shielded wiring (coaxial cable) to maintain compliance with ...

Page 24

Operation 3-7 figure 3-4a. Standard recorder output characteristics.

Page 25

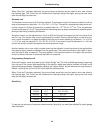

Operation 3-8 pressure pressure voltage ≥ 133 pa ≥ 1e +0 torr 10 1.3 e1 pa 1e-1torr 1 6.6 pa 5e-2torr 0.5 1.3 pa 1e-2torr 0.1 ≤ 1.3e-1 pa ≤ 1e-3torr 0.01 error e03 error e03 10.156 (over scale) optional linear recorder output for tc configuration (requires optionally puchased firmware) full scale fu...

Page 26

Operation 3-9 3-6 tc and convectorr calibration expose the desired thermocouple or convectorr to either atmospheric pressure or to a vacuum greater than 1.3 x 10 -1 pa (1 x 10 -3 torr). Press the “cal” key once to calibrate tc1, or twice to calibrate tc2. The respective pressure display will flash e...

Page 27

Operation 3-10 3-9 display test by pressing “enter” and the “up” arrow, the entire display can be lit for several seconds. This feature can be used to verify led function. 3-10 battery backup the sentorr uses a lithium battery and cmos ram for storage of all system parameters during power outages or...

Page 28

4-1 warning _____________ for continued protection against fire, both fuses must be replaced with fuses of the same type and rating as originally supplied; t, 5a, 250 v. 4-3 changing line fuses on rare occasions, it may be necessary to change the ac line fuses due to age, overload, etc. There are tw...

Page 29

Troubleshooting 4-2 4-4 application footnotes gas correction the gas correction factor tables are reproduced for the convenience of the user and do not imply that use with other gases will be safe with filament gauge controllers. The sentorr gauge controller is normally calibrated to read pressure i...

Page 30

Troubleshooting 4-3 when “gas corr” has been selected, the up and down arrow keys can be used to set a new value to the flashing digit. The “enter” key will advance the flashing through the digits, saving the new value after the last digit has been set. Emission ma the emission current is set to 4.0...

Page 31: Troubleshooting Tips

Troubleshooting 4-4 troubleshooting tips • to aid in troubleshooting and to verify the integrity of the ion gauge controller or the cold cathode gauge itself, one can use a resistive dummy load. Obtain a 5.6 meg ohm, 2 watt resistor. This value will simulate a pressure reading in the mid e-3 pa/e-5 ...

Page 32

A-1 appendix a gas correction factor table gas correction factor tables are only reproduced for the convenience of the user and do not imply that use with other gases will be safe with hot filament gauge controllers. The following table lists relative gauge gas correction factors for various gases. ...

Page 33

Appendix a-2 relative ionization gauge substance formula gas correction factor acetaldehyde c 2 h 4 o 2.6 acetone (ch 3 ) 2 co 3.6 4.0 3.6 acetylene c 2 h 2 1.9 2.0 air 1.0 0.98 ammonia nh 3 1.3 1.2 1.3 amylene: iso · iso · c 5 h 10 5.9 cyclo · cy · c 5 h 10 5.8 argon ar 1.3 1.1 1.2 0.9 benzene c 6 ...

Page 34

Appendix a-3 relative ionization gauge substance formula gas correction factor ethyl ether (c 2 h 5 ) 2 o 5.1 5.1 ethylene c 2 h 4 2.3 2.4 2.2 2.2 to 2.5 ethylene oxide (ch 2 ) 2 o 2.5 helium he 0.18 0.15 0.13 0.12 heptane c 7 h 16 8.6 hexadiene: 1.5 · 1.5 · c 5 h 10 6.4 cyclo · cy · c 6 h 10 6.0 he...

Page 35

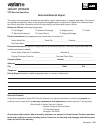

Health and safety clearance return authorization policy in compliance with federal osha safety standard 1910.1200, hazard communications “right to know”, varian is enforcing that standard to preclude the potential health risk to its service person- nel that can occur when receiving, disassembling, o...

Page 36

Returned material report this report must accompany all products returned for repair, replacement, or warranty evaluation. Full informa- tion regarding reasons for return of the product will expedite repair or adjustment. Please fill in all blanks below and furnish any other information which will h...