- DL manuals

- Varian

- Power Pump

- VHS-250

- Instruction Manual

Varian VHS-250 Instruction Manual

Summary of VHS-250

Page 1

Instruction manual vacuum technologies vhs-4, vhs-6 and vhs-250 diffusion pumps part no. 699901024 revision a february 2005.

Page 2: Vhs-4, Vhs-6 and Vhs-250

Copyright 2005 vacuum technologies vhs-4, vhs-6 and vhs-250 diffusion pumps.

Page 3: Warranty

Vhs-4, vhs-6 and vhs-250 diffusion pumps iii warranty products manufactured by seller are warranted against defects in materials and workmanship for twelve (12) months from date of shipment thereof to customer, and seller’s liability under valid warranty claims is limited, at the option of seller, t...

Page 4

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank..

Page 5: Declaration Of Conformity

Varian, inc. Declare under our sole responsibility that the product, erklären, in alleniniger verantwortung, daß dieses produkt, déclarons sous notre seule responsabilité que le produit, declaramos, bajo nuestra sola responsabilidad, que el producto, verklaren onder onze verantwoordelijkheid, dat he...

Page 6

Vhs-4, vhs-6 and vhs-250 diffusion pump this page intentionally left blank..

Page 7: Contents

Vhs-4, vhs-6 and vhs-250 diffusion pumps vii contents introduction ............................................................................................................................... 1-1 pump specifications ....................................................................................

Page 8

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank..

Page 9: Figures

Vhs-4, vhs-6 and vhs-250 diffusion pumps ix figures 1-1 vhs-4 speed and throughput curves .................................................................................. 1-4 1-2 vhs-4 wiring information .................................................................................................

Page 10

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank..

Page 11: Tables

Vhs-4, vhs-6 and vhs-250 diffusion pumps xi tables 1-1 pump operational specifications ........................................................................................ 1-1 1-2 vhs-4 dimensions ......................................................................................................

Page 12

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank..

Page 13: Preface

Vhs-4, vhs-6 and vhs-250 diffusion pumps xiii preface instructions for use this equipment is designed for use by professionals. Read this instruction manual and any other additional information supplied by vacuum technologies before operating the equipment. Vacuum technologies will not be held respo...

Page 14: Safety

Vhs-4, vhs-6 and vhs-250 diffusion pumps xiv safety diffusion pump hazards designers of systems utilizing diffusion pumps must design out hazards wherever possible. For hazards that cannot be designed out, warnings, procedures, and instructions on proper use and servicing are provided. Please use gu...

Page 15

Vhs-4, vhs-6 and vhs-250 diffusion pumps xv general hazards hazard suggested corrective action loss of utility: water and/or electricity provide sufficient backup water and power supply as necessary to effect a safe shutdown under worst case conditions. Overpressure in foreline provide an interlock ...

Page 16

Vhs-4, vhs-6 and vhs-250 diffusion pumps xvi explosion operation of the diffusion pump without continuous evacuation below 0.5 torr (0.67 mbar) or without coolant, and then introducing a strong oxidizer (such as air), explosive vapors, powders, or materials which may react with pumping fluids in a h...

Page 17

Vhs-4, vhs-6 and vhs-250 diffusion pumps xvii explosive conditions prohibited action explosion-causing condition do not run pump without cooling water. Overtemperature do not run pump with low level of pump fluid. Overtemperature do not run pump without proper backing or holding pump. Overpressure d...

Page 18

Vhs-4, vhs-6 and vhs-250 diffusion pumps xviii pressurization hazards large vacuum pumps and their components are designed for vacuum service. They are not designed to be pressurized, which can cause them to burst and possibly expel shrapnel at lethal velocities. Serious accidents have been caused b...

Page 19

Vhs-4, vhs-6 and vhs-250 diffusion pumps xix dangerous substances chemical dangers of acetone and alcohol diffusion pumps are typically cleaned with acetone or alcohol. Acetone, alcohol, and most other solvents are irritants, narcotics, and depressants, and/or carcinogenic. Their inhalation and inge...

Page 20

Vhs-4, vhs-6 and vhs-250 diffusion pumps xx high temperatures hot surfaces boiler temperatures reach 530 °f (275 °c) which can cause serious burns. Always ensure that surfaces have cooled to near room temperature before touching them. Hot cooling water and steam the water used to cool the pump can r...

Page 21: Ft 3/9

1-1 vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 section 1. Introduction and installation 1.1 introduction before unpacking and installing a vhs-4, vhs-6 or vhs-250 diffusion pump, thoroughly familiarize yourself with this instruction manual and the diffusion pump operational specifica...

Page 22: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-2 d r a ft 3/9 / 05 backstreaming rate at pump inlet 5x10 −4 mg/cm 2 /minute (with std cold cap) electrical requirements 120, 208, 240; 50/60 hz; single phase warm-up time 10 minutes cooldown time (using quick cool coil) 10 minutes fluid charge vhs-4: 300 c...

Page 23: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-3 heater circuit resistance (ohms) vhs-4: 1450 watts 120 v – 10 208 v – 29.8 240 v – 39.7 vhs-6 and vhs-250: 2200 watts 120 v – 6.5 208 v – 19.6 240 v – 26.1 clearance (for heater removal) 6" minimum materials body, flanges, foreline, baff...

Page 24: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-4 d r a ft 3/9 / 05 figure 1-1 shows the vhs-4 speed and throughput curves. Figure 1-1 vhs-4 speed and throughput curves note speed curves were generated according to avs standard 4.1. Figure 1-2 gives the vhs-4 wiring information. Figure 1-2 vhs-4 wiring i...

Page 25: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-5 table 1-2 lists the vhs-4 dimensions. Table 1-2 vhs-4 dimensions asa iso conflat in mm in mm in mm height 18.05 458 18.05 458 18.05 458 centerline to centerline 10.62 270 10.62 270 10.62 270 flange face to flange face 5.03 128 5.03 128 5...

Page 26: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-6 d r a ft 3/9 / 05 figure 1-3 shows the vhs-6 speed and throughput curves. Figure 1-3 vhs-6 speed and throughput curves figure 1-4 gives the vhs-6 schematic and wiring information. Figure 1-4 vhs-6 wiring information.

Page 27: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-7 table 1-3 lists the vhs-6 dimensions. Table 1-3 vhs-6 dimensions asa iso conflat in mm in mm in mm height 21.92 557 21.92 557 21.92 557 centerline to centerline 13.38 340 13.38 340 13.38 340 flange face to flange face 8.62 219 8.62 219 8...

Page 28: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-8 d r a ft 3/9 / 05 figure 1-5 shows the vhs-250 speed and throughput curves. Figure 1-5 vhs-250 speed and throughput curves figure 1-6 gives the vhs-250 schematic and wiring information. Figure 1-6 vhs-250 wiring information.

Page 29: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-9 table 1-4 lists the vhs-250 dimensions. Table 1-4 vhs-250 dimensions iso in mm height 22.79 579 centerline to centerline 13.38 340 flange face to flange face 9.56 243 electrical box height 9.12 232 sight glass, degrees from foreline 90° ...

Page 30: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-10 d r a ft 3/9 / 05 1.2 installation installation consists of: ❑ section 1.2.2 “unpacking” ❑ section 1.2.3 “pump oil installation” ❑ section 1.2.4 “vacuum system connections” on page 1-11 ❑ section 1.2.5 “cooling water connections” on page 1-11 ❑ section 1...

Page 31: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-11 1.2.4 vacuum system connections warning utility failure can cause damage to the equipment, overheating, and explosions. Diffusion pump equipment designers must take appropriate system design action to protect personnel and property from...

Page 32: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 1-12 d r a ft 3/9 / 05 ❑ the minimum rating of this system should be 85% of the maximum power rating of the diffusion pump. ❑ the quick cool coil feed line, located at the boiler plate, should be controlled by a separate three-way valve (open, closed, and ven...

Page 33: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 1-13 1.2.7 thermal switch the pump has been fitted with a manually-resettable thermal switch that is preset at the factory. This switch is located in a box near the bottom of the pump and provides protection to the pump in the event of exces...

Page 34: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank. D r a ft 3/9 / 05.

Page 35: Ft 2/

2-1 vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 2/ 24 /05 section 2. Operation caution ❑ before turning on the heater, ensure there is fluid in the pump. Running the heater without fluid can ruin the heater and damage the pump. ❑ do not air-release the pump while the boiler is hot. Most diffus...

Page 36: Ft 2/

Vhs-4, vhs-6 and vhs-250 diffusion pumps 2-2 d r a ft 2/ 24 /05 5. Monitor inlet and foreline pressures. During operation of the diffusion pump: ❑ the gas load at the inlet should not exceed the maximum throughput capability of the pump. ❑ the forepressure should not exceed the specified tolerable f...

Page 37: Ft 3/9

3-1 vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 section 3. Maintenance and service 3.1 general maintenance diffusion pumps generally require little attention when operated correctly. It is advisable to perform some periodic inspections to ensure trouble-free operation. By performing s...

Page 38: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 3-2 d r a ft 3/9 / 05 ❑ ensure that the cooling water flow is adequate and unobstructed. In areas where the mineral content of the water is high or where there is considerable sediment, it may be advisable to install water filters. 3.3 cleaning complete clean...

Page 39: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 3-3 3.4 vhs-4 and vhs-6 cold cap removal/installation to remove the cold cap: 1. Remove the spring (1) (figure 3-1) attached by round head screw (2), a flat washer (3) and a lock washer (4). The screw types are: ❑ vhs-4: no. 8-32x 3/16 ❑ vhs...

Page 40: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 3-4 d r a ft 3/9 / 05 3.5 vhs-250 cold cap removal/installation to remove the cold cap: 1. Remove the spring (j) attached by the 6-32x 3/16 round head screw (h), a flat washer and a lock washer (figure 3-2). 2. Loosen the nuts (l) holding the cold cap bracket...

Page 41: Ft 3/9

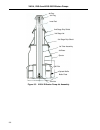

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 3-5 3.6 jet assembly removal/installation to remove the jet assembly: 1. Remove the cold cap from the pump (figure 3-3). 2. Unscrew the top cap from the jet assembly. 3. Lift out each section of the jet assembly, being careful not to dent or...

Page 42: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 3-6 d r a ft 3/9 / 05 figure 3-3 vhs-4 diffusion pump jet assembly jet cap jet plug inner rod 2nd stage drip shield 3rd stage jet 3rd stage drip shield jet tube assembly jet base ejector splash baffle boiler plate jam nut 4.00 flat.

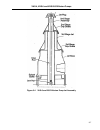

Page 43: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 3-7 figure 3-4 vhs-6 and 250 diffusion pump jet assembly.

Page 44: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 3-8 d r a ft 3/9 / 05 3.7 heater replacement refer to figure 3-5 (vhs-6 and vhs-250) and figure 3-6 (vhs-4) for this procedure: 1. Turn off the power to the diffusion pump and disconnect the power supply. 2. Remove the heater cover and the insulation from the...

Page 45: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 3-9 figure 3-6 vhs-4 heater mounting heater element 647304205 1450 w, 120 v 647304210 1450 w, 208 v 647304250 1450 w, 240 v.

Page 46: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 3-10 d r a ft 3/9 / 05 3.8 pump fluid charge the recommended fluid charge is: ❑ 300 cc for the vhs-4 ❑ 500 cc for vhs-6 and vhs-240 the fluid charge will gradually be depleted through use, but the pump will continue to operate normally. When the charge is red...

Page 47: Ft 3/9

4-1 vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 section 4. Troubleshooting 4.1 leakage analysis of general operational experience with diffusion pumps indicates that certain locations are more prone to vacuum leaks. The following locations should be checked first if leakage is the sus...

Page 48: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 4-2 d r a ft 3/9 / 05 4.3 poor pump or system performance before proceeding with a step-by-step troubleshooting program, check the performance and accuracy of the vacuum gauges used on the system. Table 4-1 shows the most frequent faults, their probable cause...

Page 49: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 4-3 inlet pressure surges incorrect heater voltage. Check and correct voltage. Fluid outgassing. Condition pump fluid by operating pump for a few hours. Leak in system ahead of pump inlet. Check and correct. High chamber contamination forepr...

Page 50: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank. D r a ft 3/9 / 05.

Page 51: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 5-1 section 5. Replacement parts table 5-1 lists the vhs-4 models. Table 5-2 lists the vhs-4 replacement parts available from vacuum technologies. Table 5-1 vhs-4 models pump voltage part number flange type asa iso conflat standard cold cap ...

Page 52: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 5-2 d r a ft 3/9 / 05 table 5-3 lists the vhs-6 models. Table 5-4 lists the vhs-6 replacement parts available from vacuum technologies. 88164301 heater clamp commercial heater clamp nut, 31/48 -16, hex, stainless steel 694492156 baffle retaining ring k0377183...

Page 53: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 5-3 table 5-4 vhs-6 replacement parts part number description 86488301 standard cold cap assembly f6455301 extended cold cap assembly f3365301 jet assembly f3373301 splash baffle l9172301 foreline baffle assembly 642906025 thermoswitch kit 6...

Page 54: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps 5-4 d r a ft 3/9 / 05 table 5-5 lists the vhs-250 models. Table 5-6 lists the vhs-250 replacement parts available from vacuum technologies. Commercial washer, flat, no. 6, stainless steel commercial washer, lock, no. 6, stainless steel commercial stud, no. 8-...

Page 55: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps d r a ft 3/9 / 05 5-5 86088301 heater cover plate l8998001 heater insulating blanket l8997001 heater cover k0377178 o-ring kit includes: ❑ 3 butyl inlet flange o-ring, parker no. 2-332 ❑ 3-butyl-n foreline flange o-ring, parker no. 2-379 ❑ 10 viton fill and d...

Page 56: Ft 3/9

Vhs-4, vhs-6 and vhs-250 diffusion pumps this page intentionally left blank. D r a ft 3/9 / 05.

Page 57

Request for return health and safety certification 1. Return authorization numbers (ra#) will not be issued for any product until this certificate is completed and returned to a varian, inc. Customer service representative. 2. Pack goods appropriately and drain all oil from rotary vane and diffusion...

Page 58

Request for return health and safety certification failure report (please describe in detail the nature of the malfunction to assist us in performing failure analysis): t urbo p umps and t urbocontrollers i on p umps / controllers v alves / components l eak d etectors i nstruments a ll o ther v aria...

Page 60

Sales and service offices 12/04 canada central coordination through: varian, inc. 121 hartwell avenue lexington, ma 02421 usa tel: (781) 861 7200 fax: (781) 860 5437 toll free: (800) 882 7426 china varian technologies - beijing room 1201, jinyu mansion no. 129a, xuanwumen xidajie xicheng district be...