- DL manuals

- Varimixer

- Mixer

- AR200

- Operating Instructions Manual

Varimixer AR200 Operating Instructions Manual

Summary of AR200

Page 1

A/s wodschow & co. Kirkebjerg søpark 6 dk-2605 brøndby phone: +45 43 44 22 88 info@wodschow.Dk www.Bearvarimixer.Com denmark ergo60 ergo100 ergo140 ar200 vl-4 032017 order no.: 00453 gb t ranslation of the original user manual operating instructions.

Page 2

2 g eneral : in case of complaints, please contact your supplier. The guarantee does not cover faults resulting from faulty operation, overloading and lacking observance of directions of maintenance. It should be checked that all loose parts are delivered with the mixer such as bowl, tools, and rubb...

Page 3

3 c onstruction of the mixer : bowl clamping system with inductive sensor: at the back of the right- hand bowl arm is an in- ductive sensor which is activated when the bowl is correctly positioned in the bowl clamping system (at the very back of the bowl arms). This sensor must be activated in order...

Page 4

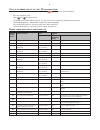

4 capacities per mix ergo 60 ergo 100 ergo 140 ar200 tool egg white 9 l 15 l 21 l 27l whip whipped cream 15 l 45 l 75 l 120l mayonnaise * 48 l 80 l 112 l 160l layer cake base 15 kg 25 kg 35 kg 50kg herb butter 45 kg 75 kg 105 kg 120kg beater muffins * 33 kg 60 kg 85 kg 100kg meatball mix 45 kg 75 kg...

Page 5

5 c ontrol p anel vl4: bowl up to raise the bowl, press the + + fields simultaneously and con- stantly until the bowl reaches the top. Start/stop bowl down lowers the bowl once the mixer has stopped. If this field is activated while the mixer is running, the bowl will be lowered auto- matically when...

Page 6

6 1 2 3 4 remix remix remix remix vl4 control panel - survey of various operating situations : the following pictures show various operating situations and corresponding explanation: if the field is activated while the mixer is running, the chosen operation time is reset and the speed is set to mini...

Page 7

7 remix remix remix remix remix remix 5 6 7 8 9 10 the safety guard has been opened while the mixer was run- ning. The bowl can be lowered. When the safety guard is closed and the operator presses twice, the mixer starts at its lowest speed. As figure 6, but automatic lowering of the bowl is selecte...

Page 8

8 o peration of the mixer : before starting the mixer: mount the required tool in the bayonet shaft. Place the bowl in the bowl arms and close the safety guard. To raise the bowl, activate the fields , and simultaneously, the activation to be continued until the bowl has reached its top position. Wh...

Page 9

9 o verload : do not overload the mixer. Sticky and heavy doughs can overload the mixer. Overloading is further exac- erbated if the speed of the mixing tool is increased beyond the recommended values or if a wrong mixing tool is used. Large lumps of fat or cooled ingredients must be cut into small ...

Page 10

10 m echanical component error : the bowl is too tight or too loose in the bowl arms. Solution: “adjustment of bowl clamping and centering”, page 12 the tool hits the sides of the bowl. Solution: “adjustment of bowl clamping and centering”, page 12 abnormal noise from the lifting actuator: solution:...

Page 11

11 c all up an error log of the last 10 disconnections : the last 10 disconnections due to errors resulting in code can be read on the mixer display: • press the emergency stop • press and to browse the log • the diodes on the speed indicator light up. The age of the error is indicated by the diode ...

Page 12

12 a djustment of bowl centering ergo60 and ergo100: first find the present bowl centering: mount the beater and the bowl, then raise the bowl arms up to normal working posi- tion. With your hand turn the beater, and then measure the distance between beater and bowl edge. By removing the rear coveri...

Page 13

13 a djusting of bowl clamping and centering ergo140 and ar200: in the rear part of the bowl arms (j) a shaft with an eccentric stud (k) has been mounted, on which the ball bearing is mounted. By turning the eccentric stud, the bowl arms can be opened and closed so that the clamping and the centerin...

Page 14

14 ¡ ¢ ¢ ¢ ¢ £ ¢ ¢ £ ¤ ¤ ¢ ¢ ¢ ¢ ¤ £ ¤ ¤ ¤ ¢ ¢ ¢ ¢ ¢ £ ¢ ¢ ¢ £ ¤ ¢ ¢ ¢ £ ¢ ¢ £ ¢ ¢ ¢ ¤ ¢ ¢ ¢ ¢ £ ¢ ¢ ¥ ¦ ¤ ¦ ¢ ¢ ¢ ¤ ¦ § § § ¤ ¦ ¤ ¢ ¦ ¤ ¢ ¥ ¥ ¤ ¦ ¤ ¦ ¤ ¥ ¦ ¤ ¦ ¤ ¥ ¦ ¦ ¢ ¢ ¥ ¦ ¤ ¢ ¥ ¢ ¥ ¢ ¥ ¥ ¢ ¥ ¤ ¢ ¥ ¦ ¦ ¤ ¦ ¢ ¥ ¦ ¤ ¢ ¤ ¢ ¢ ¢ § § ¢ ¥ ¥ ¥ ¥ ¢ ¢ ¢ ¤ § § ¥ ¤ ¥ ¢ ¢¥ ¥ ¥ ¢¥ ¤...

Page 15

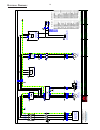

15 ¡ s afety circuit :.

Page 16

16 e lectrical d iagrams : 1 2 3 4 5 6 7 8 s id e f o rr ige s ide : n æ st e s ide : a n ta l si de r ia lt: si d st ud sk re v e t: si d st re tt e t: si de re v .: p ro jek tr e v .: g od k . ( da to /i n it ): k on st r. (p ro je k t/ si de ): t egn ing sn r. : s a g sn r. : p ro jek tt it e l: ...

Page 17

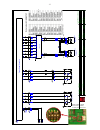

17 deep-switche must be in off-position, as they are not in use 1 2 3 4 5 6 7 8 w ire c od e , ie c /e n 6075 7 p ur p l e yegn yellowgreen ogbn orangebrown si de fo rr ige s ide : n æ st e si de : a nt al s ide r i al t: si ds t ud sk re ve t: si ds t r ett et : si de re v. : pr oj ek tr ev .: g od...

Page 18

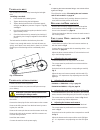

18 cc f dl fig. 2. Belt tension. T o replace a lifting actuator : lift the bowl arms to the top position. Lower the bowl arms to a pressure relief point set at ap- prox. Midway. It is very important that the bowl arms are lowered to a pressure relief point before dis- assembling the lifting actuator...

Page 19

19 a/s wodschow & co. Industrisvinget 6 dk-2605 broendby www.Bearvarimixer.Dk date: design: format: dimension: matr: 26-05-2010 mh a3 stroke 616mm rev: scale: surface: a b c x/y x/y ergo60: a = 35 mm b = 230 mm c = 520 mm ergo100: a = 60 mm b = 250 mm c = 630 mm ergo140: a = 15 mm b = 200 mm c = 633...

Page 20

20 a b c d l ubrication overview : part location oil/grease explanation frequency bushings in the bowl arms item a, fig.6 organic oil or grease, e.G texaco startplex ep remove the back cover. Lubricate the bowl arm axle with grease. Per 5,000 batches or min. Once yearly or in case of unusual noise. ...

Page 21: Prepar

21 relubricating of lifting actuator spindle on ergo 60-100-140 page 1 • the gear of the actuator is lubricated for life and does not need to be serviced. • the spindle and the spindle nut in the actual actuator are not lubricated for life and therefore need relubricating. • the actuator is thorough...

Page 22: Mar

22 relubricating of lifting actuator spindle on ergo 60-100-140 page 2 mar king of lo wer reed swi tch (proxi mity sensor) 60l • three reed switches are fitted to the spindle tube. The bottom switch must be loosened before the spindle tube can be moved. • mark with a dark marker pen around the switc...

Page 23: Reed Swi

23 relubricating of lifting actuator spindle on ergo 60-100-140 page 3 lubricate the spindle with grease 60l-100l-140l • lubricate the spindle with grease of the type mobilith shc460 from mobil. • no other type of grease may be used spindle tube in place 60l-100l-140l • lift the spindle tube into po...

Page 24

24 indhold af overensstemmelseserklæring, (maskindirektivet, 2006/42/ec, bilag ii, del a) dk contents of the declaration of conformity for machinery, (machinery directive 2006/42/ec, annex ii., sub. A) gb inhalt der konformitätserklärung für maschinen, (richtlinie 2006/42/eg, anhang ii, sub a) de co...