- DL manuals

- Varimixer

- Control Systems

- Cinnabon 40

- User Manual

Varimixer Cinnabon 40 User Manual

Summary of Cinnabon 40

Page 1

The programmable control system mk-iv user’s manual.

Page 3

General descriptions modes the system contains six different modes: 1. Manual mode: the mode when the mixer is operated like a man- ual controlled mixer. Instead of executing a programmed recipe, the mixer is started and operated until it is manually shut off. 2. Programming mode: the mode where all...

Page 4

The keypad the keypad is used for entering data to the system. Item function explanation 1. Program no. Displays the program number being executed. 2. Step displays the step number being executed. 3. Speed displays the set-speed. 4. Time displays the elapsed time since start or displays the remainin...

Page 5

6. Enter used for stepping through a program. 7. Clr 8. Speed up/down arrows. 9. Time up/down arrows. 10. Program 11. Pause 12. Numeric keys 13. Emergency stop clears a flashing display. Used for adjusting the the speed while the mixer is running. Used for adjusting the the time. Used to enter/exit ...

Page 6

How to run the mixer manually. Speed mode. Enter the speed desired. Push enter the time desired. Push push how to input a program. A flashing display indicates that it is expecting the operator to key in a value. A step is always a combination of speed and time. An example is 100 r.P.M. For 5:00 min...

Page 7

To program a recipe. Push push enter the speed desired. “hold for 3 seconds” repeat this process for as many as 9 steps per program, after the 9th step , the next program num- ber will display, ready to enter a new recipe.This will continue up to 25 programs. Push push enter the time desired. Exampl...

Page 8

To run a programmed recipe. Push push enter the program number. Push after the enter key has been pushed, the data in step 1 will be displayed along with the program number. After the last program step has been executed, the mixer will slow to minimum speed and shut off. The mixer can be stopped at ...

Page 9

To enter “fixed mode” push push “99” “hold for 3 seconds” push push “1 2 3 4” push push the program number. Push to exit “fixed mode” push “hold for 3 seconds” push “1 2 3 4” push 7.

Page 10

Control data for program 26 program 26 contains the control data required by the computer to operate. This data differs from model to model. To access program 26. Push “hold for 3 seconds” push push “26” push “1 2 3 4” push push until you reach step 7. Enter the value on the following chart that mat...

Page 11

A d in the electronics fail. It is possible to bypass the control system if the electronics fail. Please note, when the system is bypassed, the safety devices do not operate. Extreme care should be taken when operating the mixer. 1. Switch off the main power. 2. Open the top lid, flip the dip switch...

Page 12: Error Codes

E:401 e:301 e:201 error codes a error in the mixer will trigger an error code in the time display. See the chart below for an explanation of error codes and the procedure for correcting them. E:201 the servo motor block actuator (b) did not contact the minimum speed microswitch (a) after the stop bu...

Page 13: E:301

E:301 there is no signal from the speed pickup (hall effect sensor). To correct this error: 1) check that the sensor (d) is centered directly above the track of the 3 magnets (f) on the pulley and the gap between the sensor and magnets is 1/16”. If not , bend and / or move the bracket (i) holding th...

Page 14: E:4:01

E:4:01 the values in program 26 steps 7, 8 and 9 are missing or incorrect. To correct this error: push “hold for 3 seconds” push push “26” push “1 2 3 4” push push until you reach step 7. Enter the value on the following chart that matches the mixer model. Repeat for step 8 and 9. Step 7 mixer model...

Page 15

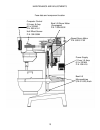

Maintenance and adjustments computer control 2 fuses: 8 amp 6.3 x 32 mm p.N. 20e-418.1 power supply 1 fuse:1.5 amp 6.3 x 32 mm p.N. 20e-418 fuse data and component location hall effect sensor p.N. 30e-500m bowl lift servo motor (if equipped) p.N. 100n-86.02 speed servo motor p.N. 60e-517.02 bowl lif...

Page 16

Models w30, w40, w40p, w60,w60p bowl adjustments w30 = 6 3/8” w40 = 6 3/8” w60 = 7” 14.

Page 17

Bowl adjustments models w80, w100, w150n w80 = 9 1/8” w100 = 11 5/8” w150 = 11 7/8” 15.

Page 18

Lubrication white lithium grease (ie lubriplate ) nye fluorocarbon gel 868vh order from authorized service agent part number: white grease 16.

Page 19

Belt adjustments 17 never move the base for motor (r)(in the oblong holes) , this is a factory setting and is not used to tighten the belts.If the entire unit is to be exchanged, reference the below table. Models w30-w40(p) distance (b) 11 1/2 inches models w60-w150 distance (b) 12 1/4 inches 1. Sta...

Page 20: Belt Exchange

Belt exchange 18 1. Loosen bolt (j) and remove washers (h). 2 2. Remove cotterpin (t) and dowel pin (e) from servo linkage. 2 . 3. Remove vari drive belt (a) from pulleys. 2 4. Remove hall effect sensor (x) from the rear of the computer. 3 5. Loosen bolts (d) and remove the front v-belts (c) by tilt...

Page 21: Belt Exchange

Belt exchange 19.

Page 22

Adjustment of low and high speed microswitches. 20

Page 23

Adjustment of low and high speed microswitches. 21.

Page 24: I.D.

Speed servo system figure number description w30, w40 , w40p w80, w100 , w150 1..........................Sensor..........................30e-500m.........................30e-500m 2..........................Bolt m6.................. ......Sta 5432.........................Sta 5432 3......................

Page 25

Speed servo system 23.

Page 26

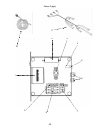

Power supply figure number description all models 1..........................Transformer..............................................................60e-430 2..........................Filter....................................................................... . ..20e-419 3...........................

Page 27

Power supply 1 2 3 4 5 6 7 8 9 11 10 25.

Page 28

26.

Page 29

27.

Page 30

Power supply wiring diagram 1.5 amp 28.

Page 32

5489 campus drive shreveport la 71129 (800) 222-1138 (318) 635-3131 fax.