Summary of V30

Page 1

1 spare part and operation manual food mixer models v30, v40, and v60 012016.

Page 2

2 caution -read before operating- caution varimixer recommends that mixer operators be at least 18 years of age and be thoroughly trained on the use of the mixer. Varimixer recommends that the following precautions be adopted to help make the mixer operation safer and more efficient. ........ - all ...

Page 3

3 varimixer warrants its commercial mixers to the original purchaser against defects in material or manufacture for a period of one year from the date of original purchase, subject to the following exclusions and limitations. The warranties provided by varimixer do not apply in the following instanc...

Page 4

4 table of contents i nstallation i nstructions .......................................................................................................5 c onstruction of the mixer : ....................................................................................................6 t he maximum cap...

Page 5

5 read this page entirely before beginning installation. Installation instructions the mixer must be mounted with the rubber feet, which neutralize both shaking and rusting. Spacers can be inserted under the mixer’s feet if the floor is uneven. The mixer can be bolted to the floor if desired. Before...

Page 6

6 maskin- størrelse motor v30 2 hp v40 3 hp v60 3 hp speed adjustment lift/lowering of bowl motor relay / thermal over- load relay safety switch for safety guard fuse safety switch for lid (not standard) safety switch for bowl lift size of mixer c onstruction of the mixer : t he maximum capacity of ...

Page 7

7 e rror codes : if the mixer is overloaded, the motor will stop and will be shown for ‘overheat’ in the display. • allow the mixer to cool down. • after a short time, the display will change to normal mode. • the mixer can be started again. See also the section “start-up after stop at high speed” o...

Page 8

8 emergency stop fig. 3 mixer seen from above, the bowl has been pushed all the way into the bowl arms. Notice: the centre “ear” of the bowl is facing the mixer fig. 4 speed selector lever fig. 2 mixer with open safety guard, lowered bowl and mounted tool. First “ear” second “ear” centre “ear” fig. ...

Page 9

9 c orrect use of tools : whips should not be struck against hard objects as e.G. The edge of the bowl. This will make the life of the tool shorter due to increasing deformity. Recommended applications for tools: for production of mashed potatoes the special wing whip or the whip with thicker wires ...

Page 10

10 5 l ist of errors : p ossible solution : a rattling sound from the closed part of the mixer. Adjustment of special v-belt the mixer starts “striking” when kneading dough adjustment of special v-belt which normally causes no problems. The mixer changes its speed by itself. Adjustment of special v-...

Page 11

11 5 v30 = 11 1/2 " +/- 1/8" (x) v40 = 11 1/2" +/- 1/8" v60 = 12" +/- 1/8" fig.6 adjustment of special v-belt and speed.

Page 12

12 v30 = 14 1/4” v40 = 15 13/32” v60 = 17 47/64” a djustment of bowl fixing : the bowl arms must be raised to normal working posi- tion. Loosen the counter nuts (1) (fig. 7) and remove the cotter pins (2). Turn the bolts (3) until correct fixing of the bowl is achieved. By turning the bolts out of t...

Page 13: Ixer

13 m ixer s pare p arts.

Page 14

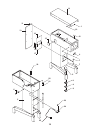

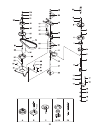

14 1 14 8 7 5 4 3 2 6 7 9 11 13 10 12 16 17 19 18 15 20 22 21 23 24 25.

Page 15

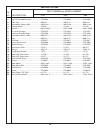

15 top lid threaded bushing ...................... Sta 6580 ................................. Sta 6580 ...........................Sta 6580 knee pad ................................................ 30n-212 ................................... 30n-212 .............................60n-212 intermediate p...

Page 16

16 27-62m 30-69m w40-600w ar31-23/24.1m2 4 23 22 15 11 13 13 14 19 1 20 21 2 14 13 12 11 18 23 17 11 16 9 8 6 5 7 3 10 24 15.

Page 17

17 bowl arm set ..................................Ar31-23/24.1m2 ................................. ? .....................................60n-23 shock absorber, assy ......................... W40-600m ...............................W40-600m .......................... W60-600m crank arm ................

Page 18

18 a b c d e f g 1 1a 1b 2 3 4 4a 4b 5 6 7 8 9 10 6 14 15 16 17 18 15 14 20 23 24 19 21 22 5 11 12 13 37 36 34 35 33 31 32 31 30 26 25 29 28 27 26.

Page 19

19 p lanetary h ead part number per model number v30 v40 v60 description fig. No. 0 1. 1a. 1b. 2. 3. 4. 4a. 4b. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. A b c d e f g v-belt (60 hz) 3 per unit ................. 40-...

Page 20

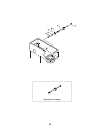

20 b 5, 28 2 a 26.

Page 21

21 t ransmission part number per model number v30 v40 v60 description fig. No. 0 1. 2. 3. 4. 5. 6. 7. 7a . 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. A b washer ...

Page 22

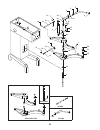

22 speed lever assemply.

Page 23

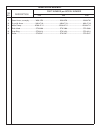

23 s peed l ever a ssemply part number per model number v30 v40 v60 description fig. No. 0 1. 2. 3. 4. 5. 6. Speed lever, assemply .............. W30-47m .....................................W30-47m ...................................W30-47m disc with arrow ...........................30n-47.10.........

Page 24

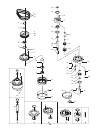

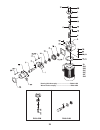

24 29 29a 29b 29c 29e 29f 29g rn30-5.6m rn30-52m bearing hub assemply ................................Rn30-5.6m worm shaft assemply ...................................Rn30-52m.

Page 25

25 a ttachment d rive g earbox v30 v40 v60 description fig. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 29a. 29b. 29c. 29d. 29e. 29f. 29g. Bearing hub ........................................... 15-5 ....................................

Page 26

26 19 21 23 4 13 9 3, 3a 11 16 8 24 22 ar31-152.1z 10 12 ar31-530.3m 5 1 2 6 7 14 18 17 15 20 19 front panel, assemple (inclusive print) .......Ar31-530.3m cover for front panel, assemply ................... Ar31-152.1z.

Page 27

27 e lectrical p anel v30 v40 v60 description fig. No. 1. 2. 3. 3a. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. Front panel vl1, assemply .................................................... Ar31-530.3m ....................Ar31-530.3m ............. Ar31-530.3m gaske...

Page 28

28 6 1 2 4 12 7 3 5 18 16 9 11 9 8 16 18 10 15 14 17 13.

Page 29

29 b owl s creen v30 v40 v60 description fig. No. 0 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. Bowl screen kit ......................... 14030-0018 ......................................... ? ..................................................? Nut ...................................

Page 30

30 22 16 17 18 19 20 21 24 23 1,2 5 6 6 6 6 6 27 28 29 30 31, 31a 32 33 25, 26 34 3, 4 7, 8 9 11, 12, 13, 14 15 10

Page 31

31 a ttachments a nd o ptional p roducts v30 v40 v60 description fig. No. 0 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 31a 32. 33. 34. Stainless steel bowl (standard) ..................203/30a ......................................

Page 32

32 14240 south lakes drive charlotte, nc 28273 (800) 222-1138 www.Varimixer.Com.