- DL manuals

- VDH

- Grinder

- PX-150BG

- Operator's Manual

VDH PX-150BG Operator's Manual

Summary of PX-150BG

Page 1

1 px-150hdbg px-150bg bench grinder vdh machines & gereedschappen bv texasdreef 8, 3565 cl utrecht tel.:+31 30 296 32 70, fax: +31 30 293 66 00 www.Vdhbv.Nl.

Page 2: Operator’S Manual

2 operator’s manual 1. Spark protection guard 2. Eye protection shield 3. Tool rest knob 4. Motor 5. Emergency switch 6. Grinding wheel housing 7. Grinding wheel 8. Tool rest content of delivery bench grinder abrasive wheels grit 36 and 60 2 tool rests 2 spark protection guards 2 eye protection shie...

Page 3: Table of Contents

3 table of contents specifications 3 safety rules 4-5 assembly 6 main connection 7 starting- machine operation 7 startup and adjustments 8-9 maintenance and inspection 10 trouble shooting 10 specifications model no. Px-150hdbg / px-150bg motor 230v~50hz – 0,52kw / 0,25kw no load speed 2950 min- 1 gr...

Page 4

4 caution : read and follow all safety rules and operating instructions before first use of this product. This manual provides important information on proper operation and maintenance. Every effort has been made to ensure the accuracy of this manual. We reserve the right to change this product at a...

Page 5

5 (13) disconnect tools - when not in use, before servicing and when changing accessories such as wheels, bits and cutters, disconnect tools from the power supply. (14) remove adjusting keys and wrenches - form the habit of checking to see that keys and adjusting wrenches are removed from the tool b...

Page 6

6 keep hands away from the rotating grinding wheels wear protective gloves and use safety glasses. The noise level when working can exceed 85 db(a); wear ear protection anyone entering the work area must wear personal protective equipment (fragments of the work piece or of a broken accessory may fl ...

Page 7

7 adjust the spark protection guard to within 2mm of the grinding wheel. As the wheel wears down, the spark guard must be re-adjusted. Mount the bench grinder: to prevent the grinder from moving during operation, it must be securely mounted to a work bench or stand. Main connection do not connect be...

Page 8

8 - grounding plug should be plugged directly into a properly installed and grounded 2- prong grounding- type receptacle, as shown. - do not remove or alter grounding prong in any manner. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electrical shock. ...

Page 9

9 setup and adjustments changing the abrasive wheel the abrasive wheel may only be changed when the mains plug is pulled! The abrasive wheel has to meet the technical specification. Use only abrasive wheels rated at 3000 min- 1 or higher. Check abrasive wheel for flaws (cracks) before installation. ...

Page 10

10 adjusting the tool rest as the wheel wears down, the tool rest must be re-adjusted to maintain a maximum 2mm clearance. Loosen screws (a) to adjust. Maintenance and inspection make all machine adjustments or maintenance with the machine unplugged from the power source. Maintenance, cleaning and r...

Page 11

11 trouble shooting motor doesn’t start *no electricity – check mains and fuse. *defective switch, motor or cord – consult an electrician. Machine vibrates excessively * stand on uneven surface – adjust base for even support. *abrasive wheel damaged – replace abrasive wheel immediately grinding surf...

Page 12

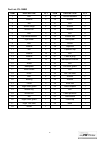

12 exploded drawing part list: px-150hdbg item description qty item description qty 1 left outer cover 1 38 wheel lock nut 1 2 wheel lock nut 1 39 right tool rest 1 3 outer wheel flange 2 40 washer 2 4 nameplate of wheel 4 41 knob nut 2 5 wheel 2 42 cable protector 1 6 inner wheel flange 2 43 bolt 3...

Page 13

13 16 stator 1 53 tooth washer 1 17 bearing 2 54 bolt 2 18 rotor 1 55 flat washer 2 19 bolt 3 56 bolt 2 20 label 1 57 cord bushing plate 1 21 waved spring 1 58 bolt 1 22 end cover 1 59 flat washer 1 23 screw 6 60 capacitor clip 1 24 washer 6 61 capacitor 1 25 flat washer 6 62 washer 2 26 eye shield ...

Page 14

14 part list: px-150bg item description qty item description qty 1 bolt 6 29 ground terminal 1 2 washer 6 30 washer 1 3 nut 1 31 bolt 1 4 wheel flange 4 32 washer 4 5 wheel a36 1 33 washer 4 6 bolt 2 34 bolt 4 7 eye shield bracket 2 35 rubber feet 4 8 eye shield 2 36 base plate 1 9 bolt 2 37 screw 2...